Three dimensional cell culture construct and apparatus for its making

A three-dimensional cell and cell culture technology, applied in the field of forming and manufacturing the insert, porous three-dimensional cell culture insert, and culturing mammalian cells, can solve the problem of difficult control of fiber size, difficult determination of matrix pore size and shape, and difficult operation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

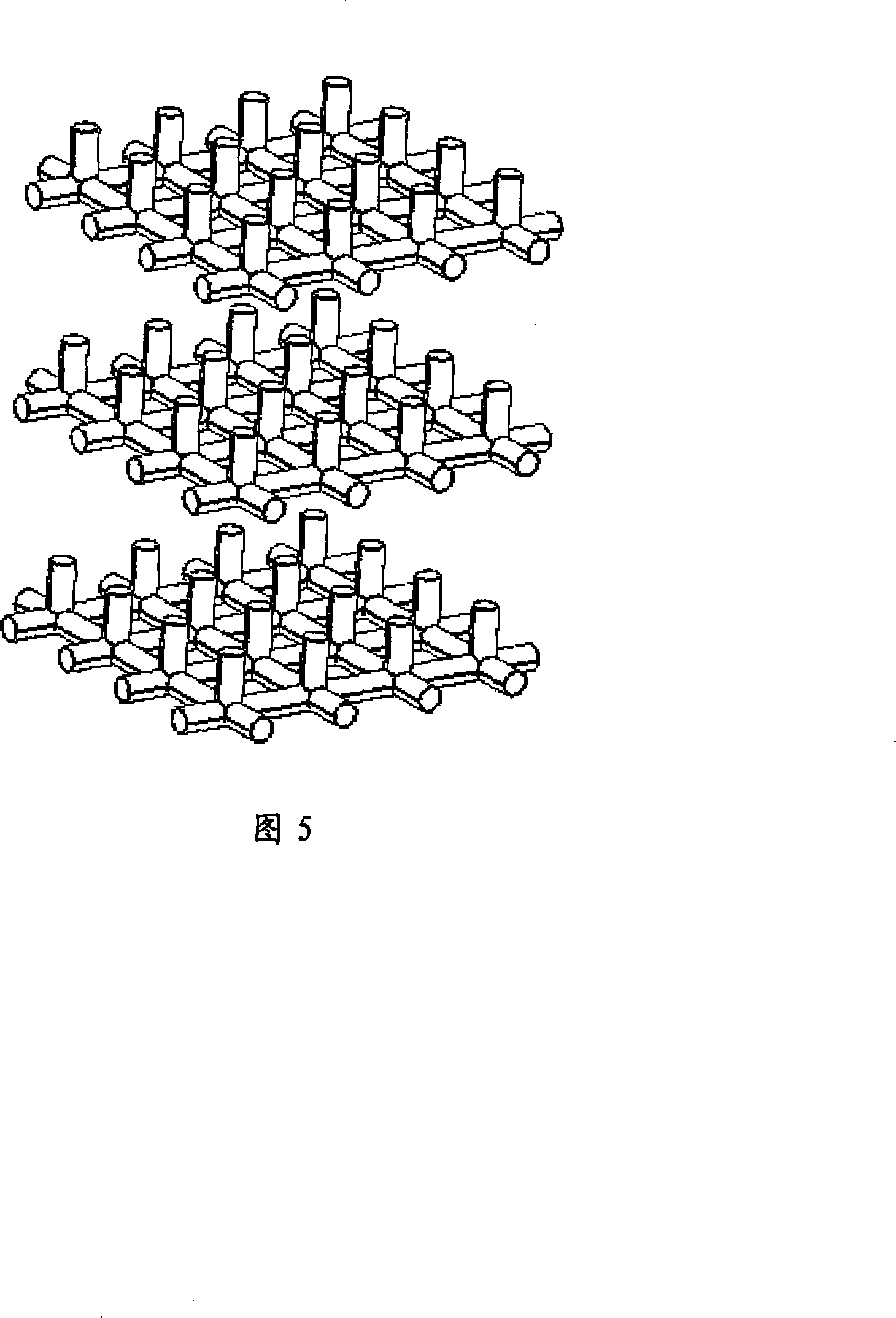

[0149] Example 1: Method of Manufacturing Cell Culture Inserts

[0150] Fabricate cell culture inserts using polystyrene material. The components of the cell culture insert shown in Figure 5 were used for assembly in the cell culture insert. These parts are injection molded according to design. After the parts are made, the first layer is first placed into the assembly guide, and then the second, third and fourth layer of parts are sequentially placed in the guide. Thus, the total number of parts is four. These 4 parts are then joined together using a polystyrene fiber connector as shown in Figure 7. The ends of the connector are further secured by knotting or deforming the ends so that they cannot escape from the holes of the insert. After assembly, the cell culture inserts were plasma treated in an argon atmosphere using a Polaron PT7300 RF plasma barrel etcher (Quorum Technology, East Sussex, UK). Its RF power, pressure and processing time are fixed at 296 watts, 1×1...

Embodiment 2

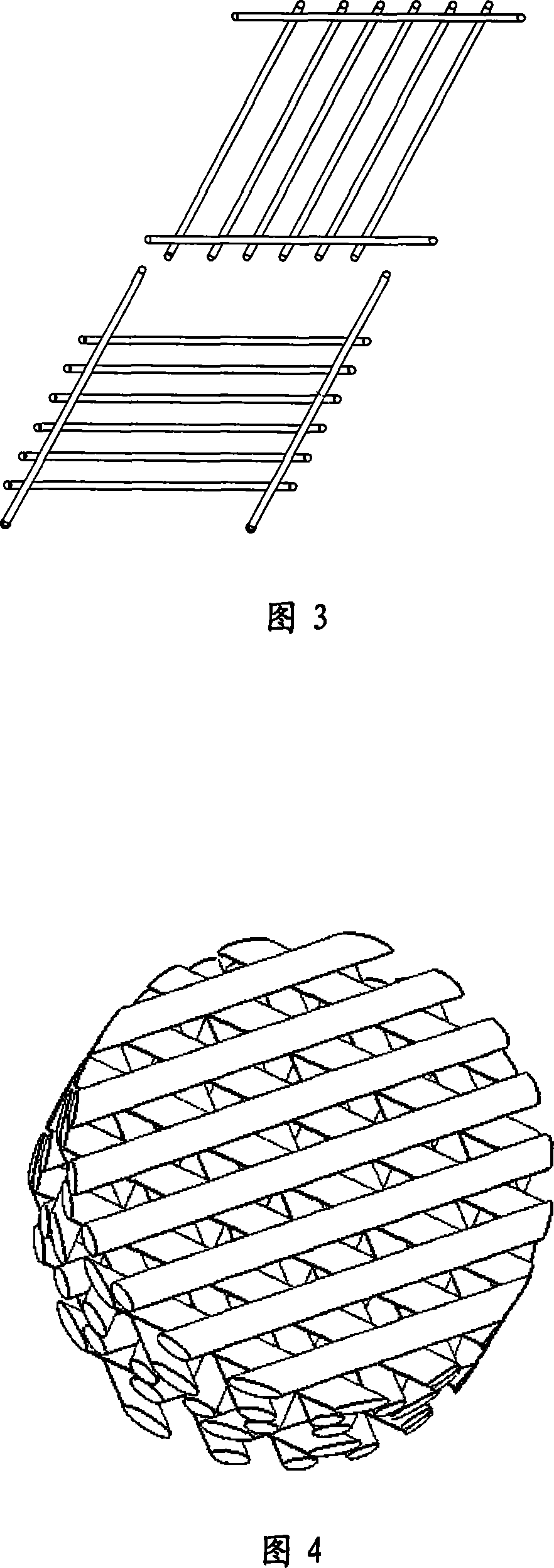

[0152] Example 2: Using Cell Culture Inserts to Cultivate Cells

[0153] The present invention also provides a method for culturing living cells using the cell culture insert in a tissue culture polystyrene plate. The cell culture inserts used for this study had dimensions of 10 mm wide by 10 mm long by 0.3 mm thick, with square pores of 200 μm and fiber diameters of 400 μm. Inoculate smooth muscle cells using the static inoculation method: pipette 500 μl of smooth muscle cell suspension (1×10 5 cells / ml) from the upper surface of the insert, allowing the cells to attach for 2 hours at 37°C before perfusing more cell culture medium. After seeding the cells, the cell culture inserts were placed in multi-well plates containing cell culture medium and incubated at 37°C in a 90% humidity chamber containing 5-10% CO. 2 cultured in an incubator in an air atmosphere. The growth medium consisted of Dulbecco's Modified Eagle's Medium (DMEM) containing 5% (v / v) fetal bovine serum. ...

Embodiment 3

[0156] Example 3: Cultivating cells in bioreactors using cell culture inserts

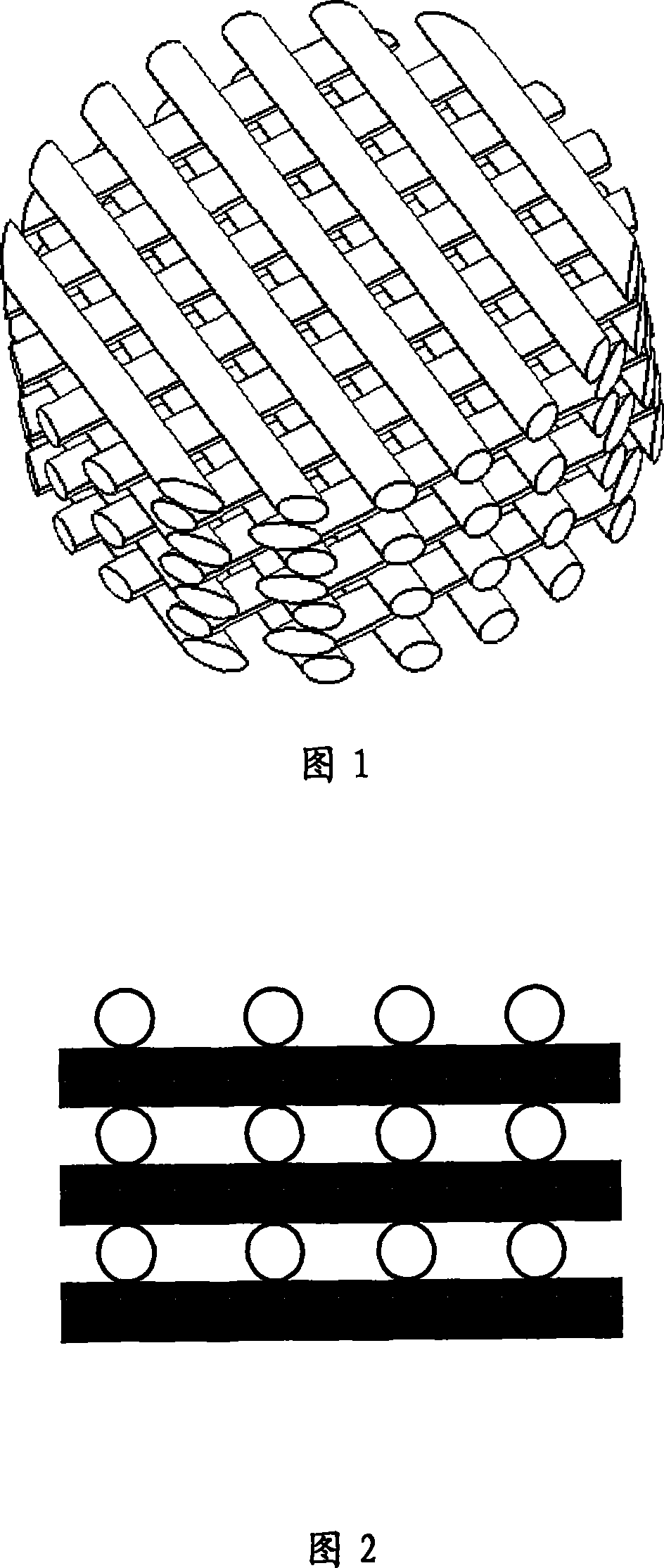

[0157] The present invention also provides a method for culturing living cells in a bioreactor using the cell culture insert. The cell culture inserts used here are disc-shaped (10 mm diameter disc, 0.8 mm thick, 80% porosity, and 200 μm fiber diameter) and fit the bioreactor as described.

[0158] Rat bone marrow stromal cells (MSCs) were first statically seeded on the cell culture insert. 500 μL of MSC suspension containing 250,000 rat MSCs was pipetted from the upper surface of the cell culture insert, cells were allowed to attach at 37° C. for 2 hours, and then flushed with cell culture medium. After seeding the cells, the seeded cell culture inserts were maintained in flow perfusion cell culture vessels. The cell culture inserts seeded with cells were submerged in a complete osteodifferentiation medium and incubated at 37[deg.]C, 90% humidity in an air atmosphere containing 5-10% carbon di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com