Fault detection in rotor driven equipment using rotational invariant transform of sub-sampled 3-axis vibrational data

a technology of vibrational data and rotor drive, which is applied in the direction of machine parts testing, structural/machine measurement, instruments, etc., and can solve problems such as controlling sampling errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

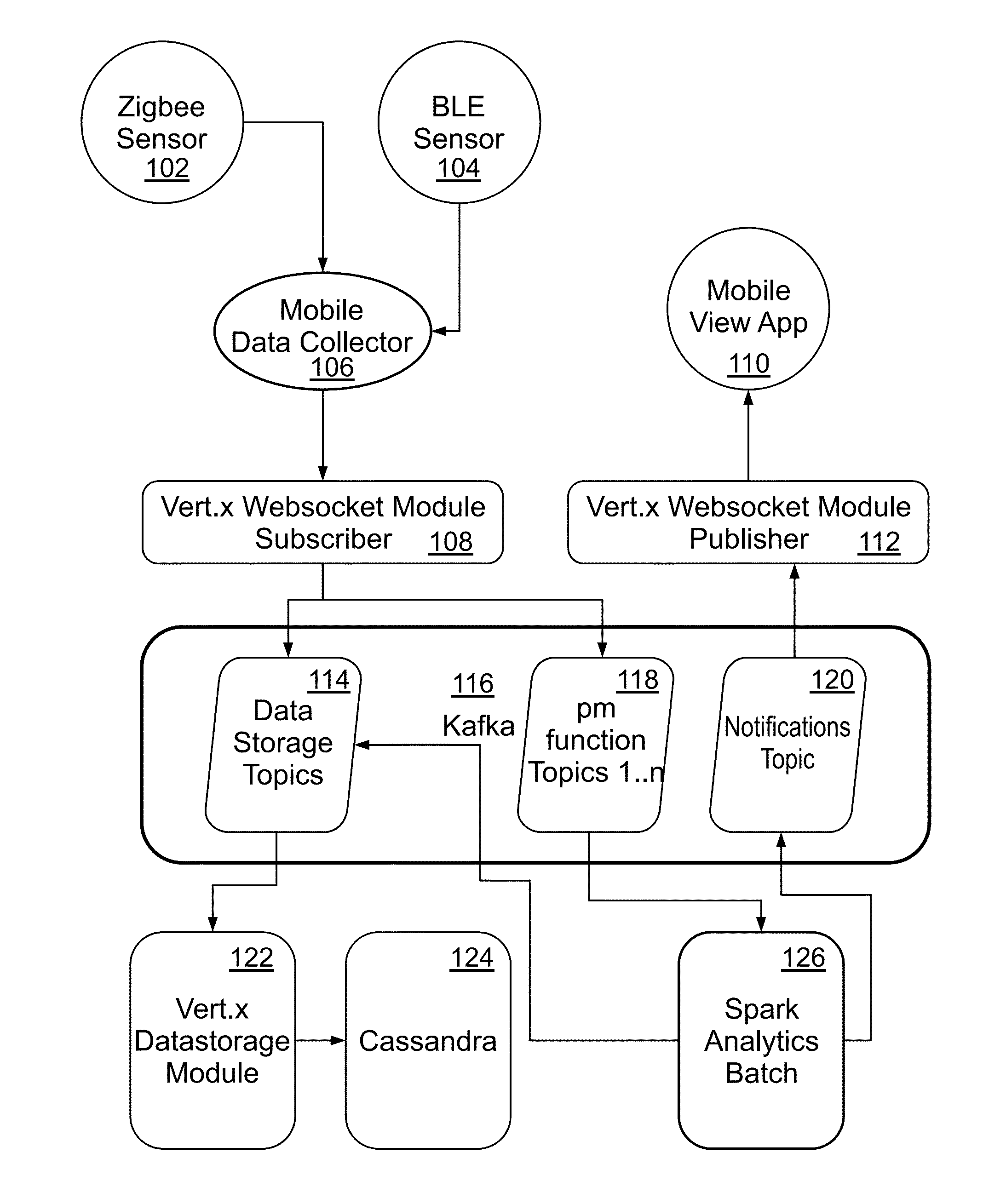

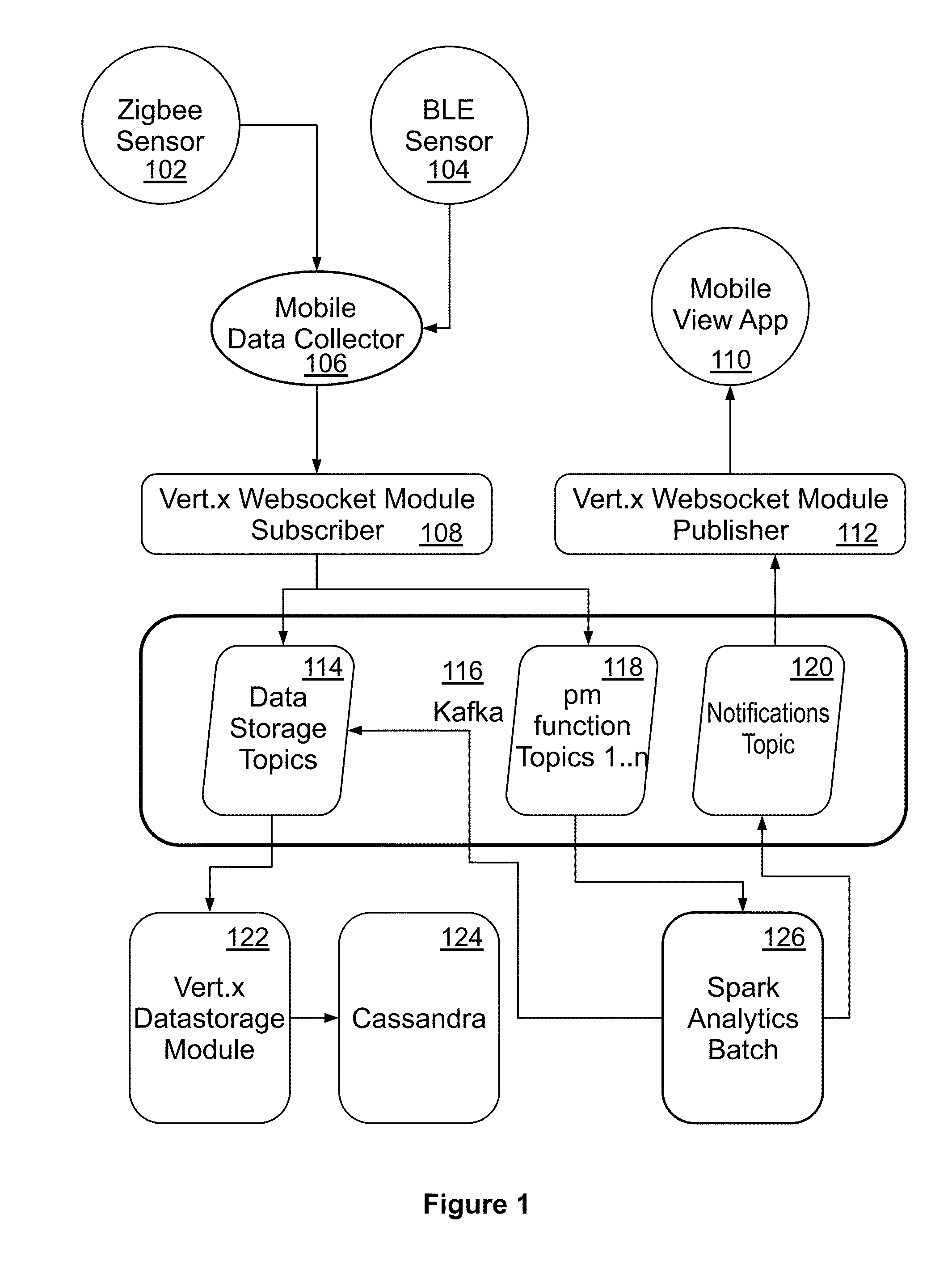

[0030]Example embodiments as described below may be used to provide a method, an apparatus and / or a system for fault detection in rotor driven equipment through big data analytics. Although the present embodiments have been described with reference to specific example embodiments, it will be evident that various modifications and changes may be made to these embodiments without departing from the broader spirit and scope of the various embodiments.

[0031]In one or more embodiments, vibrations of a fault free rotor in time domain may be represented by

x_j(t)=Σi=1∞αi*sin(i*Ω*t)|j=1,2,2

Ω is fundamental frequency and i, j, and k are three Cartesian vectors. In vibration analysis of a rotor, revolution per second of rotor may be multiplied by 2π.

[0032]Fundamental harmonics and other harmonics generated by a rotor may depend on the rotor's speed. Rotation speed of the rotor may commonly vary between 200-3000 RPM (Revolutions Per Minute). With such rotation speeds, the fundamental harmonics ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com