A kind of preparation method of large-diameter aspheric lens

An aspheric lens, large-diameter technology, used in glass manufacturing equipment, manufacturing tools, glass pressing, etc., can solve the problems of large diameter and high-precision aspheric lens size and volume, and achieve low internal stress and heat transfer distance. Short, reduce the effect of poor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The glass material of the glass material is K~VC89, the diameter of the glass material is 120mm, and the diameter of the aspheric lens after molding is 150mm:

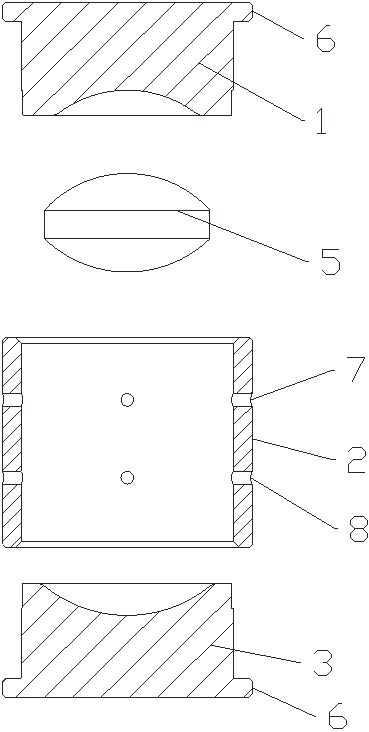

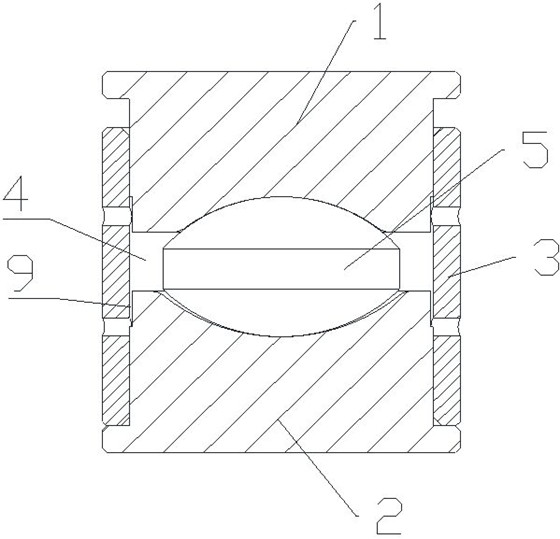

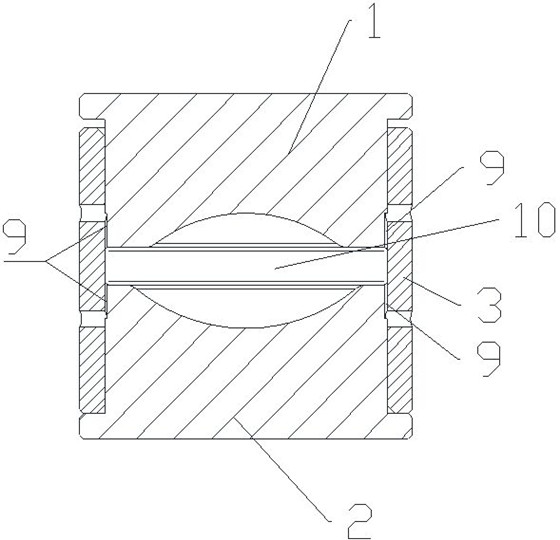

[0044] (1) Making mold cores and glass materials: making mold cores and glass materials for molding large-diameter aspheric lenses. The inner diameter of the molding cavity of the mold core is 150 mm, and the diameter of the glass material is 120 mm;

[0045] (2) Put the glass nitrate material into the mold core: put the glass nitrate material into the mold core, the spherical surface of the glass nitrate material corresponds to the aspheric surface of the mold core;

[0046] (3) Put the mold core into the molding station: put the mold core filled with glass nitrate material into the lower working surface of the molding station;

[0047] (4) Vacuuming the station: seal the molding station and evacuate it, and stop vacuuming when the vacuum degree reaches 5×10-1Pa;

[0048] (5) Inject nitrogen into the station: ...

Embodiment 2

[0061] The glass material of the glass material is K~PBK40, the diameter of the glass material is 40mm, and the diameter of the aspheric lens after molding is 50mm;

[0062] (1) Making mold cores and glass materials: making mold cores and glass materials for molding large-diameter aspheric lenses. The inner diameter of the molding cavity of the mold core is 50 mm, and the diameter of the glass material is 40 mm;

[0063] (2) Put the glass nitrate material into the mold core: put the glass nitrate material into the mold core, the spherical surface of the glass nitrate material corresponds to the aspherical surface of the mold core;

[0064] (3) Put the mold core into the molding station: put the mold core filled with glass nitrate material into the lower working surface of the molding station;

[0065] (4) Vacuuming the station: seal the molding station and evacuate it, and stop vacuuming when the vacuum degree reaches 6×10-1Pa;

[0066] (5) Inject nitrogen into the station: i...

Embodiment 3

[0079] The glass material of the glass material is D~ZK3, the diameter of the glass material is 70mm, and the diameter of the aspheric lens after molding is 80mm:

[0080] (1) Making mold cores and glass materials: making mold cores and glass materials for molding large-diameter aspheric lenses. The inner diameter of the molding cavity of the mold cores is 80 mm, and the diameter of the glass materials is 70 mm;

[0081] (2) Put the glass nitrate material into the mold core: put the glass nitrate material into the mold core, the spherical surface of the glass nitrate material corresponds to the aspheric surface of the mold core;

[0082] (3) Put the mold core into the molding station: put the mold core filled with glass nitrate material into the lower working surface of the molding station;

[0083] (4) Vacuuming the station: seal the molding station and evacuate it, and stop vacuuming when the vacuum degree reaches 6×10-1Pa;

[0084] (5) Inject nitrogen into the station: injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com