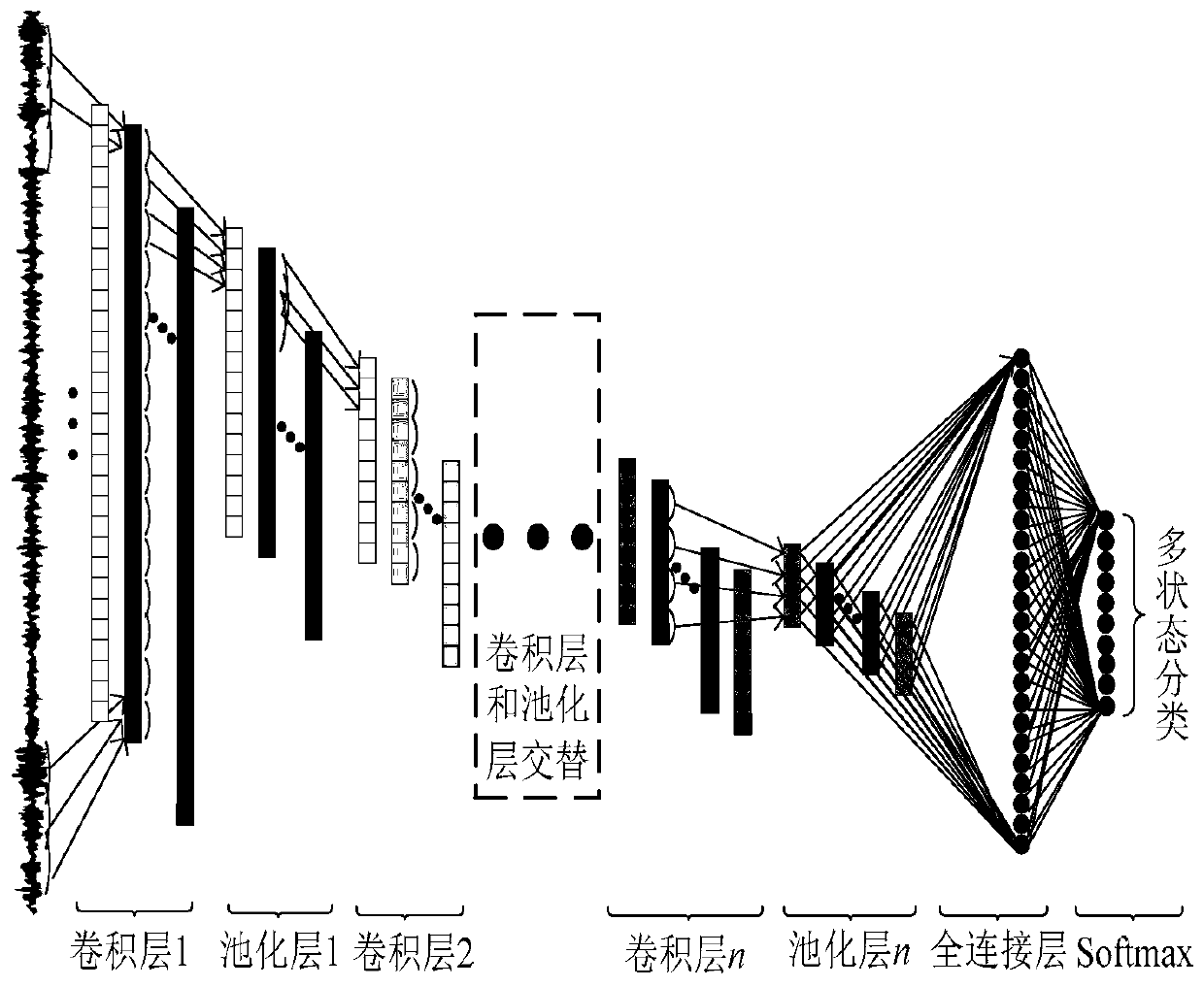

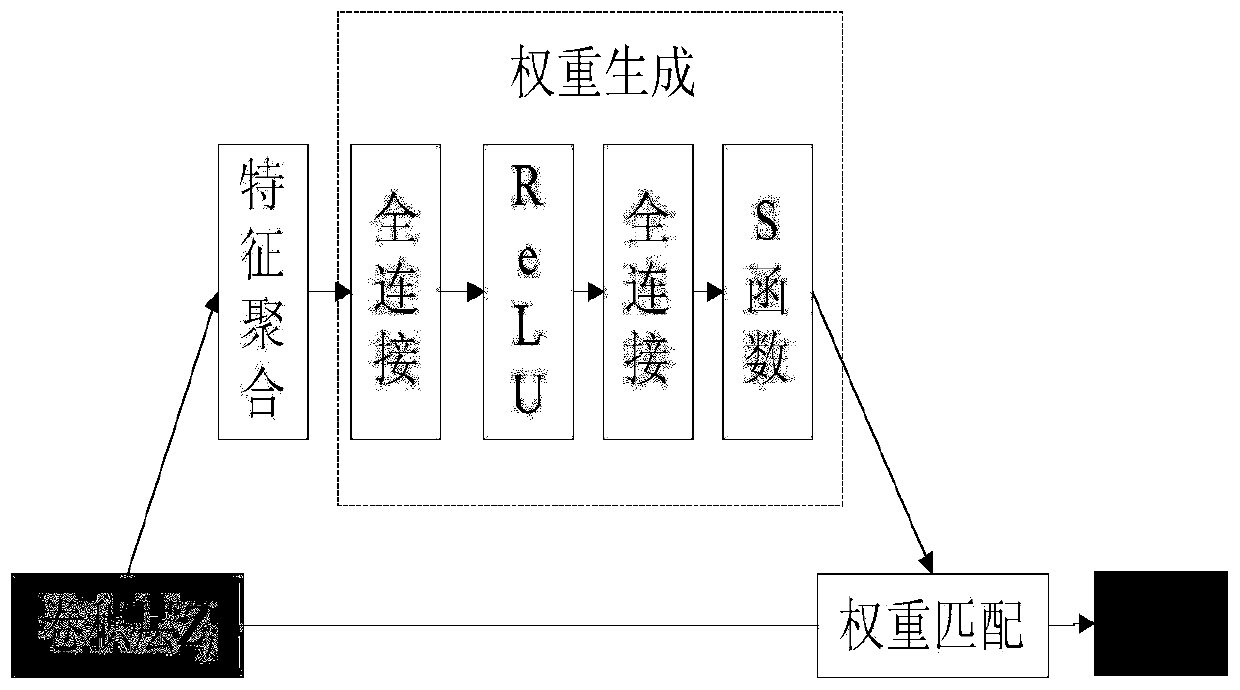

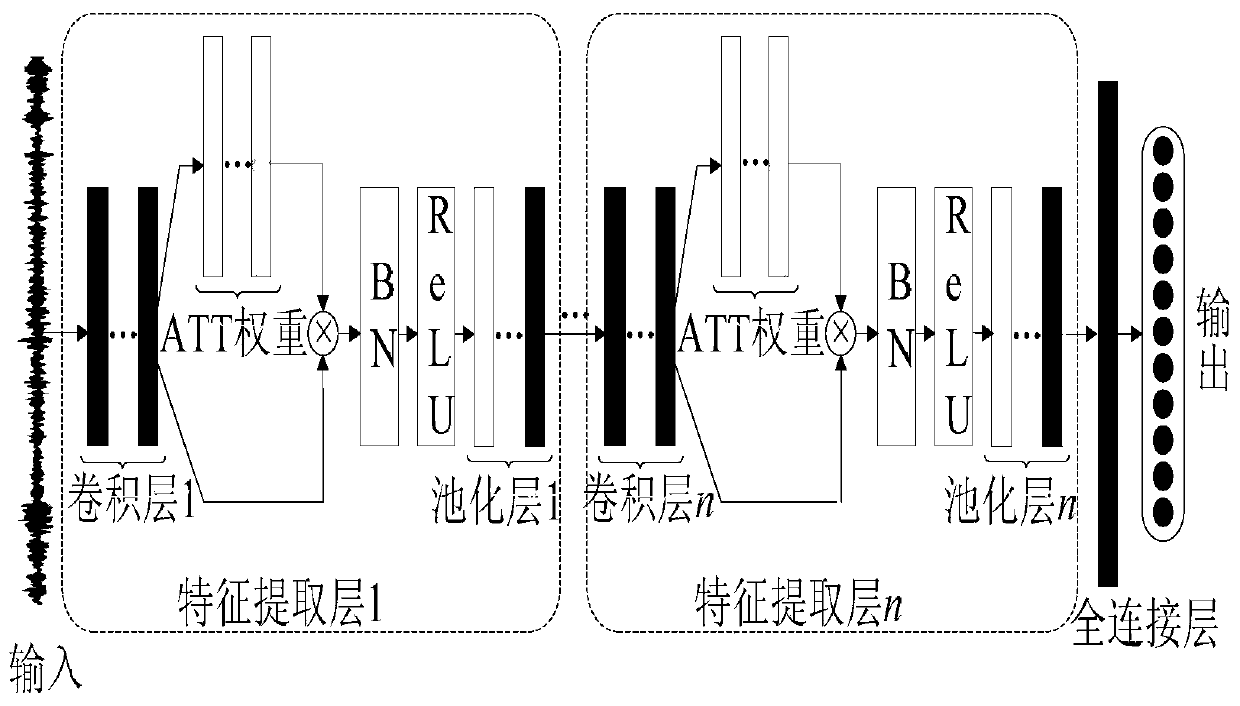

A rolling bearing fault identification method under variable working conditions based on ATT-CNN

An ATT-CNN, rolling bearing technology, used in mechanical bearing testing, instruments, biological neural network models, etc., can solve problems such as generalization ability constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment approach 2

[0140] In order to verify the generalization ability of the algorithm proposed in this paper, experiments are carried out on the data of all load types. All state data sets under two loads are used as the training set, and the data under the other two different loads are used as the test set. The data settings and experimental results are shown in Table 4. The structure of multi-working condition data is more complex and diverse, and it is more difficult to identify the fault state when testing and diagnosing single working condition data.

[0141] Table 4 Experimental Scheme 2 Dataset Settings and Accuracy Comparison

[0142]

[0143] Through the analysis of multiple groups of experiments, the average test accuracy of the ATT-CNN model is 96.48%, which is 3.3% higher than that of CNN. It shows that under more complex working conditions, the data structure and distribution of the test set and the training set are quite different, and the ATT-CNN model can well adapt to the...

experiment approach 3

[0146] In order to further verify the robustness of the model, the data under one load is used as the training set, and the data under the other three loads are used as the test set. The data settings and experimental results are shown in Table 5. It is well known that for deep neural networks, a more robust model can be obtained by using a large amount of training data. However, in practical applications, some working condition data are difficult to obtain or unknown working condition data will appear, so it is hoped that small data sets can be used to realize fault diagnosis under variable working conditions.

[0147] Table 5 Experimental scheme three data set settings and accuracy comparison

[0148]

[0149]

[0150] The average test accuracy based on the ATT-CNN model is 83.40%, while the unimproved CNN model is only 77.98%, which is 5.5% higher. The overall performance of the proposed algorithm on the data set set by scheme three is not as good as that of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com