Preparation method of large-diameter aspheric lens

A technology of aspheric lens and large diameter, applied in glass manufacturing equipment, manufacturing tools, glass pressing, etc., can solve the problems of large diameter and high precision aspheric lens size and volume, achieve low internal stress and reduce structure Poor, fast heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The glass material of the glass material is K~VC89, the diameter of the glass material is 120mm, and the diameter of the aspheric lens after molding is 150mm:

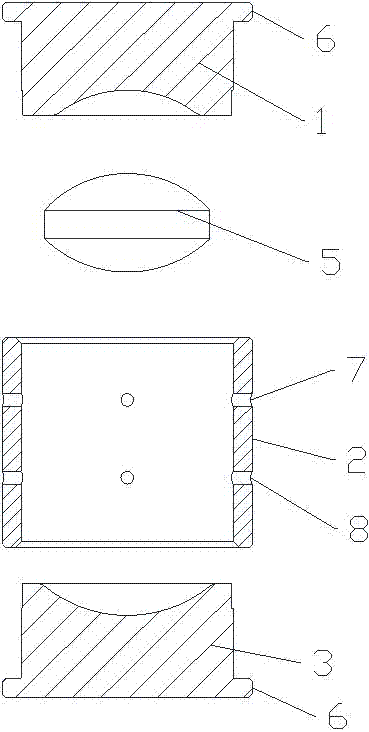

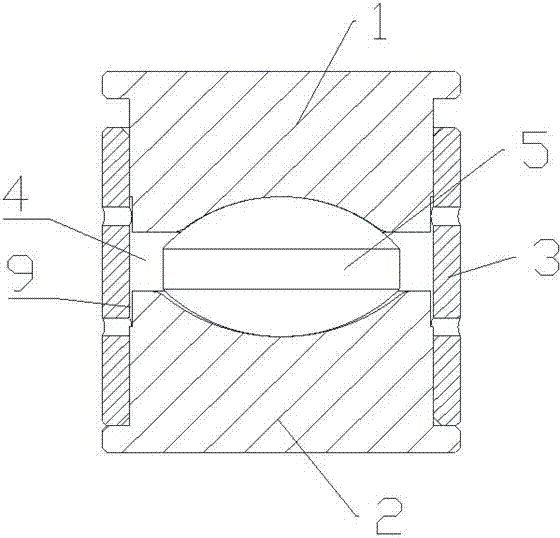

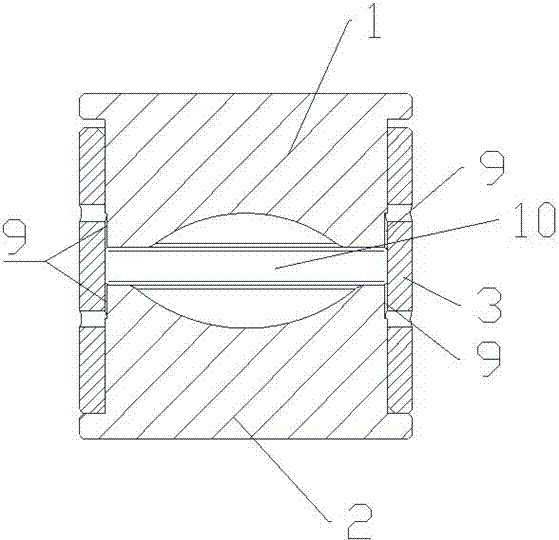

[0044] (1) Making mold cores and glass materials: making mold cores and glass materials for molding large-diameter aspheric lenses. The inner diameter of the molding cavity of the mold core is 150 mm, and the diameter of the glass material is 120 mm;

[0045] (2) Put the glass nitrate material into the mold core: put the glass nitrate material into the mold core, the spherical surface of the glass nitrate material corresponds to the aspherical surface of the mold core;

[0046] (3) Put the mold core into the molding station: put the mold core filled with glass nitrate material into the lower working surface of the molding station;

[0047] (4) Vacuuming the station: seal the molding station and evacuate it, and stop vacuuming when the vacuum degree reaches 5×10-1Pa;

[0048] (5) Inject nitrogen into the station...

Embodiment 2

[0061] The glass material of the glass material is K~PBK40, the diameter of the glass material is 40mm, and the diameter of the aspheric lens after molding is 50mm;

[0062] (1) Making mold cores and glass materials: making mold cores and glass materials for molding large-diameter aspheric lenses. The inner diameter of the molding cavity of the mold core is 50 mm, and the diameter of the glass material is 40 mm;

[0063] (2) Put the glass nitrate material into the mold core: put the glass nitrate material into the mold core, the spherical surface of the glass nitrate material corresponds to the aspherical surface of the mold core;

[0064] (3) Put the mold core into the molding station: put the mold core filled with glass nitrate material into the lower working surface of the molding station;

[0065] (4) Vacuuming the station: seal the molding station and evacuate it, and stop vacuuming when the vacuum degree reaches 6×10-1Pa;

[0066] (5) Inject nitrogen into the station: i...

Embodiment 3

[0079] The glass material of the glass material is D~ZK3, the diameter of the glass material is 70mm, and the diameter of the aspheric lens after molding is 80mm:

[0080] (1) Making mold cores and glass materials: making mold cores and glass materials for molding large-diameter aspheric lenses. The inner diameter of the molding cavity of the mold cores is 80 mm, and the diameter of the glass materials is 70 mm;

[0081] (2) Put the glass nitrate material into the mold core: put the glass nitrate material into the mold core, the spherical surface of the glass nitrate material corresponds to the aspherical surface of the mold core;

[0082] (3) Put the mold core into the molding station: put the mold core filled with glass nitrate material into the lower working surface of the molding station;

[0083] (4) Vacuuming the station: seal the molding station and evacuate it, and stop vacuuming when the vacuum degree reaches 6×10-1Pa;

[0084] (5) Inject nitrogen into the station: inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com