Patents

Literature

50results about How to "Offsetting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

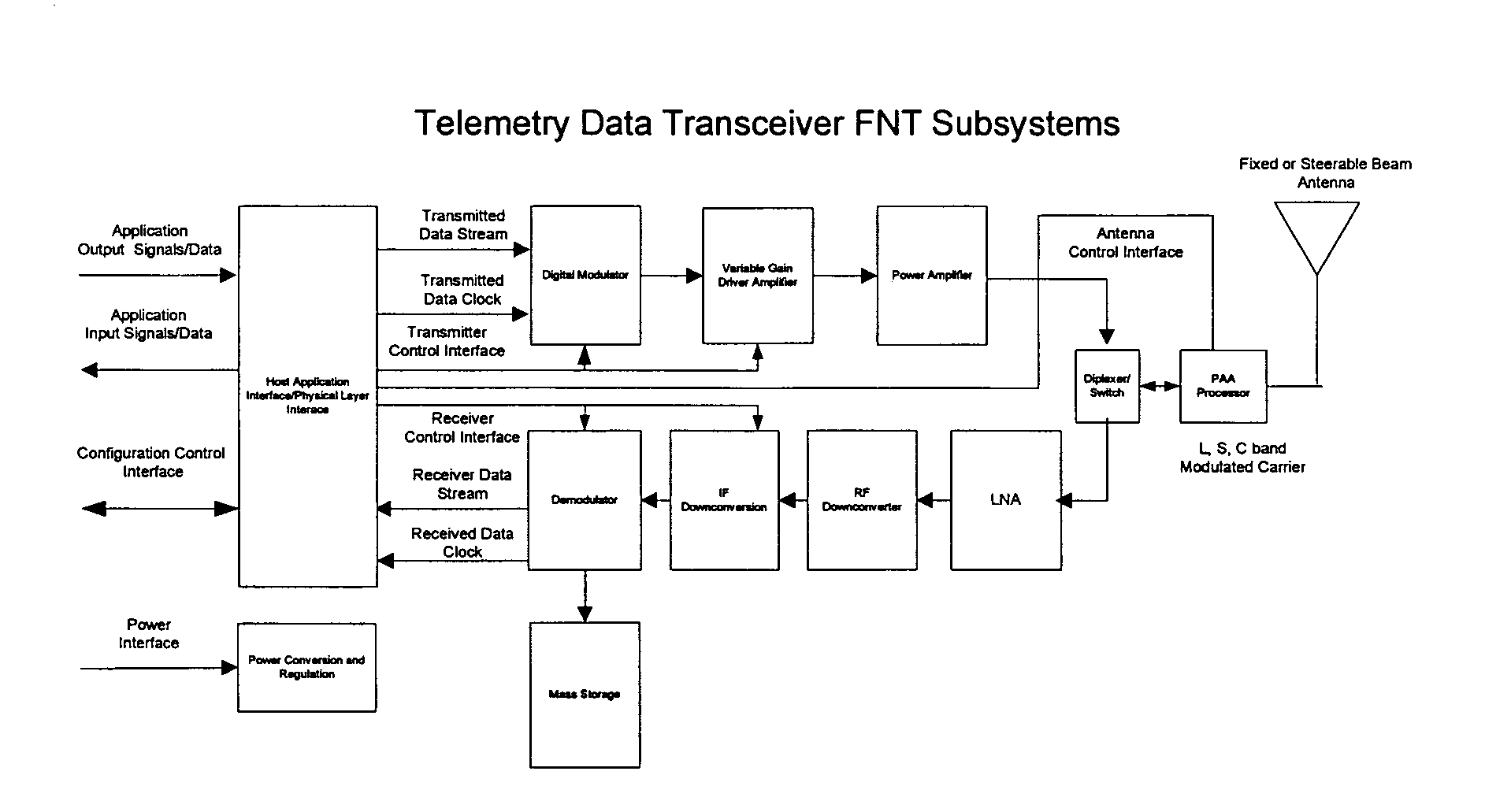

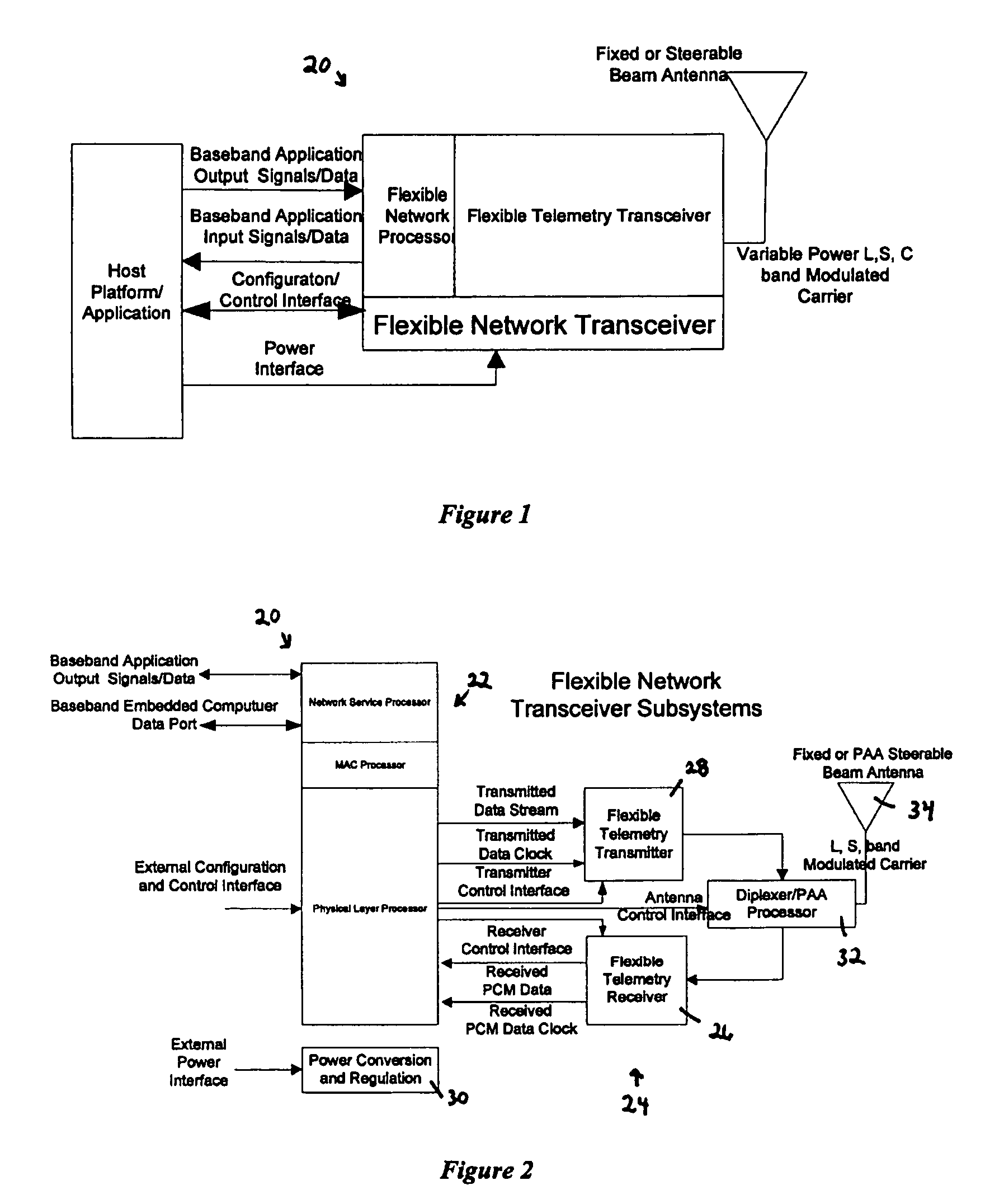

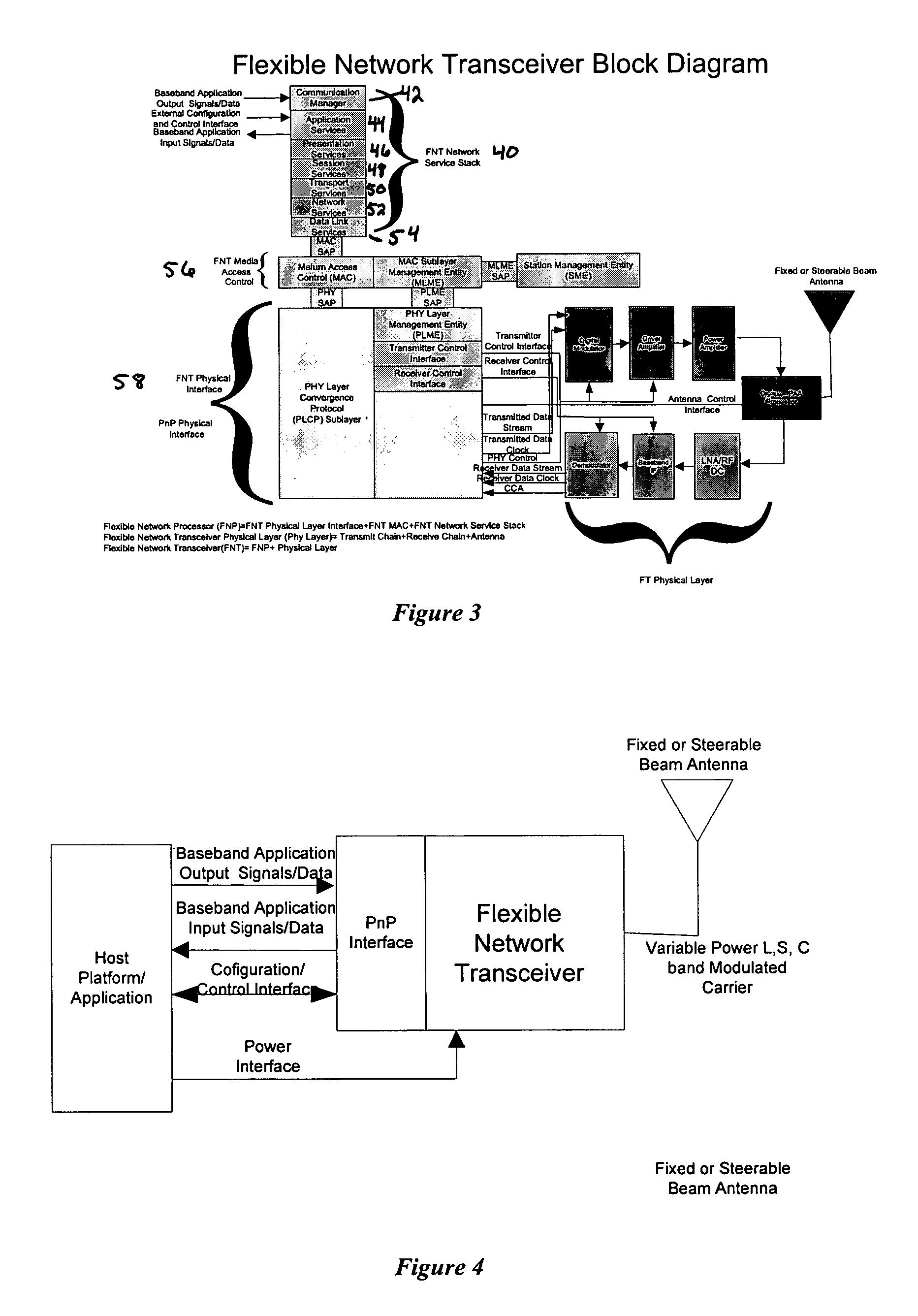

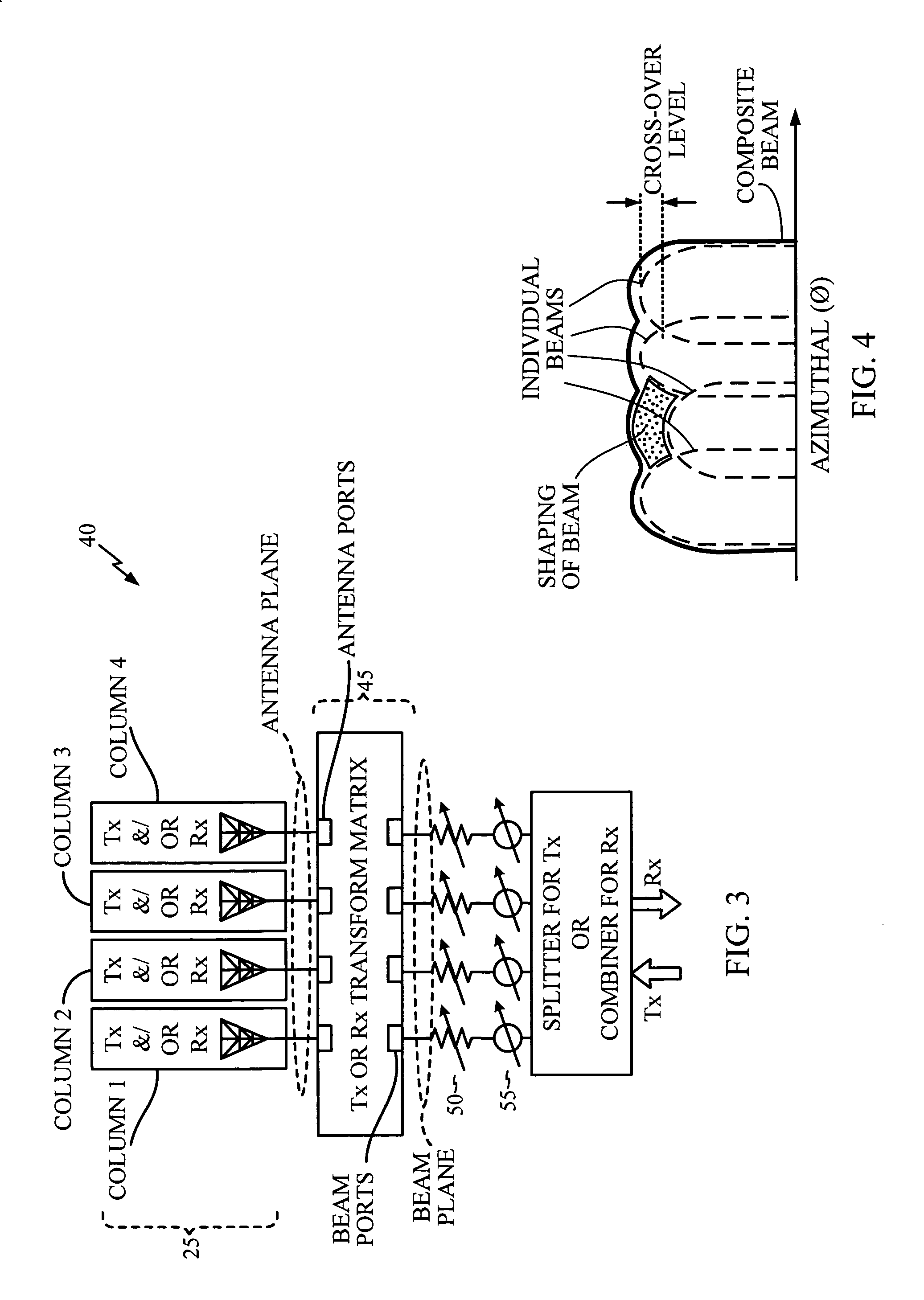

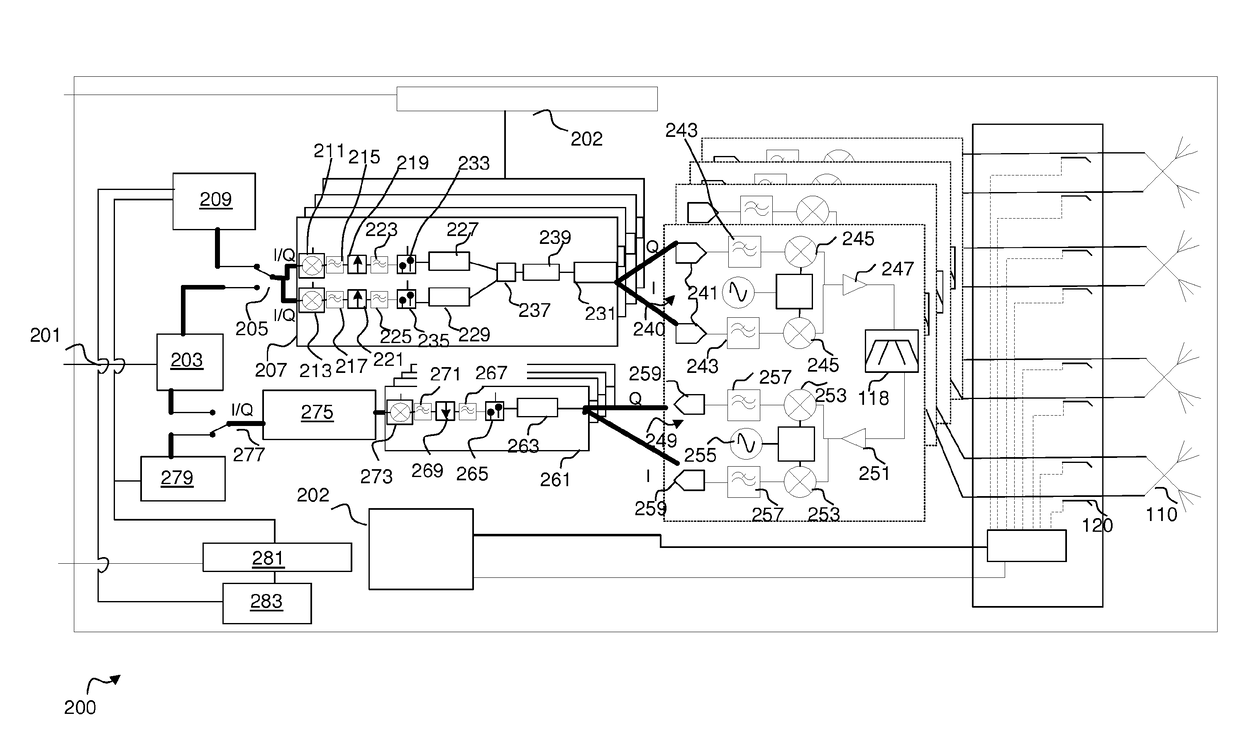

Flexible network wireless transceiver and flexible network telemetry transceiver

InactiveUS7408898B1Improve performanceIncrease data rateError preventionFrequency-division multiplex detailsTransceiverGround vehicles

A transceiver for facilitating two-way wireless communication between a baseband application and other nodes in a wireless network, wherein the transceiver provides baseband communication networking and necessary configuration and control functions along with transmitter, receiver, and antenna functions to enable the wireless communication. More specifically, the transceiver provides a long-range wireless duplex communication node or channel between the baseband application, which is associated with a mobile or fixed space, air, water, or ground vehicle or other platform, and other nodes in the wireless network or grid. The transceiver broadly comprises a communication processor; a flexible telemetry transceiver including a receiver and a transmitter; a power conversion and regulation mechanism; a diplexer; and a phased array antenna system, wherein these various components and certain subcomponents thereof may be separately enclosed and distributable relative to the other components and subcomponents.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

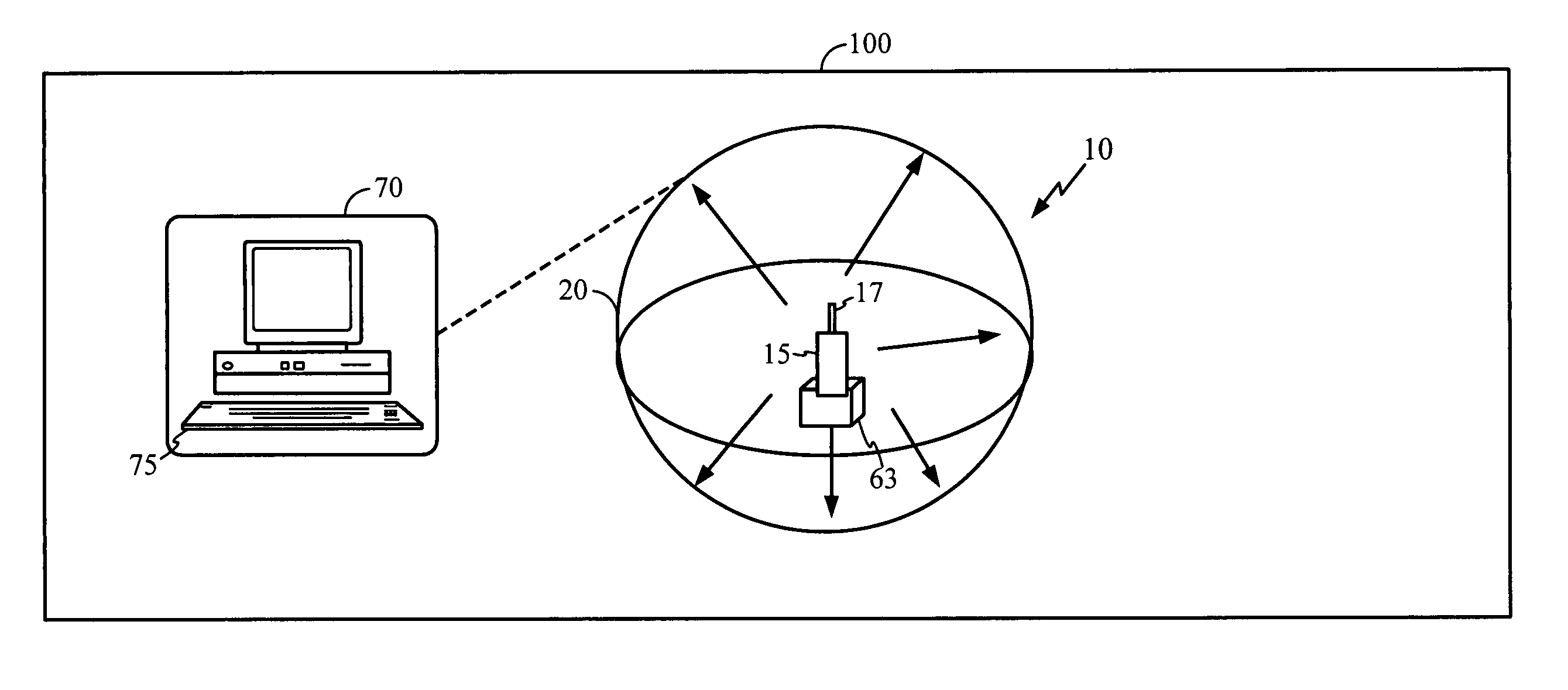

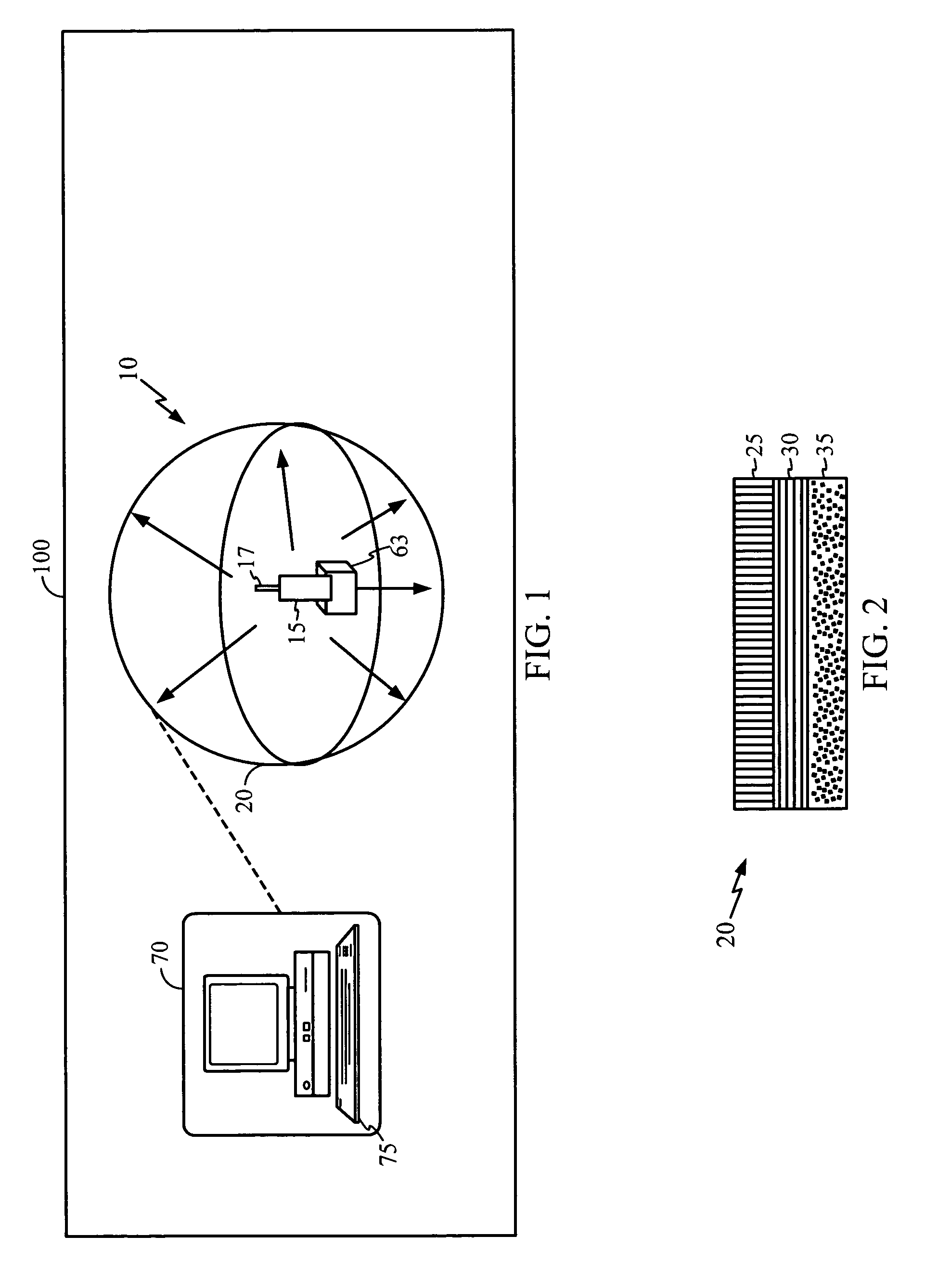

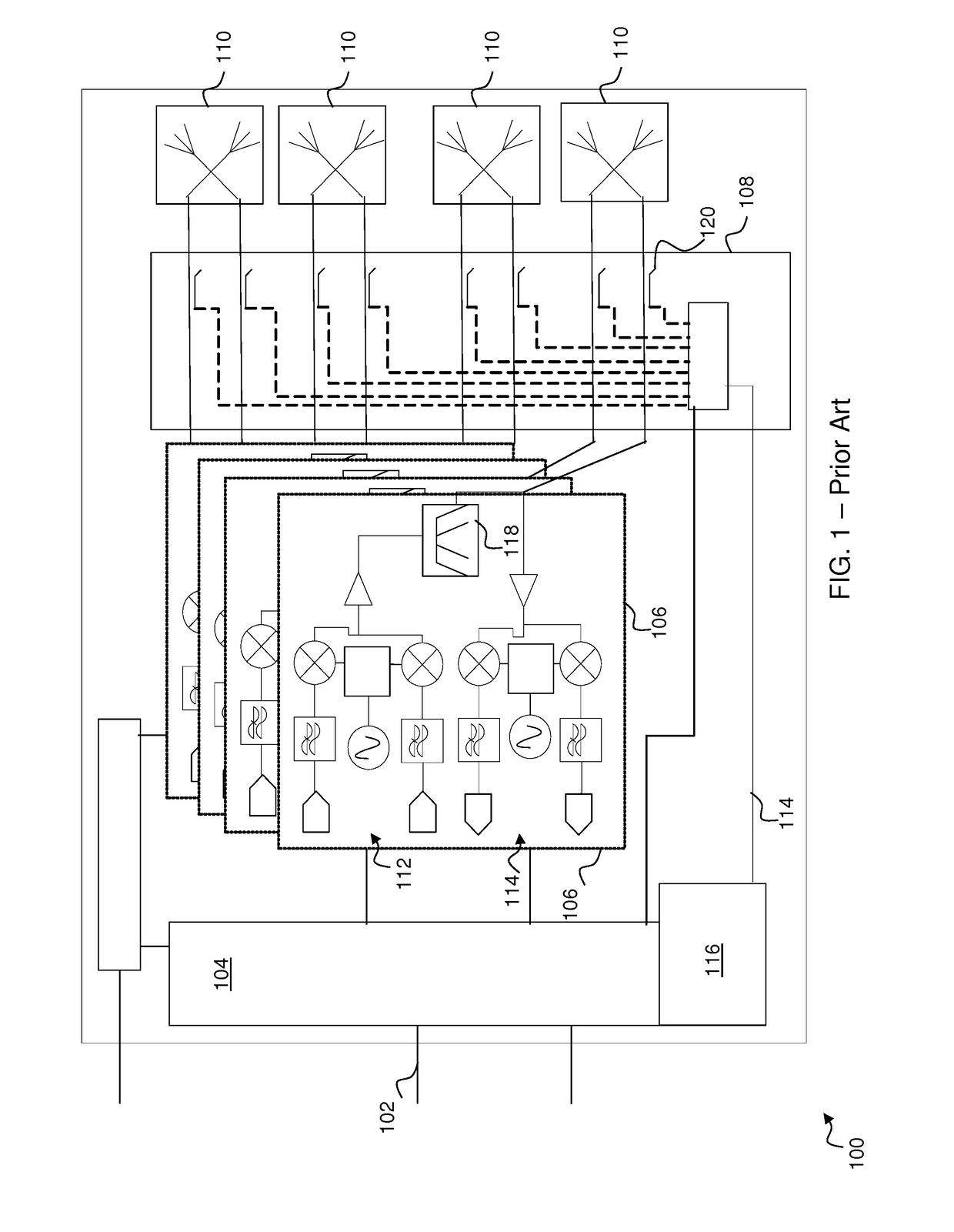

Method and apparatus for testing and evaluating wireless communication devices

ActiveUS7035594B2Deleterious effectOffsetting effectTransmitters monitoringReceivers monitoringTelecommunications linkCommunication link

A testing chamber is configured to evaluate the accuracy of a wireless communication device under test in a production environment. The configuration of the testing chamber may resemble an enclosed structure having a wall that includes multiple layers. An array of antennas, which serves as a layer of the wall, is strategically positioned within the testing chamber to receive and transmit signals emitted to / from the wireless communication device. Located within the testing chamber is either a stationary or moveable holder to support the wireless communication device. Furthermore, during testing, the forward link and the reverse communication links are monitored by selectively or alternatively adjusting and shifting the phase / amplitude of the antenna of the wireless communication device to mitigate the effects of multi-path fading.

Owner:QUALCOMM INC

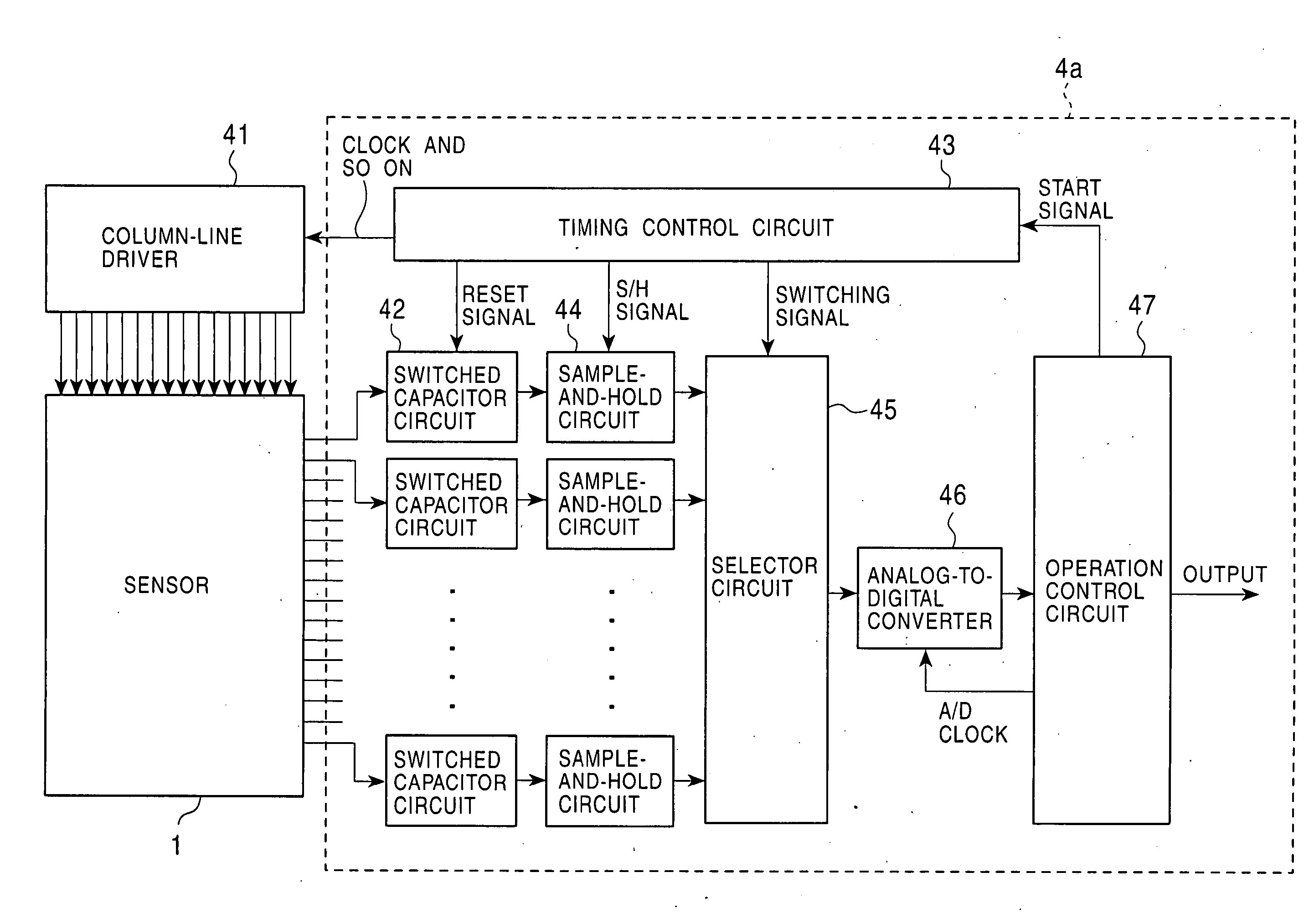

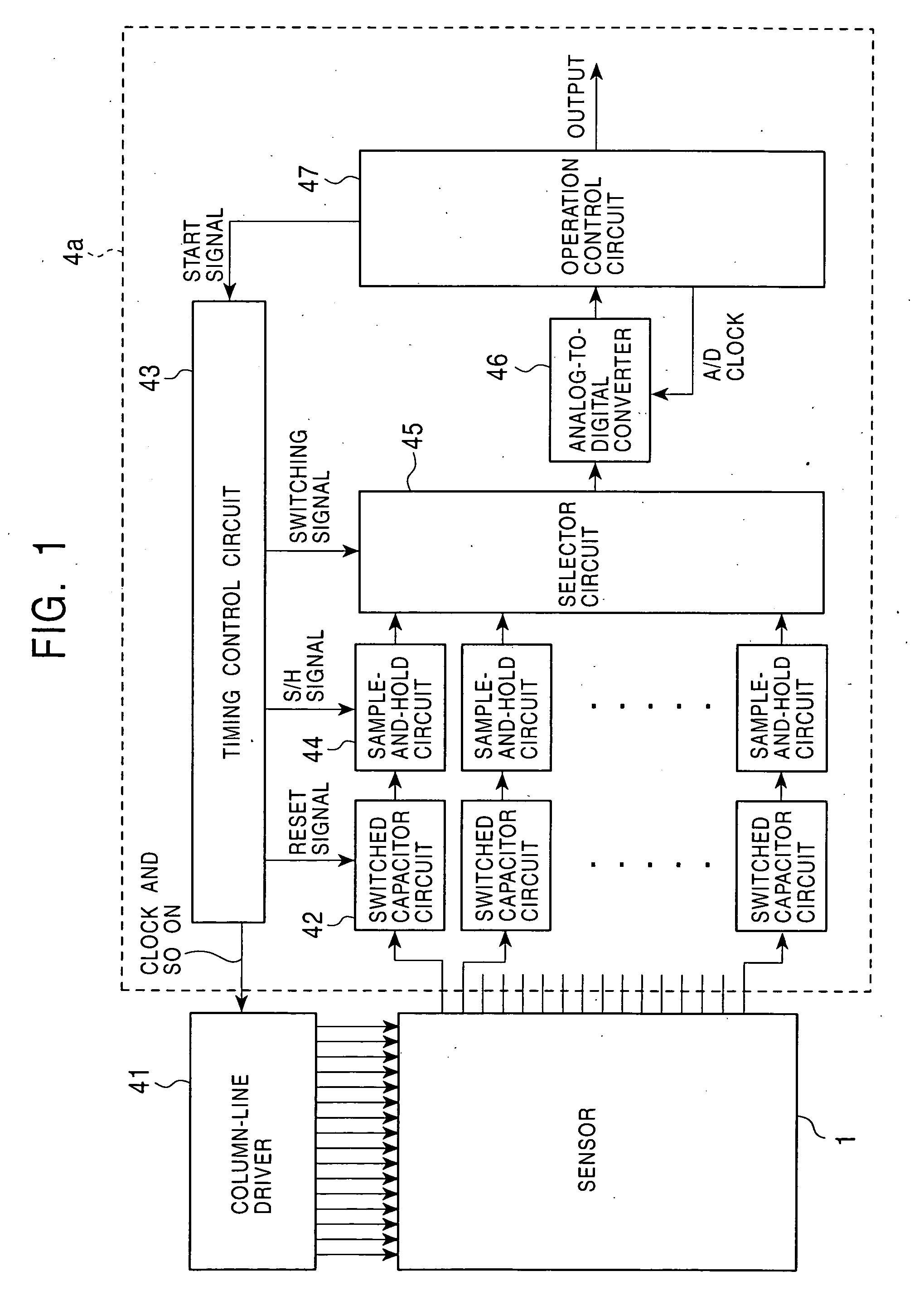

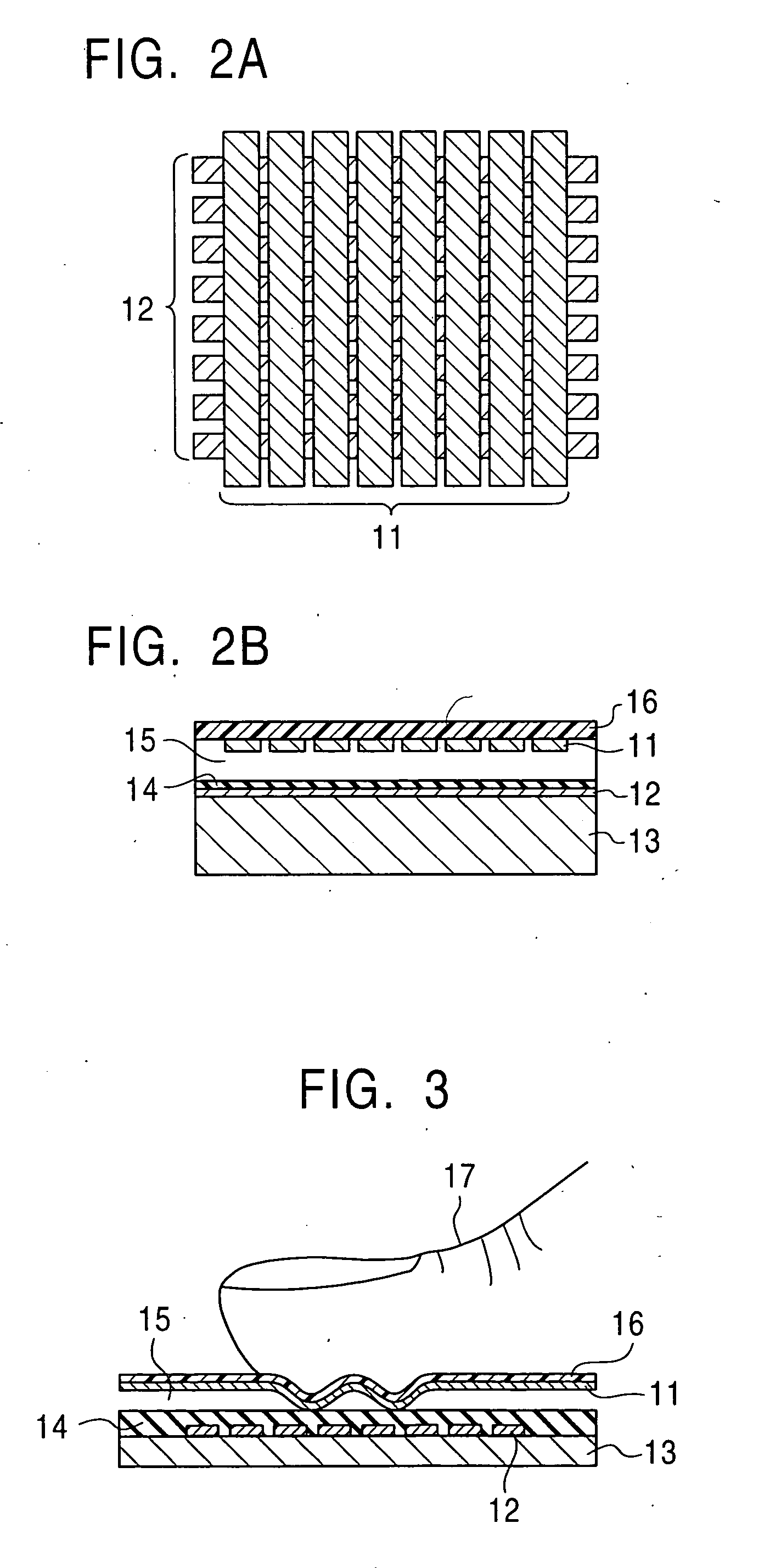

Capacitance detector, method of detecting capacitance, and fingerprint sensor

InactiveUS20050024065A1Offsetting effectCorrect offsetResistance/reactance/impedencePerson identificationEngineeringLine driver

A capacitance detector, used in an area sensor having a matrix of detection lines, detects minute capacitances near intersections of a plurality of column lines and a plurality of row lines. The capacitance detector includes a column-line driver for outputting to the column lines a signal that rises in response to a first voltage and then falls in response to a second voltage; a row-voltage outputter for outputting a third voltage corresponding to a current for charging the capacitance at each of the intersections when the column lines are driven by the first voltage and for outputting a fourth voltage corresponding to a current for discharging the capacitance at each of the intersections when the column lines are driven by the second voltage; and a calculator for calculating the difference between the third voltage and the fourth voltage. The difference is calculated at each of the intersections.

Owner:ALPS ALPINE CO LTD

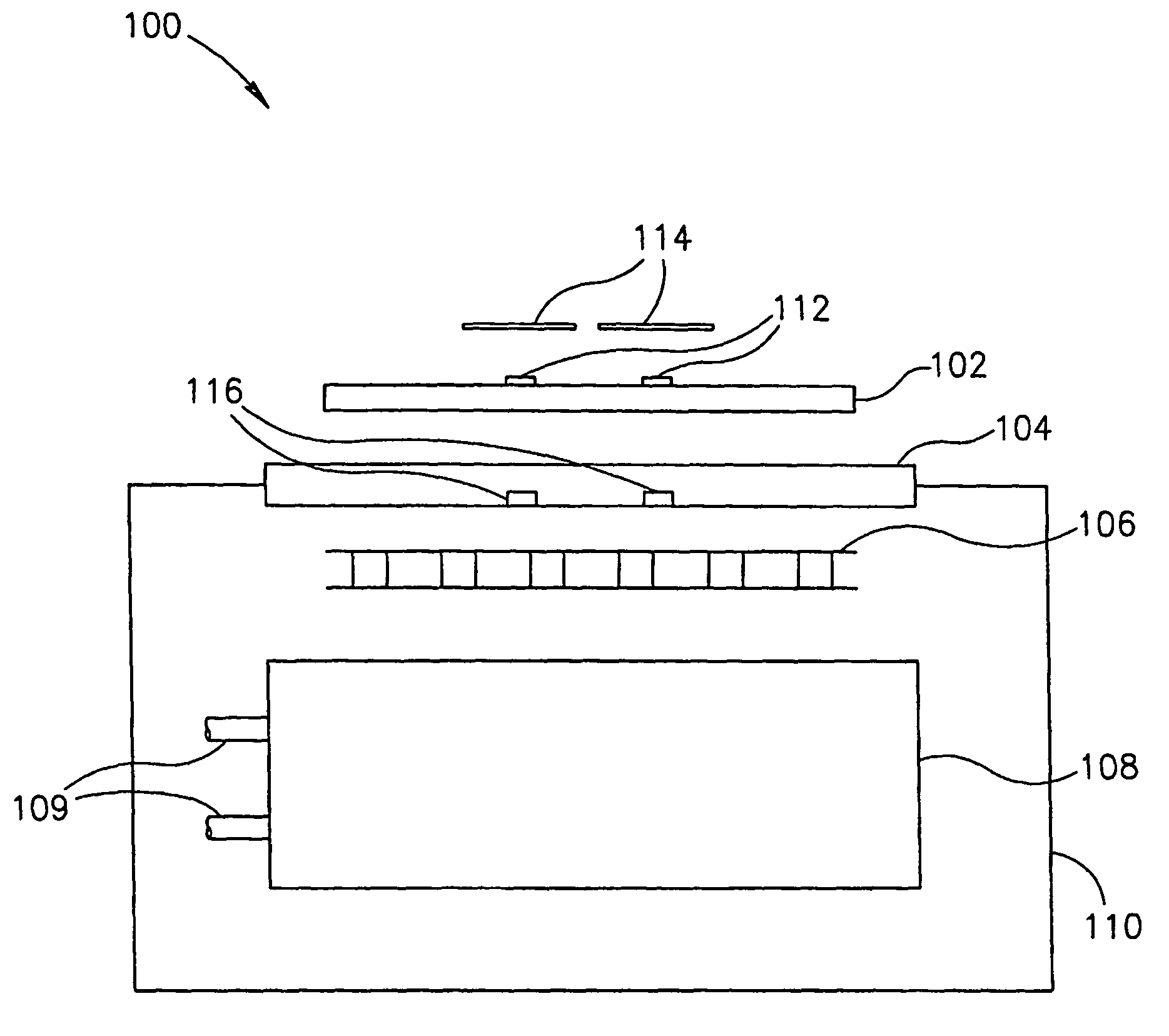

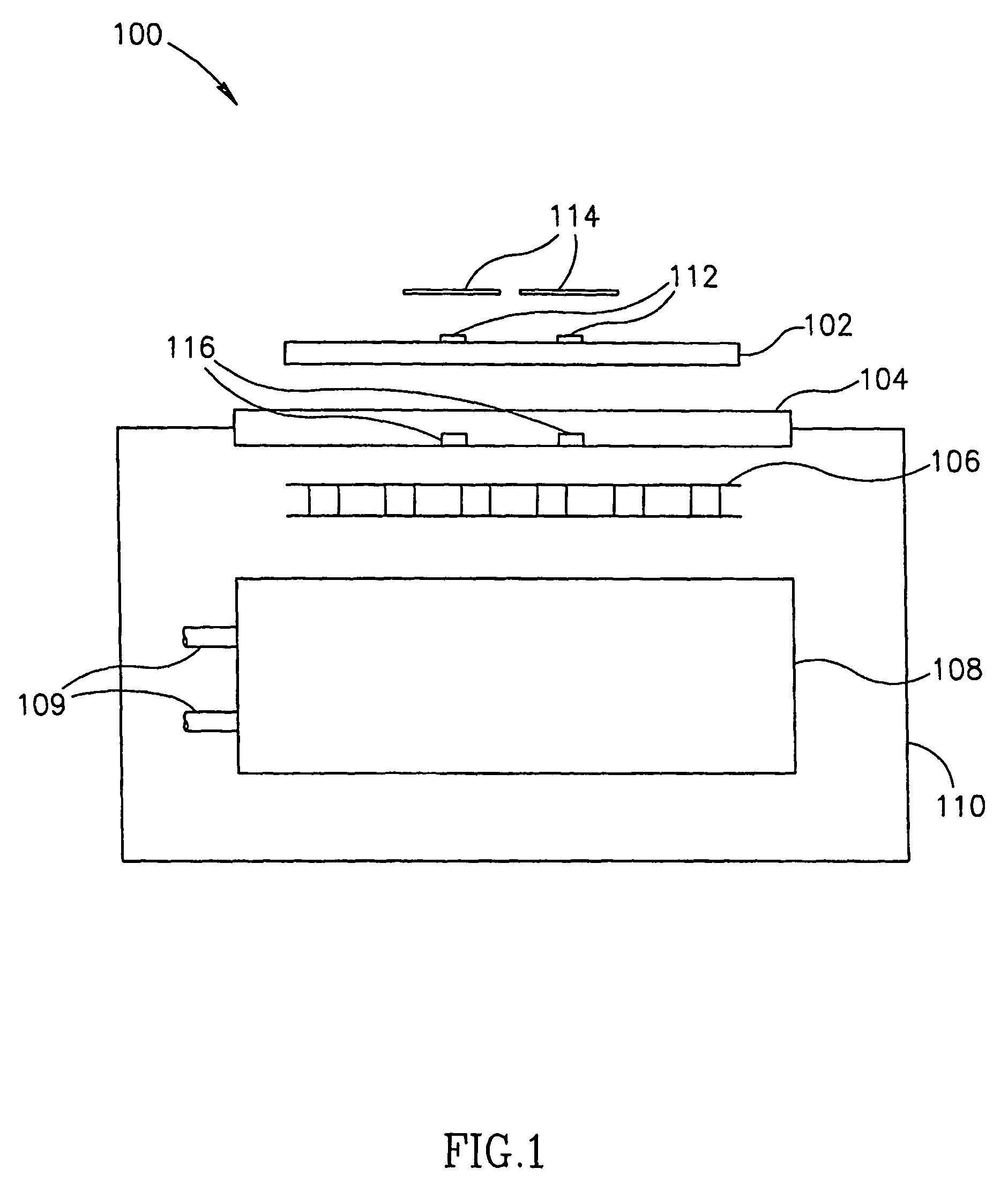

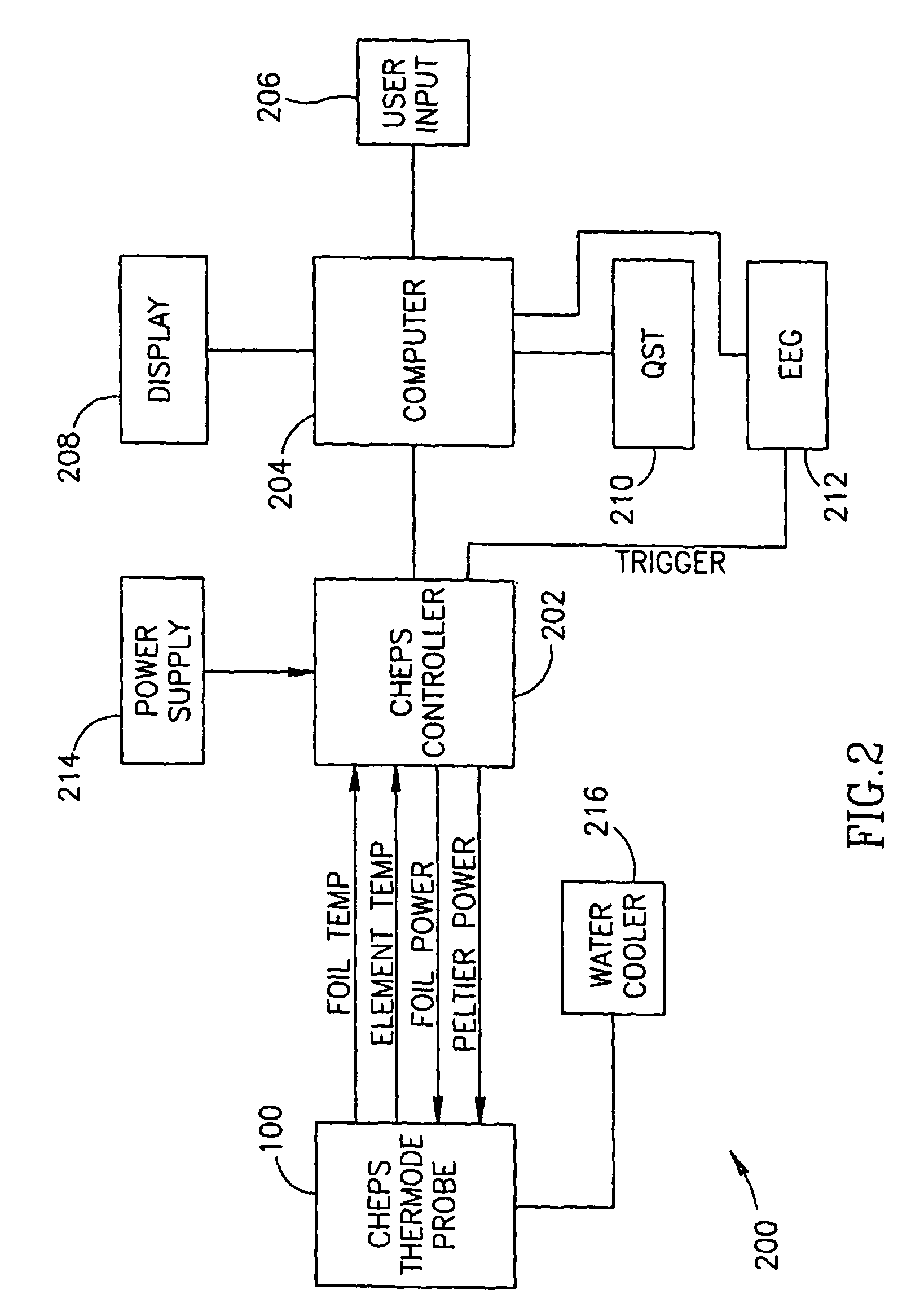

Thermal stimulation probe and method

ActiveUS8083786B2Quick changeLow enough thermal impedanceElectroencephalographySensorsCelsius DegreeThermal stimulation

A physiological thermal stimulation probe, comprising: (a) an electrically controlled heat control element with a relatively low thermal capacity and adapted for contact with tissue on one side thereof; (b) a thermal sink / source with a relatively high effective thermal capacity and a relatively low thermal impedance, such that said thermal sink / source sink can rapidly change a temperature of said heat control element, at a rate above 10 degrees Celsius per second, from a temperature of below 100 degrees Celsius; and (c) circuitry which activates said heat control element to achieve a desired temperature stimulation profile of said tissue.

Owner:MEDOC

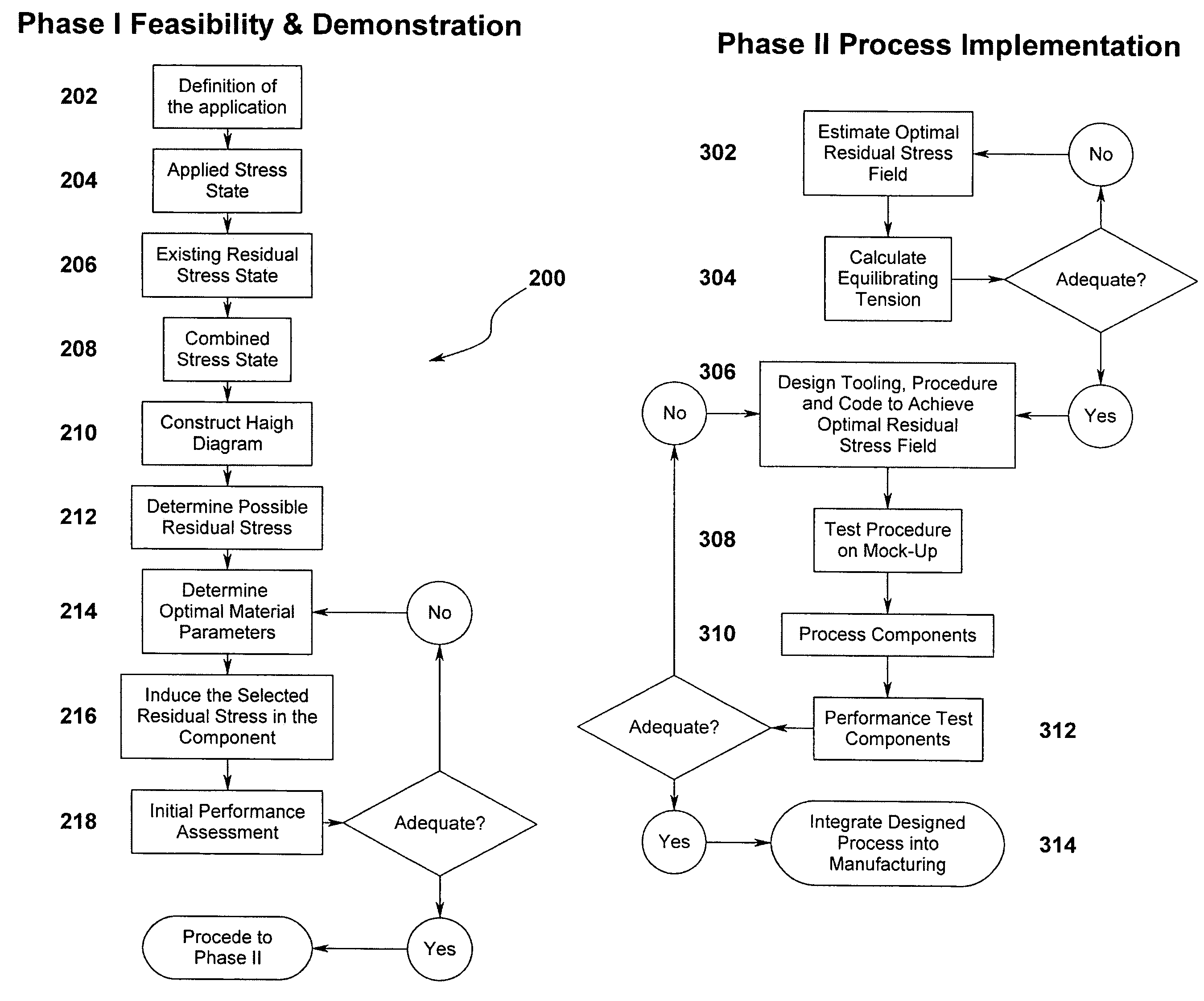

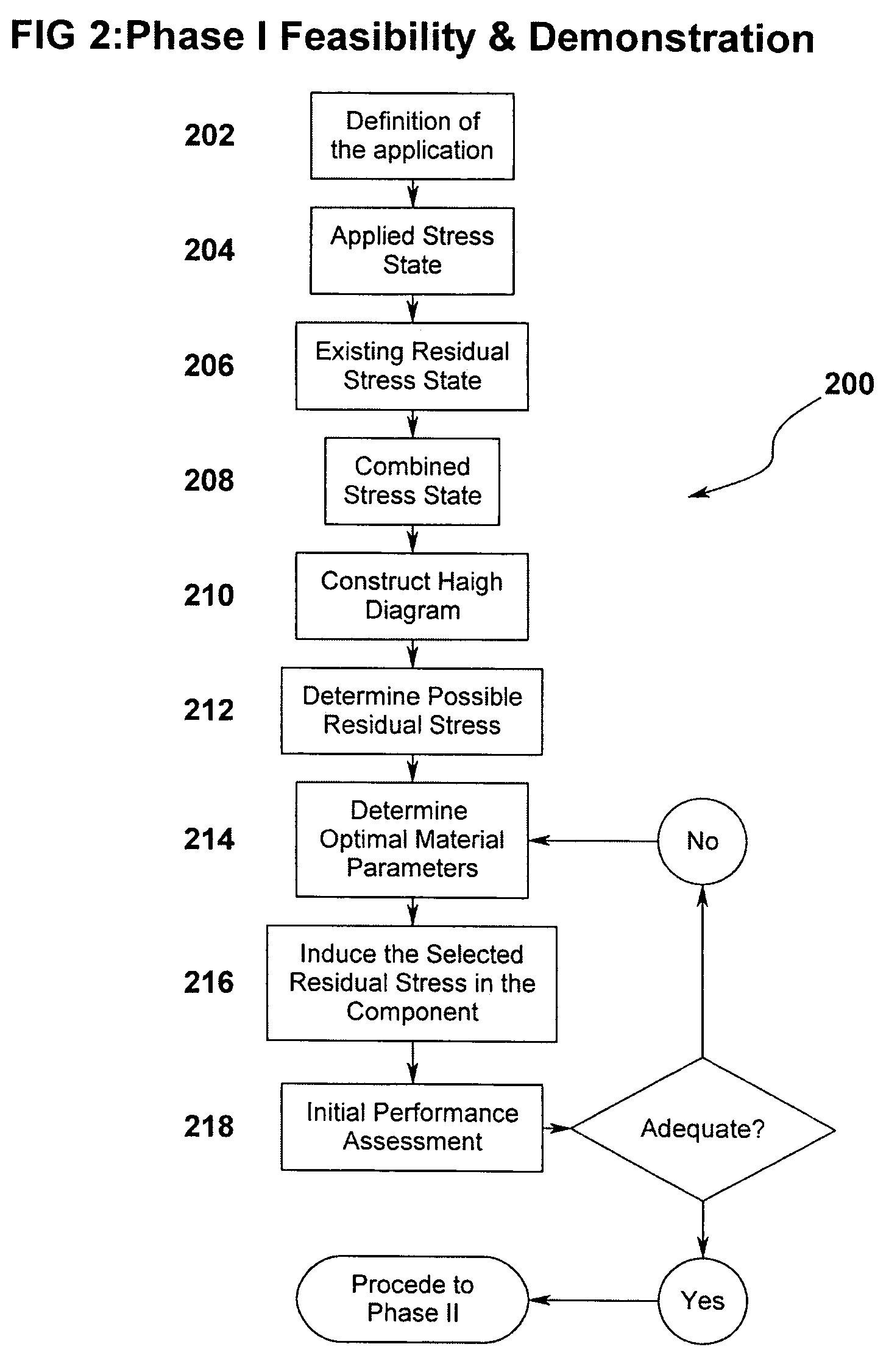

Method and system for improving a part's resistance to stress induced failure

ActiveUS7219044B1Offsetting effectUsing mechanical meansComputer aided designStress inducedStressed state

A method and system for designing a part with improved fatigue life and resistance to stress corrosion cracking in which residual stresses existing in the part are accounted for. The performance criteria and operating conditions of the part are assessed and a total stress state is determined from the sum of the residual stresses and applied stresses acting on the part. Unified Fatigue Performance Model or Smith-Topper-Neuber parameters are used to determine fatigue life functions which, in turn, are used in conjunction with a fatigue design diagram to determine the appropriate residual stress to introduce in order to optimize the part's resistance to stress induced failure mechanisms. A residual stress distribution is then designed to avoid distortion of the part while still imparting the beneficial effects of compressive residual stress.

Owner:SURFACE TECH HLDG

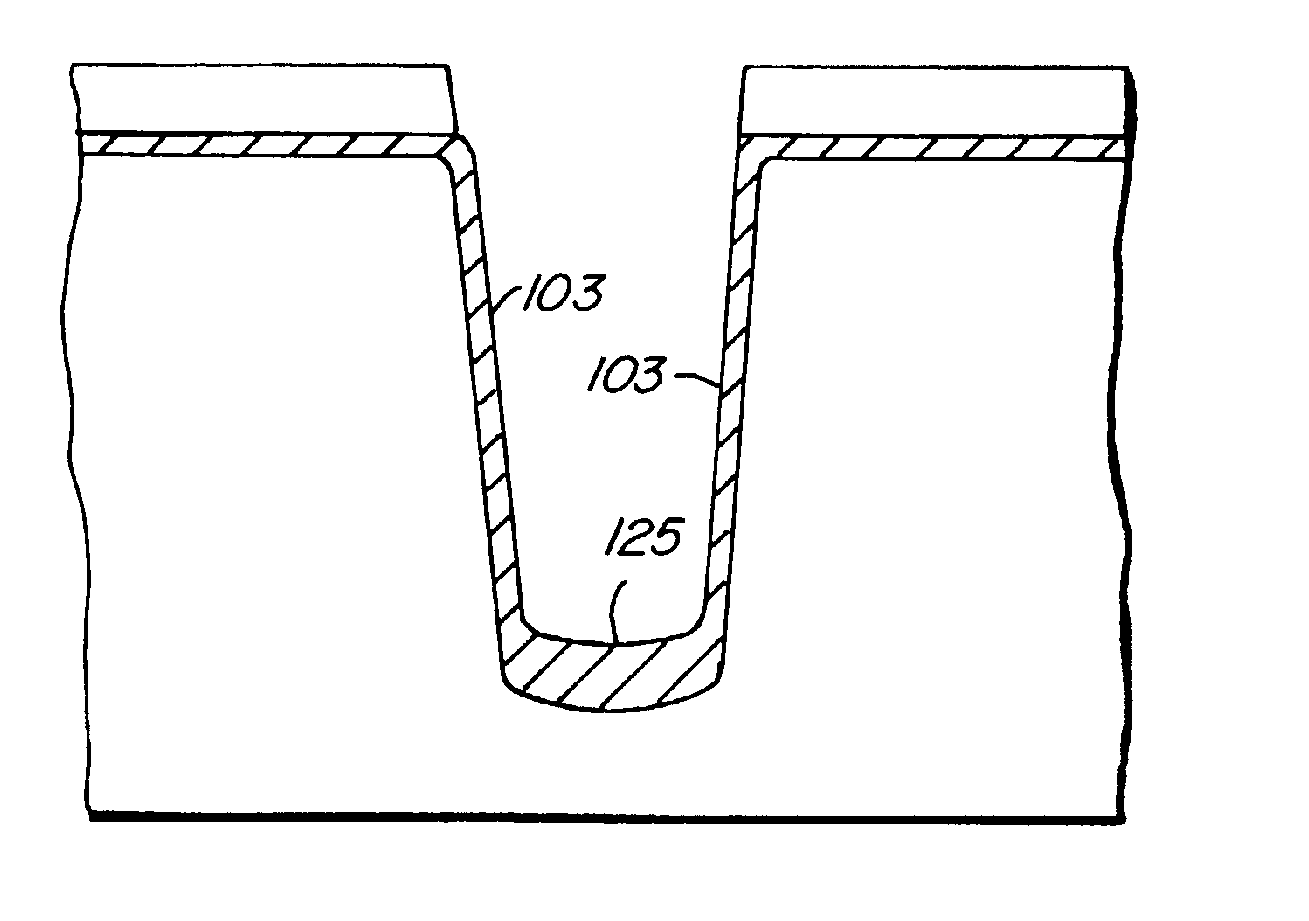

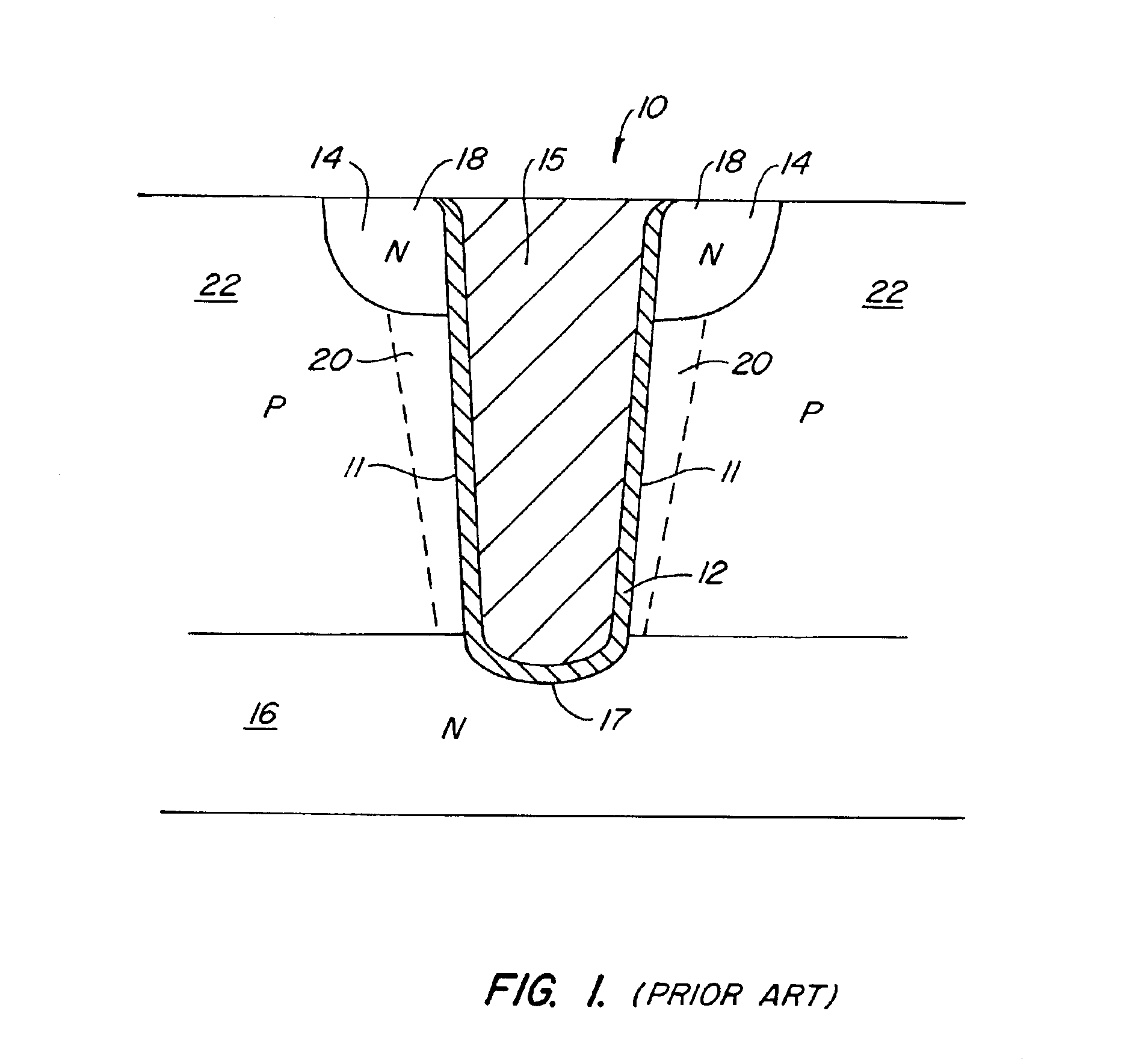

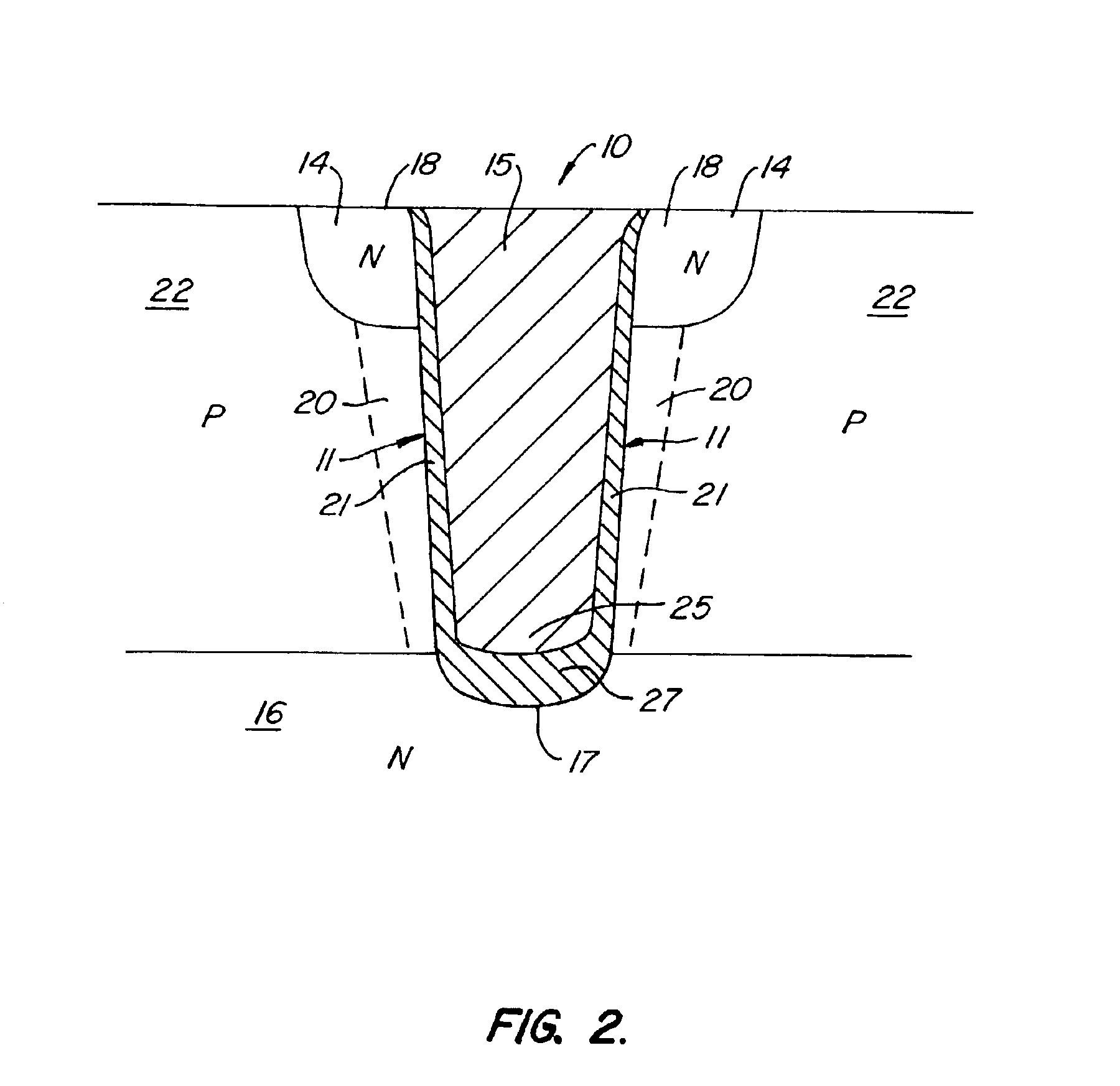

Method for creating thick oxide on the bottom surface of a trench structure in silicon

InactiveUS6861296B2Relieve pressureReduce materialTransistorSemiconductor/solid-state device manufacturingCapacitive effectCapacitance

A gate isolation structure of a semiconductor device and method of making the same provides a trench in a silicon substrate, wherein a dielectric layer is formed on sidewalls and bottom of the trench, the dielectric layer having a first thickness on the sidewalls and a second thickness at the bottom that is greater than the first thickness. The thicker dielectric layer at the bottom substantially reduces gate charge to reduce the Miller Capacitance effect, thereby increasing the efficiency of the semiconductor device and prolonging its life.

Owner:SEMICON COMPONENTS IND LLC

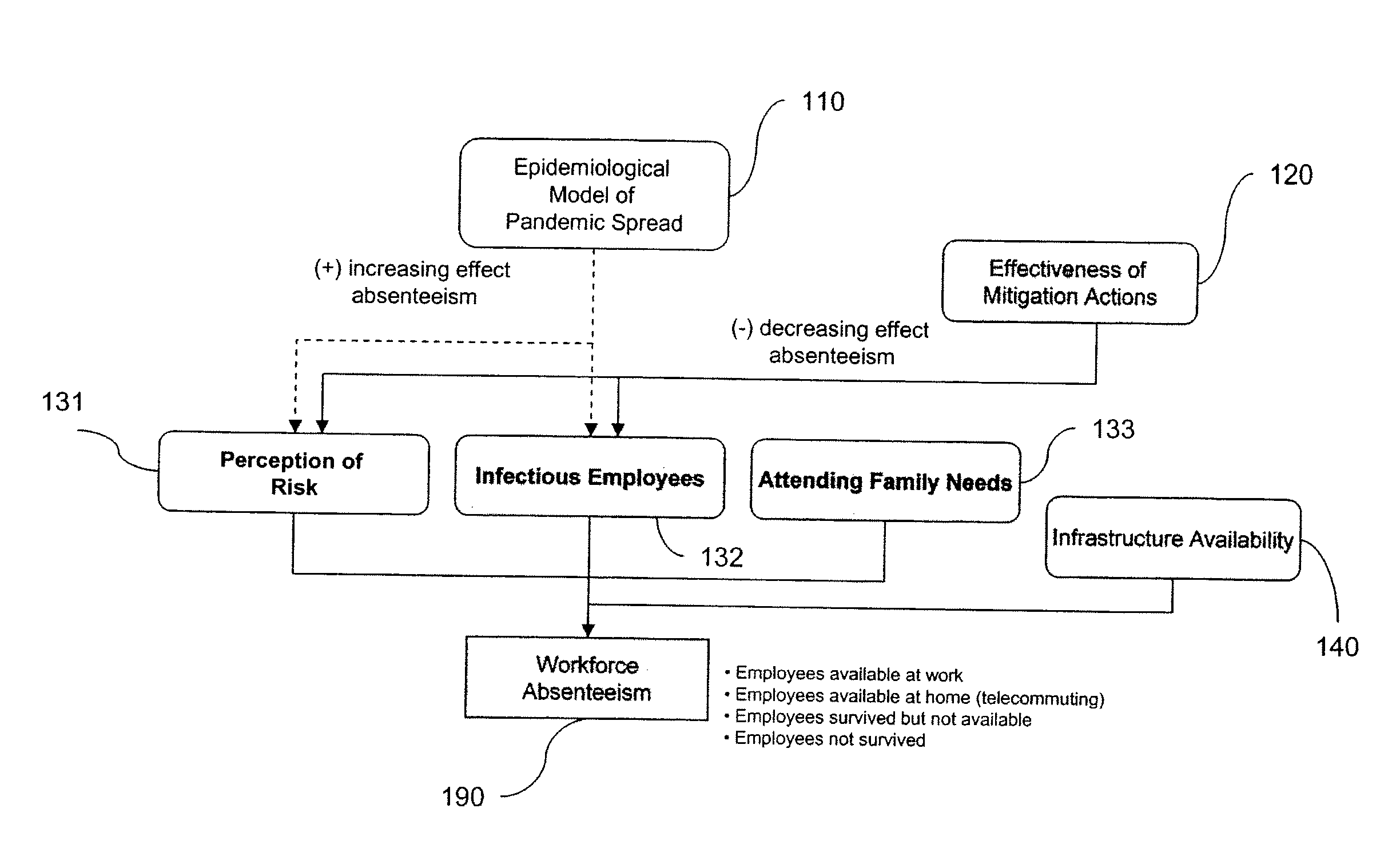

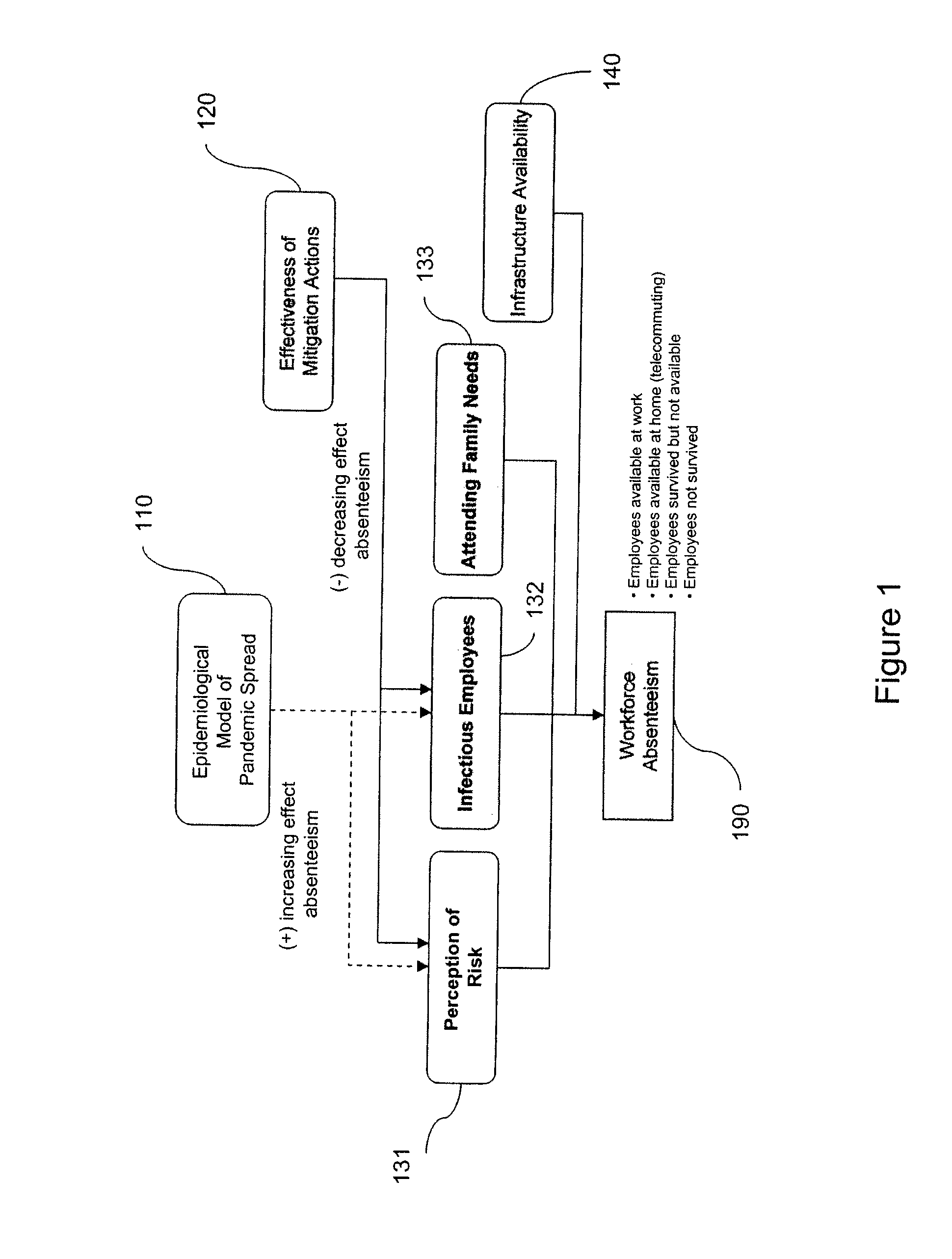

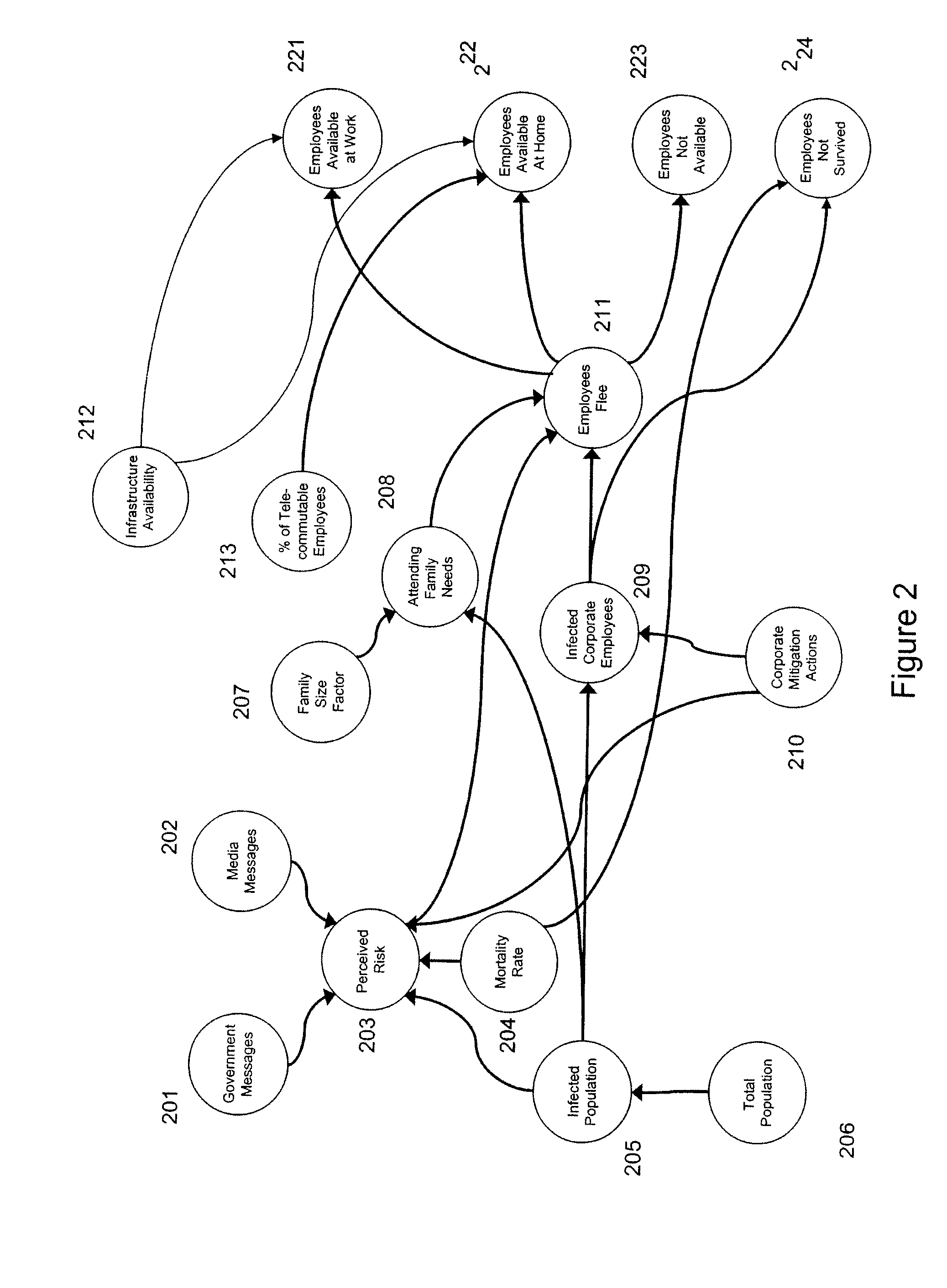

Method and system for estimating dynamics of workforce absenteeism using information on pandemic spread and mitigation actions

InactiveUS20080177614A1Offsetting effectReduce impactMedical simulationEpidemiological alert systemsInfection ratePandemic

The present invention provides a method and system estimating the likelihood of employees not being available for work as a result of pandemic occurrence and effectiveness of related mitigation actions. The invention allows users to assess the impact of pandemic on availability of corporate workforce and to estimate the effectiveness of various corporate mitigation actions in terms of how such actions may reduce the adverse effects of a pandemic on employee availability by incorporating information on infection rate, perception, needs for family care and infrastructure availability into a system of algebraic and differential equations.

Owner:IBM CORP

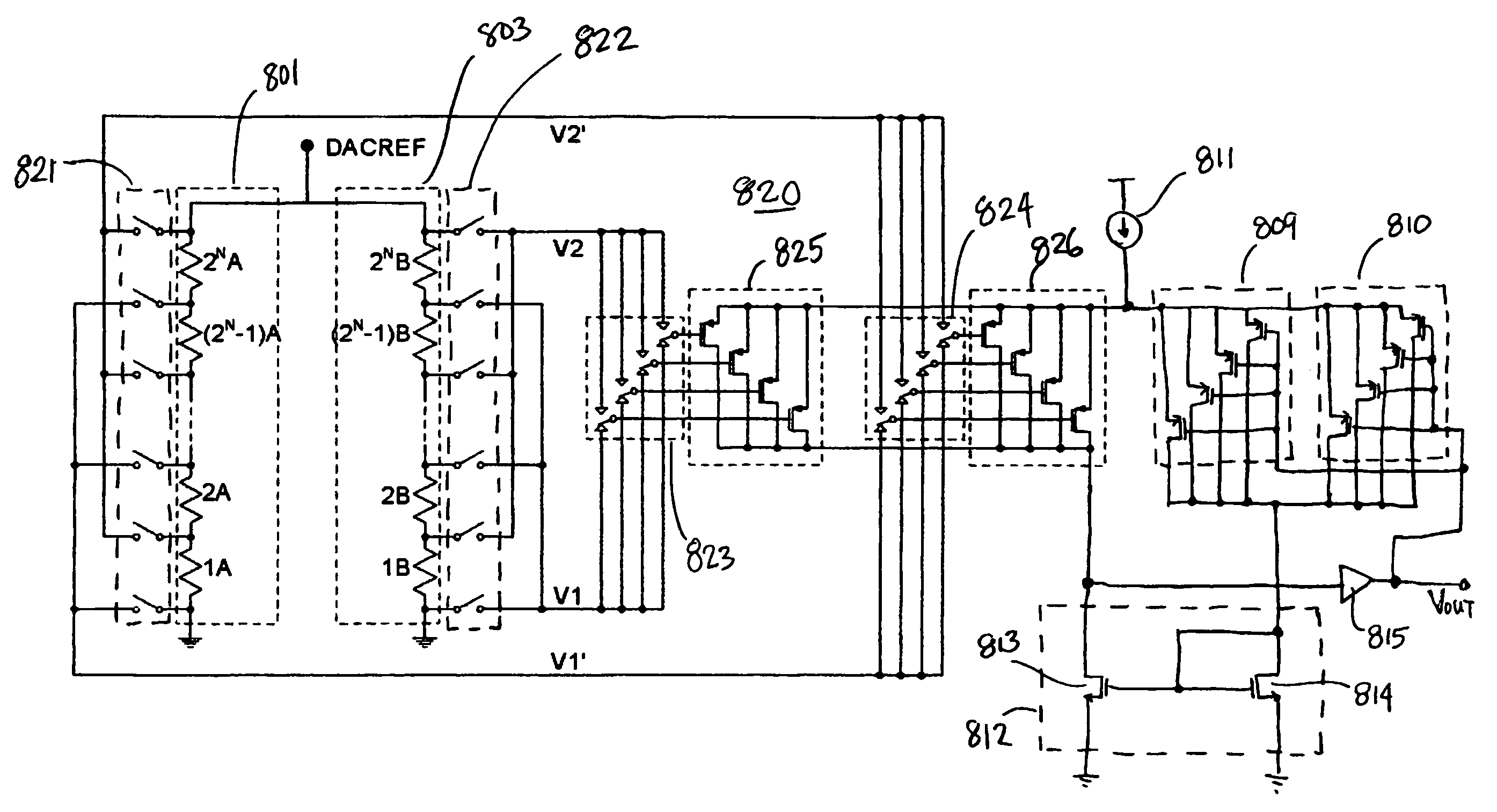

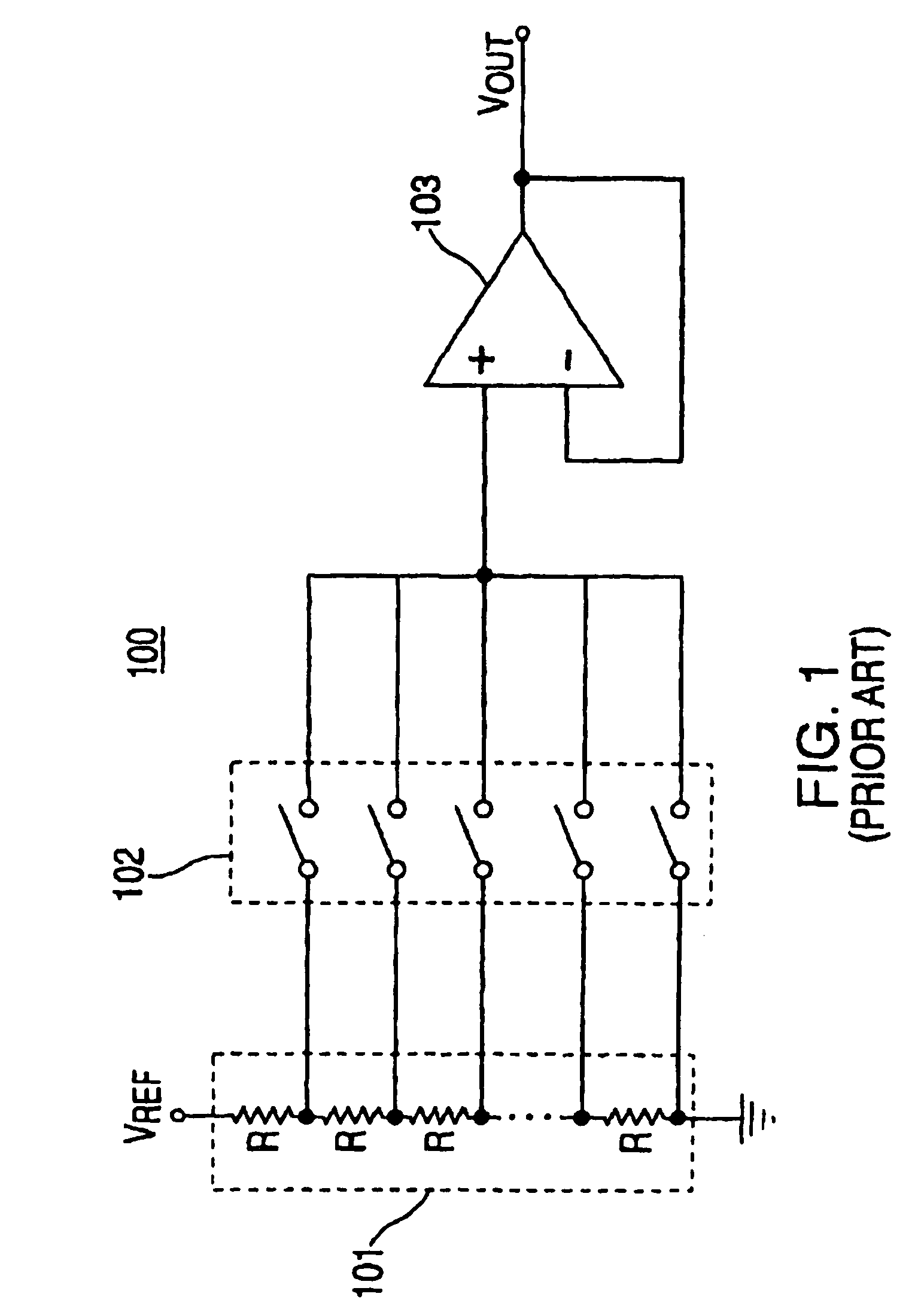

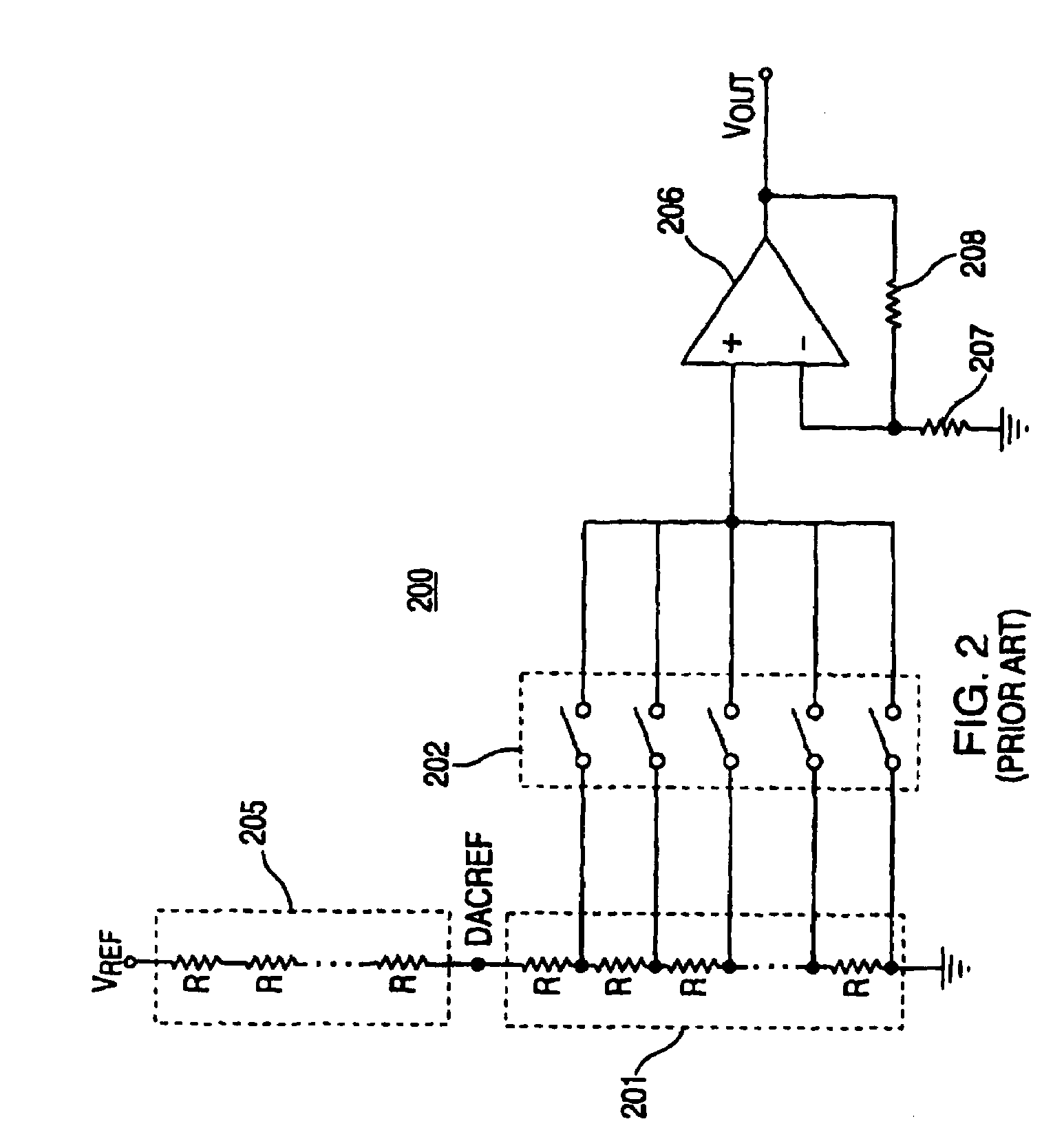

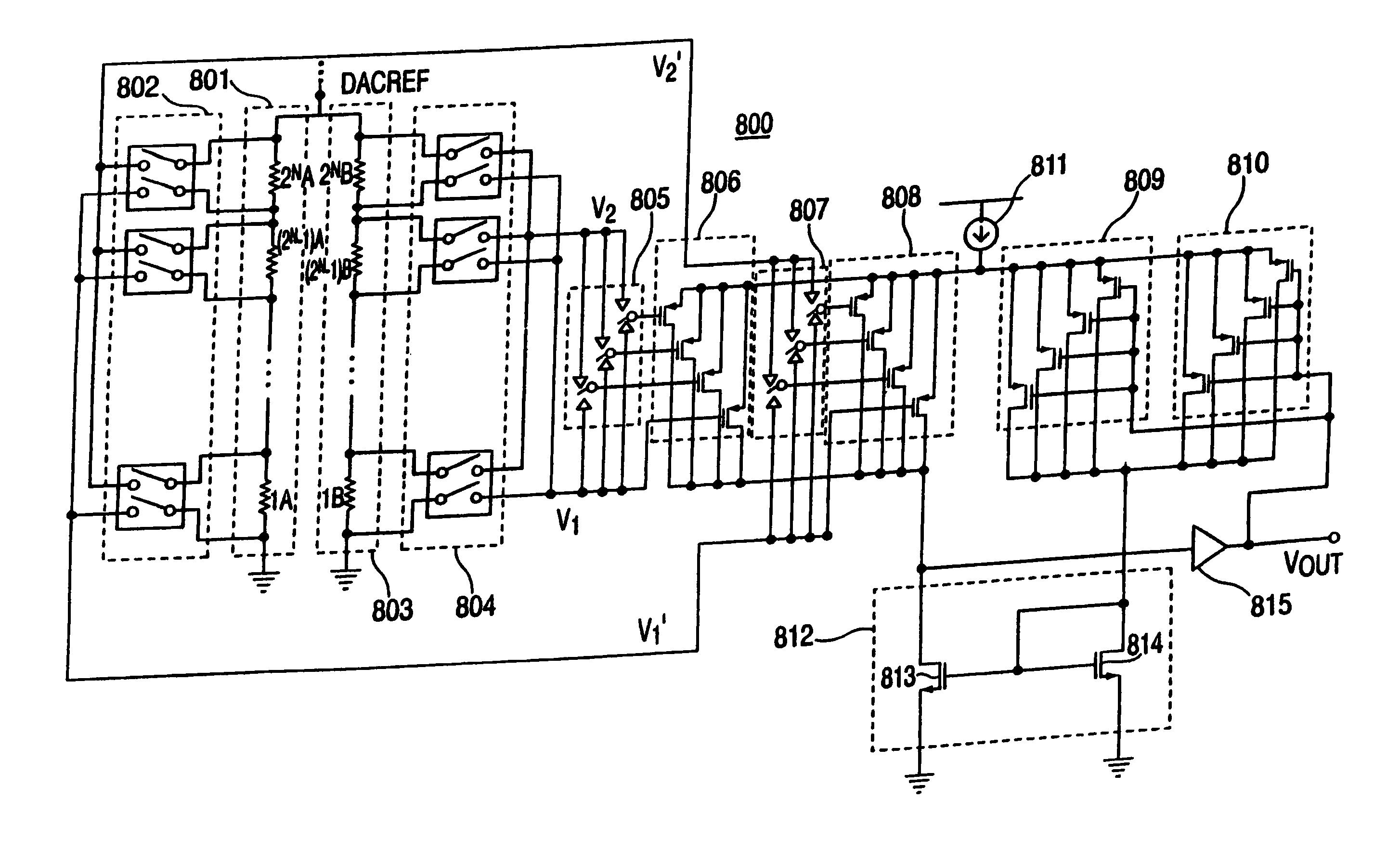

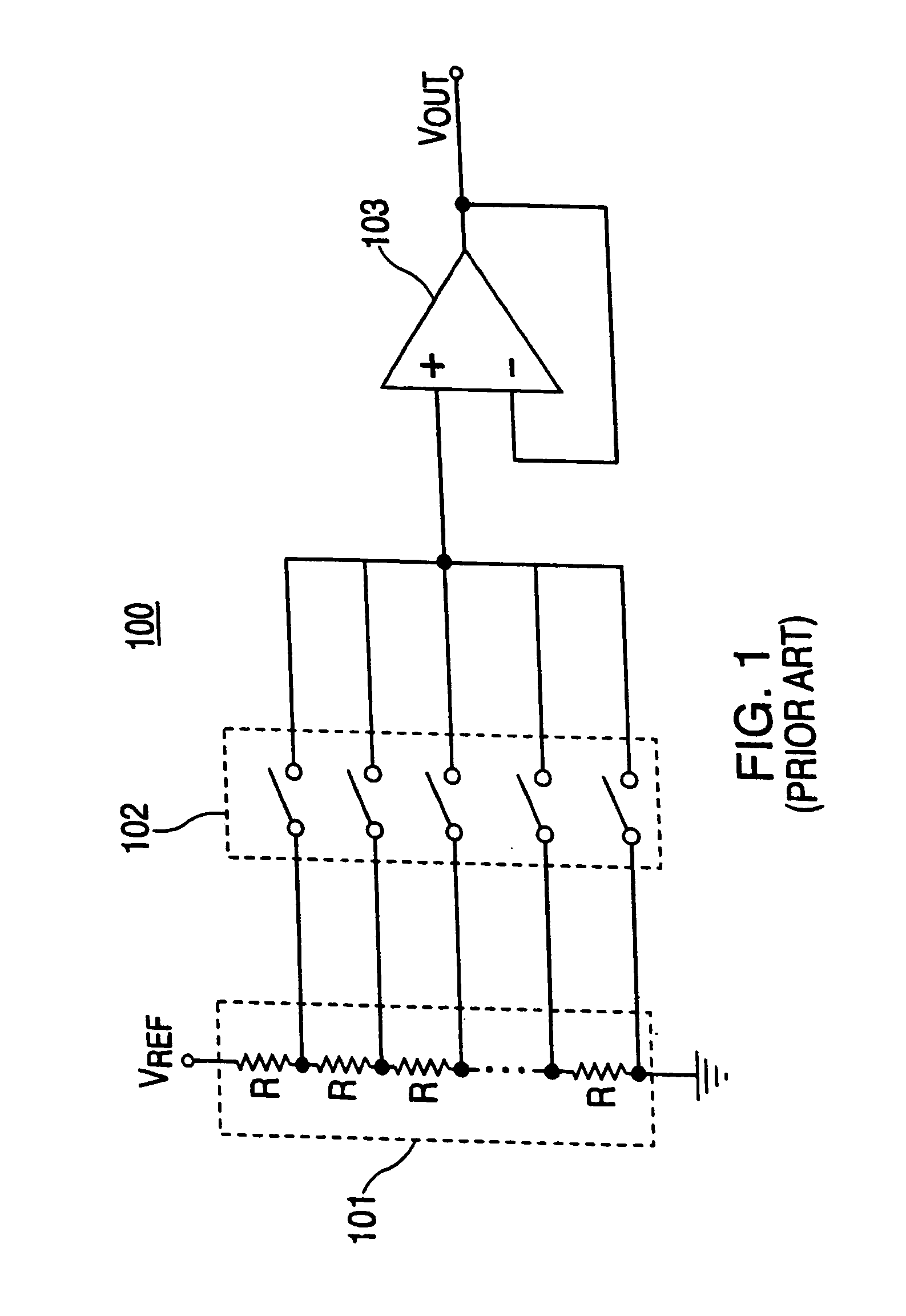

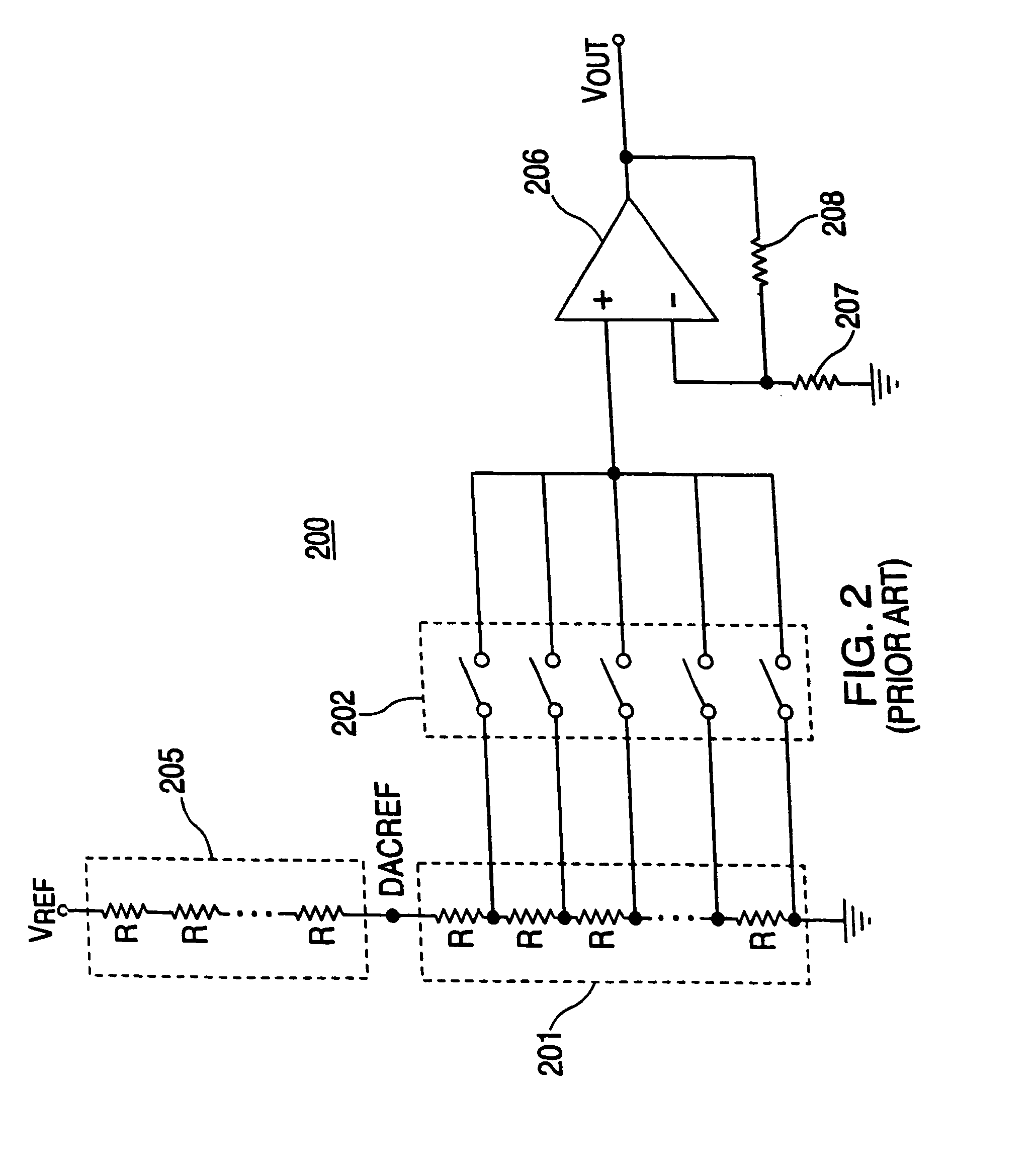

Gradient insensitive split-core digital to analog converter

InactiveUS7414561B1Reduced sensitivity or substantial insensitivity to error gradientsOffsetting effectElectric signal transmission systemsDigital-analogue convertorsElectrical resistance and conductanceDigital analog converter

Digital to analog converter circuits and methods are provided for producing an analog output voltage indicative of a digital input signal with at least partial insensitivity to error gradients. Described are split-core resistive elements, which include a plurality of one-dimensional or multi-dimensional resistive strings, that may be used to reduce or substantially eliminate the effects that error gradients have on the linearity of the analog output voltages of a resistive string or interpolating amplifier DACs. The resistor strings that make up the split-core resistive elements are configured in such a manner that combining respective output voltages from each of the resistor strings results in an analog output voltage that is at least partially insensitive to the effects of error gradients.

Owner:ANALOG DEVICES INT UNLTD

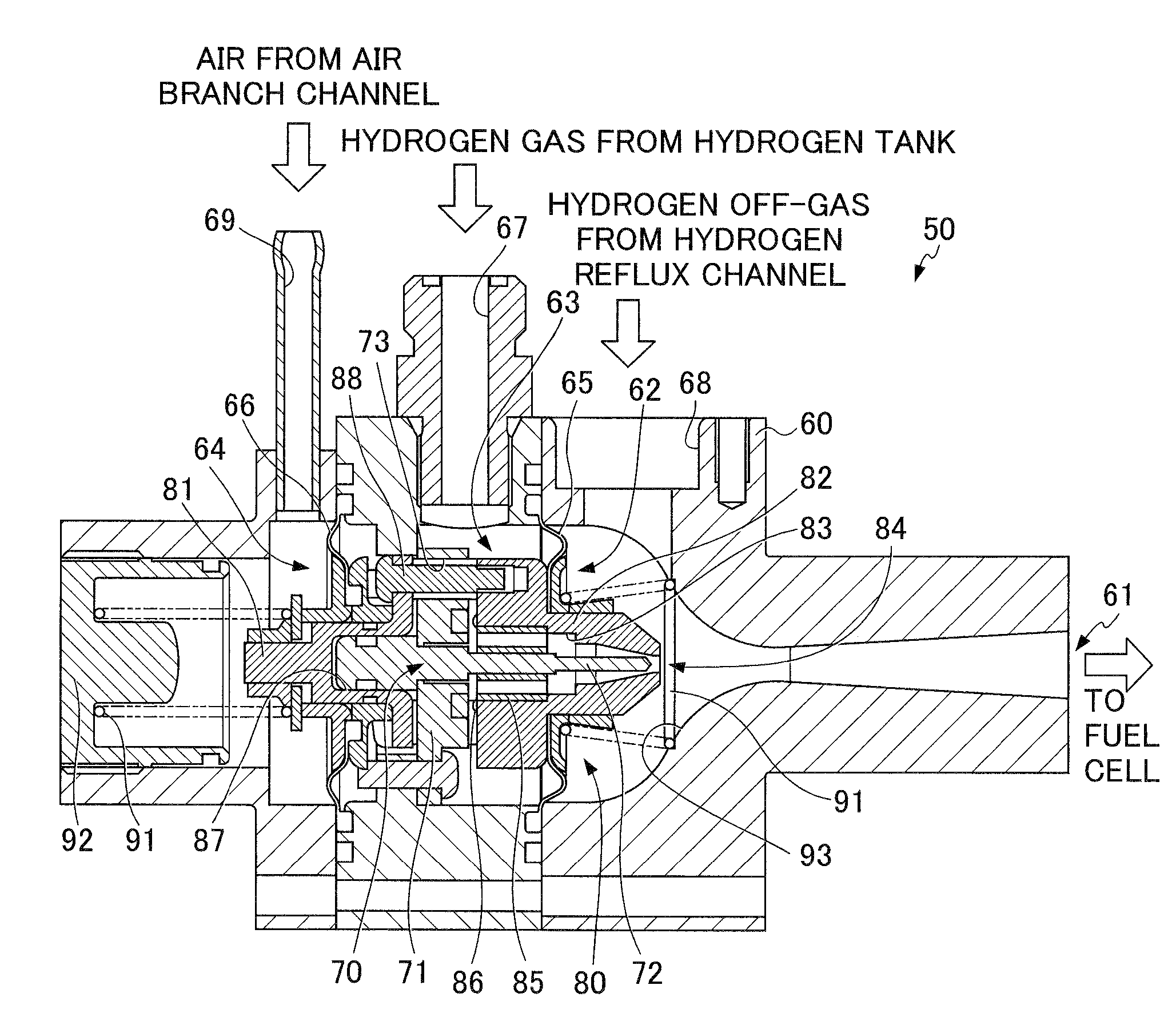

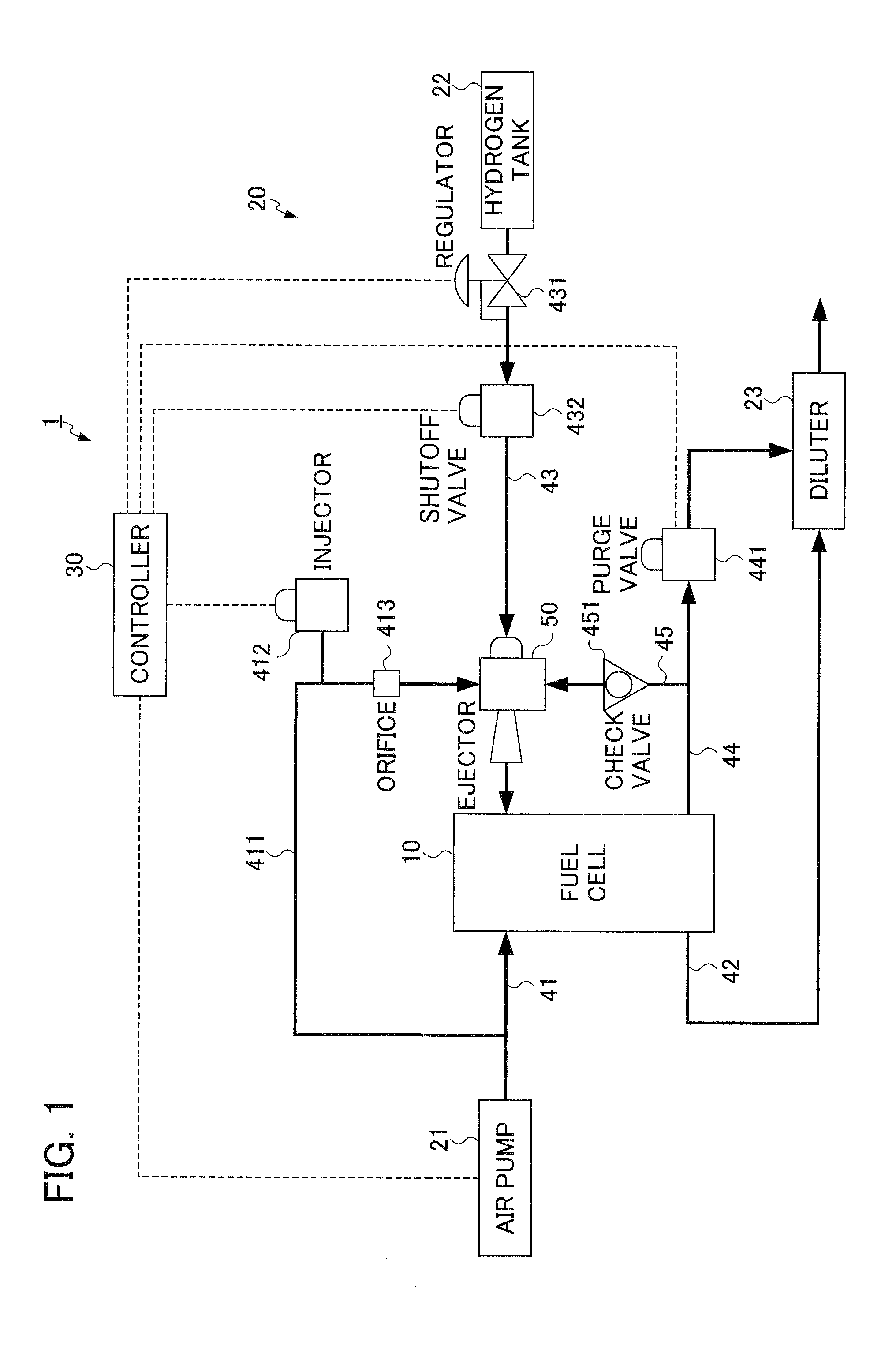

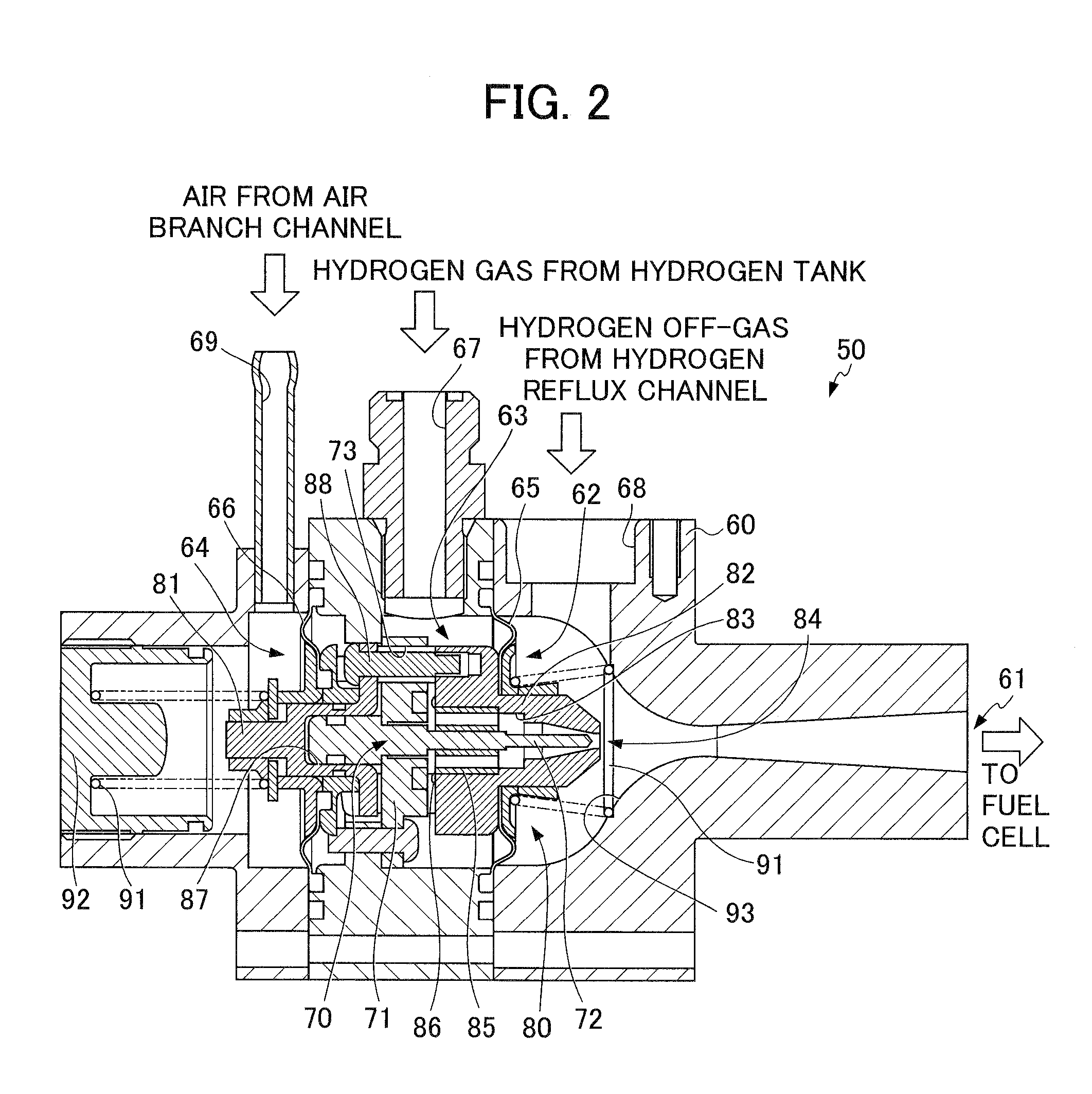

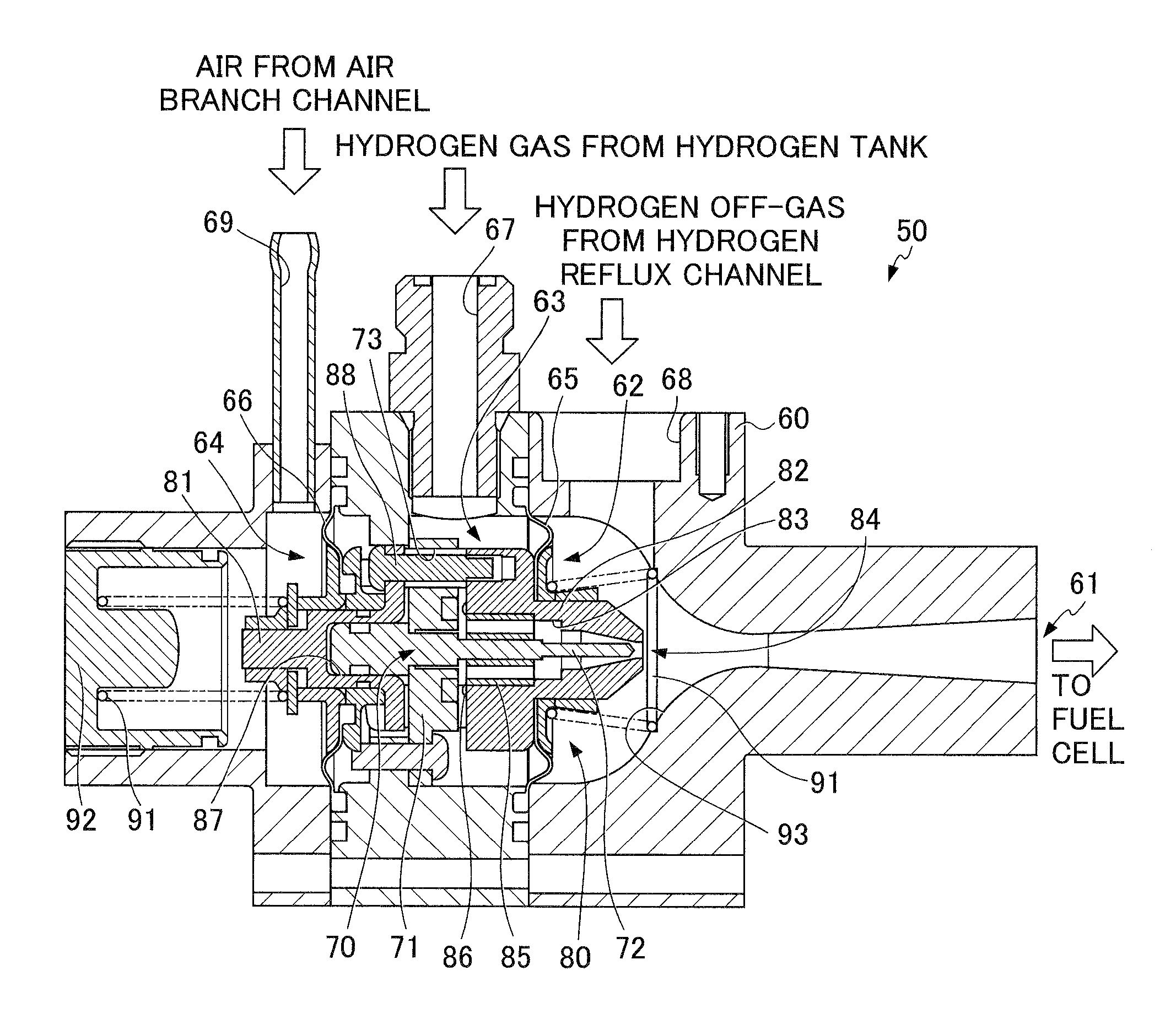

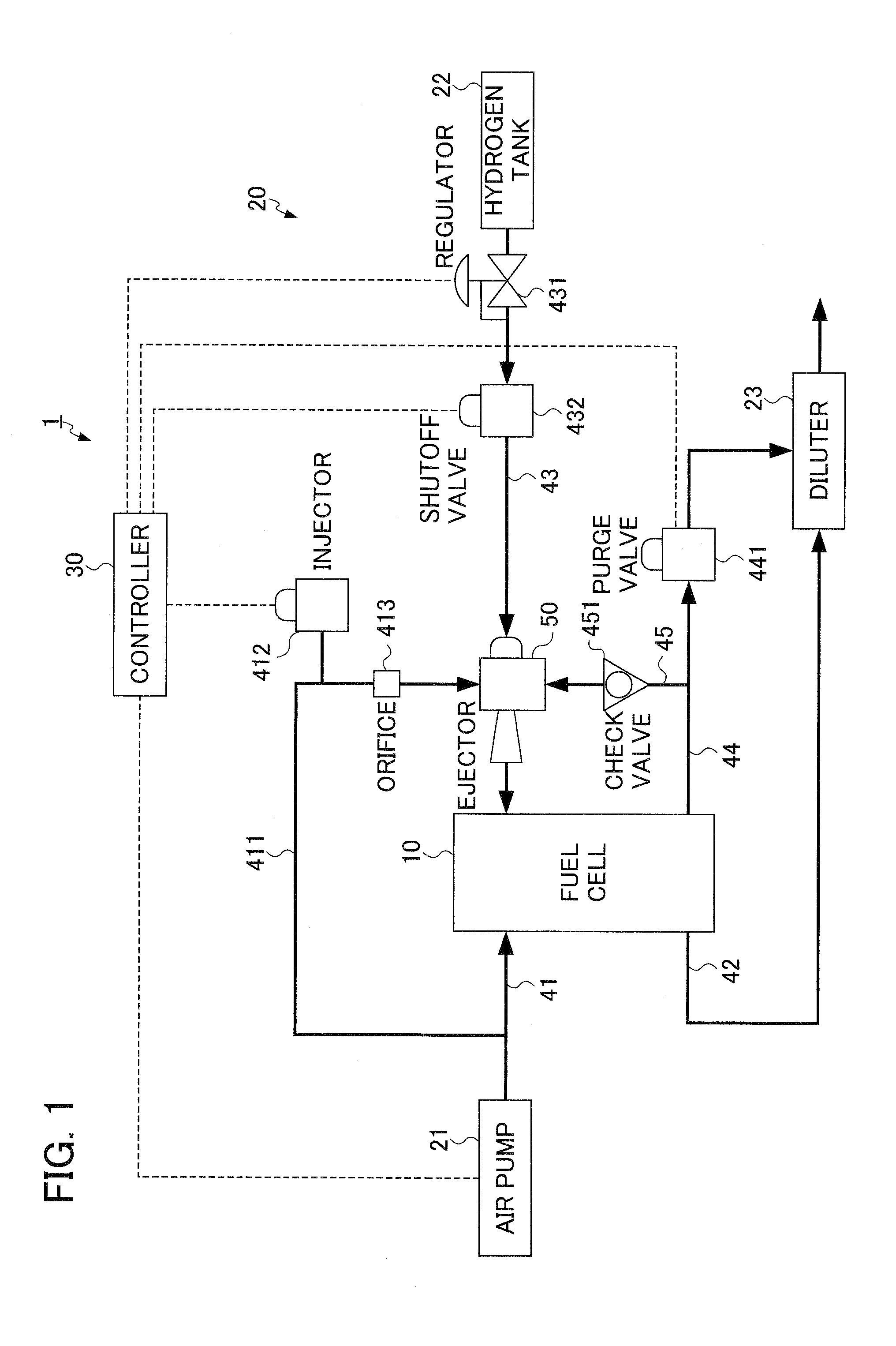

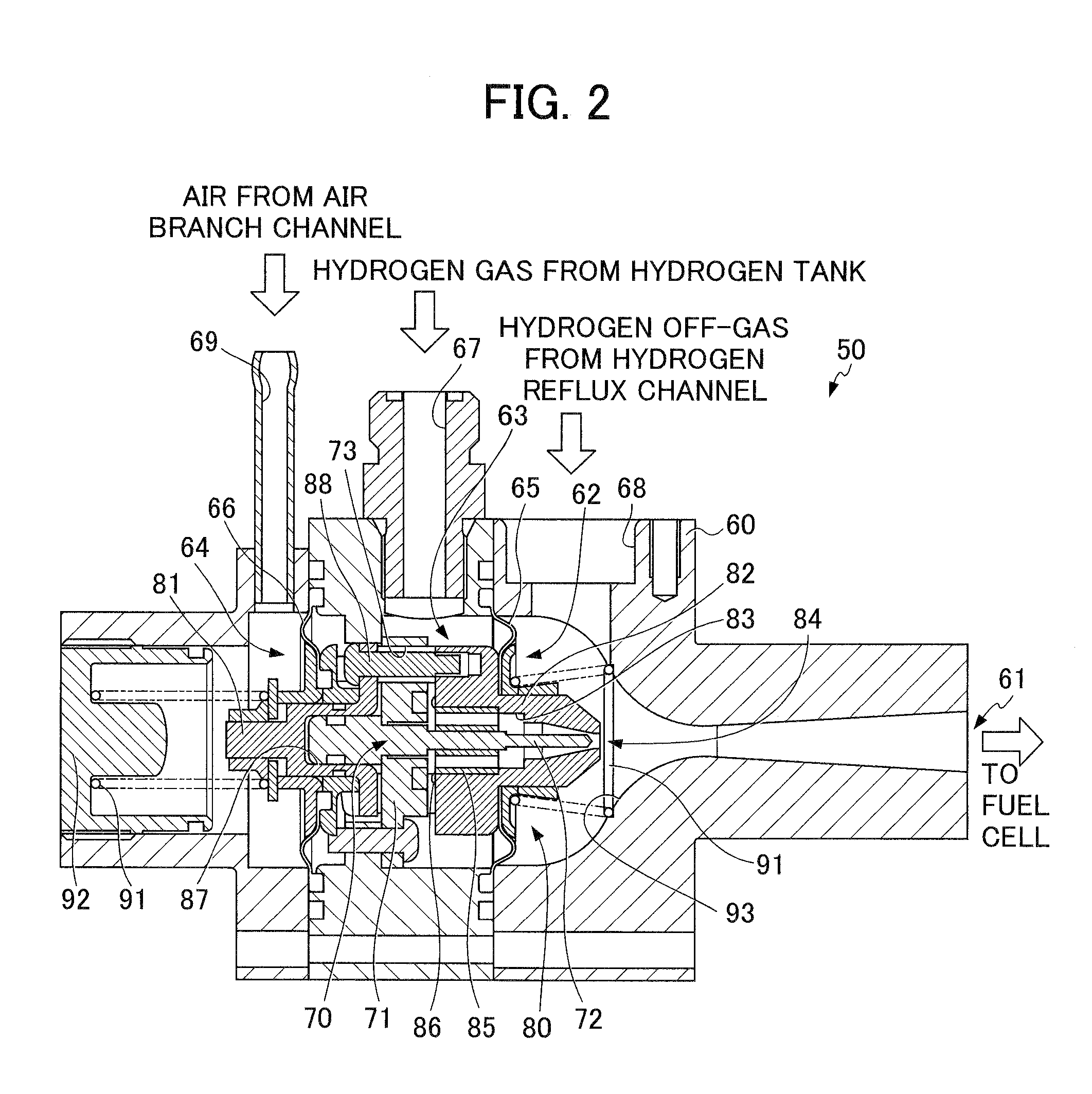

Fuel cell system

ActiveUS20090155092A1Avoid damageDamage can be preventedFuel cell auxillariesJet pumpsFuel cellsHydrogen

An ejector is provided with a first fluid chamber into which hydrogen gas is introduced; a rod-shaped needle; a nozzle exhausting hydrogen gas introduced into the first fluid chamber from an exhaust port; a second fluid chamber into which hydrogen off-gas is introduced; a diffuser provided at the exhaust port of the nozzle; and a third fluid chamber into which air is introduced. The first fluid chamber is provided between the second fluid chamber and the third fluid chamber. The first diaphragm 65 separates the first fluid chamber and the second fluid chamber and the second diaphragm separates the first chamber and the third fluid chamber. Then, the needle and the nozzle moves to approach each other by the pressure of air introduced into the third fluid chamber and isolate each other by the pressure of hydrogen off-gas introduced into the second fluid chamber.

Owner:HONDA MOTOR CO LTD

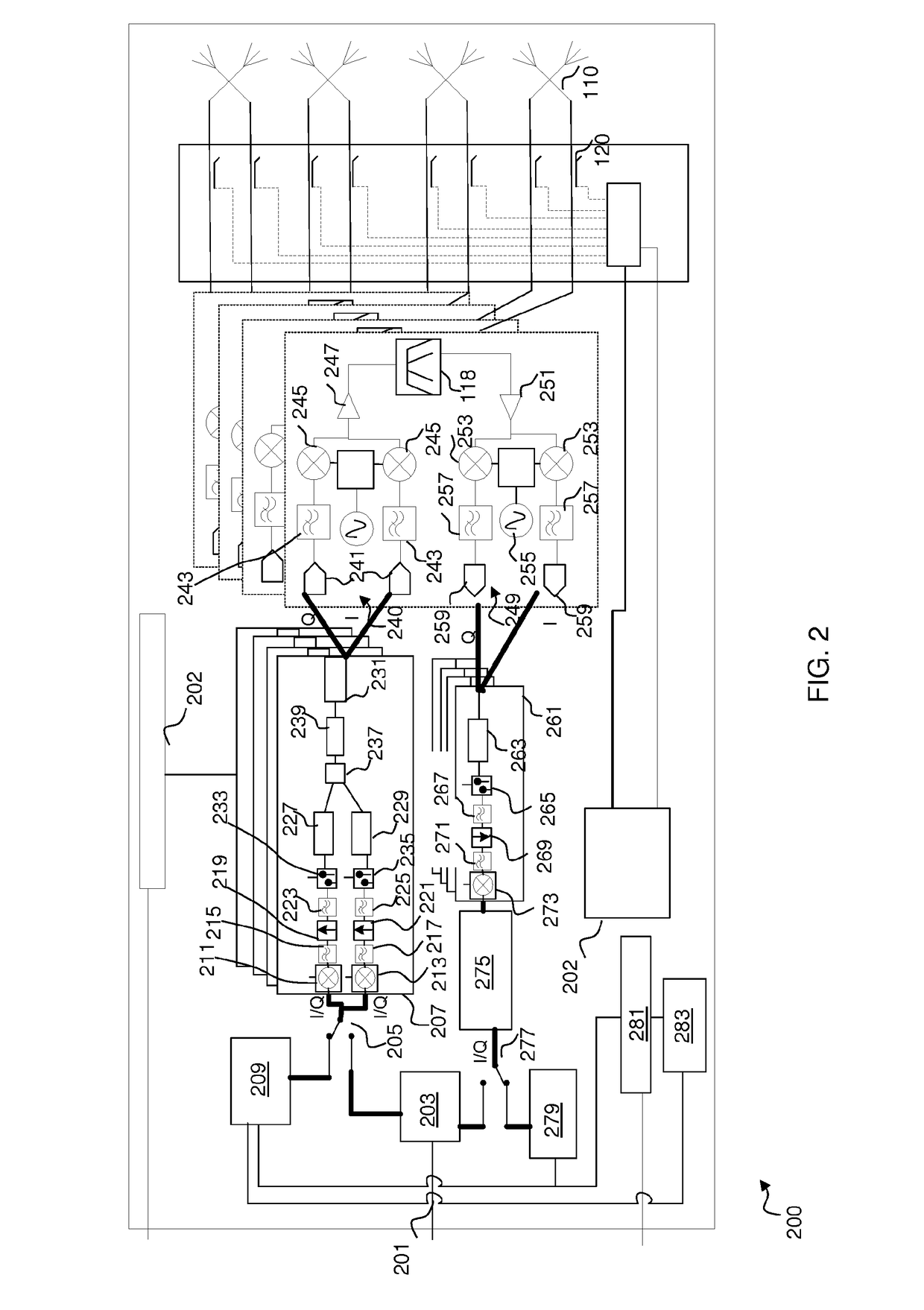

Active antenna system and methods of determining intermodulation distortion performance

ActiveUS20170176507A1Offsetting effectAccurate readingTransmitters monitoringAntenna detailsSpectral bandsComputer module

An active antenna test system comprising an active antenna unit comprising: a test signal generator arranged to generate at least a first test signal and at least one second test signal; a plurality of transmitter modules operably coupled to the test signal generator wherein the plurality of transmitter modules are arranged to simultaneously process the first test signal and at least one second test signal to produce at least one radio frequency test signal therefrom; and at least one receiver module arranged to process one or more signals falling in at least one spectral band determined to be susceptible to intermodulation distortion products caused by the at least one radio frequency test signal being generated from the first test signal and at least one second test signal; and an intermodulation determination module operably coupled to the at least one receiver module and arranged to determine a first received intermodulation performance. A first transmitter module of the plurality of transmitter modules is operably uncoupled from the test signal generator and at least a first test signal and at least one second test signal re-applied to the remaining transmitter modules, such that the intermodulation determination module determines a second received intermodulation performance in order to determine an intermodulation distortion contribution of the first transmitter module therefrom.

Owner:ANALOG DEVICES GLOBAL UNLTD

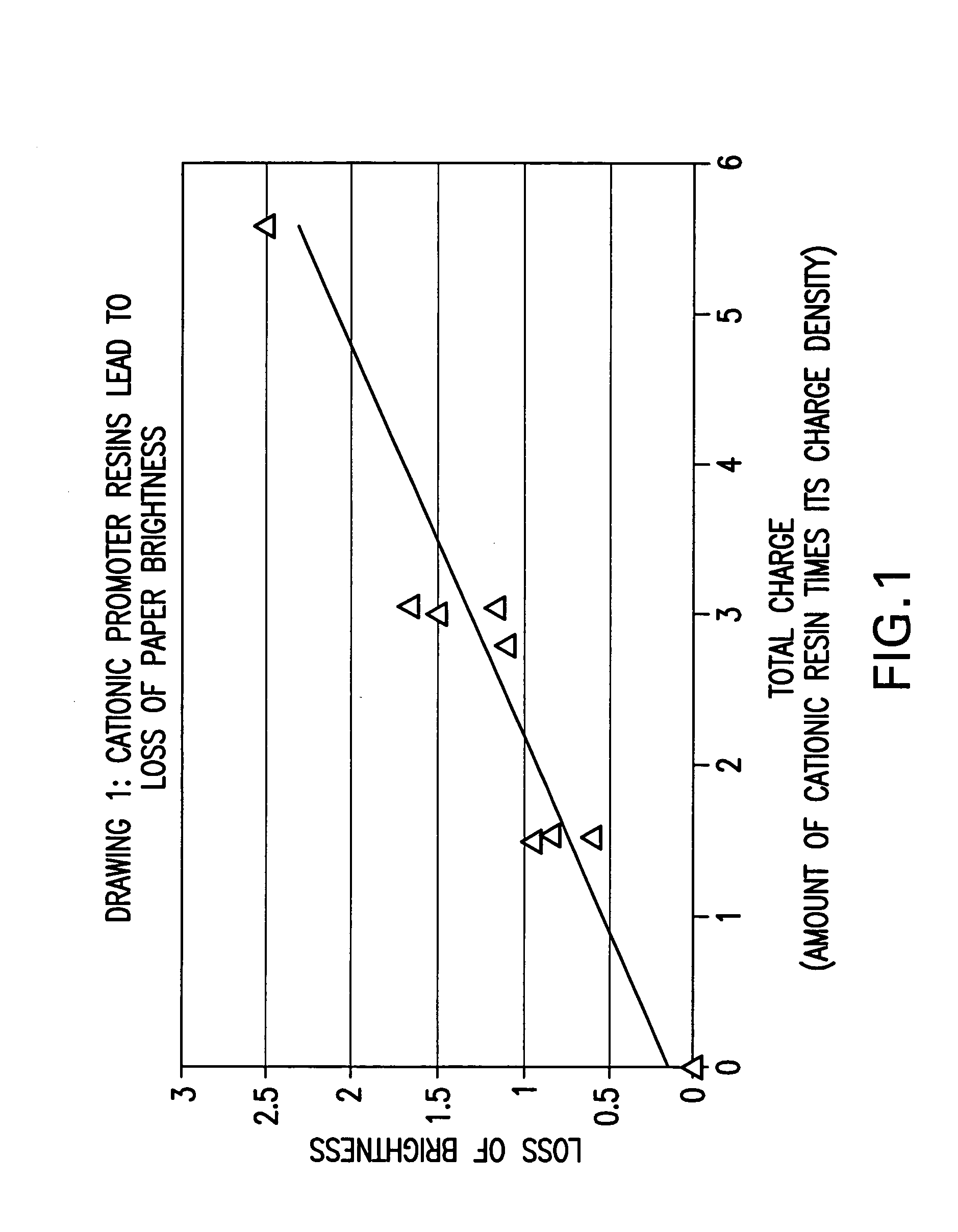

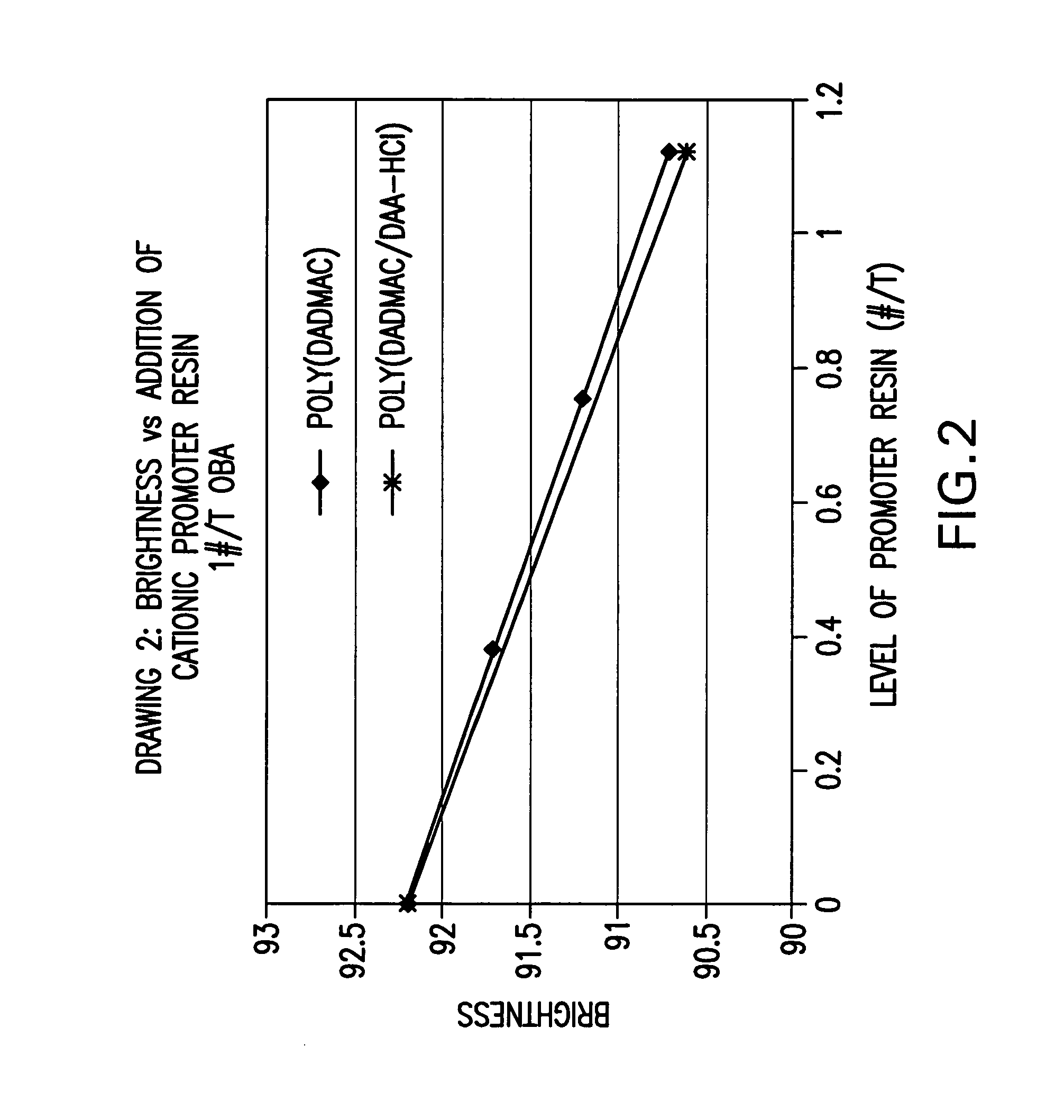

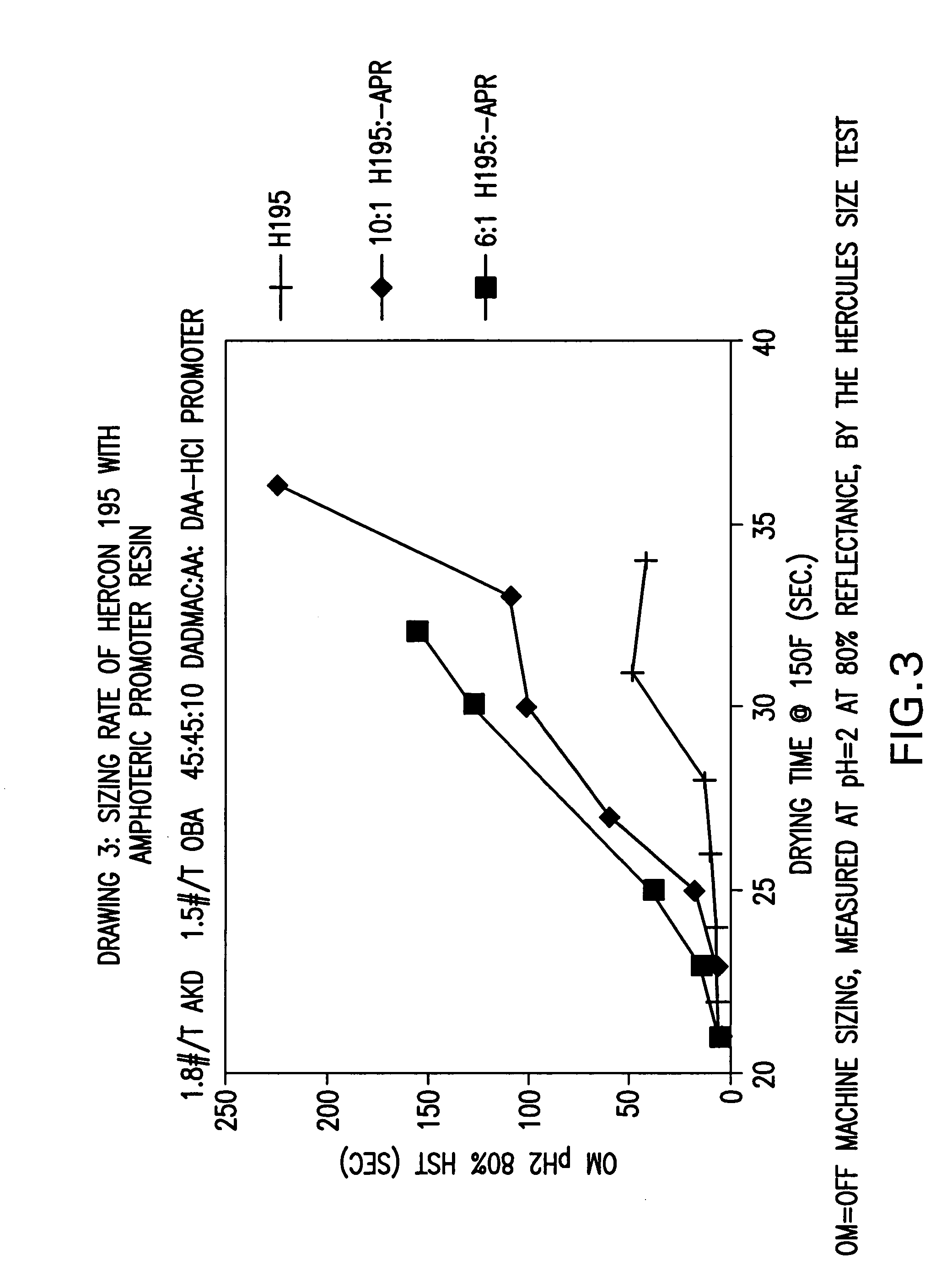

Paper sized with a sizing agent and a selected sizing promoter

InactiveUS7270727B2Increase ratingsOffsetting effectNatural cellulose pulp/paperSpecial paperOrganic acidOptical brightener

Sized paper containing an amphoteric promoter resin that is a polymerization reaction product of a quaternary diallylammonium monomer, optionally a diallylammonium monomer, and an unsaturated organic acid is described. The method of sizing paper with such amphoteric promoter resin compound and a sizing agent provides sized paper with significantly improved sizing property characteristics, and the sized paper exhibits superior retention of brightness due to added optical brighteners.

Owner:SOLENIS TECH CAYMAN

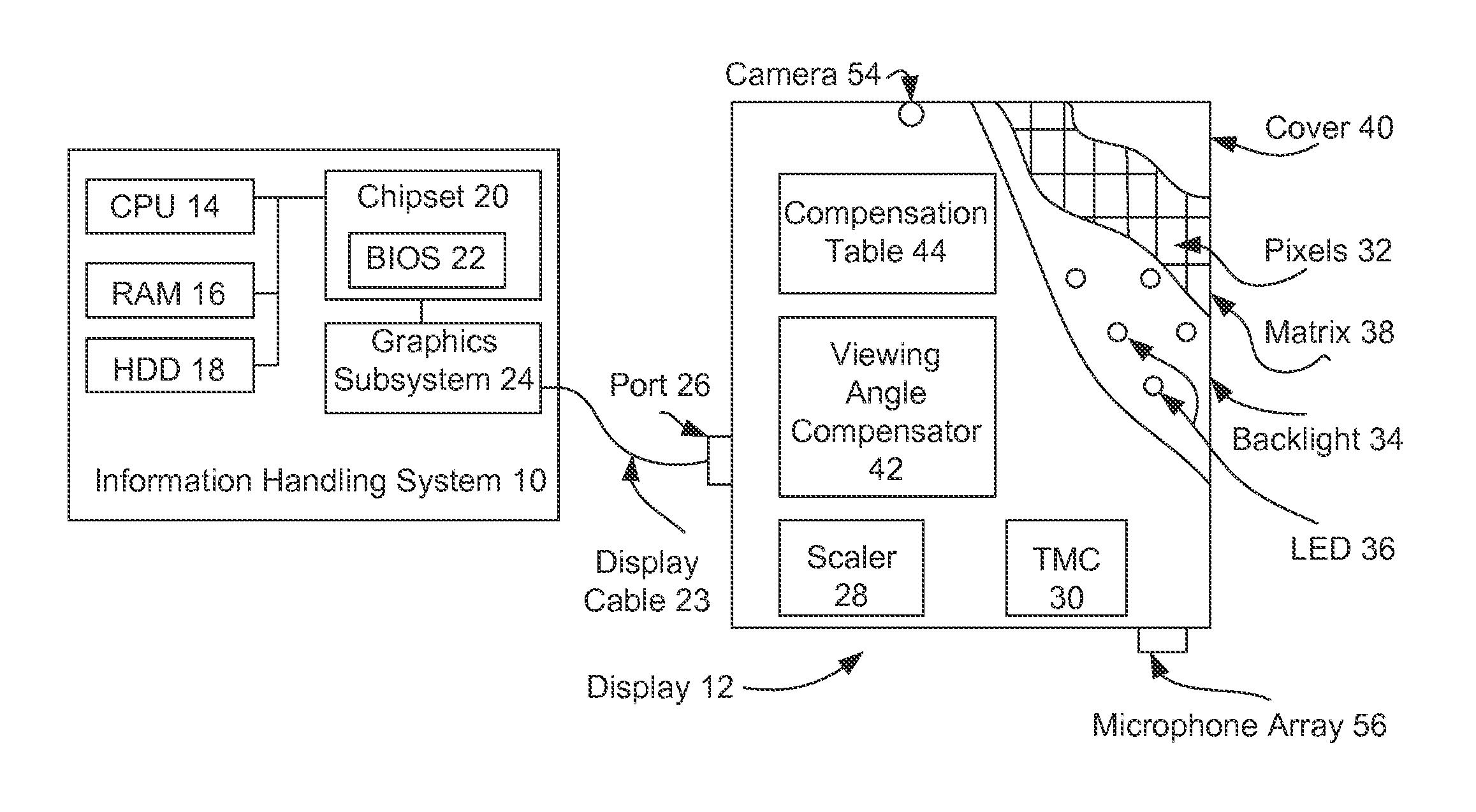

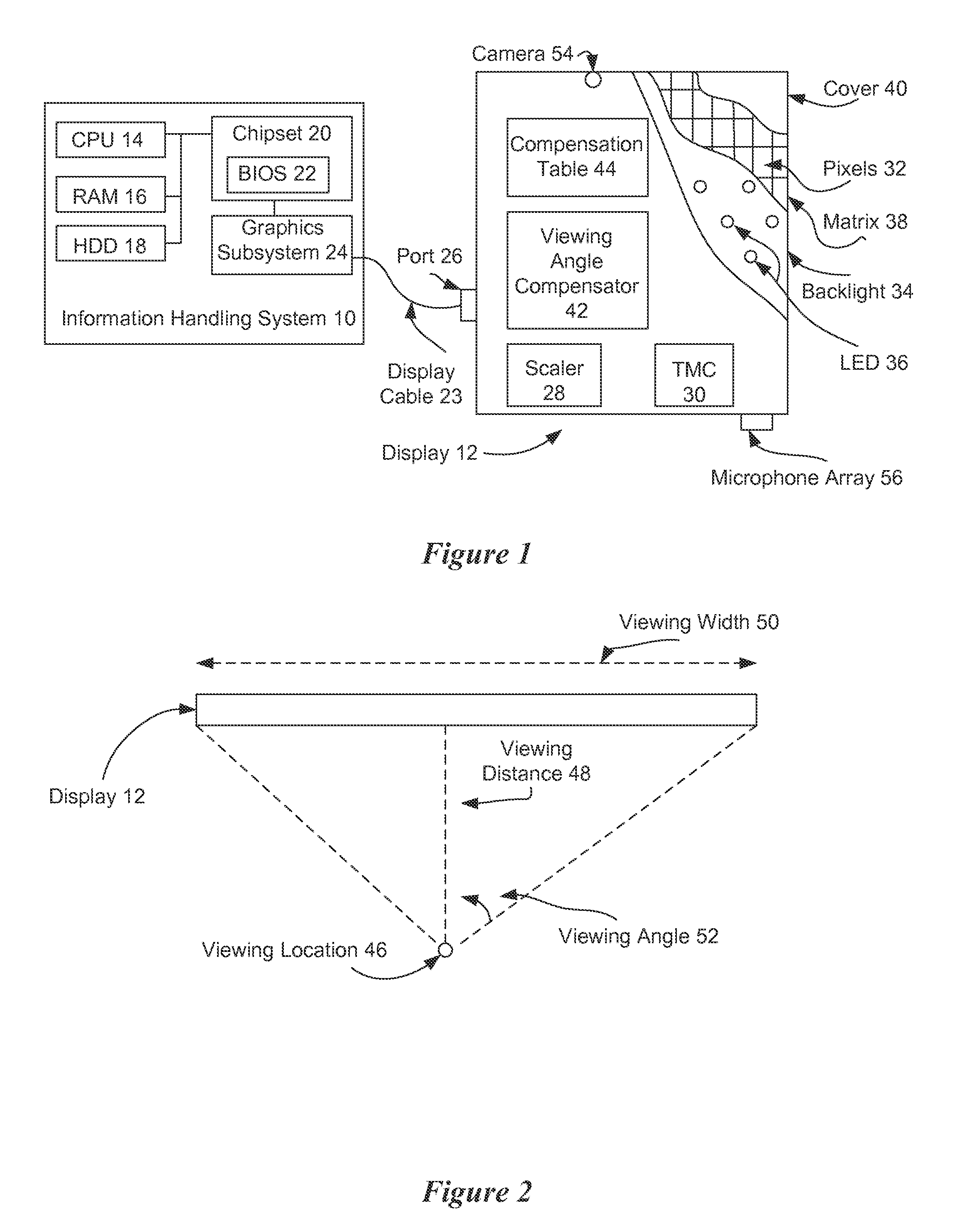

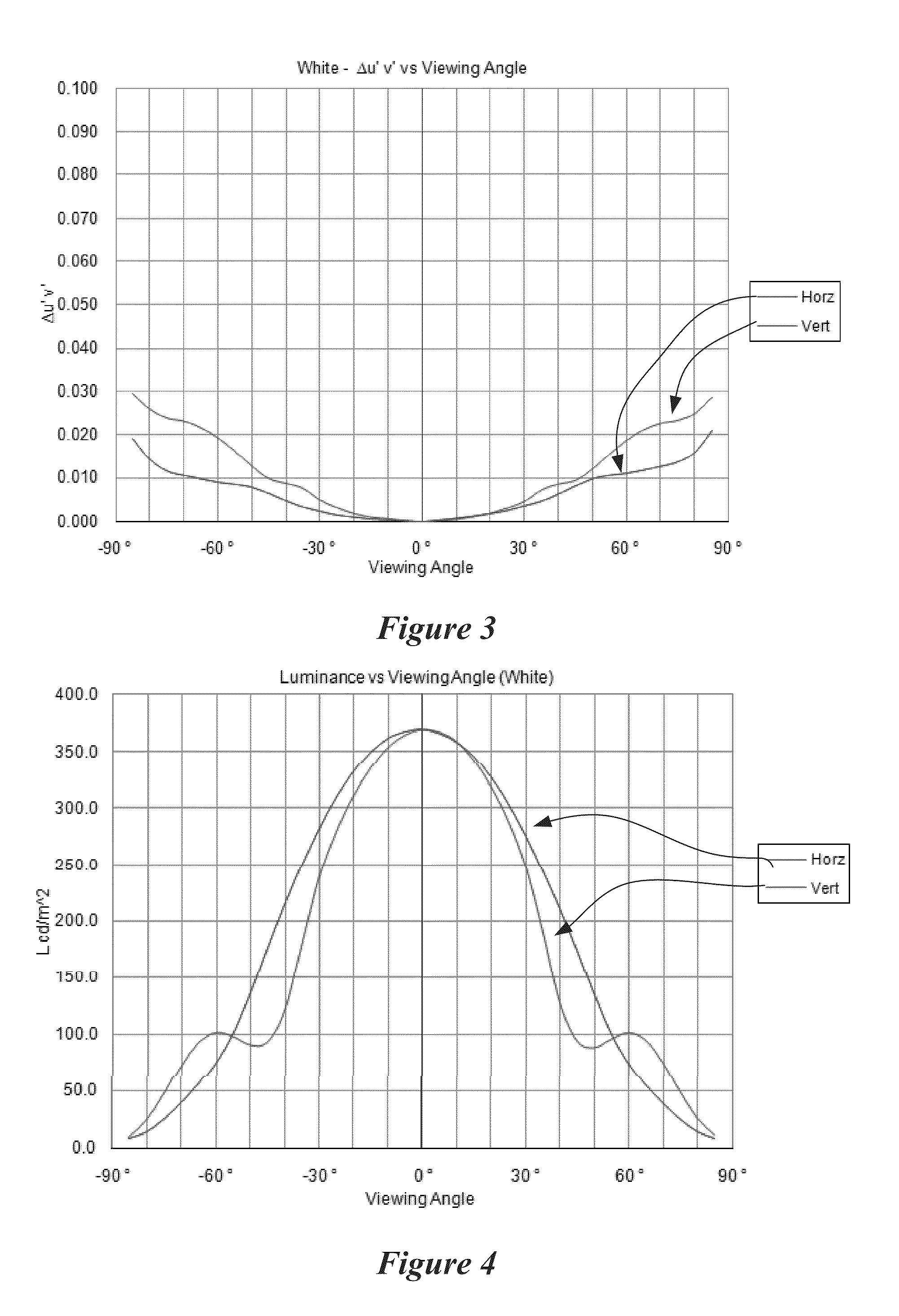

Information handling system display viewing angle compensation

InactiveUS20140146069A1Uniform presentationIncrease brightnessInput/output for user-computer interactionGeometric image transformationComputer graphics (images)Display device

A viewing angle compensator adjusts the presentation of an image at a display so that the image has a uniform appearance to an end user at a viewing location. The angle of viewing from the viewing location to plural groups of pixels is used to compensate the pixel values in each group, such as the brightness, contrast and color presented by each pixel in each group, from original values to compensated values that make the picture appear uniform to the end user at the viewing location.

Owner:DELL PROD LP

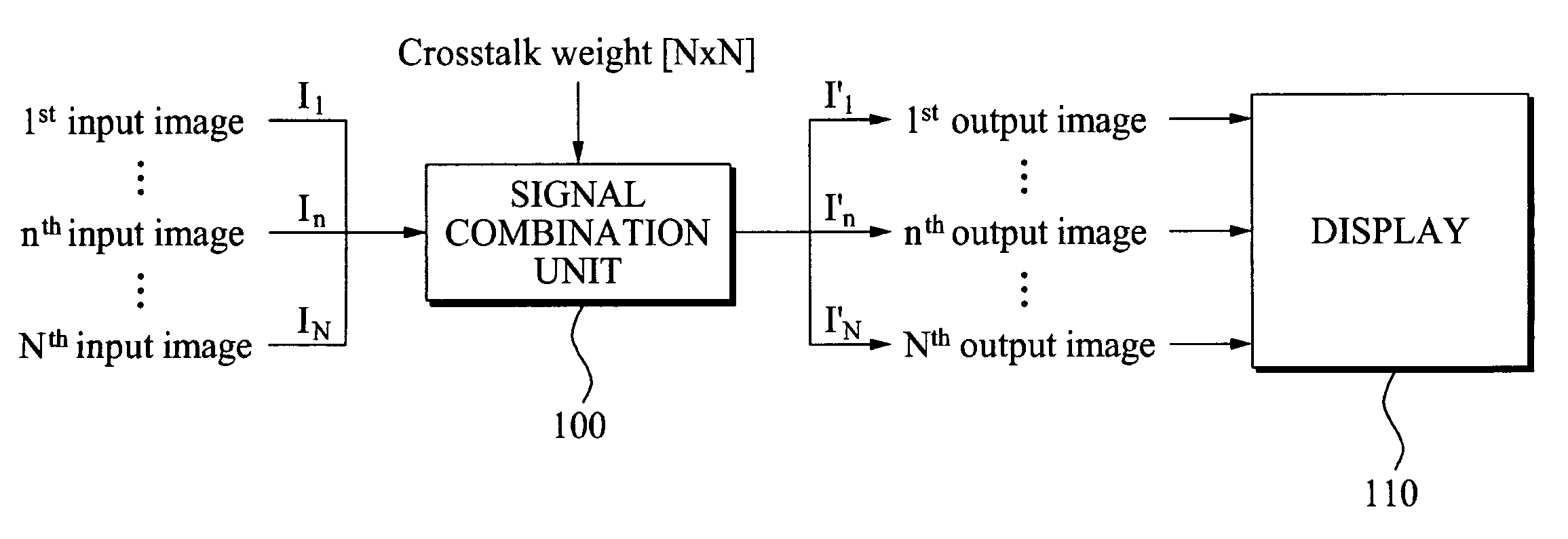

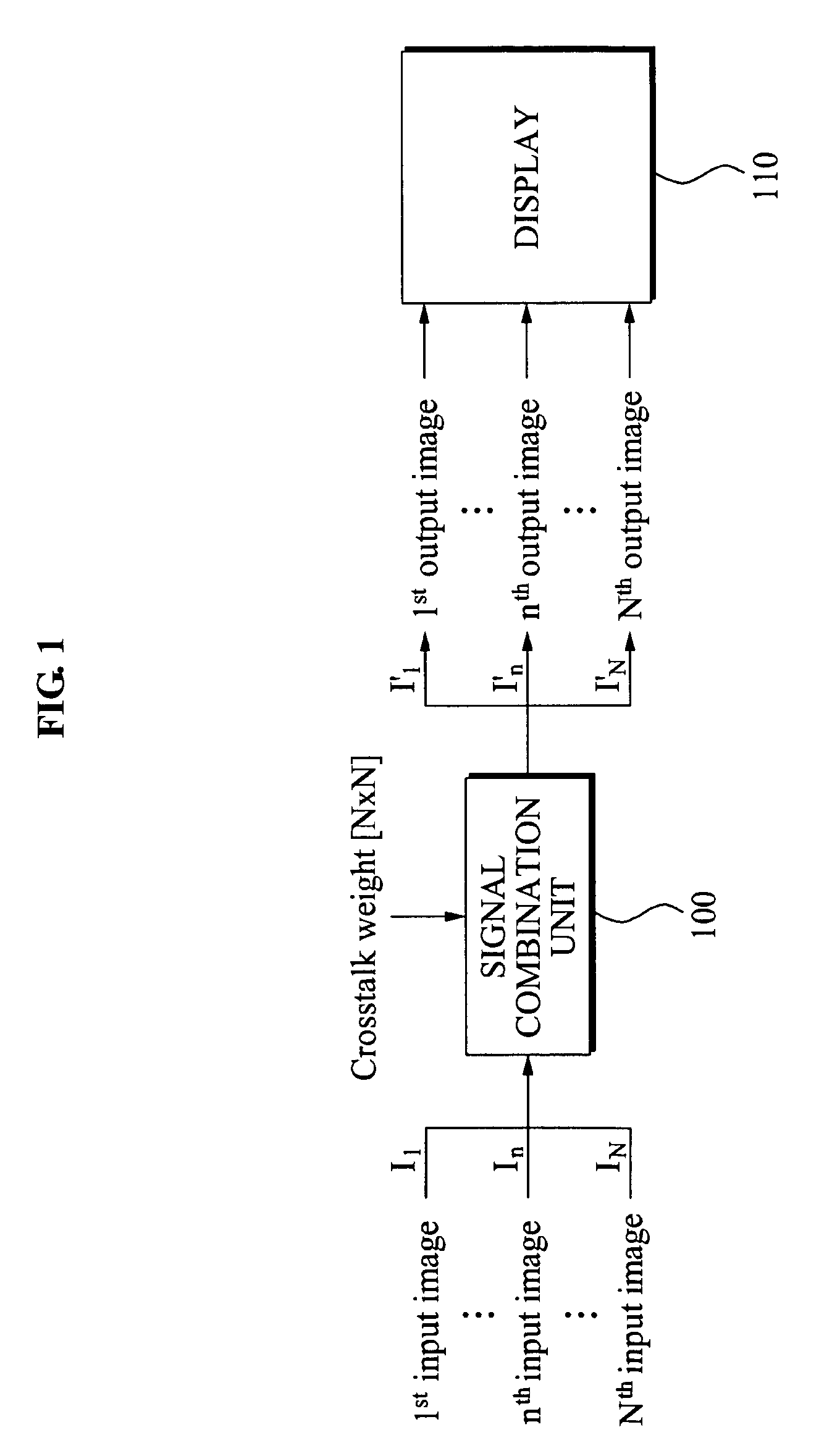

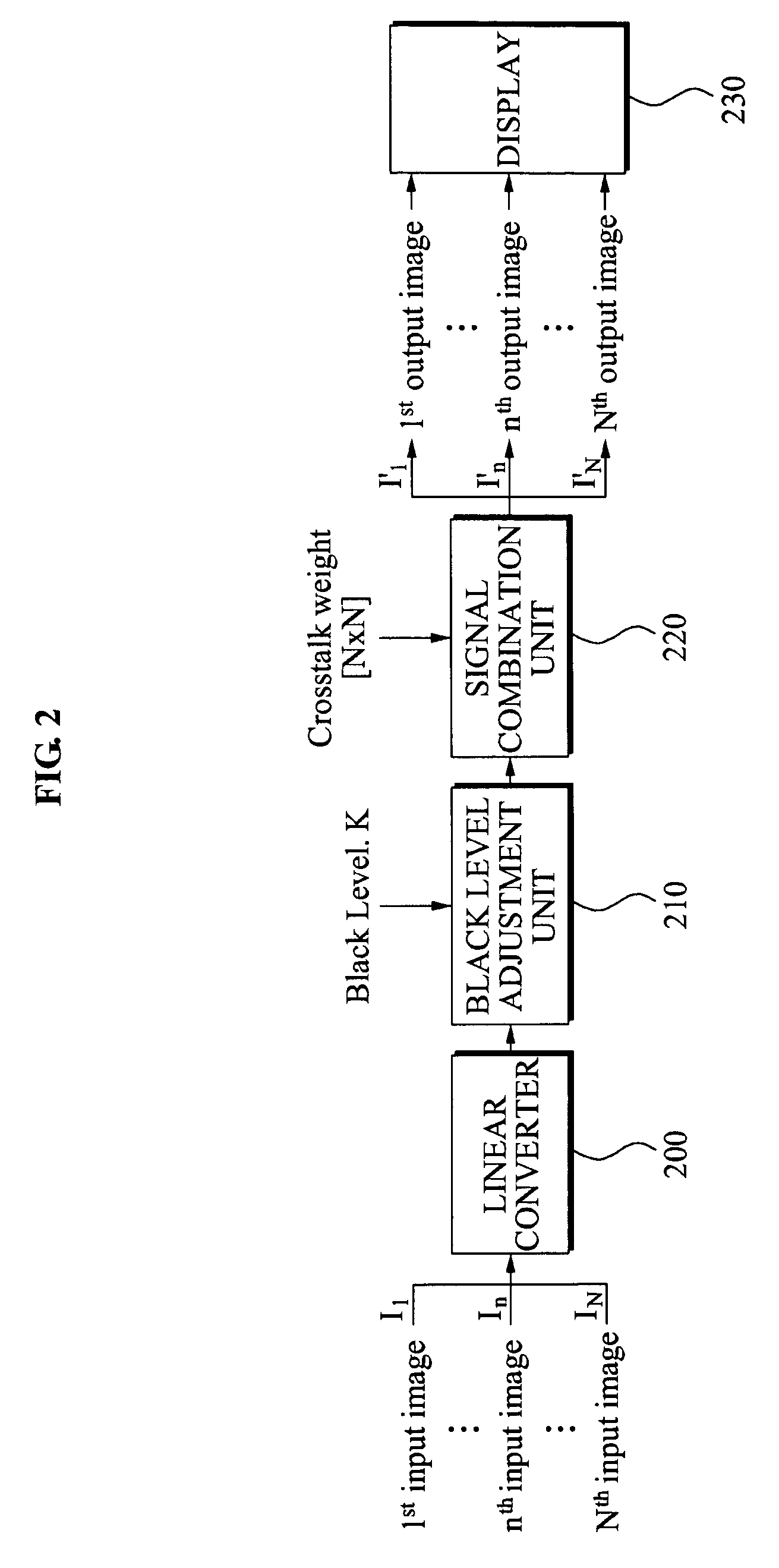

Apparatus and method for compensating for crosstalk between views in three dimensional (3D) display apparatus

InactiveUS20100134493A1Offsetting effectStatic indicating devicesSteroscopic systemsDisplay deviceComputer science

Provided are a method and apparatus for compensating for a crosstalk between views in a three-dimensional (3D) display apparatus. The method and the apparatus may pre-set a crosstalk weight matrix through an actual measurement by considering a characteristic of a display. The crosstalk weight matrix may offset an effect that each of multiple views affects other different views. Also, when multi-view input signals are received, the method may generate luminance-compensated multi-view input signals by multiplying the crosstalk weight matrix and a luminance matrix that includes a luminance of each of the multi-view input signals, and may output the luminance compensated multi-view input signals as input signals of the display.

Owner:SAMSUNG ELECTRONICS CO LTD

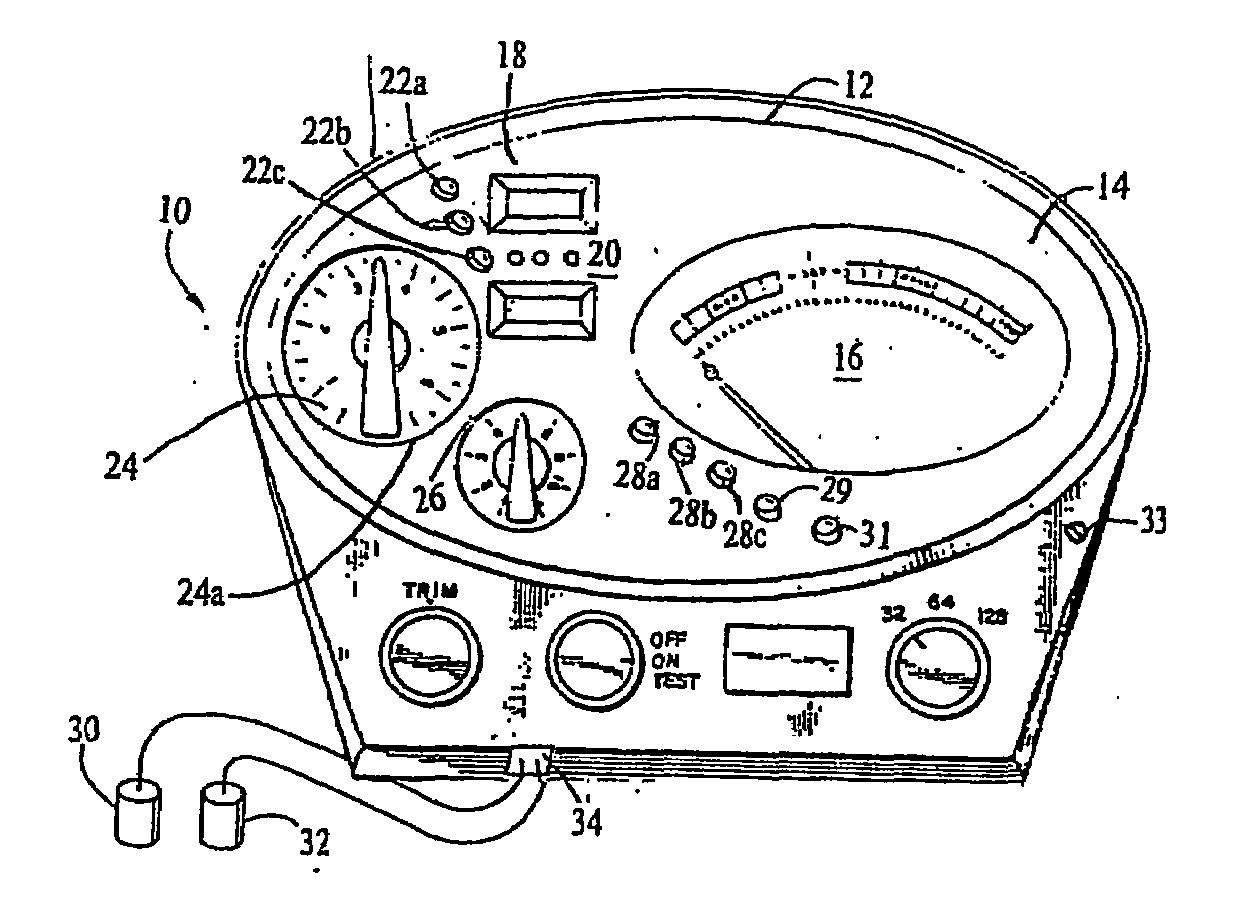

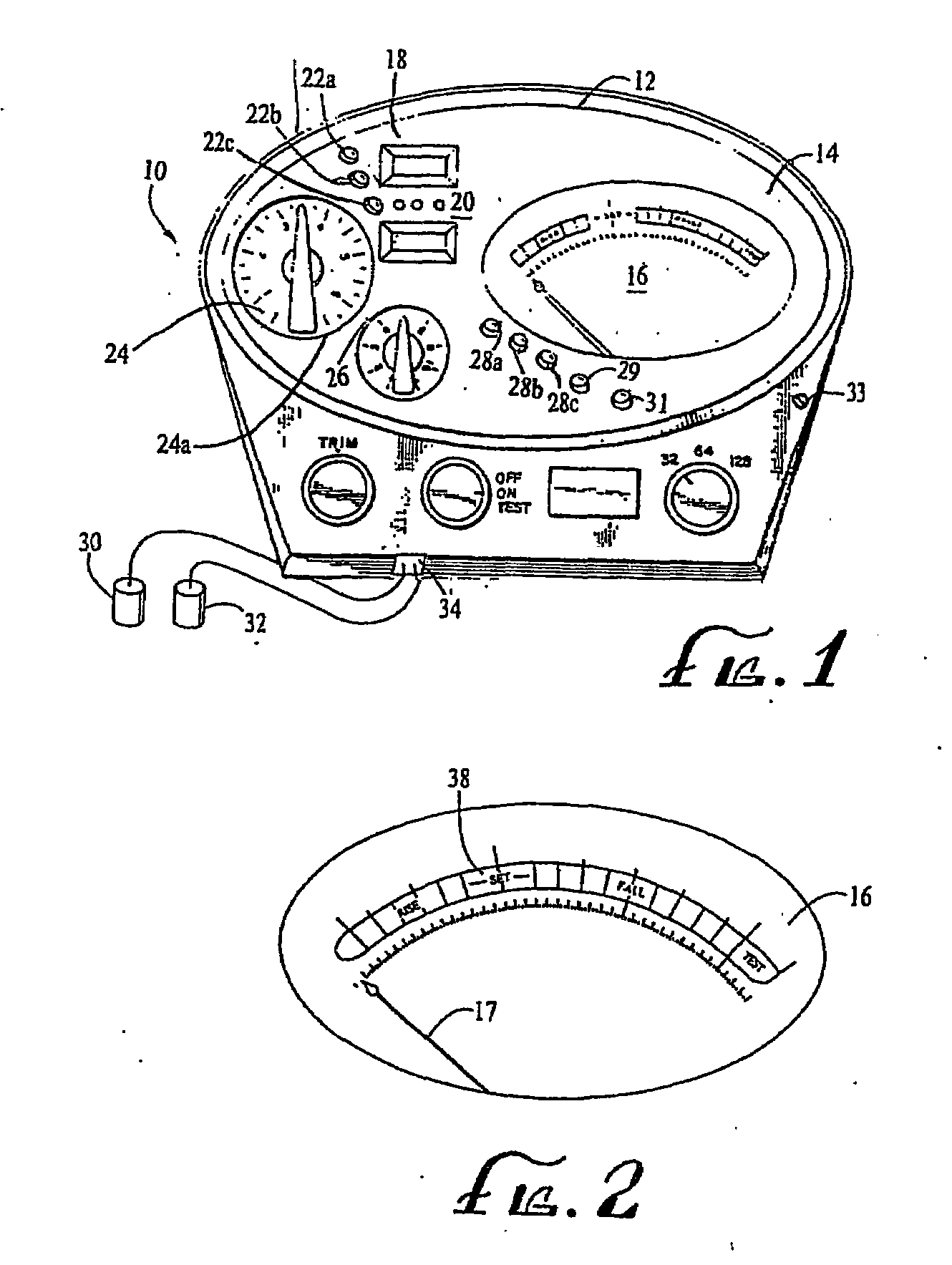

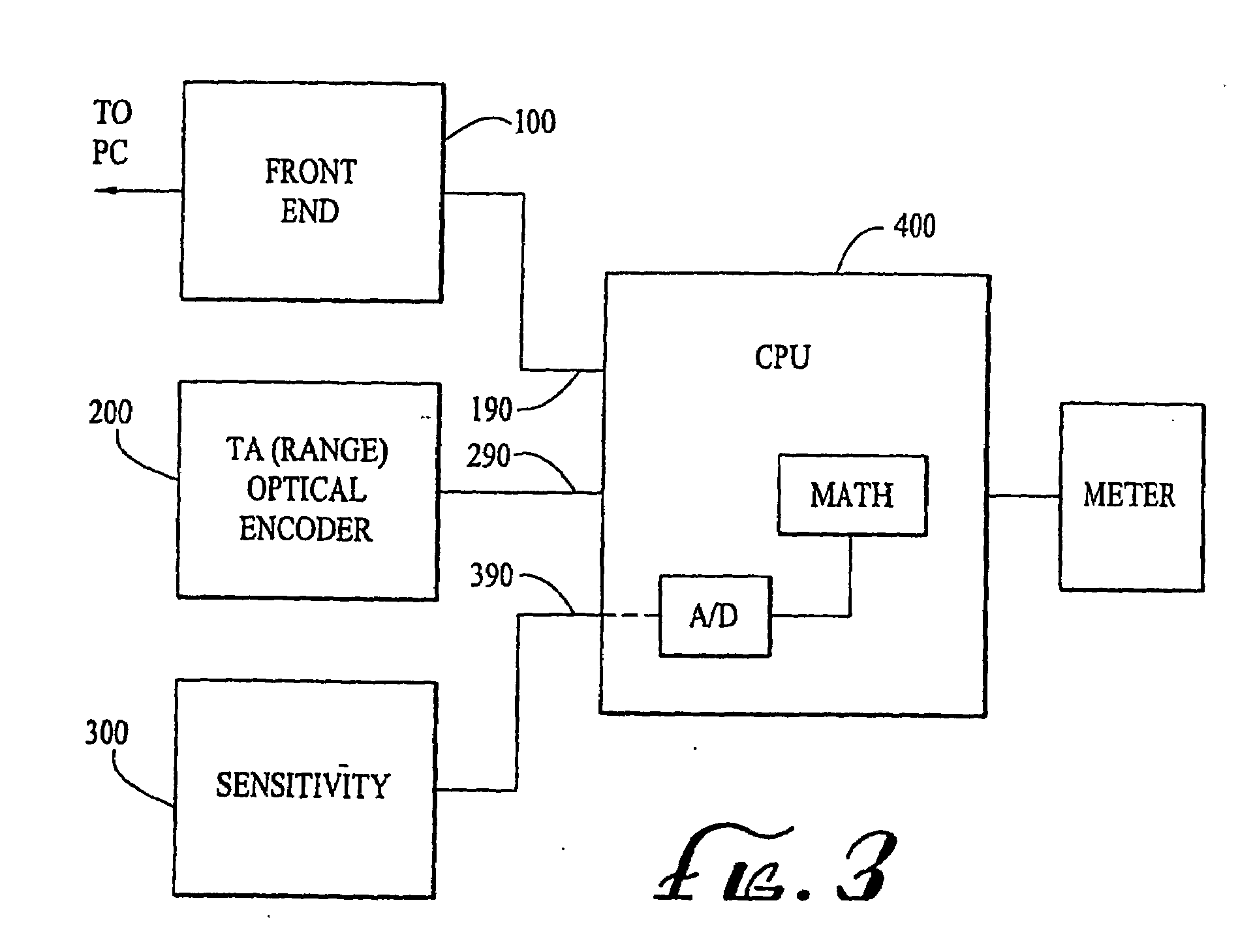

System For Measuring And Indicating Changes In The Resistance Of A Living Body

ActiveUS20080139957A1Improve accuracyImprove display responseDiagnostic recording/measuringSensorsElectricityElectrical resistance and conductance

An improved device for indicating and measuring small variations in the resistance of a living body is disclosed which utilizes a central processing unit to digitally process sensed body resistances and drive a resistance-indicating display while compensating for the effects of component aging, component tolerances and component temperatures. The device includes an automatic calibration circuit that is automatically activated on each powering up of the device to measure and store measurement values for a plurality of synthesized body resistances that are used to form a compensation model against which sensed body resistances are, subsequently compared for automatic adjustment of display driving measurement values. The central processing unit additionally adjusts the gain of the meter-driving signal by a gain factor dependant on a user-selected meter-sensitivity setting to avoid previously experienced difficulties in monitoring small changes in body resistance caused by difficulty in setting the initially desired meter reading at certain meter-range values, as well as occasional false and unexpected reversals of meter reading as the meter's range was adjusted.

Owner:CHURCH OF SPIRITUAL TECH

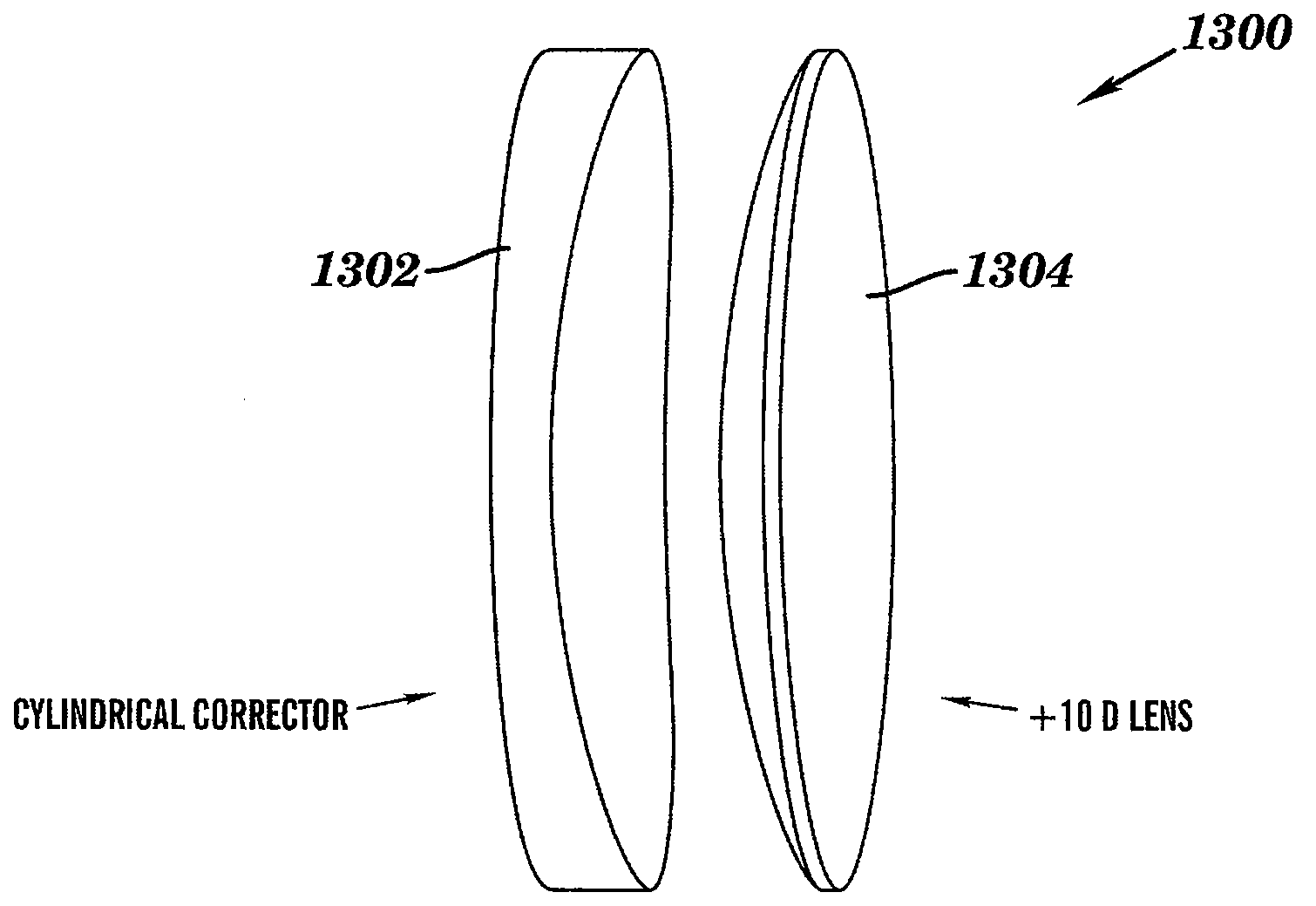

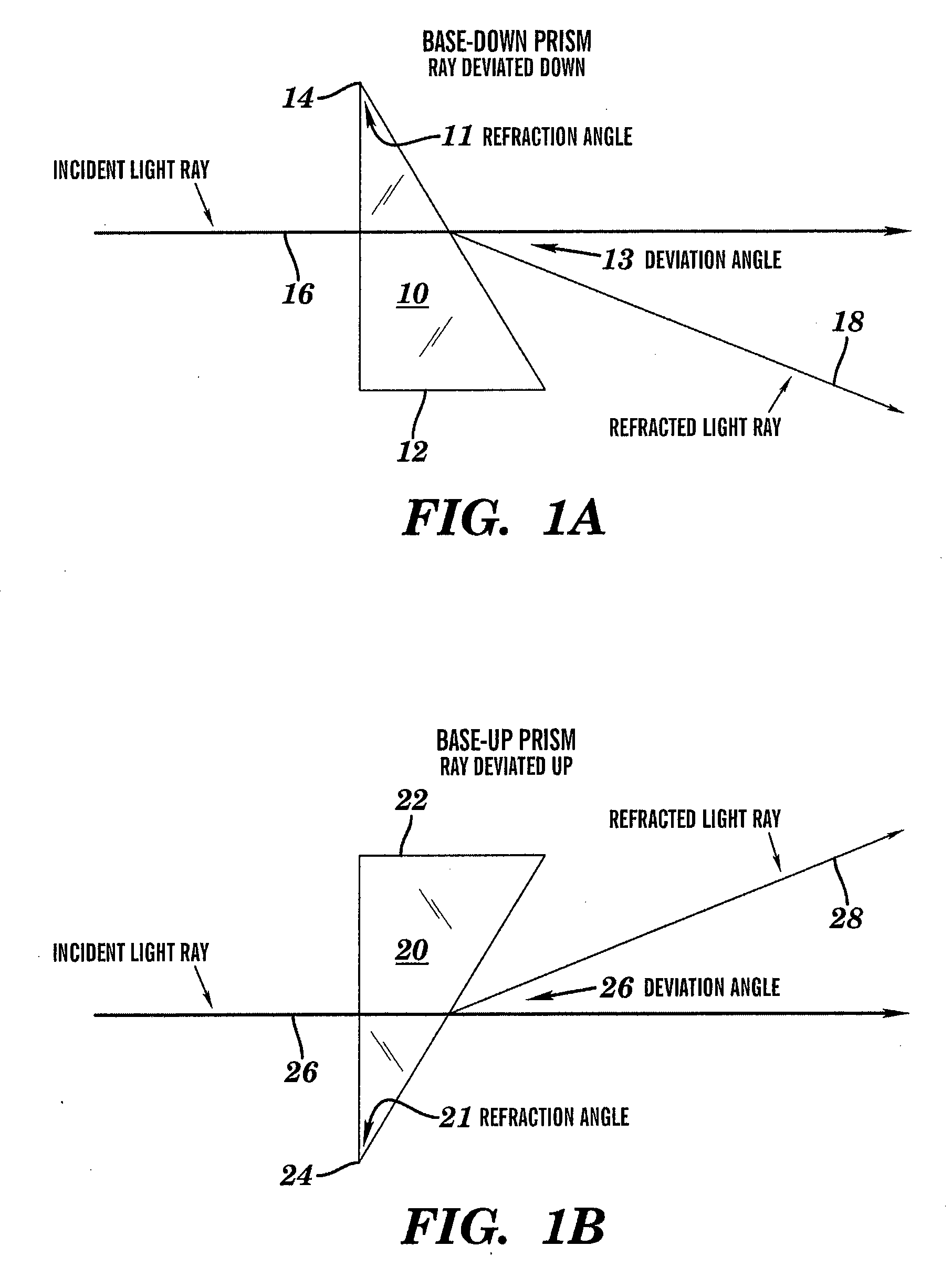

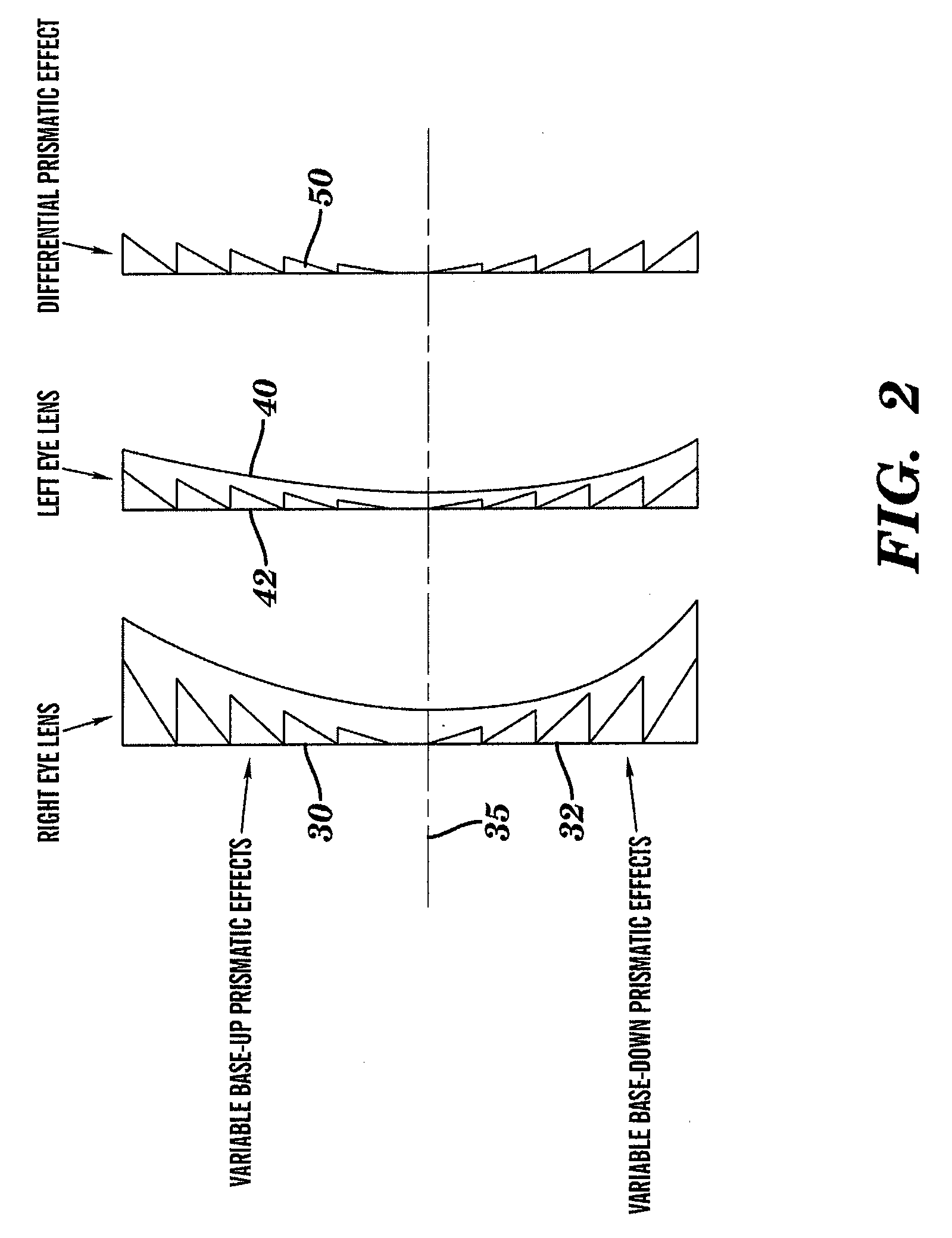

Optical elements having variable power prisms

Optical elements having a plurality of integral prism facets having varying prismatic power are provided. These optical elements address the disadvantages of conventional therapeutic optical prisms by addressing the undesirable variation in prismatic effect that results when conventional prisms are combined with optical lenses in binocular vision. Specifically, the present invention can equalize differential prismatic effects of right and left eye lenses over their entire aperture. The optical elements may include a plurality of prism facets having base-down and base-up prismatic power. The elements may include individual elements having variable prismatic elements, individual elements combining both conventional prisms and variable prism, or separate elements having conventional prisms and variable prism. The plurality of integral facets or a substantially continuous smooth surface may be provided, for, example, a cylindrical surface having a circular or non-circular profile. Methods of correcting binocular vision are also disclosed.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

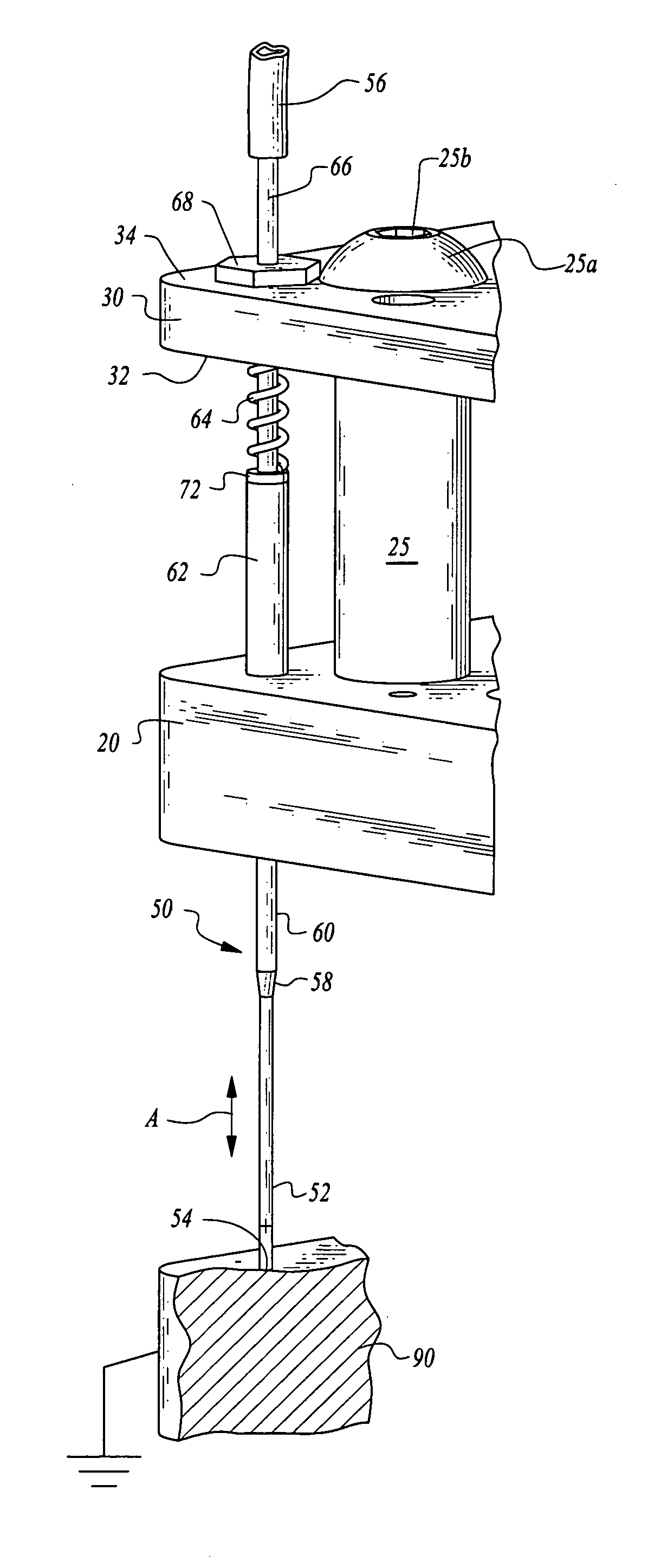

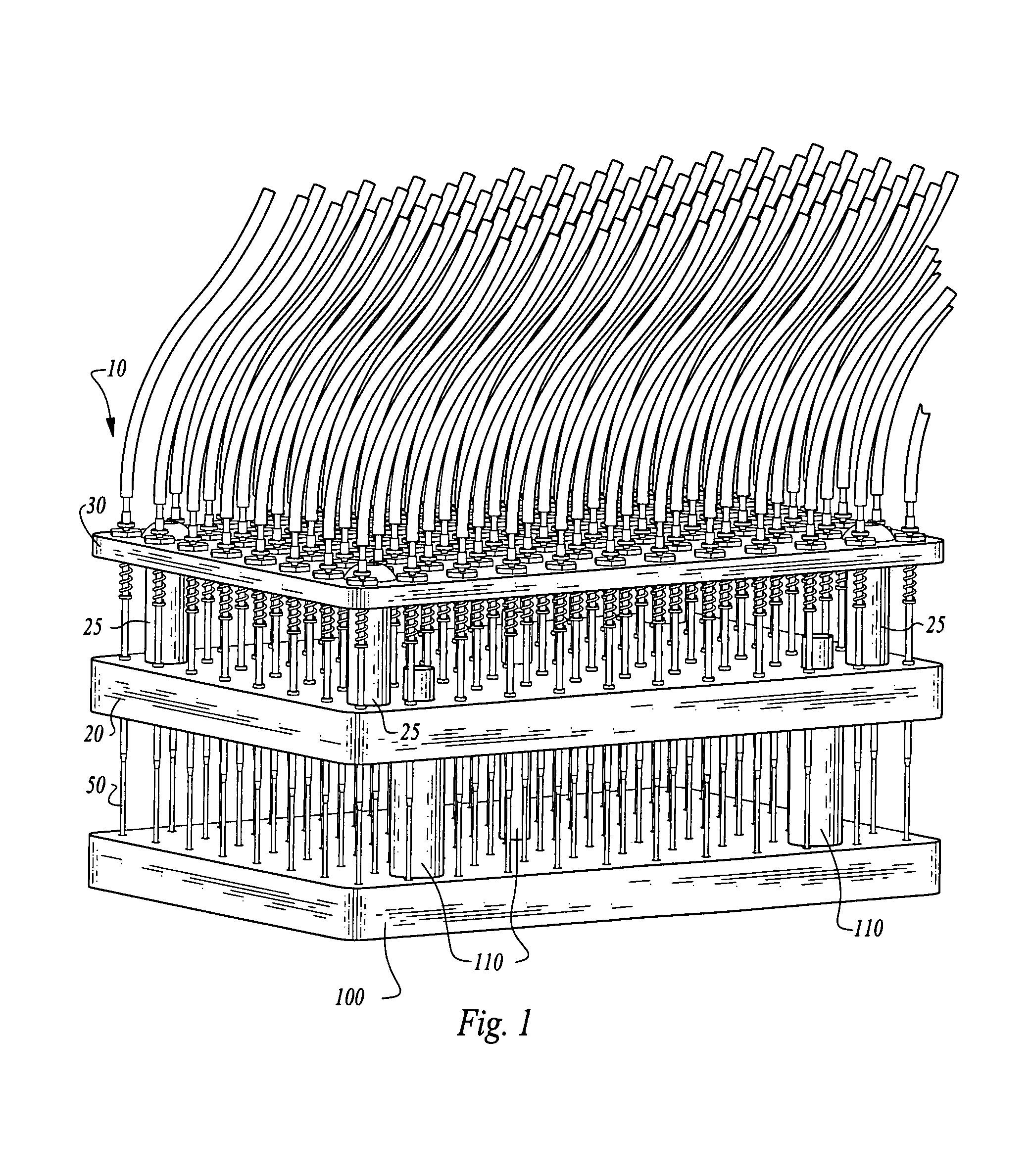

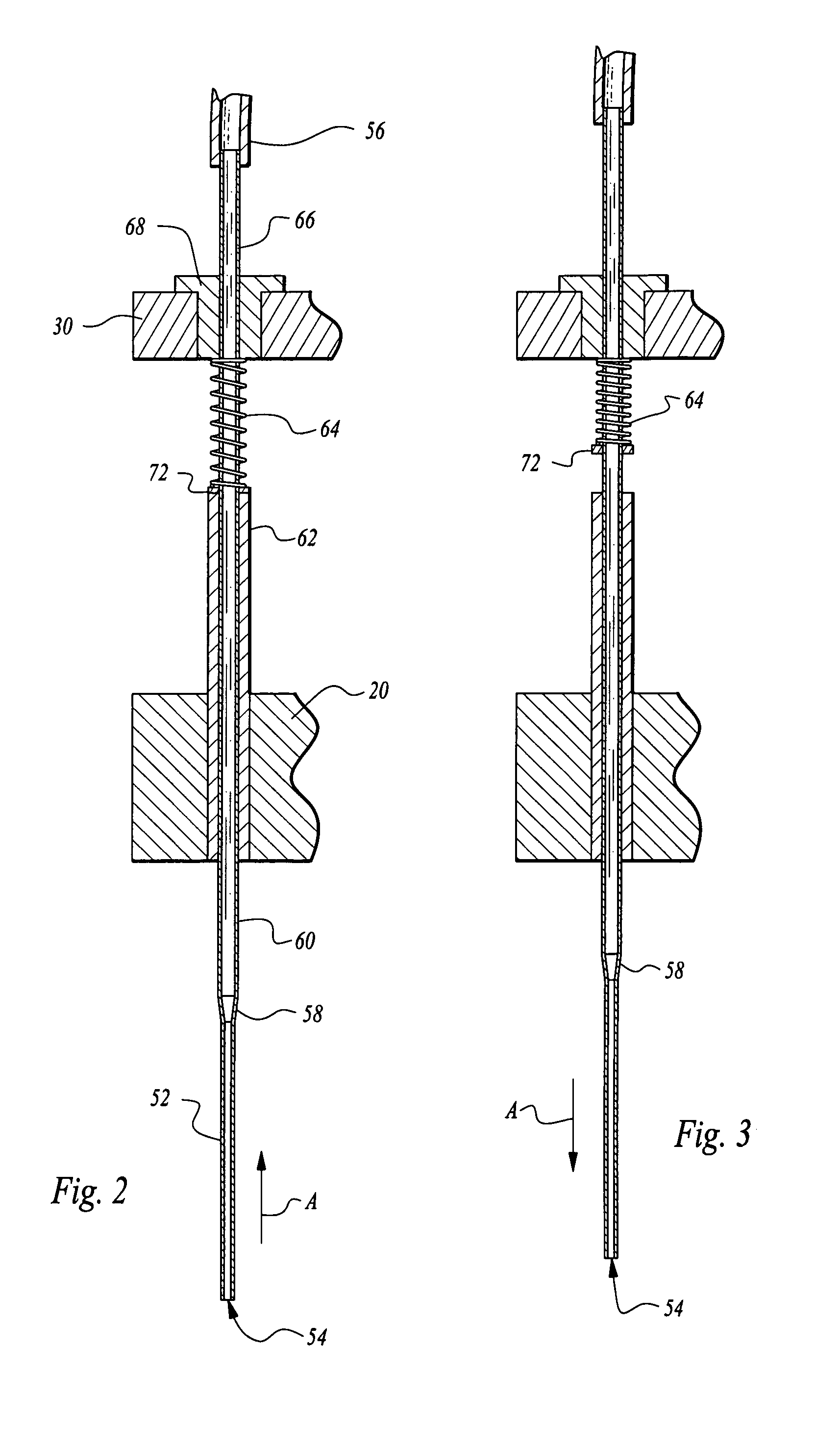

Ultra low volume probe

InactiveUS7144554B1Reduce errorsEasy to useBurette/pipette supportsWithdrawing sample devicesUltra-low volumeBiomedical engineering

A probe head used in robotic assays for transferring liquid in miniscule quantities. The probe head includes an array of liquid transferring needles which move as a unit with the probe head. As the needles contact a surface, high spots or other irregularities on the surface are accommodated by needle compliance to assure all needles ultimately touch the surface. Touching contact assures reliable liquid transfer.

Owner:HAMILTON

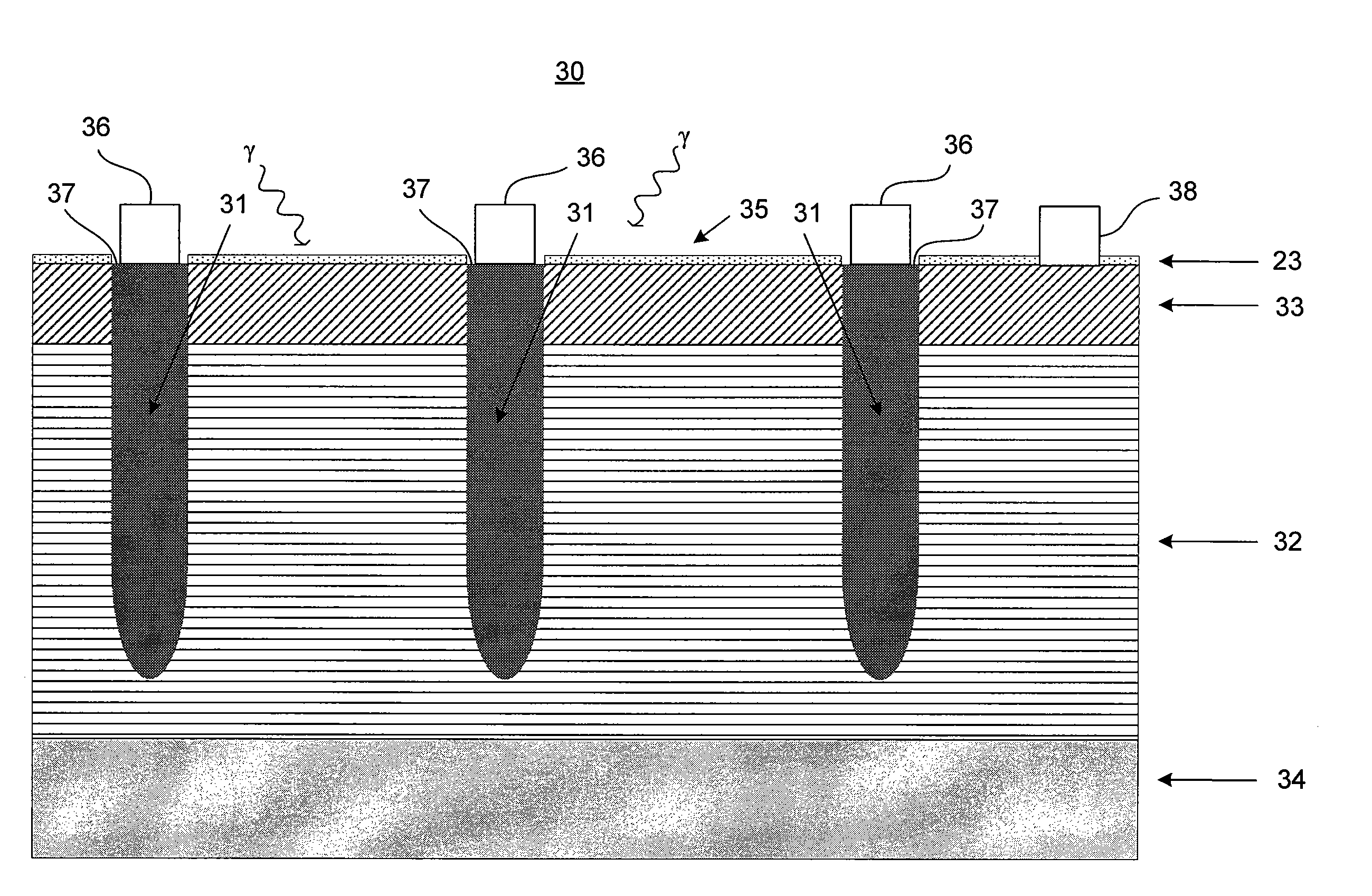

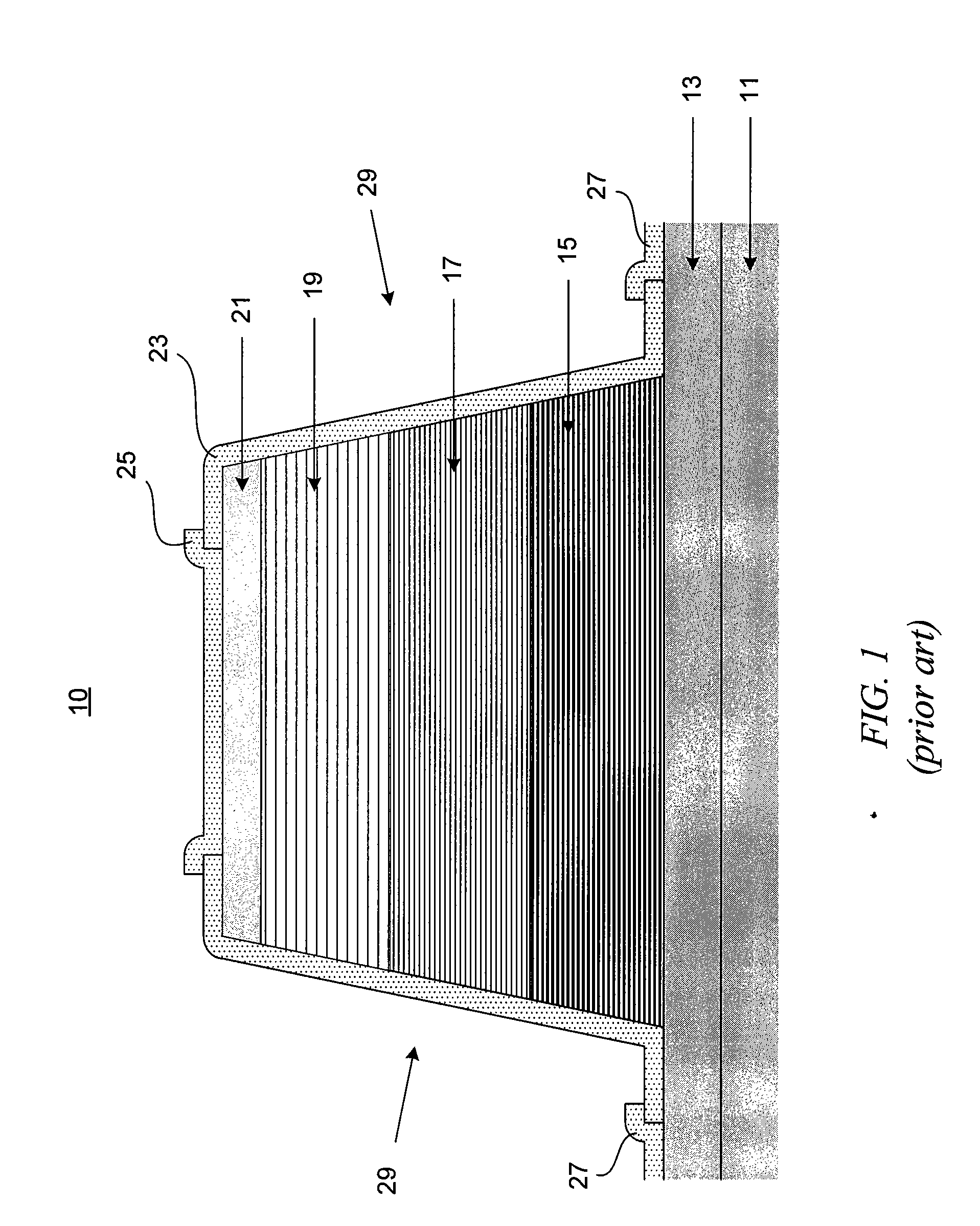

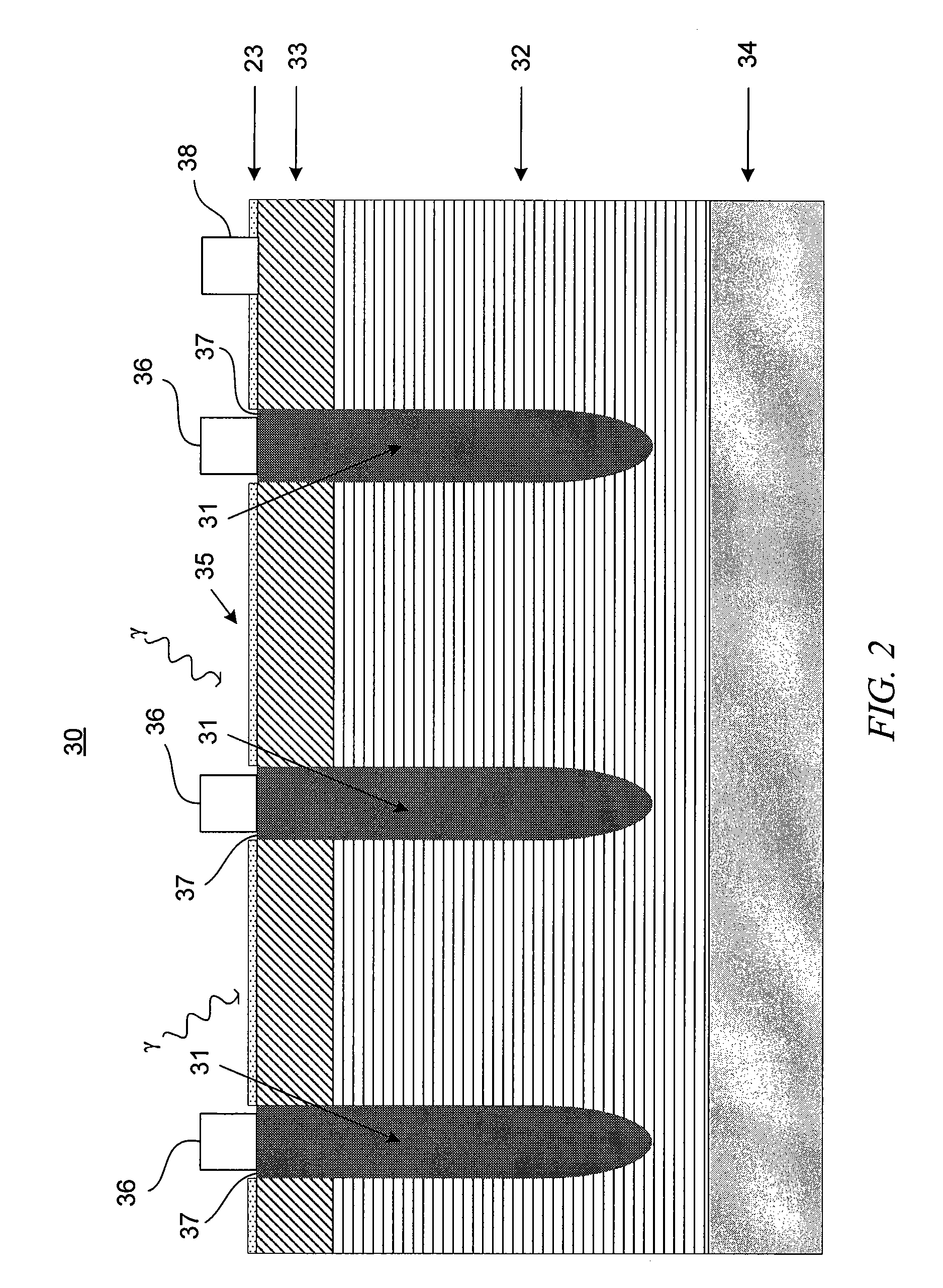

Lateral collection architecture for sls detectors

ActiveUS20100301309A1Promote lateral collectionImprove fill factorSolid-state devicesSemiconductor/solid-state device manufacturingDopantPhotovoltaic detectors

Lateral collection architecture for a photodetector is achieved by depositing electrically conducting SLS layers onto a planar substrate and diffusing dopants of a carrier type opposite that of the layers through the layers at selected regions to disorder the superlattice and create diode junctions oriented transversely to the naturally enhanced lateral mobility of photogenerated charge carriers within the superlattice. The diode junctions are terminated at a top surface of the photodetector within an SLS layer of wide bandgap material to minimize unwanted currents. A related architecture disorders the superlattice of topmost SLS layers by diffusing therethrough a dopant configured as a grid and penetrating to a lower SLS layer having the same carrier type as the dopant and opposite that of the topmost layers to isolate pixels within the topmost layers. Ohmic contacts may be deposited on doped regions, pixels, and substrate to provide desired external connections.

Owner:TELEDYNE SCI & IMAGING

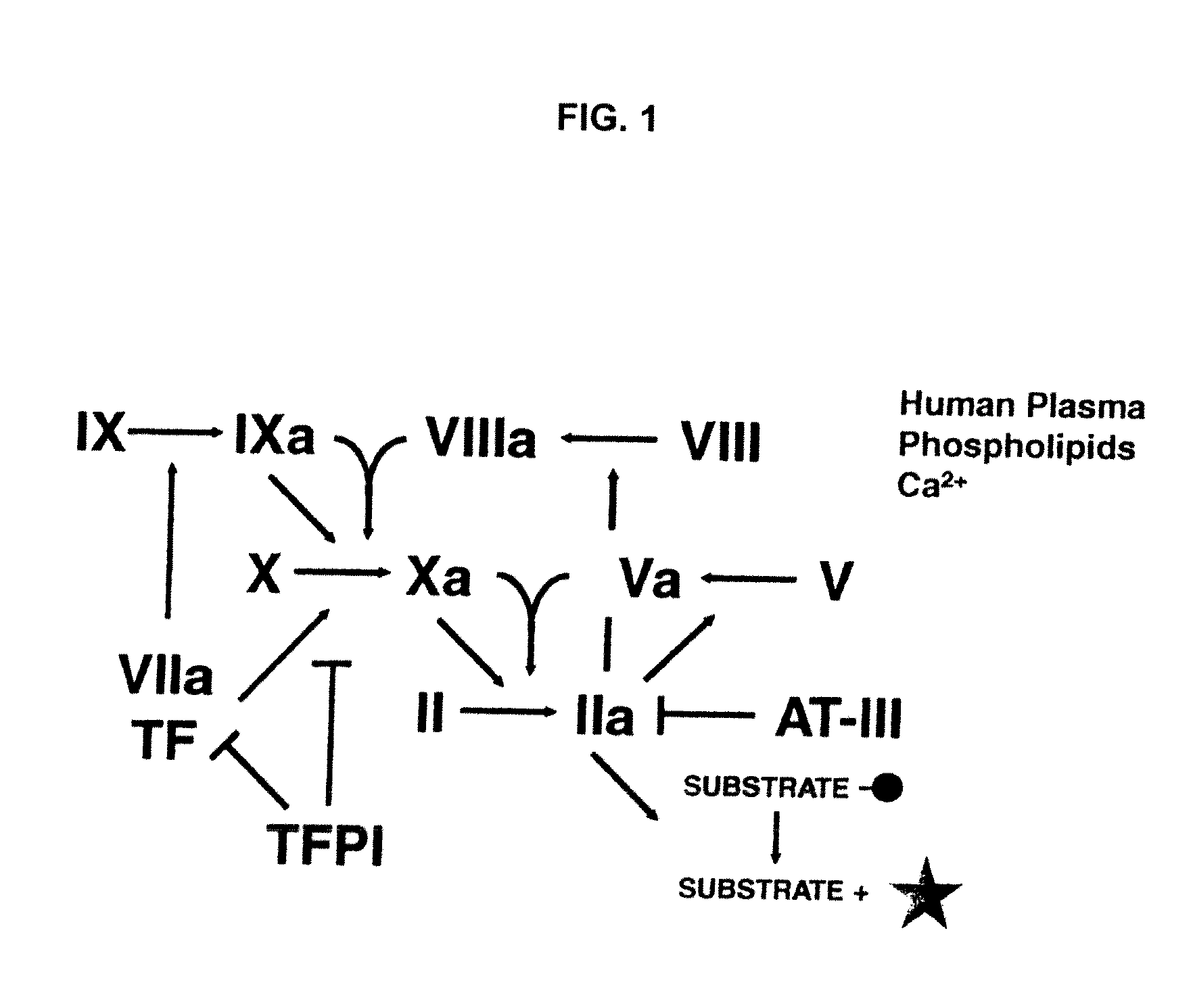

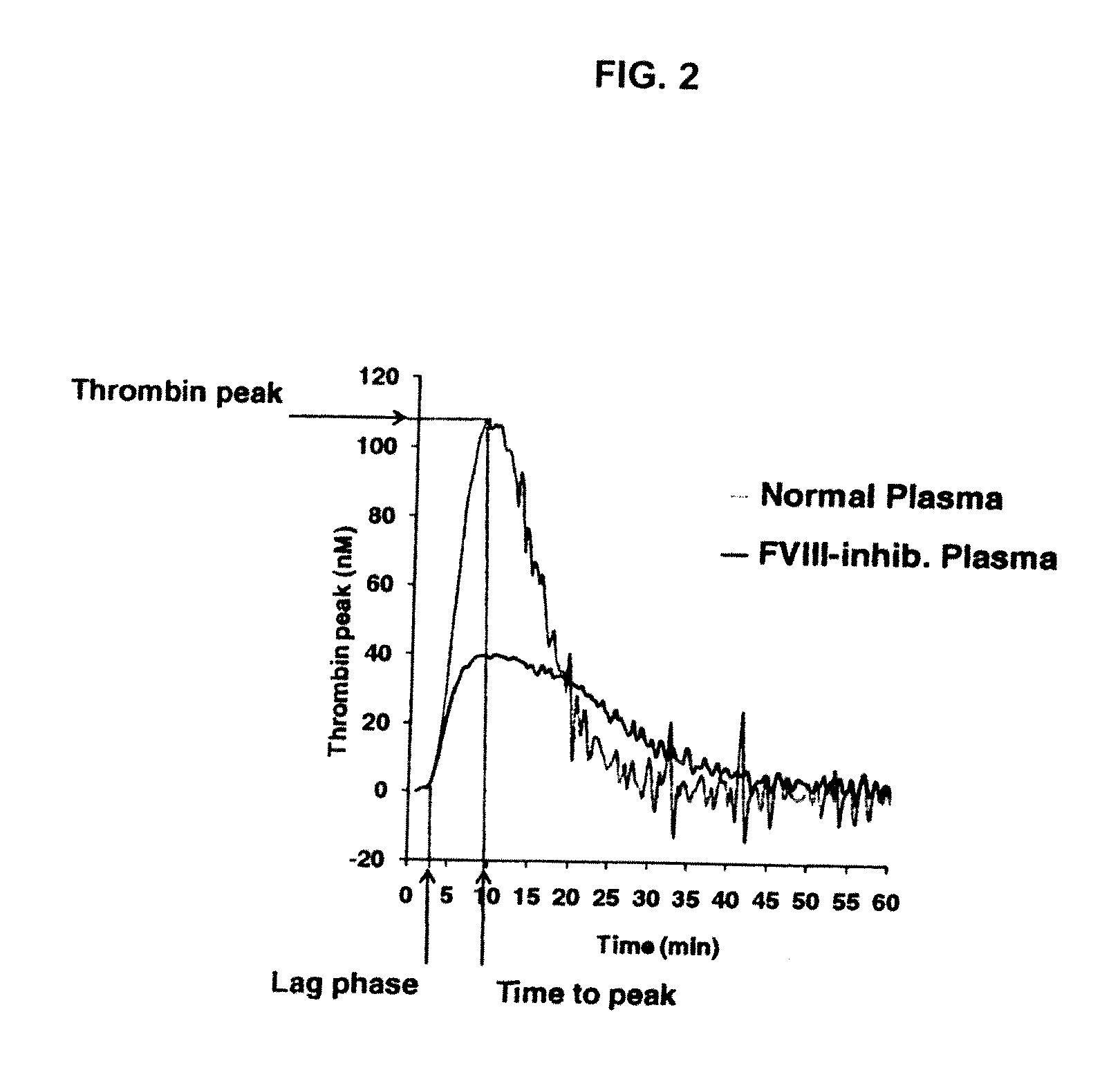

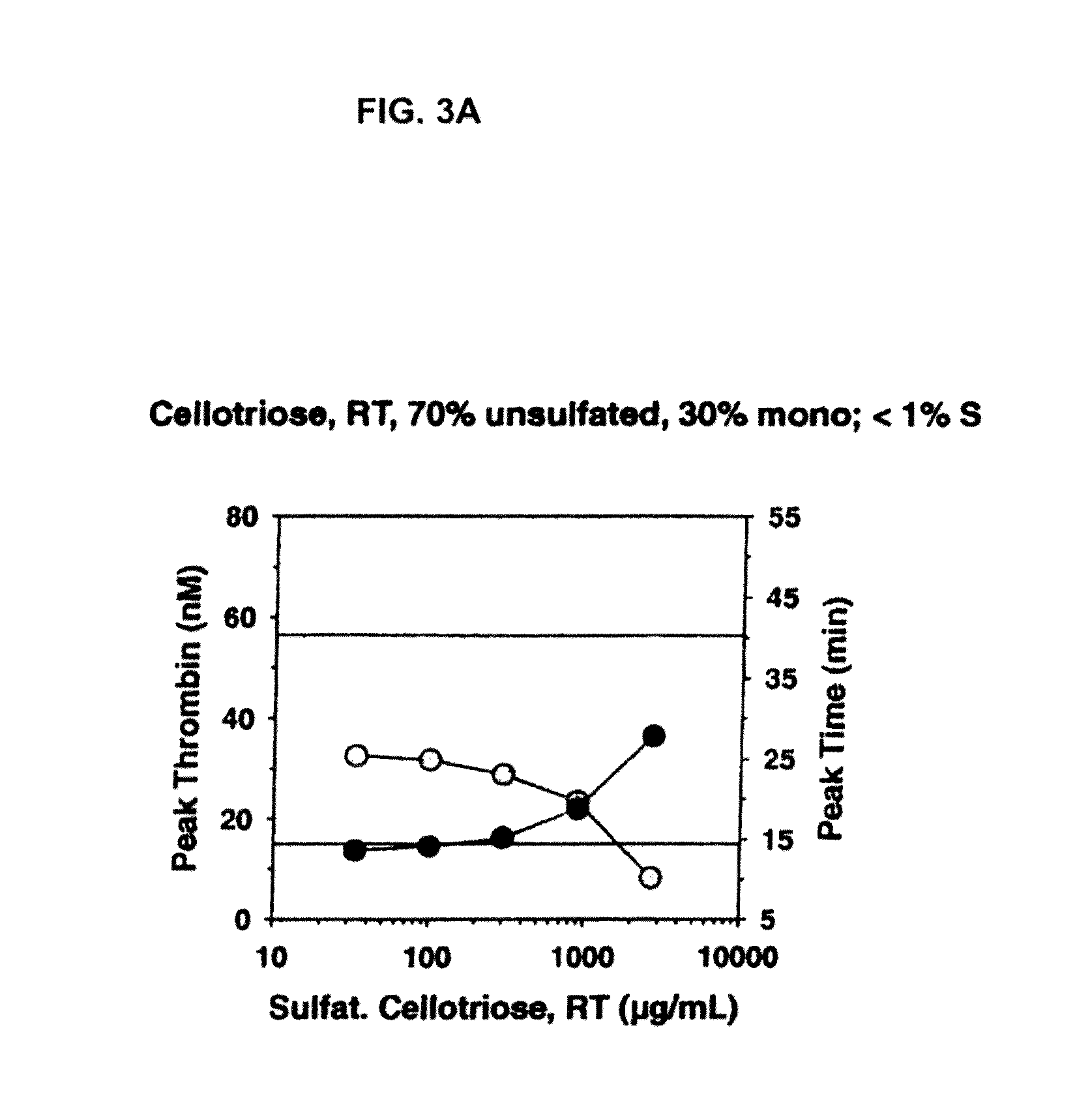

Non-anticoagulant sulfated or sulfonated polysaccharides

InactiveUS20130209444A1Offsetting effectShorten clotting timeOrganic active ingredientsBiocideSulfationMedicine

The present invention provides non-anticoagulant sulfated or sulfonated polysaccharides (NASPs), which accelerate the blood clotting process. Also provided are pharmaceutical formulations comprising a NASP of the invention in conjunction with a pharmaceutically acceptable excipient and, in various embodiments, these formulations are unit dosage formulations. The invention provides a NASP formulation, which is orally bioavailable. Also provided are methods for utilizing the compounds and formulations of the invention to promote blood clotting in vivo as therapeutic and prophylactic agents and in vitro as an aid to studies of the blood clotting process.

Owner:BAXALTA GMBH

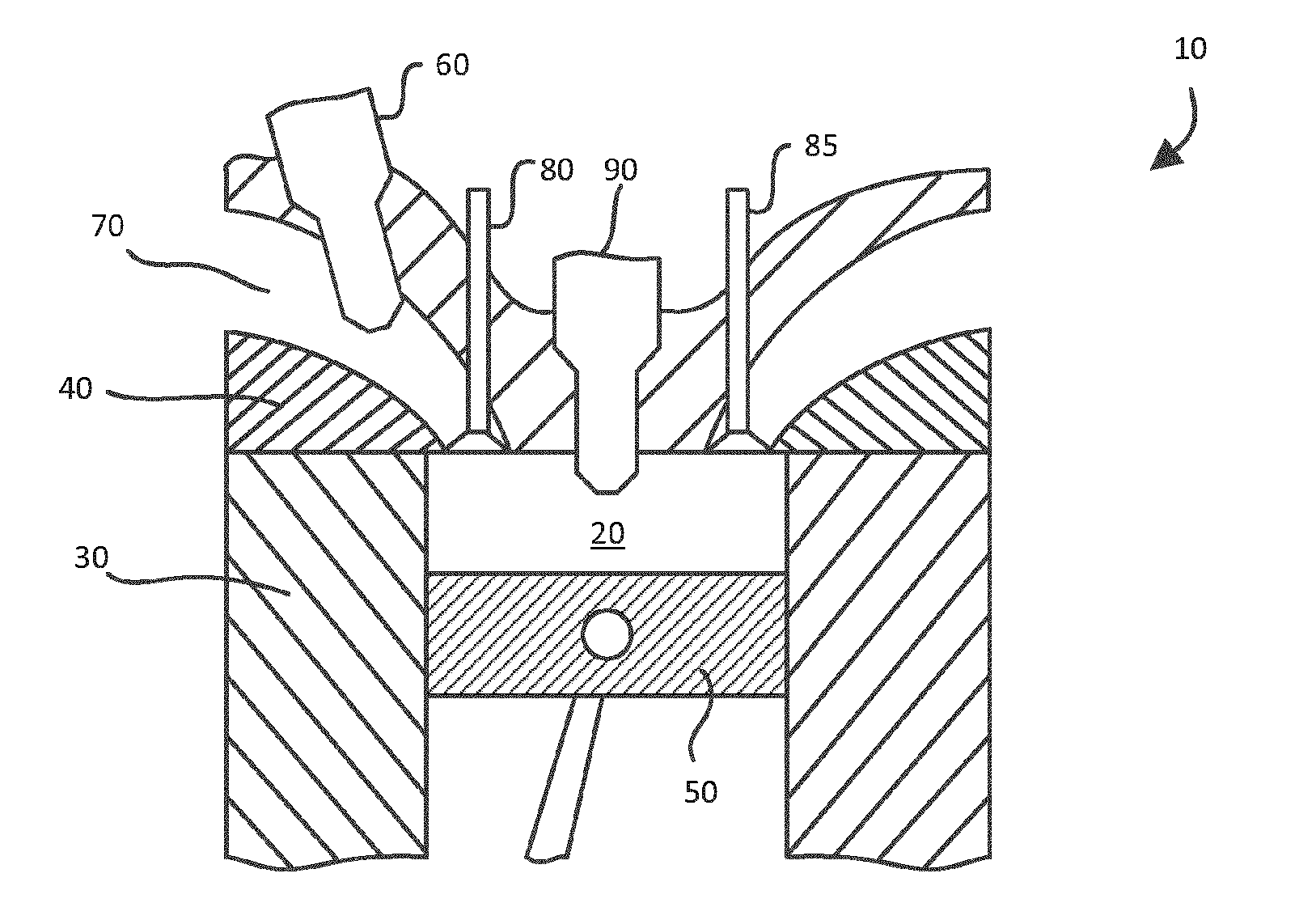

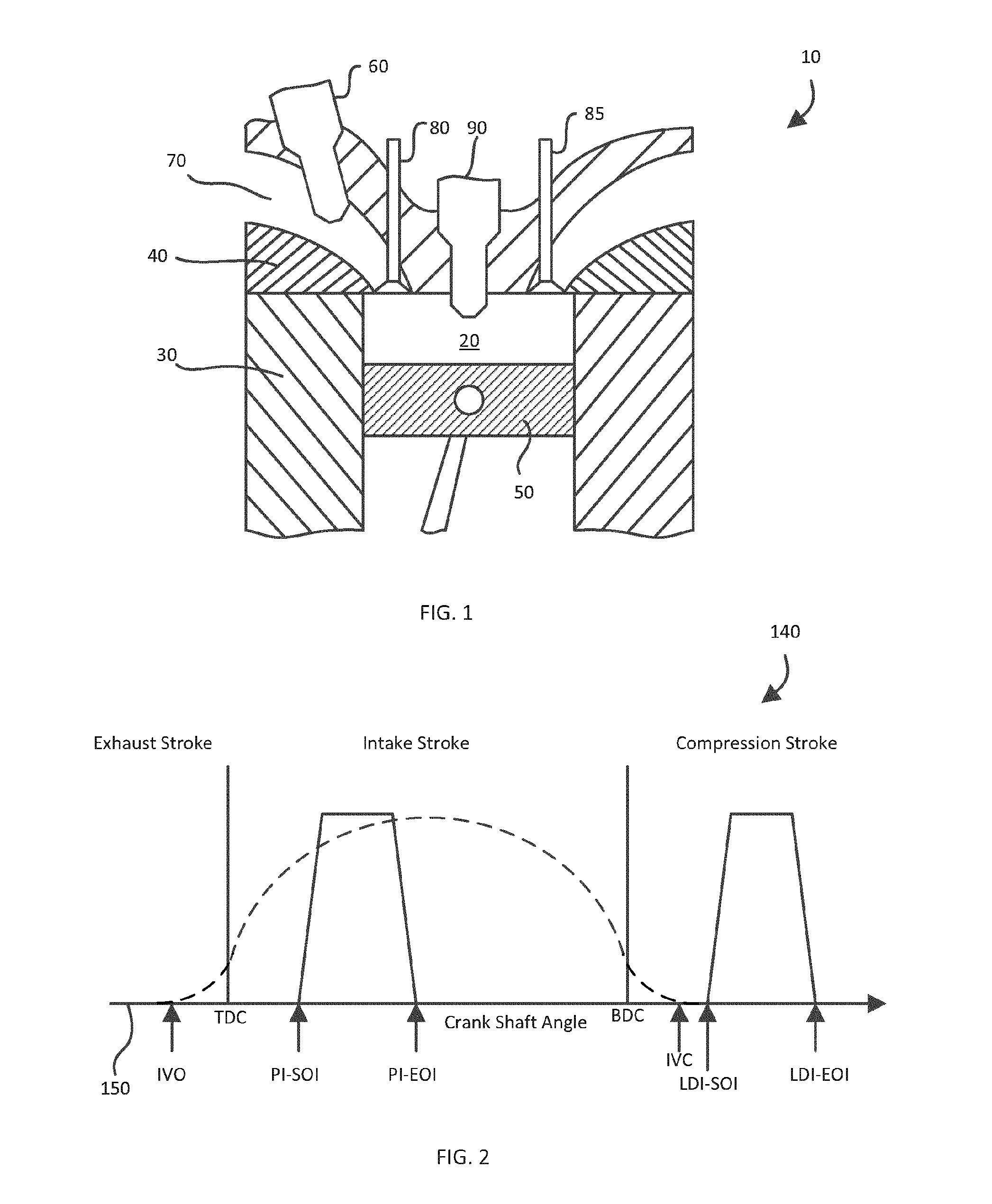

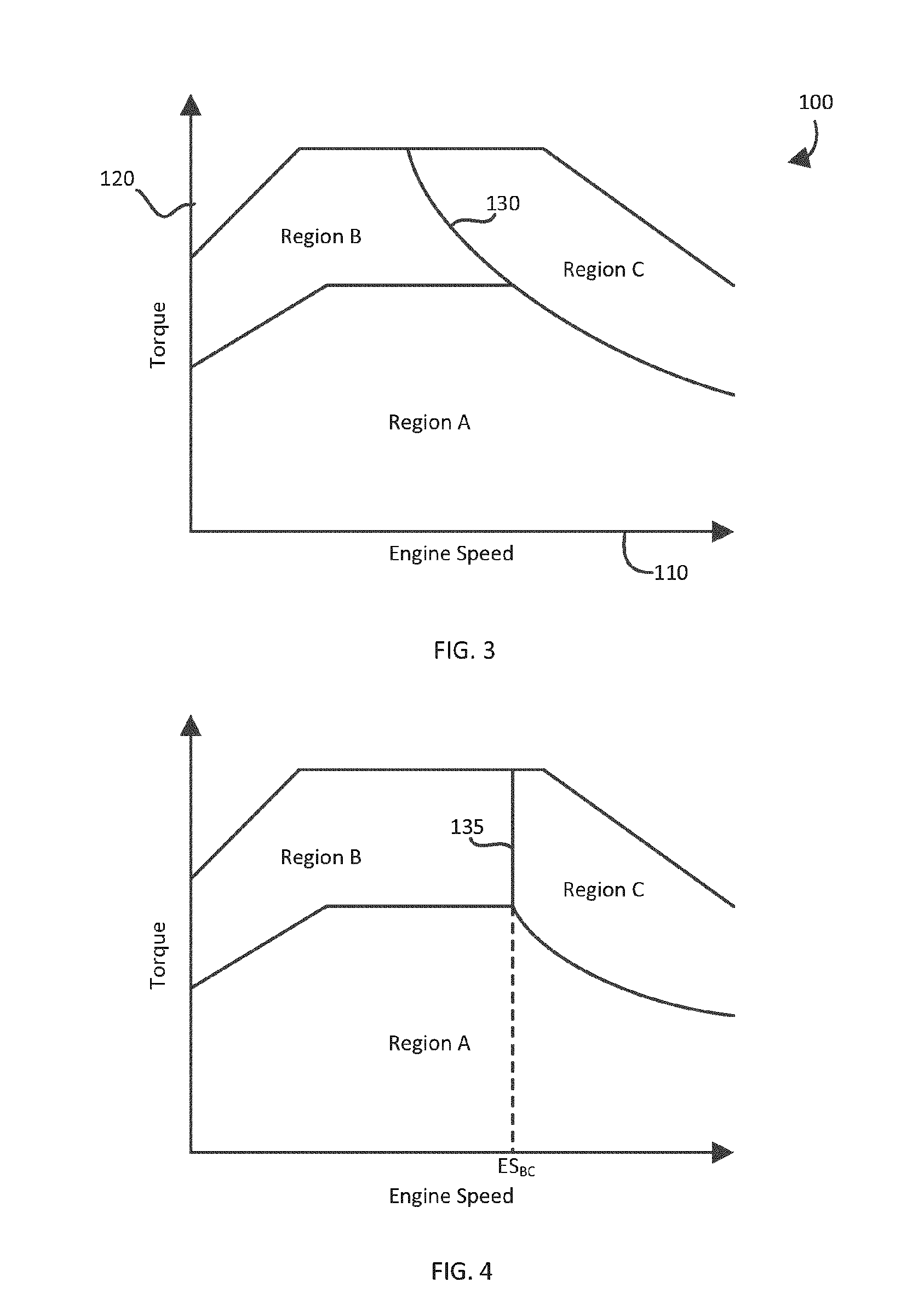

Mid-Cycle Fuel Injection Strategies

ActiveUS20150308362A1Many timesReduce system complexityElectrical controlInternal combustion piston enginesLow speedCombustion chamber

A method and apparatus are disclosed for introducing a gaseous fuel into a combustion chamber of an internal combustion engine. The method includes dividing the engine map into three distinct operating regions, with different operating modes in each region. When the engine is operating in a low load region, gaseous fuel is introduced to the combustion chamber during an intake stroke before an intake valve associated with the combustion chamber closes. When the engine is operating in a high load low-speed region, gaseous fuel is directly injected into the combustion chamber during a compression stroke after the intake valve is closed. When the engine is operating in a high load high-speed region, a split injection strategy is employed with a first portion of the gaseous fuel introduced into the charge before the intake valve closes and a second portion being injected after the intake valve is closed.

Owner:WESTPORT FUEL SYST CANADA INC

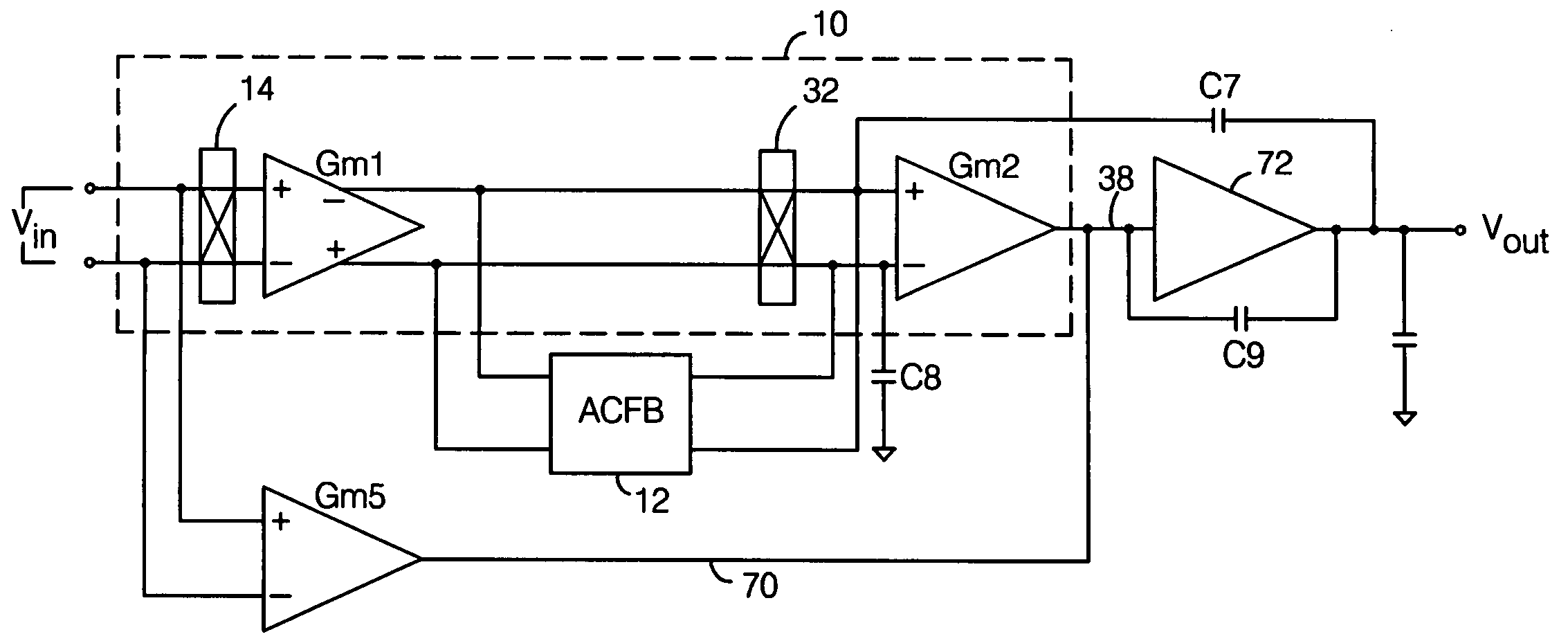

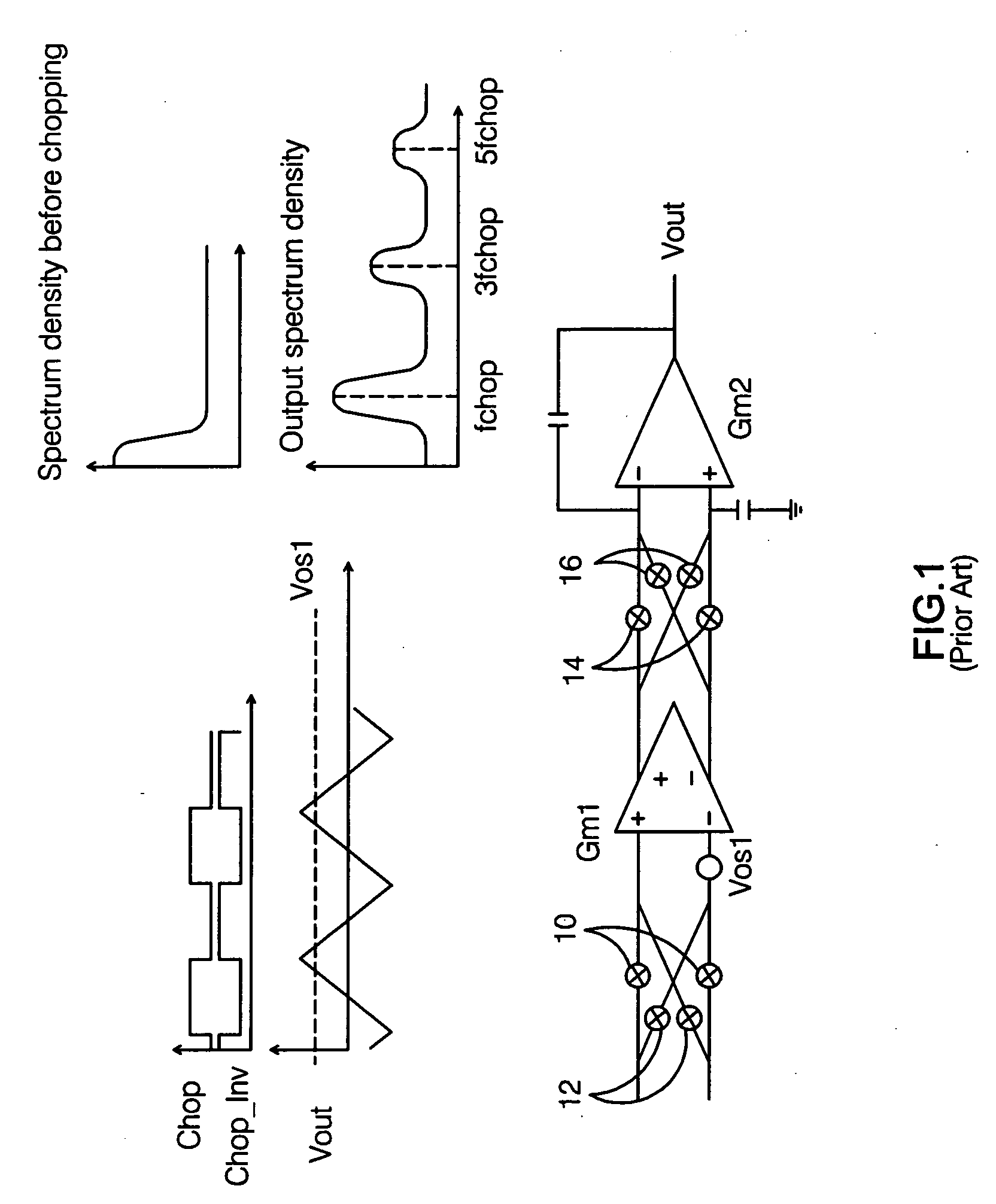

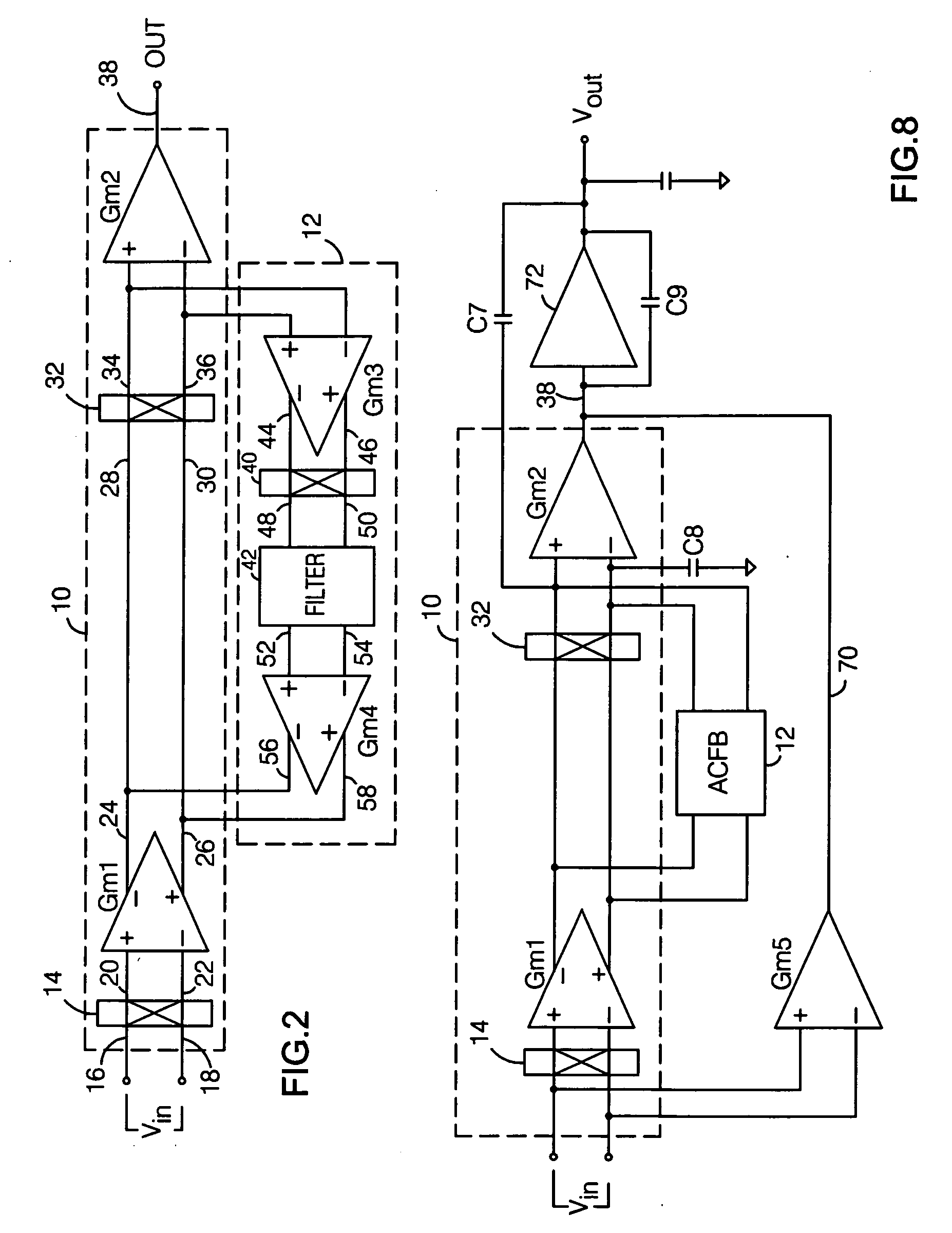

Auto-correction feedback loop for offset and ripple suppression in a chopper-stabilized amplifier

ActiveUS20100060352A1Offsetting effectSuppress both input offset voltage effects and offset voltage-inducedAmplifier modifications to raise efficiencyAmplifier with semiconductor-devices/discharge-tubesAc componentsAudio power amplifier

A chopper-stabilized amplifier includes a main signal path having first and second chopping circuits at the inputs and outputs of a transconductance amplifier, and an auto-correction feedback loop. The feedback loop includes a transconductance amplifier connected to amplify the chopped output from the main signal path, a third chopping circuit which chops the amplified output, a filter which filters the chopped output to substantially reduce any offset voltage-induced AC component present in the signal being filtered, and a transconductance amplifier which receives the filtered output and produces an output which is coupled back into the main signal path. When properly arranged, the auto-correction feedback loop operates to suppress transconductance amplifier-related offset voltages and offset voltage-induced ripple that might otherwise be present in the amplifier's output.

Owner:ANALOG DEVICES INC

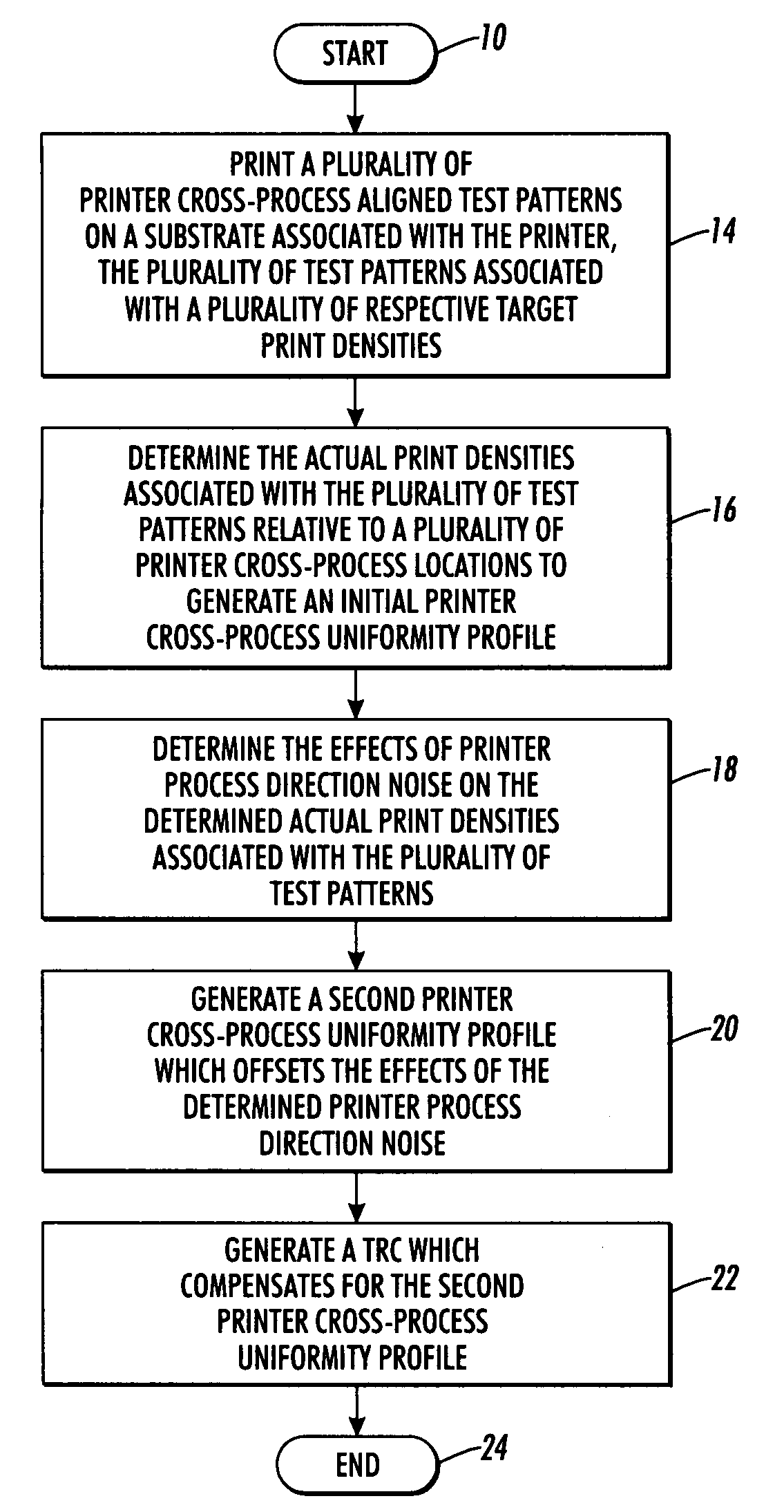

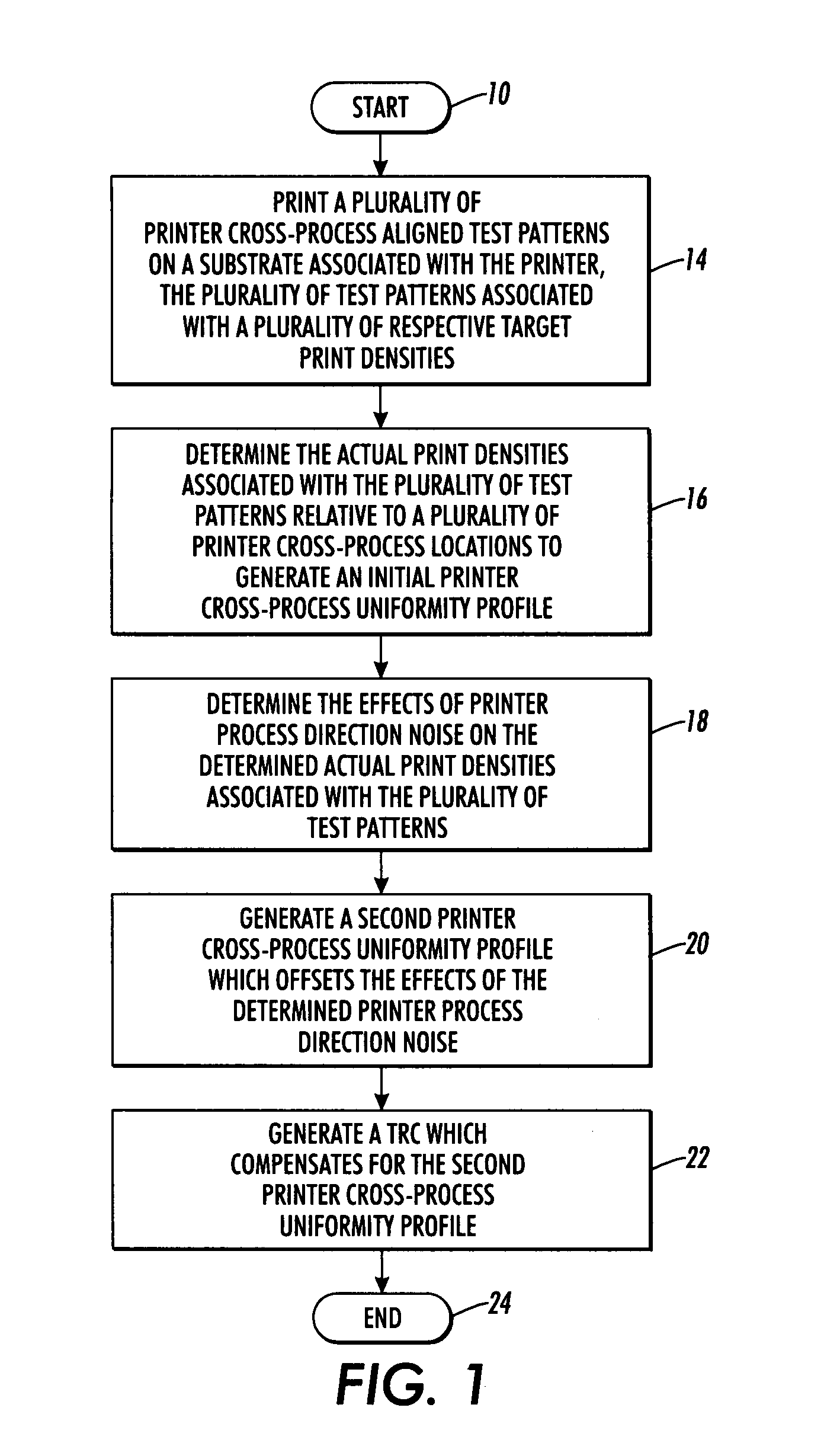

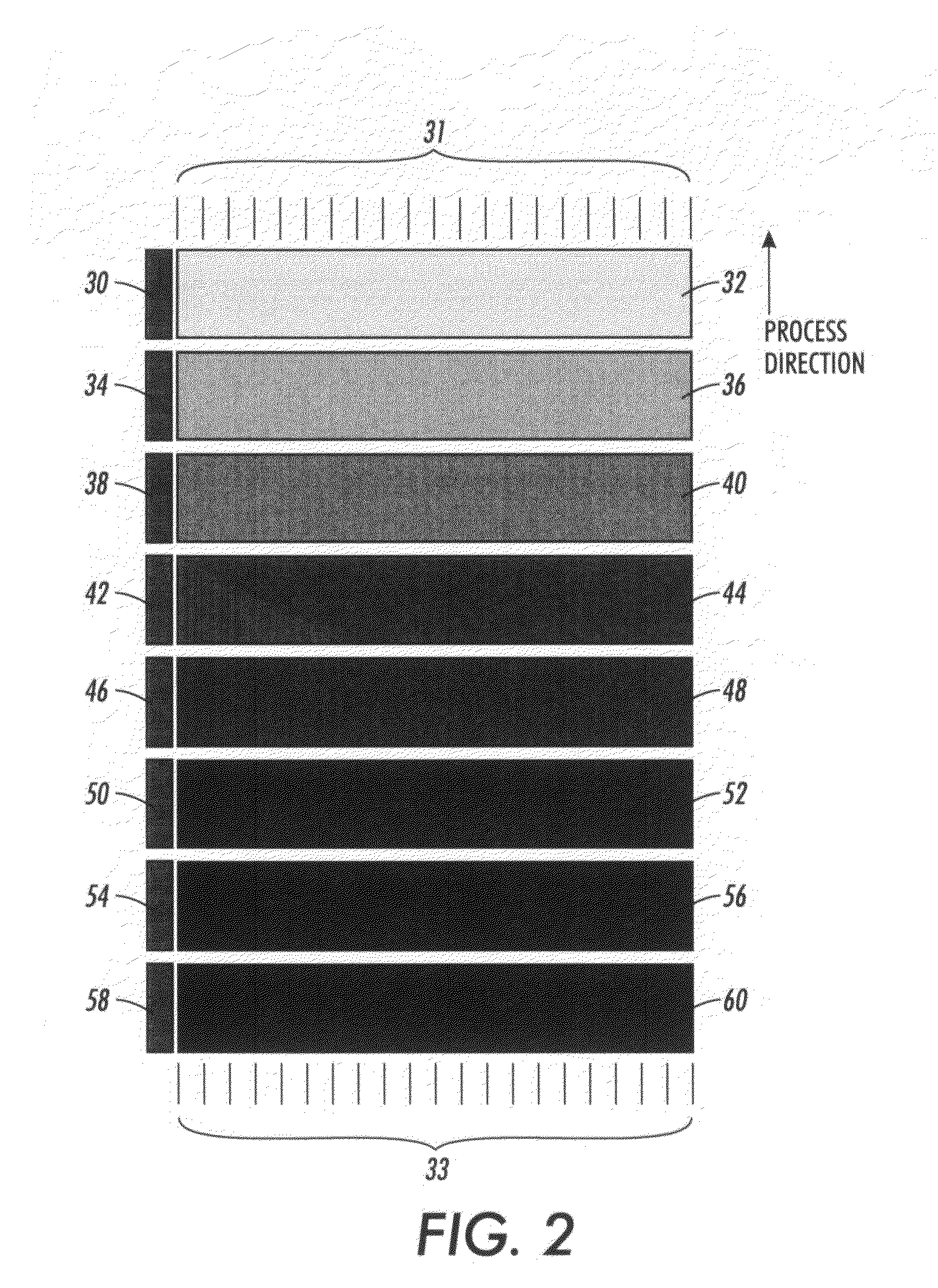

Measurement of engine response curve in the presence of process direction noise

Disclosed is a method and system for compensating for printer cross-process nonuniformity. The method and system provide a means to offset a cross-process uniformity profile associated with an image output device, such as a printer, where process direction noise is measured and the cross-process uniformity profile is adjusted accordingly to provide a better representation of the image output device cross-process uniformity profile.

Owner:XEROX CORP

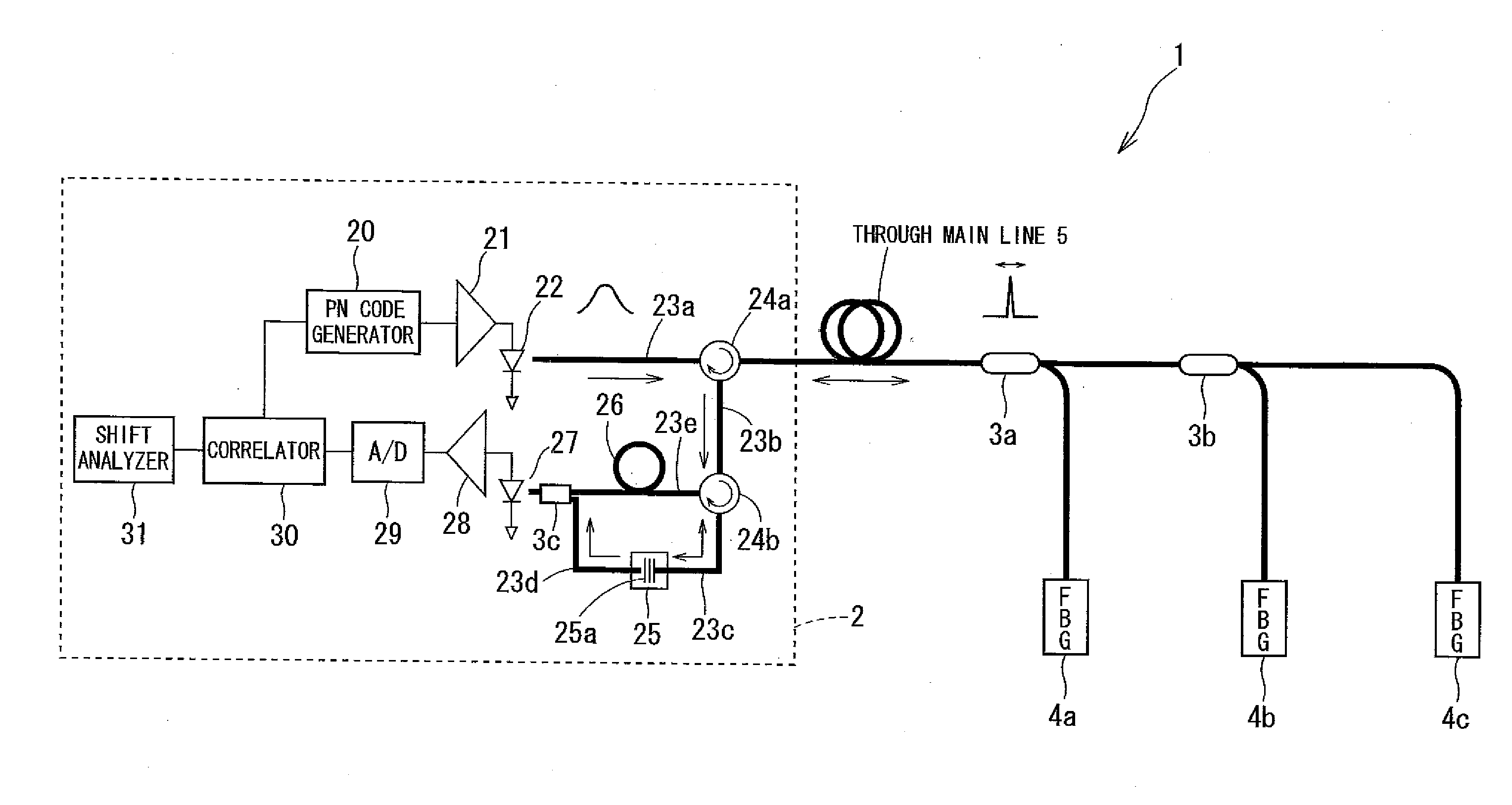

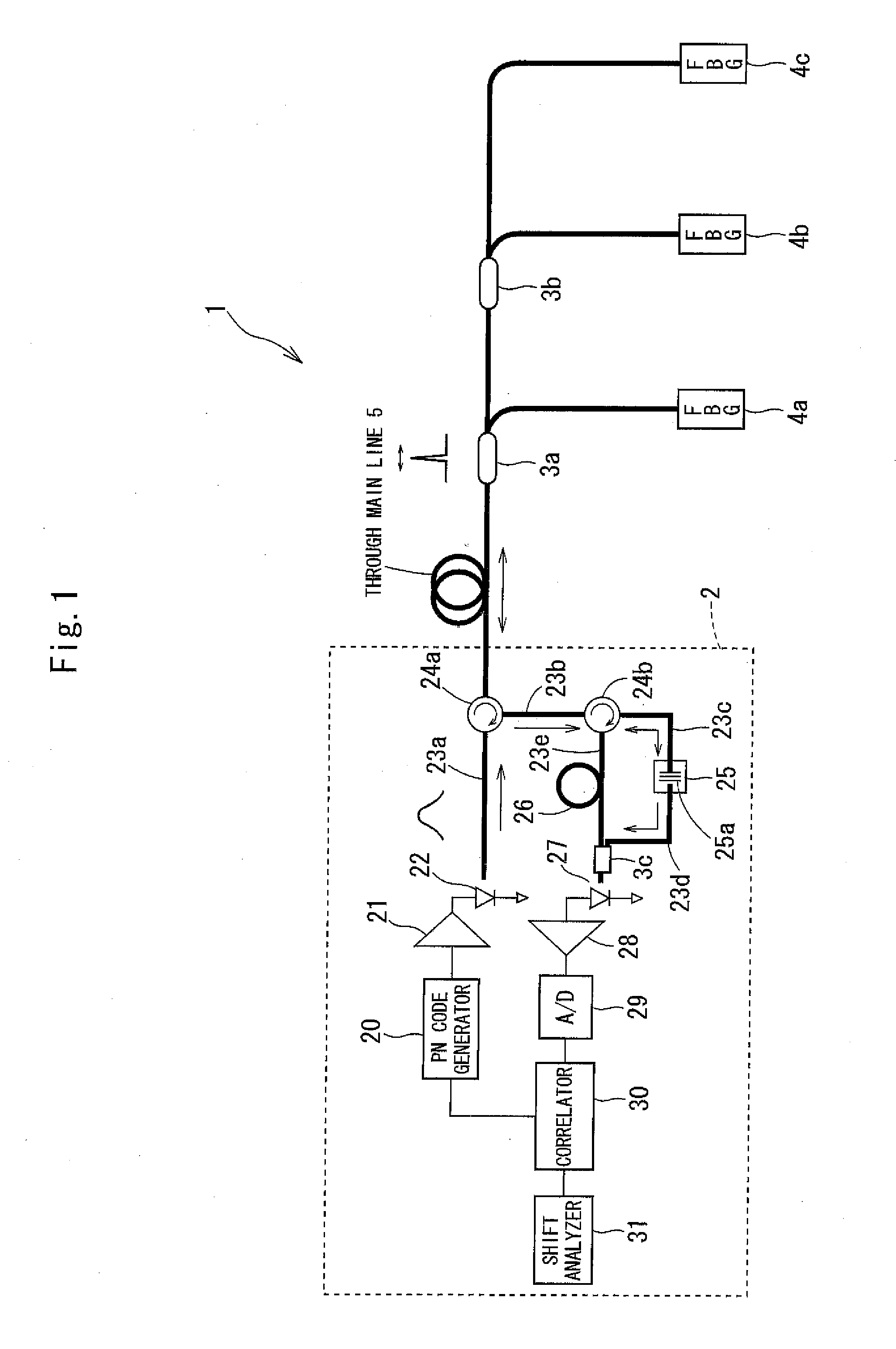

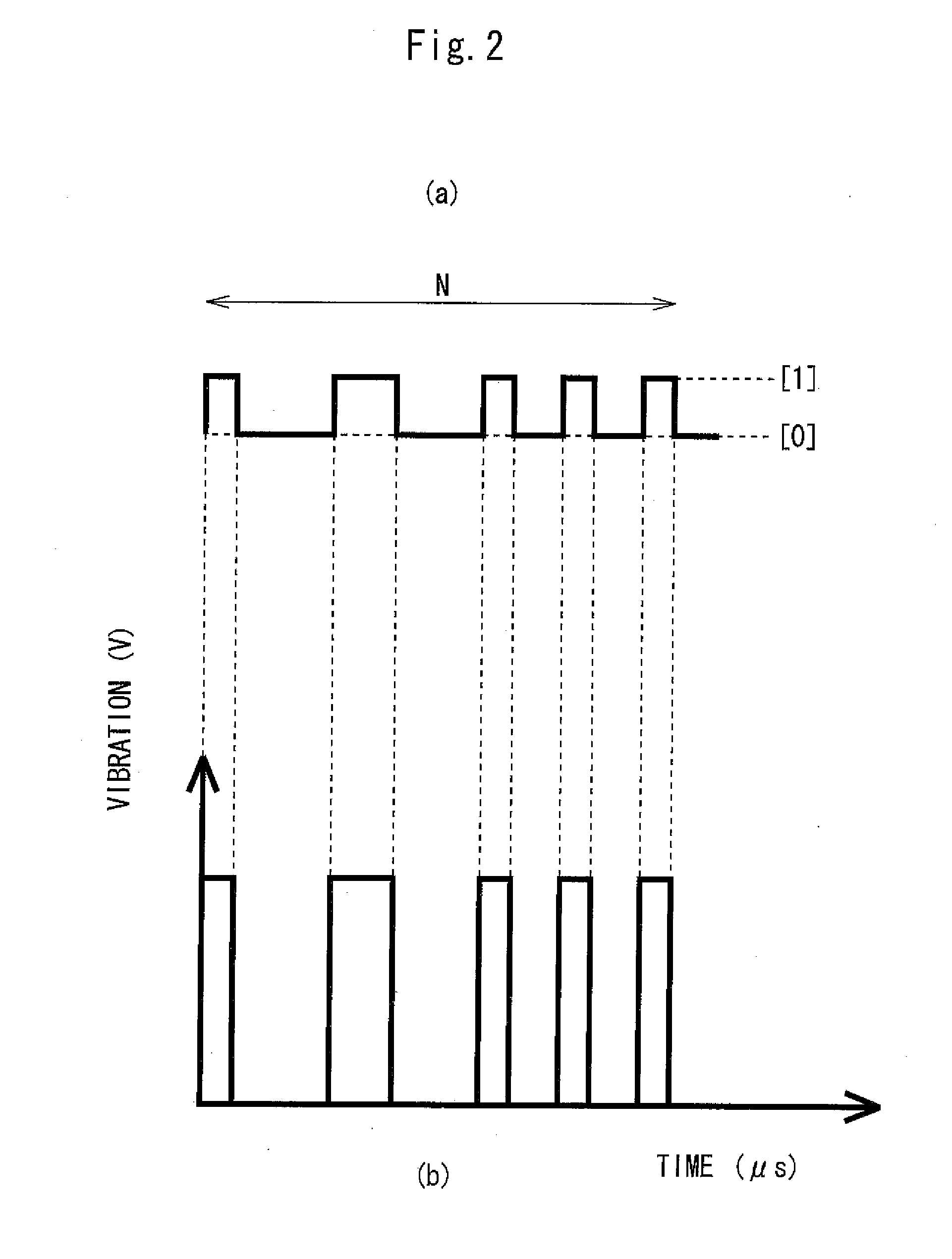

Optical fiber sensing system

InactiveUS20110141459A1Easily controlSmall changeMaterial analysis by optical meansUsing optical meansPhotovoltaic detectorsLight source

Provided is an optical fiber sensing system that can carry out measurement accurately without being affected by measurement noise factors other than the physical-quantity attribute of a measurement target object, for example, the effects of the emission power of a light source, fiber insertion loss, fluctuations in the sensitivity of a photo detector, fluctuations in the amplitude of an amplifier or other fluctuations, the loss of optical energy due to the bending of an optical fiber (bending loss), the loss of optical energy due to the connecting of two or more optical fibers by means of connectors (connector loss), the gain fluctuations of electric circuitry provided on a platform, and so forth. A reflective sensor is connected to an end of an optical fiber connected to a light source. The light source outputs physical measurement light. Reflected light coming from the reflective sensor is separated into two beams of light. Information on the physical quantity of a measurement target object is detected on the basis of an intensity ratio of the two beams.

Owner:KABUSIKIKAISHA WATANABESEISAKUSYO +1

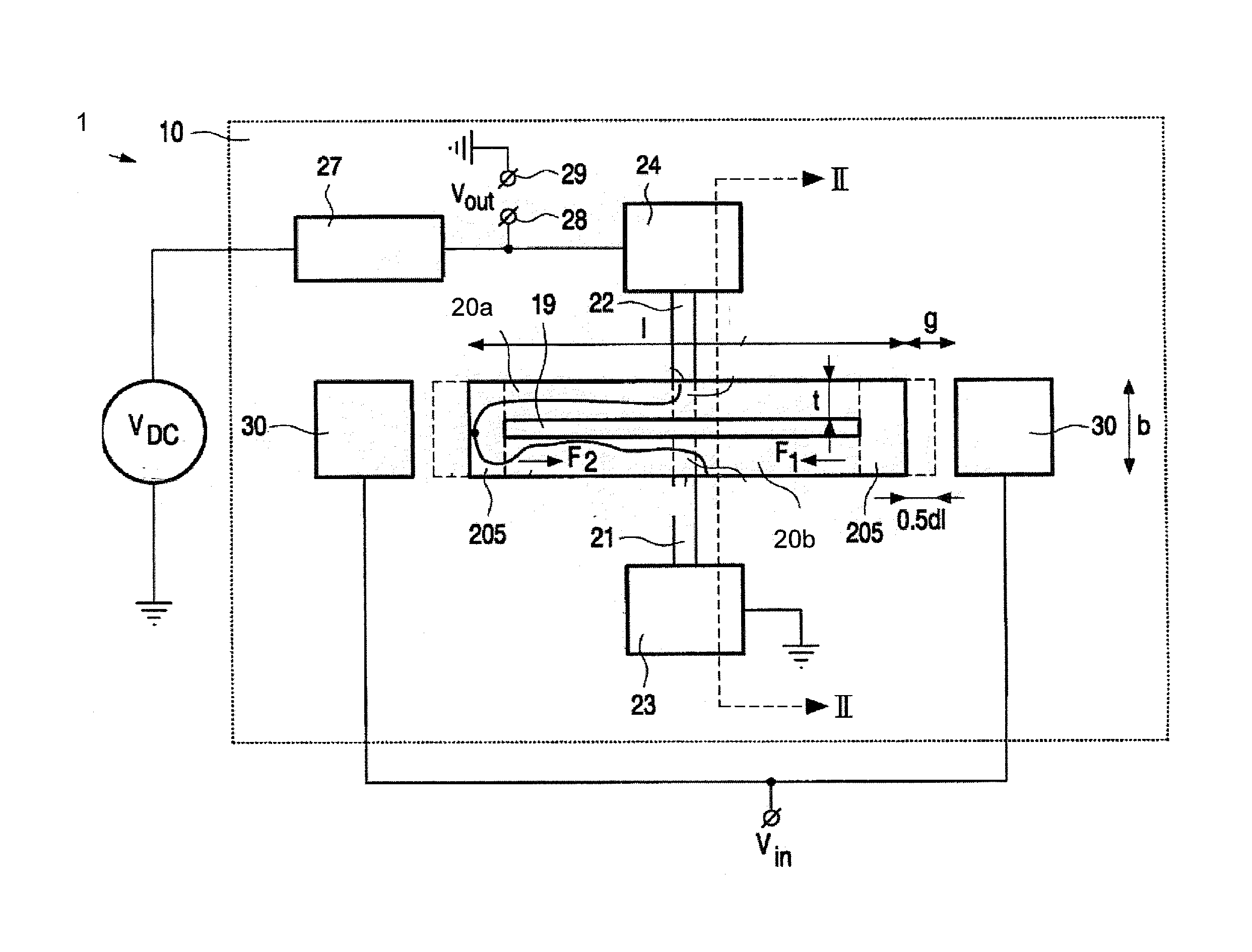

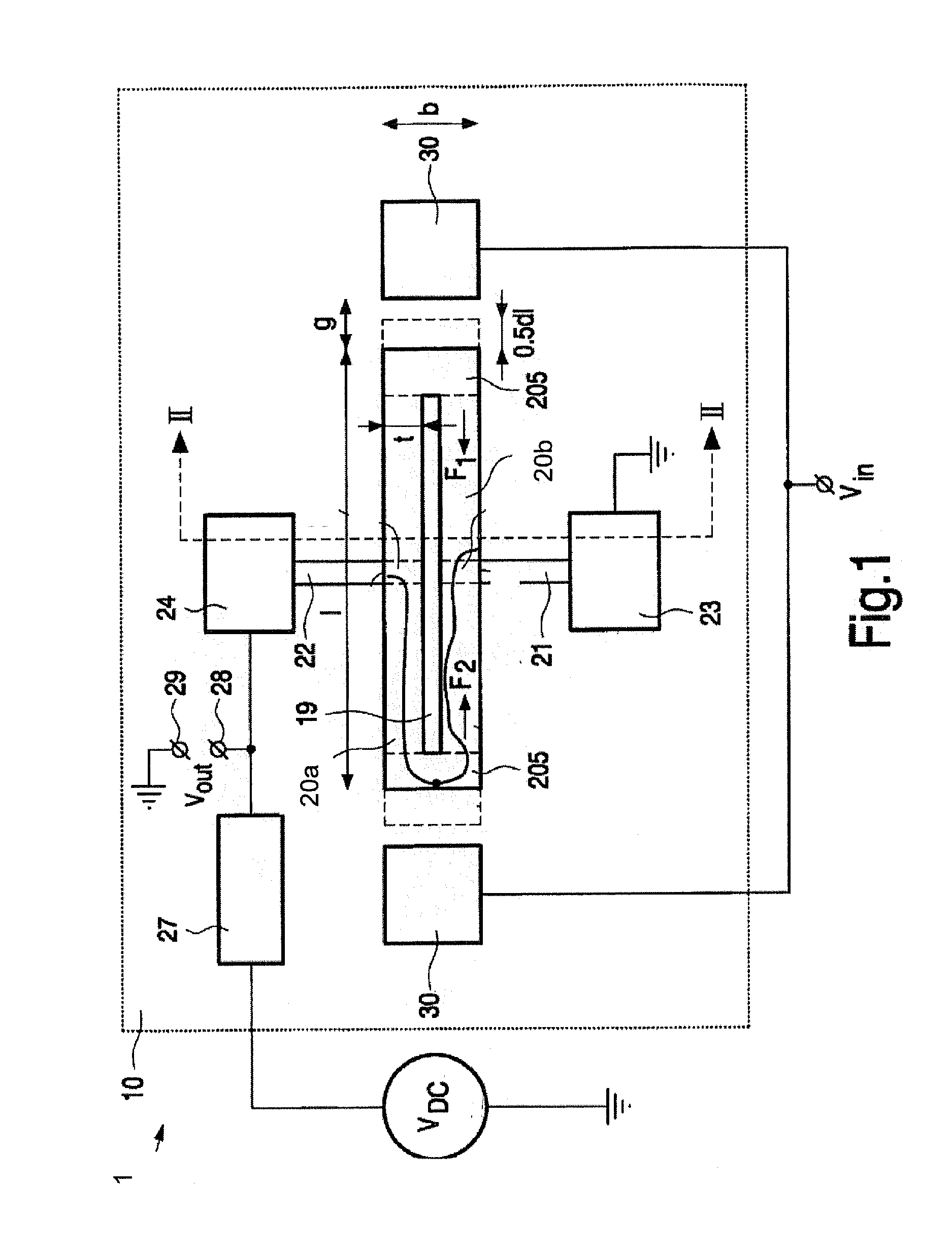

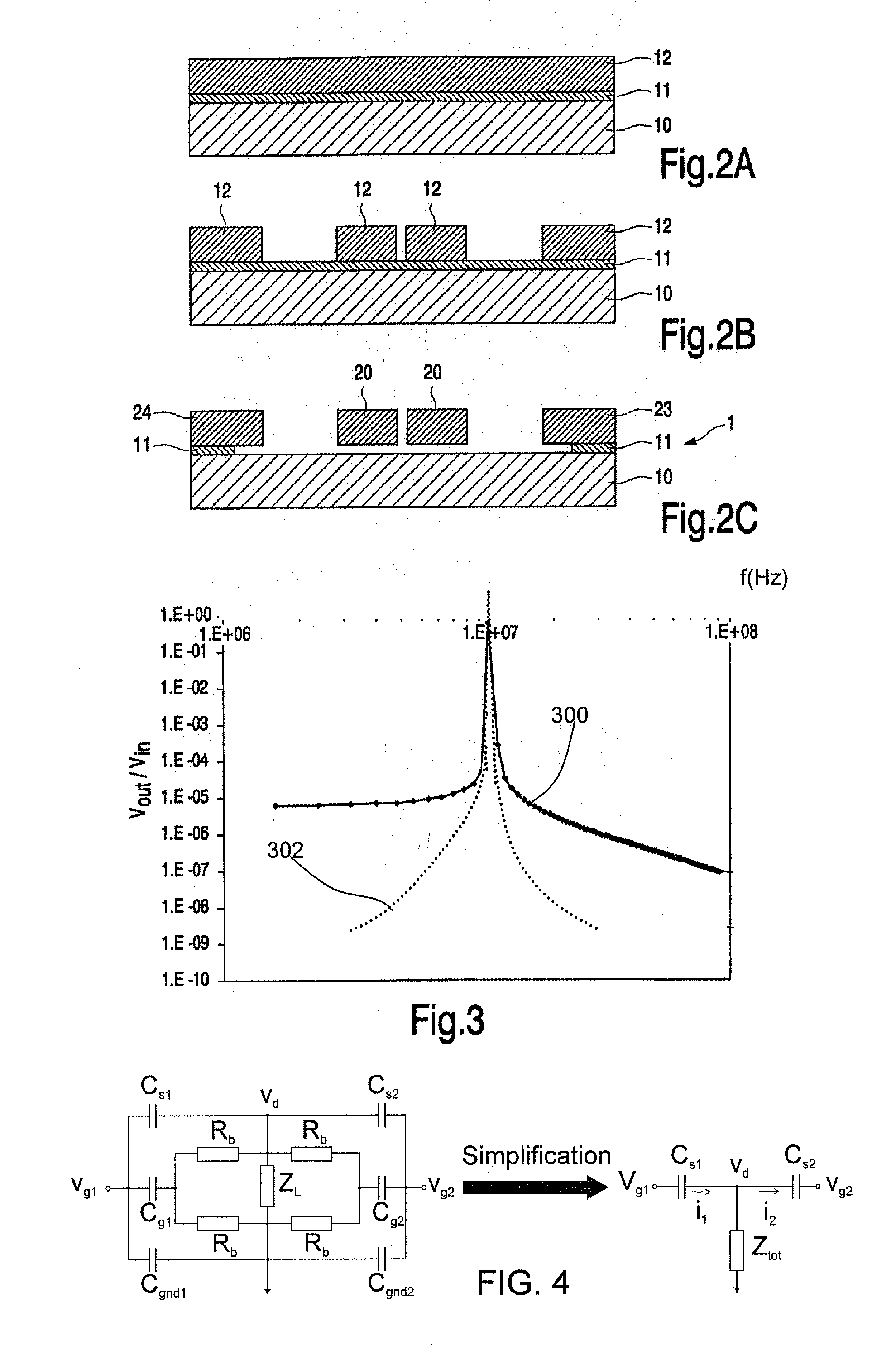

MEMS oscillator

ActiveUS20120032747A1Offsetting effectImpedence networksOscillations generatorsEngineeringAnchor point

A piezoresistive MEMS oscillator comprises a resonator body, first and second drive electrodes located adjacent the resonator body for providing an actuation signal; and at least a first sense electrode connected to a respective anchor point. The voltages at the electrodes are controlled and / or processed such that the feedthrough AC current from one drive electrode to the sense electrode is at least partially offset by the feedthrough AC current from the other drive electrode to the sense electrode.

Owner:NXP BV

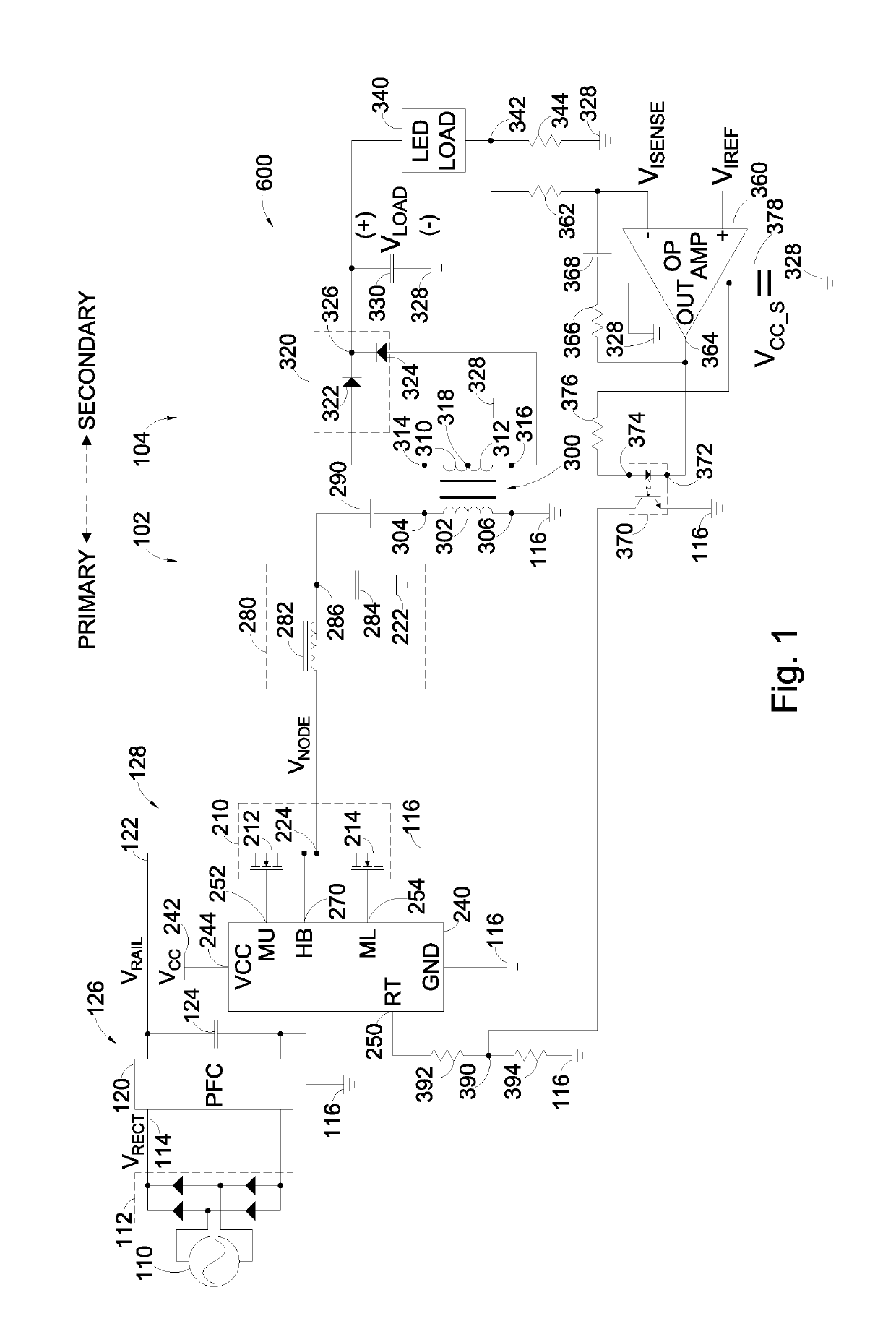

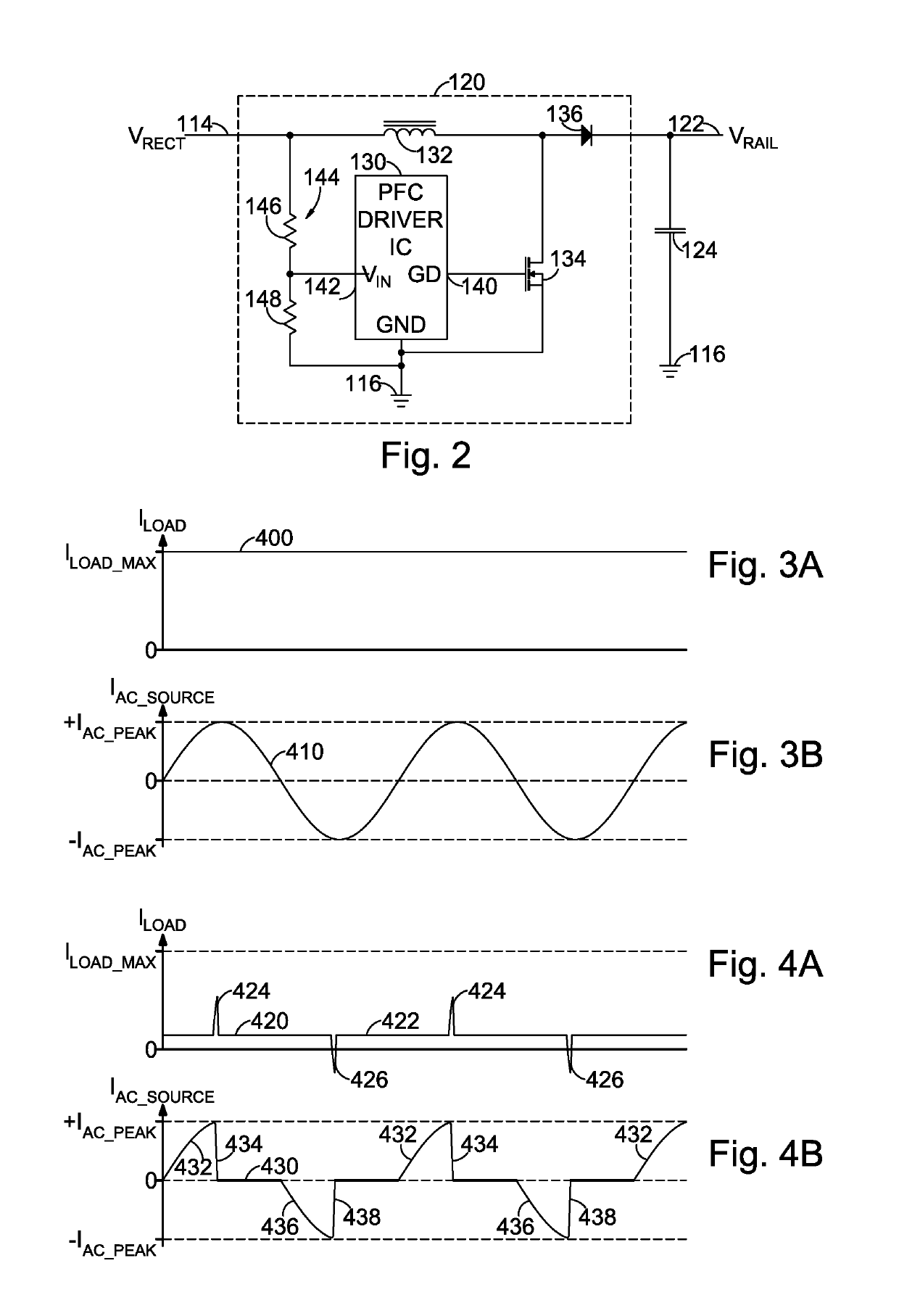

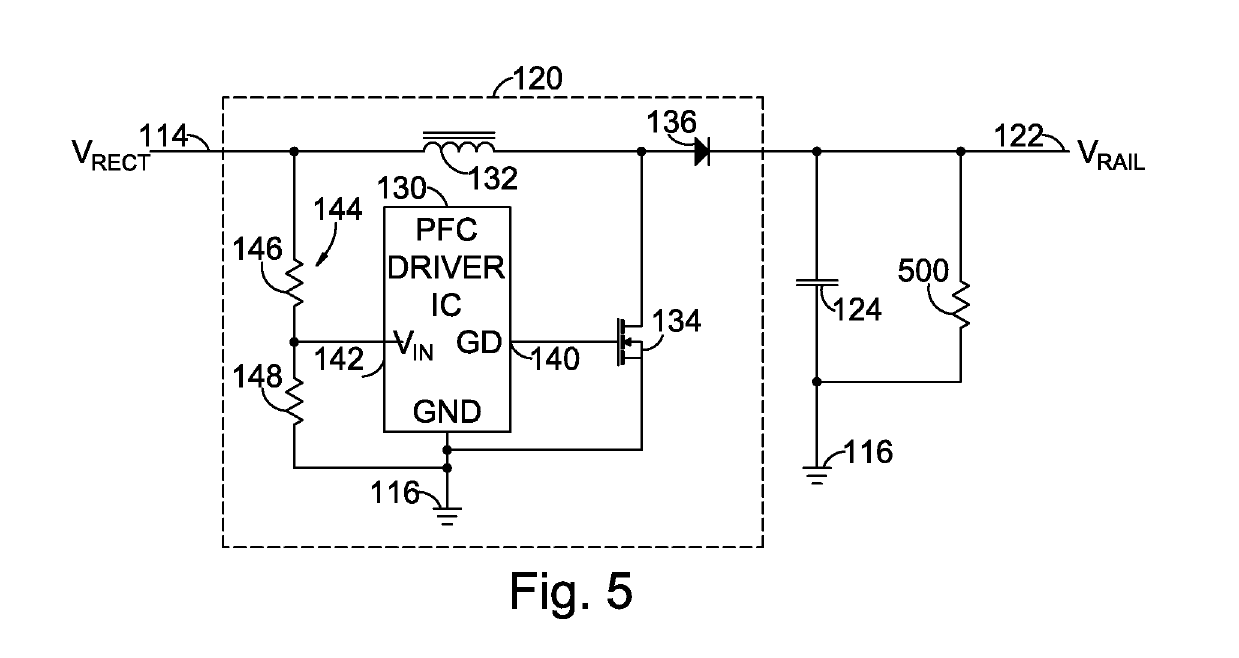

Frequency controlled dummy load to stabilize PFC operation at light load conditions

ActiveUS10320303B1Eliminate rapid changeOffsetting effectEfficient power electronics conversionDc-dc conversionPower factor controlEngineering

A system and a method offset the effect of a reduced load current on a power factor controller connected to a DC-to-DC converter having a switching DC-to-AC inverter driving an output rectifier that produces the load current. A frequency-dependent load impedance is coupled to the output of the inverter. The frequency-dependent load impedance is configured to have a first impedance when the inverter is operating at the minimum operating frequency. The frequency-dependent load impedance has a second impedance when the inverter is operating at the maximum operating frequency. The second impedance is lower than the first impedance and produces a dummy load current that is added to the actual load current to provide a sufficient total load current to cause the power factor controller to operate in a continuous mode even when the actual load current is insufficient to cause the power factor controller to operate in a continuous mode.

Owner:UNIVERSAL LIGHTING TECHNOLOGIES

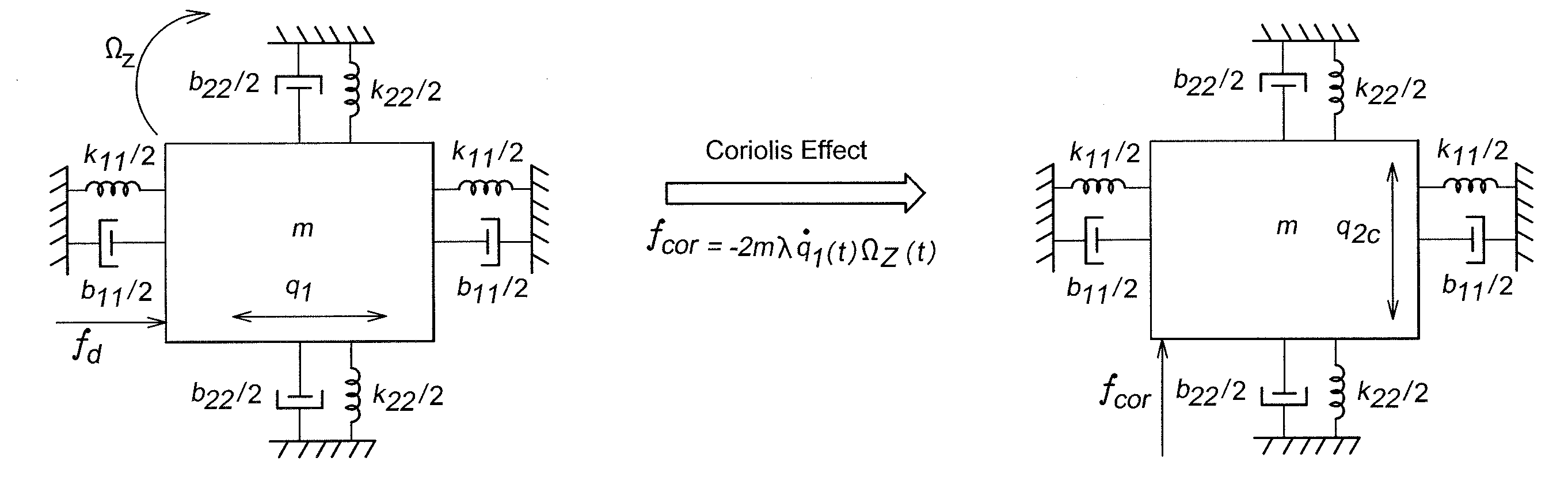

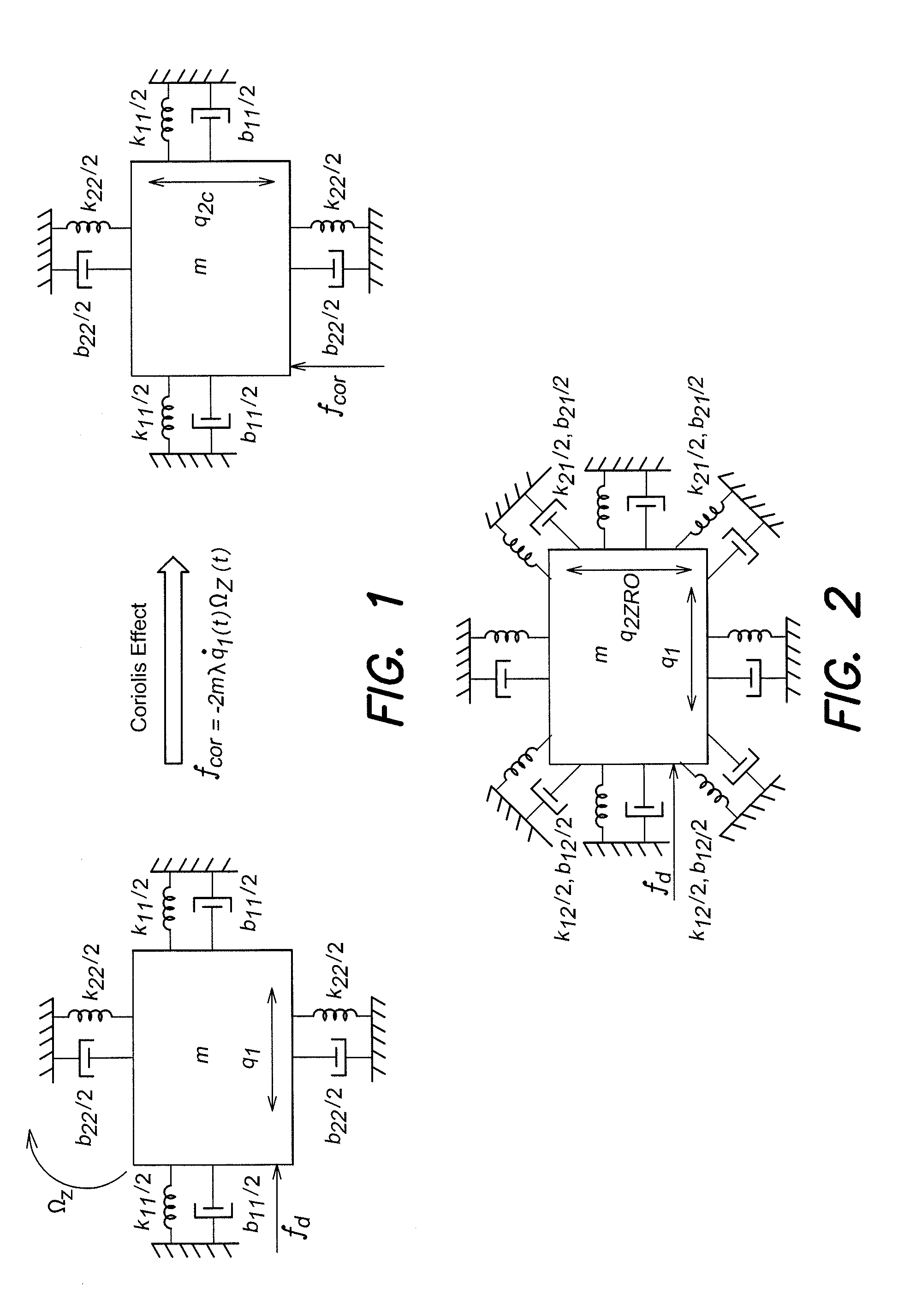

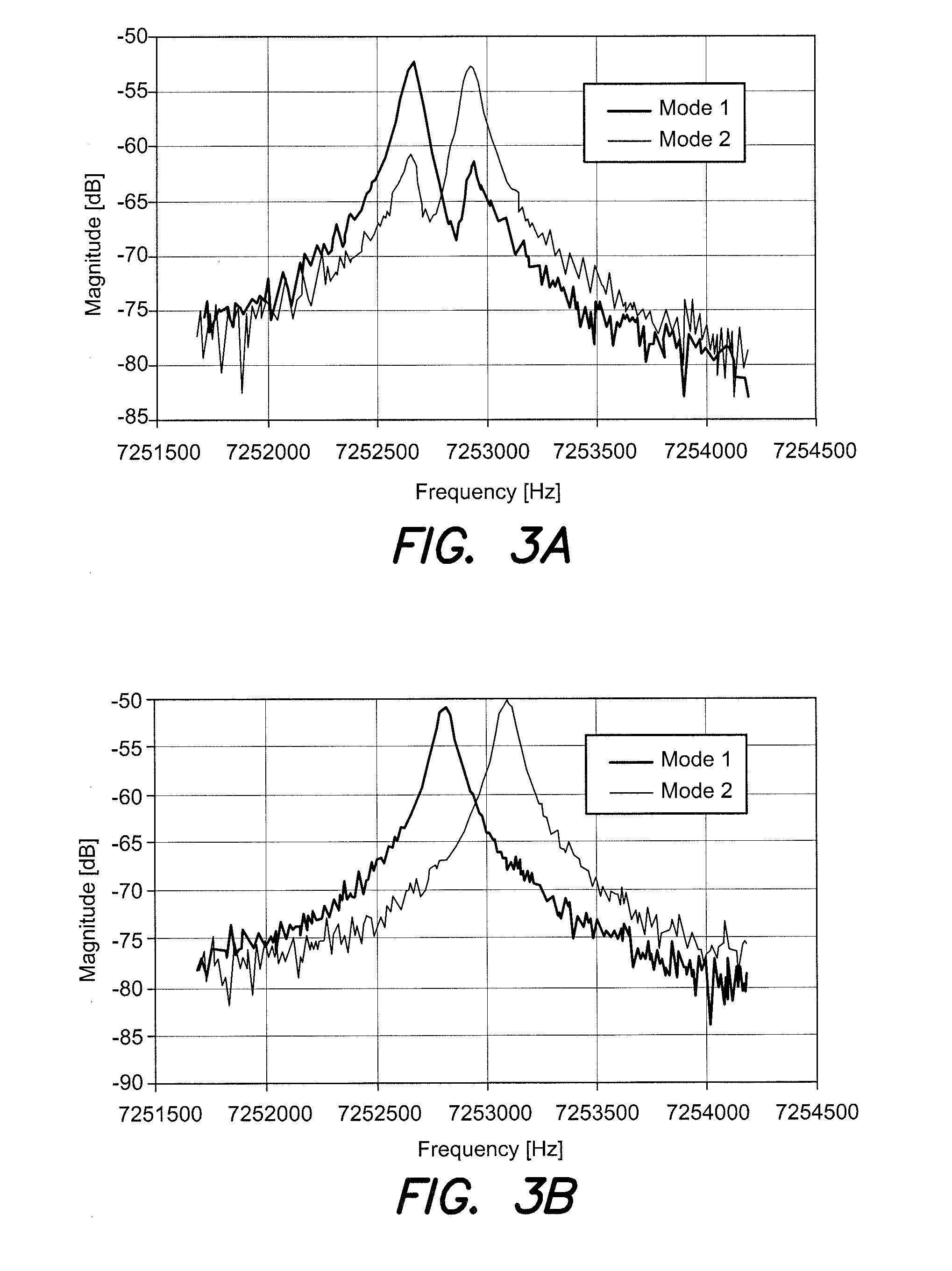

Method and apparatus for decoupling environmental and modal dependencies in inertial measurement devices

InactiveUS20160327390A1Effectively decoupling the resonant structure of the gyroscopeReduces environment-dependent discrepancyImpedence networksSpeed measurement using gyroscopic effectsIn planeGyroscope

A resonant gyroscope apparatus has a decoupling mechanism implemented with spring-like flexure members to effectively isolate an axis-symmetric bulk-acoustic wave (BAW) vibratory gyroscope from its substrate, thereby minimizing the effect that external sources of error have on offset and scale-factor. The spring-like structure enables degeneracy of in-plane resonance modes of the annulus and aids in decoupling the in-plane and out-of-plane resonance modes of the resonant annulus, thereby enabling the mode-matched and / or near mode-matched operation of the structure as a vibratory gyroscope in the pitch, roll and yaw-modes. In various embodiments, the decoupling mechanism may be coupled to either an interior or exterior perimeter of an annulus shaped resonator element of the gyroscope

Owner:PANASONIC HLDG CORP

Gradient insensitive split-core digital to analog converter

InactiveUS7532140B1Reduced sensitivity or substantial insensitivity to error gradientsOffsetting effectElectric signal transmission systemsDigital-analogue convertorsElectrical resistance and conductanceLinearity

Owner:ANALOG DEVICES INT UNLTD

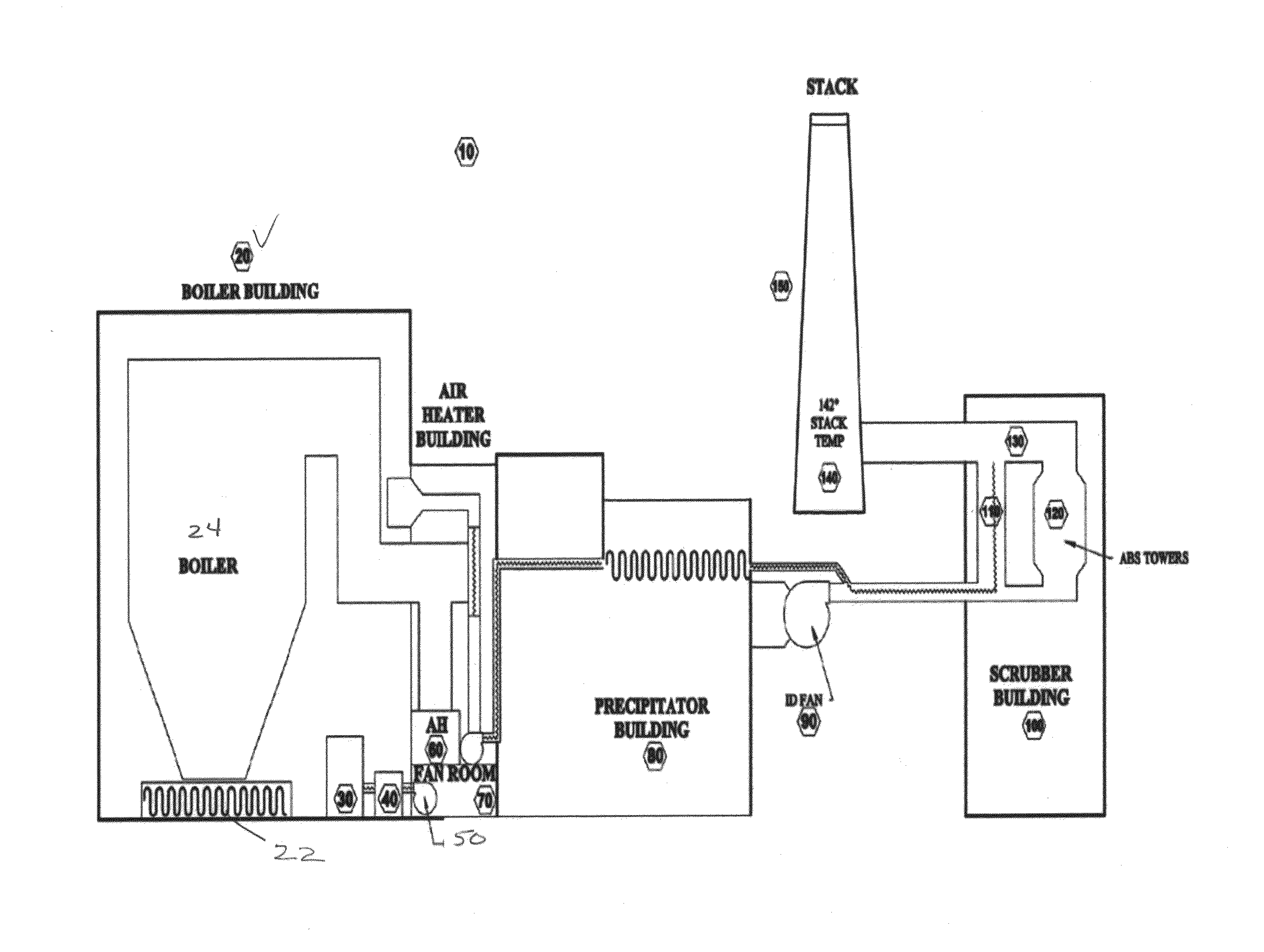

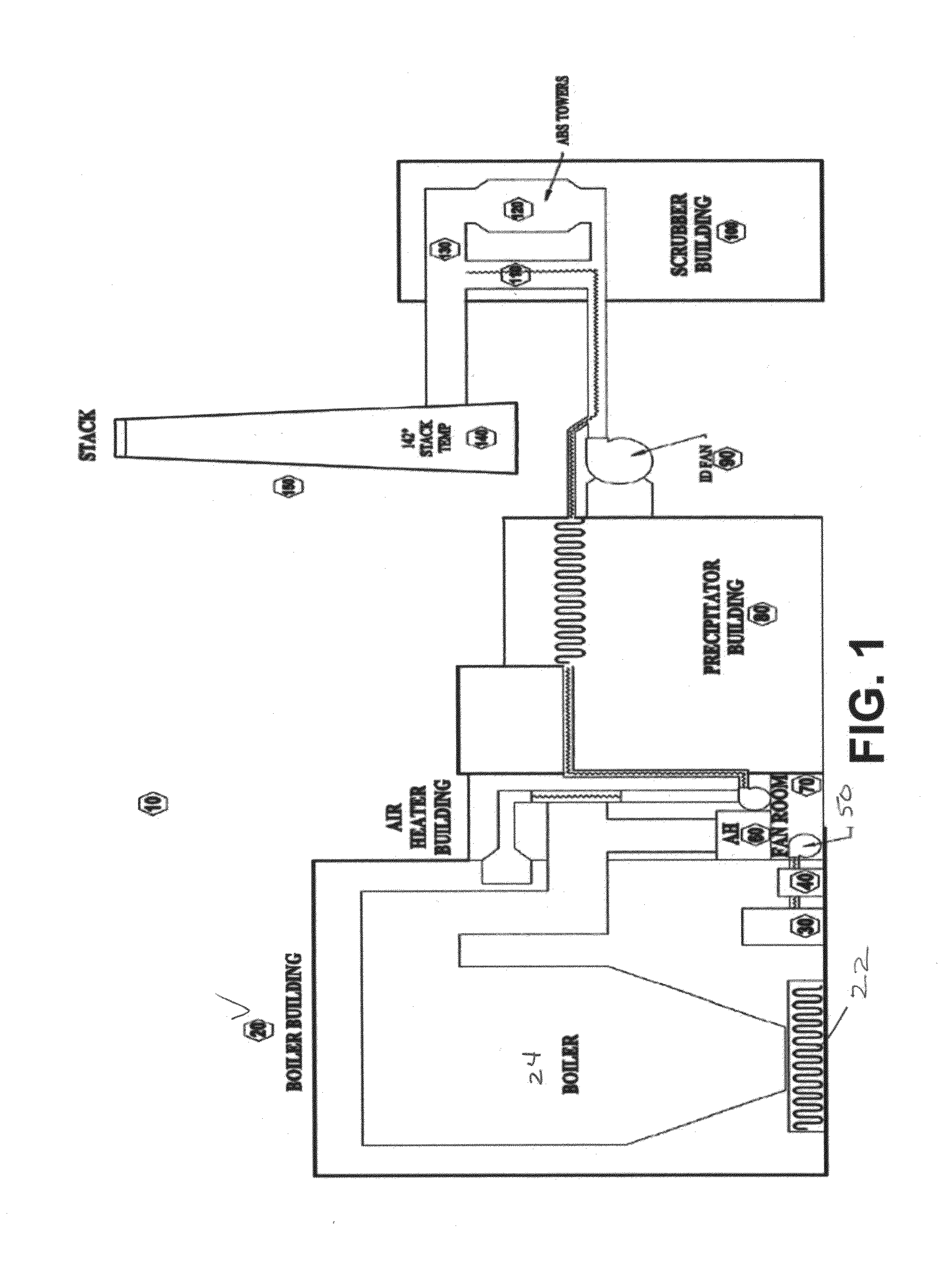

Method and system for reheating flue gas using waste heat to maintain dry chimney stack operation

ActiveUS20160169510A1Improve energy efficiencyEliminate condensation and corrosionEmission preventionChemical industryWorking fluidWater vapor

Flue gas is a by-product of many energy and industrial plants and is typically emitted through a chimney stack. If the flue gas temperature in the chimney stack drops below the flue gas dew point, condensation of water vapor and acid gases ensues. These gases are very corrosive for chimney stacks designed to operate in a dry condition. The Flue Gas Reheat System of the present invention continuously and proactively manages flue gas chimney stack temperatures above the dew point in order to optimize emission control and effectuate energy efficiency improvements in industrial plants. Waste heat is harvested from the exterior surfaces of existing steam and pollution control equipment through conduction, convection and radiation. This heat is transferred to a working fluid. The working fluid is then directly mixed with the flue gas prior to the flue gas entering the chimney stack to raise the temperature of (or re-heat) the flue gas above its dew point to maintain a dry chimney stack condition. The use of residual or waste heat from throughout the plant and the minimal equipment required to harvest the waste heat reduces the operating cost and improves the overall reliability of the system. This method is useful in many industries, including electric power generation plants and other energy intensive process industries that seek emission control and various boiler and fuel energy efficiency improvements, many of which improvements result in a reduction in normal chimney stack temperature.

Owner:RAINBOW ENERGY CENT LLC

Fuel cell system

InactiveUS8017275B2Performance can be prevented from deterioratingAvoid damageFuel cell auxillariesJet pumpsFuel cellsHydrogen

An ejector is provided with a first fluid chamber into which hydrogen gas is introduced; a rod-shaped needle; a nozzle exhausting hydrogen gas introduced into the first fluid chamber from an exhaust port; a second fluid chamber into which hydrogen off-gas is introduced; a diffuser provided at the exhaust port of the nozzle; and a third fluid chamber into which air is introduced. The first fluid chamber is provided between the second fluid chamber and the third fluid chamber. The first diaphragm 65 separates the first fluid chamber and the second fluid chamber and the second diaphragm separates the first chamber and the third fluid chamber. Then, the needle and the nozzle moves to approach each other by the pressure of air introduced into the third fluid chamber and isolate each other by the pressure of hydrogen off-gas introduced into the second fluid chamber.

Owner:HONDA MOTOR CO LTD

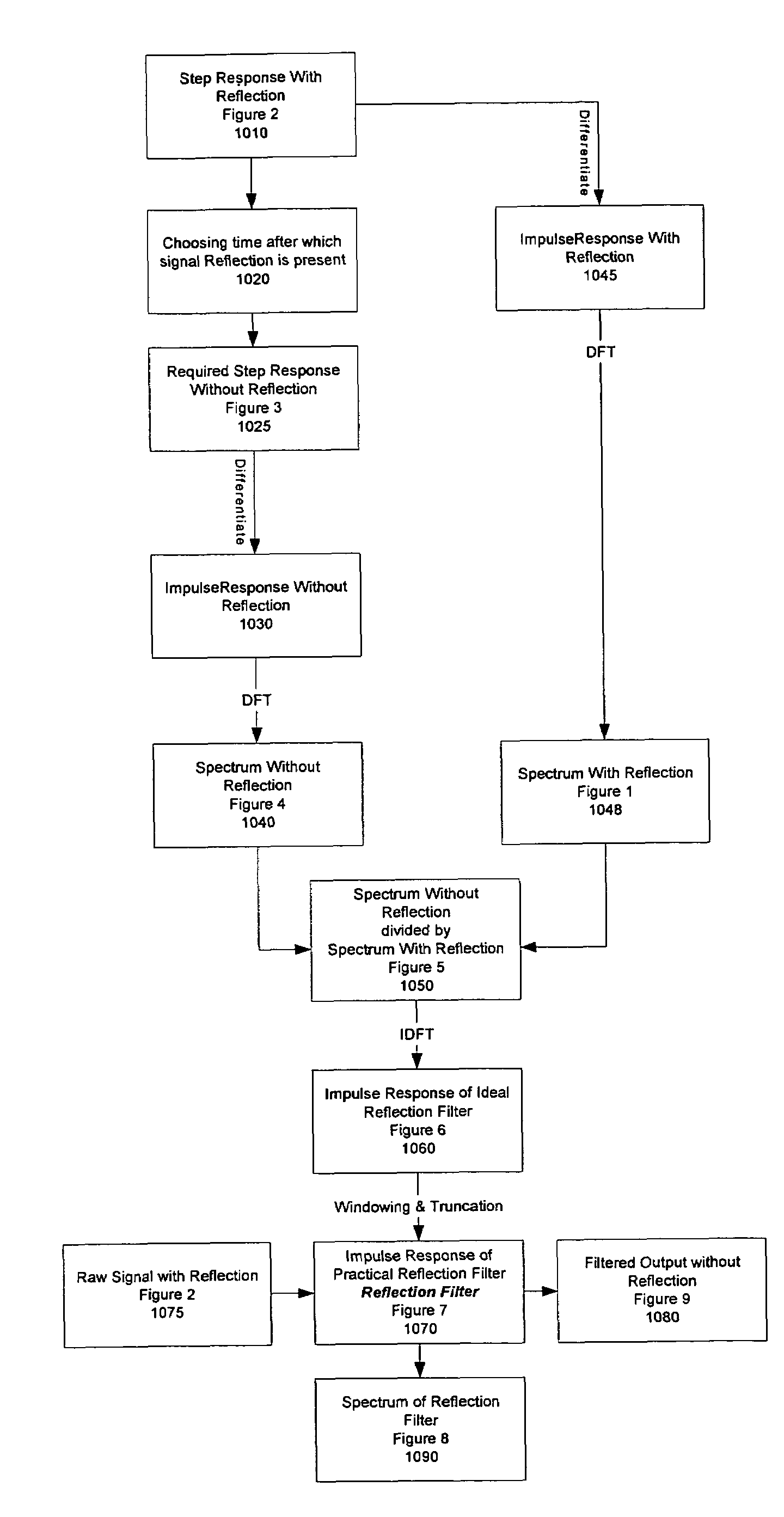

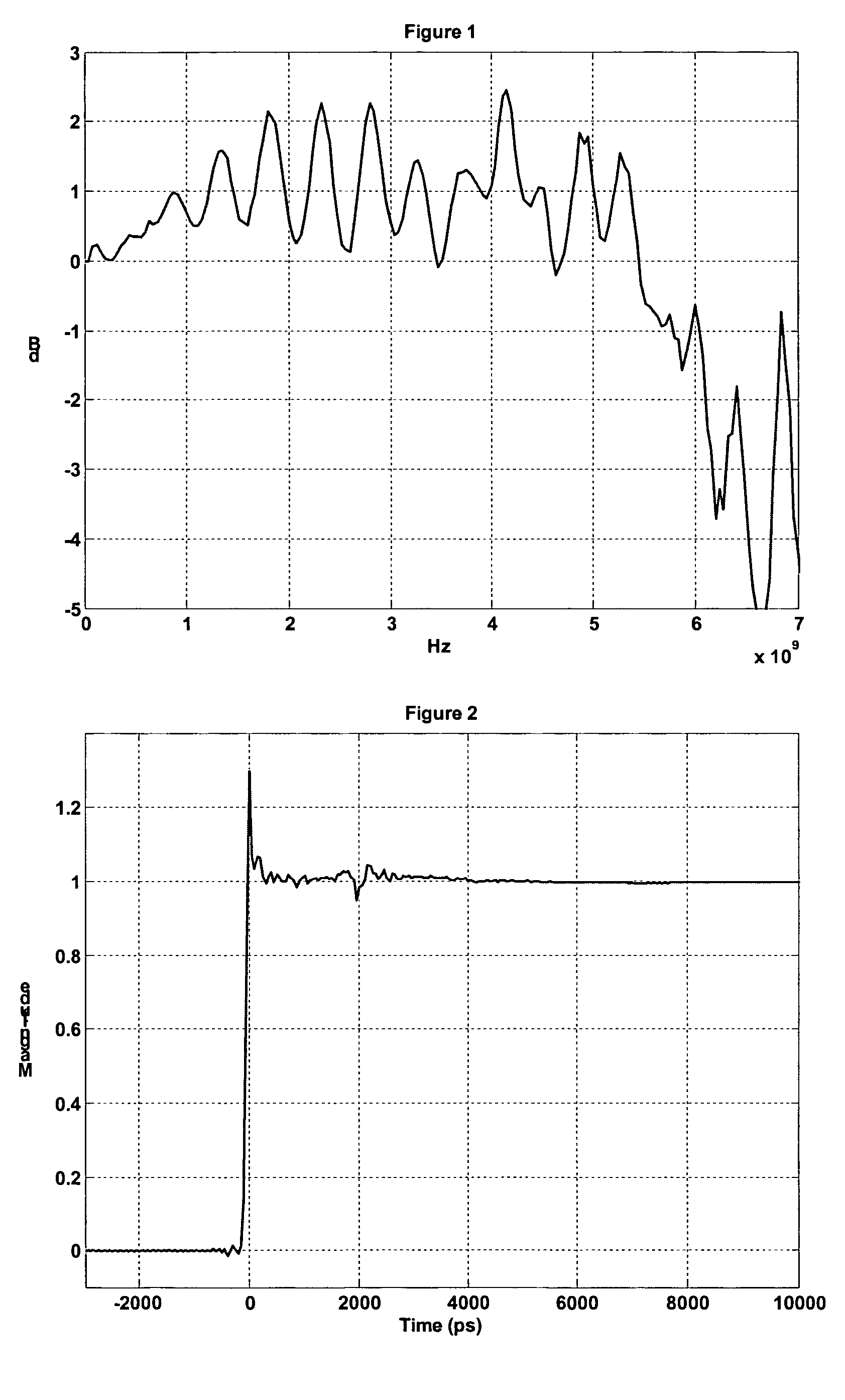

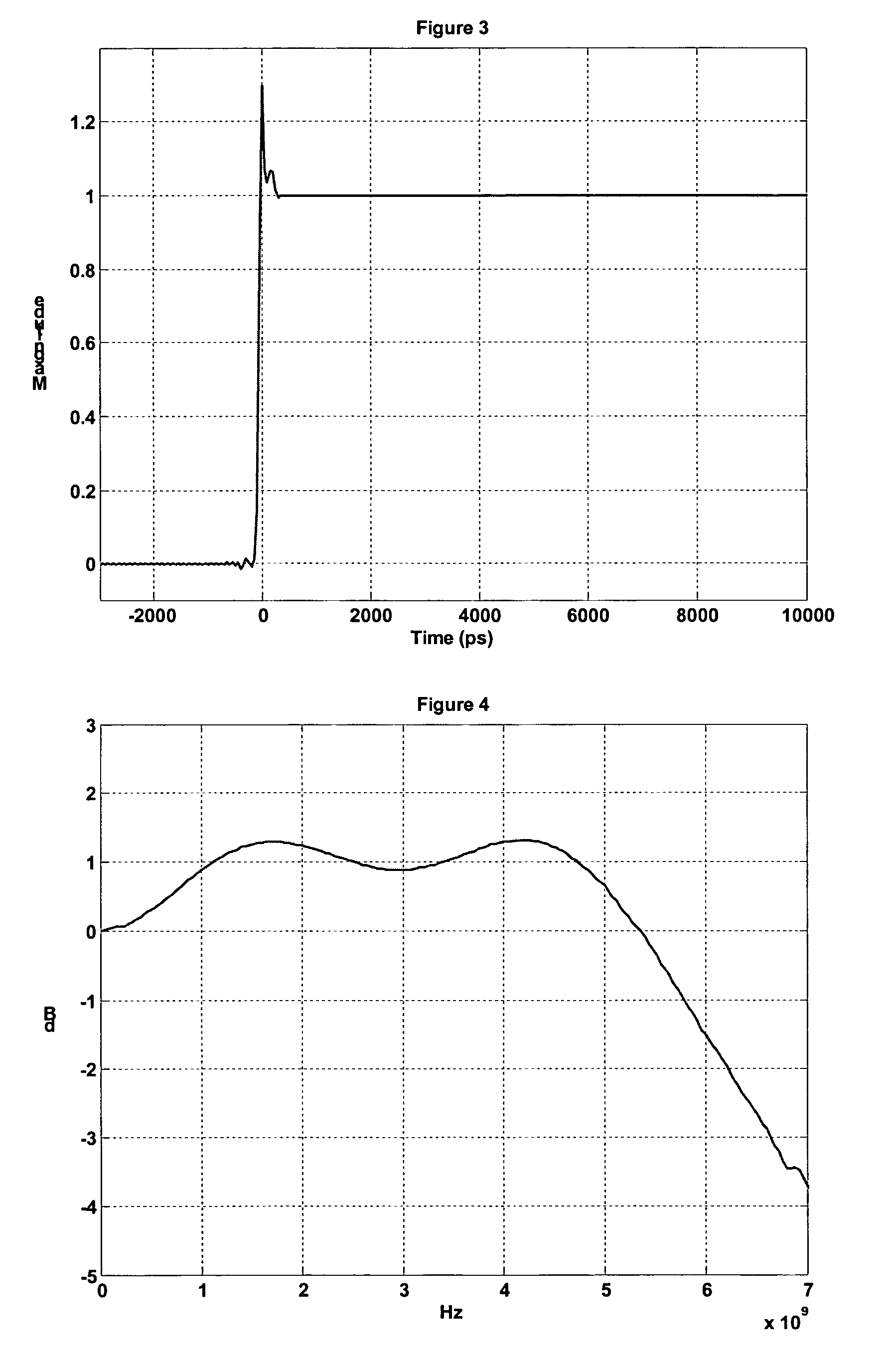

Reflection filter

ActiveUS7233967B2Easy to useOffsetting effectDigital technique networkComplex mathematical operationsFrequency spectrumStep response

A method and apparatus for generating a reflection filter. The method comprises the steps of determining an averaged step response of an acquired signal and generating a spectrum response from the averaged step response. A time at which a reflection in the averaged step response begins is determined and information in the averaged step response after the determined time when the reflection begins is replaced with an ideal flat line response to generate a required step response. A spectrum response is generated from the required step response and each frequency point of the spectrum response corresponding to the required step response is divided by each frequency point of the spectrum response corresponding to the averaged step response to generate a spectrum of the reflection filter. The result of the dividing step is processed to generate a reflection filter impulse response.

Owner:TELEDYNE LECROY

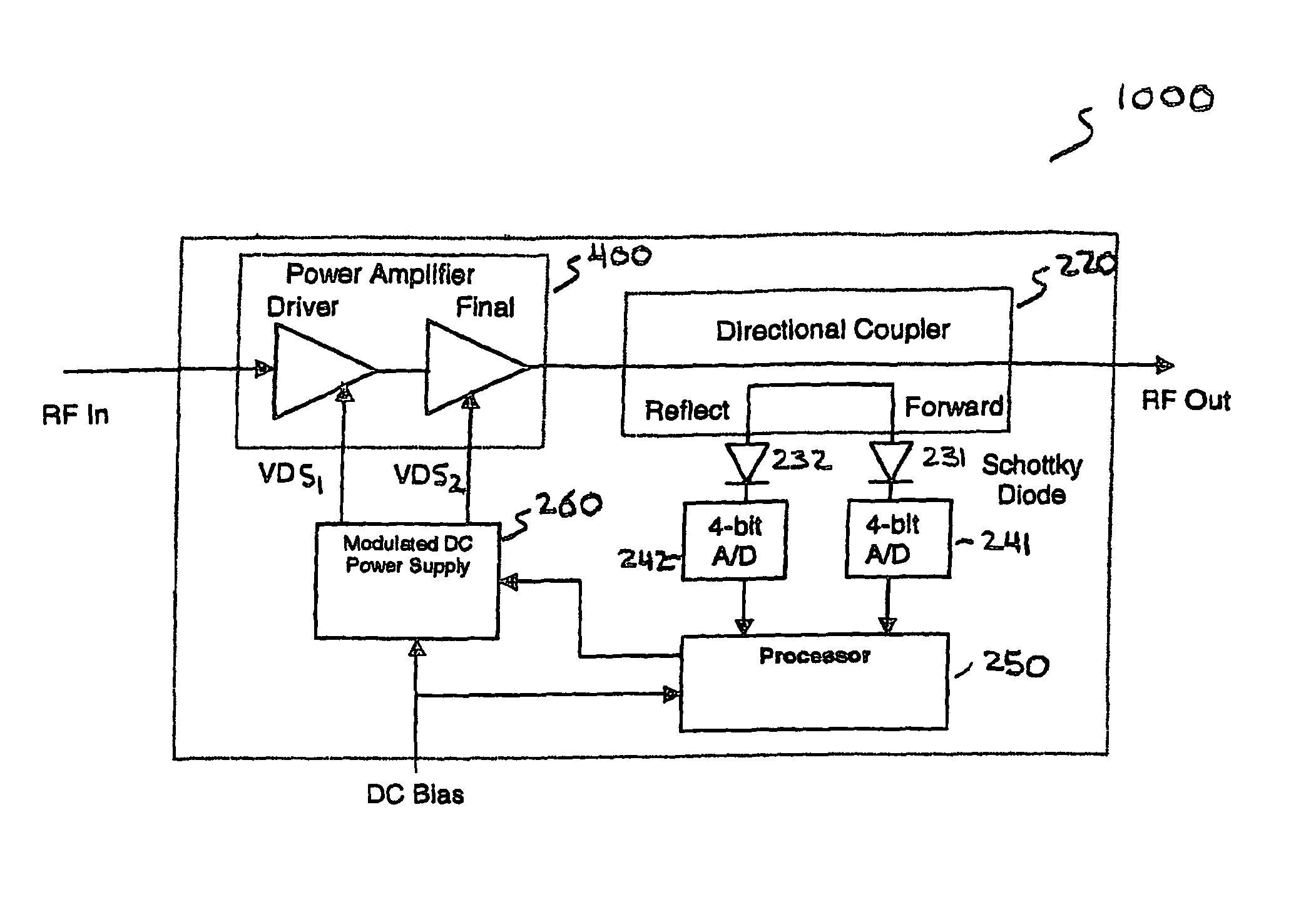

High efficiency linear microwave power amplifier

ActiveUS7852153B1Reduce distortion problemsImprove efficiencyHigh frequency amplifiersSupply voltage varying controlPhase responseLow distortion

A post-distortion method for cascading amplifier stages in a two-stage microwave power amplifier and a dynamic biasing method using back-end processing for correcting nonlinearity in the power amplifier output. A first or driver stage biased in a near-A region with low distortion is cascaded with a second or power stage biased in a near-C region with high efficiency. The amplitude and phase responses of the two stages compensate another to yield a more linear overall gain for the overall power amplifier. The dynamic biasing scheme modulates the source to drain voltages of the transistors used in the amplifier stages based on the harmonics in amplifier output in order to minimize the harmonics and correct non-linearity in the output.

Owner:HRL LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com