Bearing fault diagnosis method based on fuzzy support vector machine

A fuzzy support vector, fault diagnosis technology, applied in the direction of mechanical bearing testing, special data processing applications, instruments, etc., can solve the problem of not considering bearing fault data interference, bearing fault diagnosis small sample problem and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention is a bearing fault diagnosis algorithm. The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0082] Take SKF's 6205-2RS deep groove ball bearing in part of the experimental data of the bearing vibration database of Western Reserve University as an example.

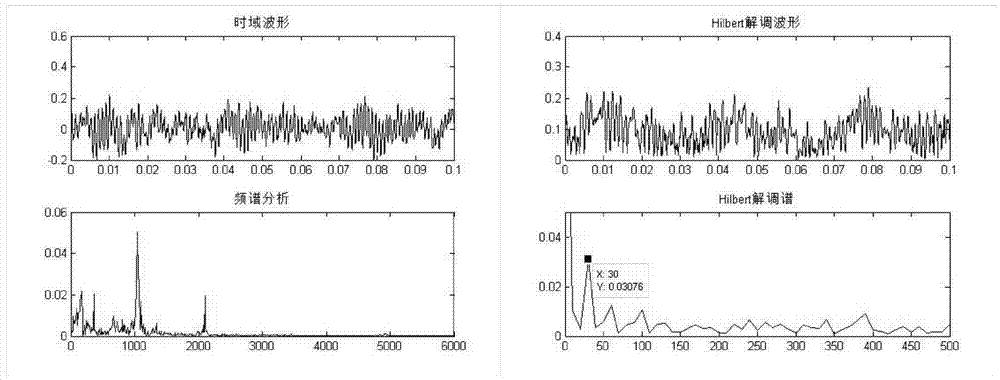

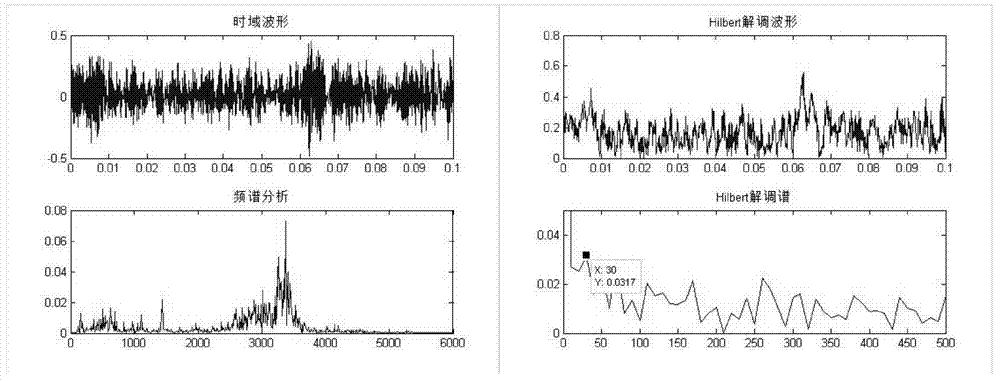

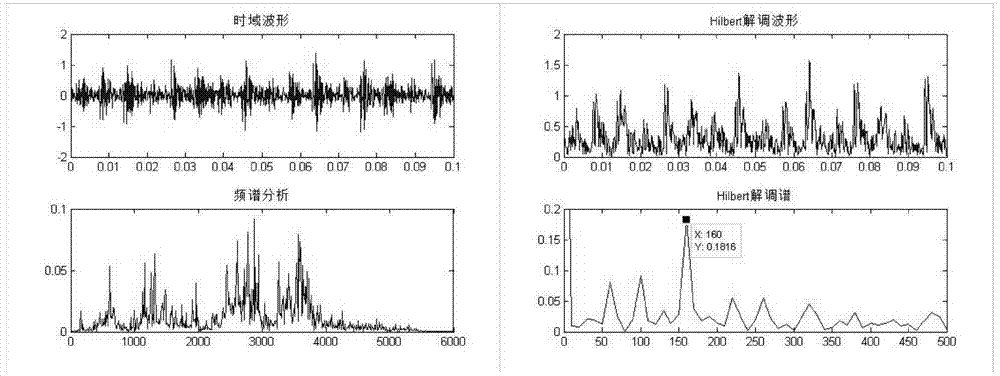

[0083] 1. Data preprocessing and feature parameter selection

[0084] A total of 240 samples were selected for the analysis of normal bearings, 0.18mm inner ring single point fault, 0.18mm outer ring single point fault and 0.18mm rolling element single point fault.

[0085] The collected vibration signal of the rolling bearing is a typical time-domain signal, and its time-domain statistical characteristic parameters such as root mean square value, kurtosis, peak-peak value, kurtosis and other statistics can well reflect the vibration intensity, signal energy, impact time and so on. Domain and other information, so some p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com