Horizontal cutting technology and cutting equipment for aerated concrete block

A technology of aerated concrete and horizontal cutting, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of low yield of aerated concrete blocks and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in further detail below in conjunction with embodiment.

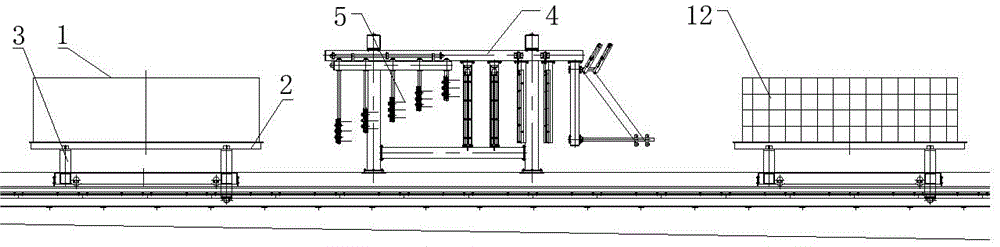

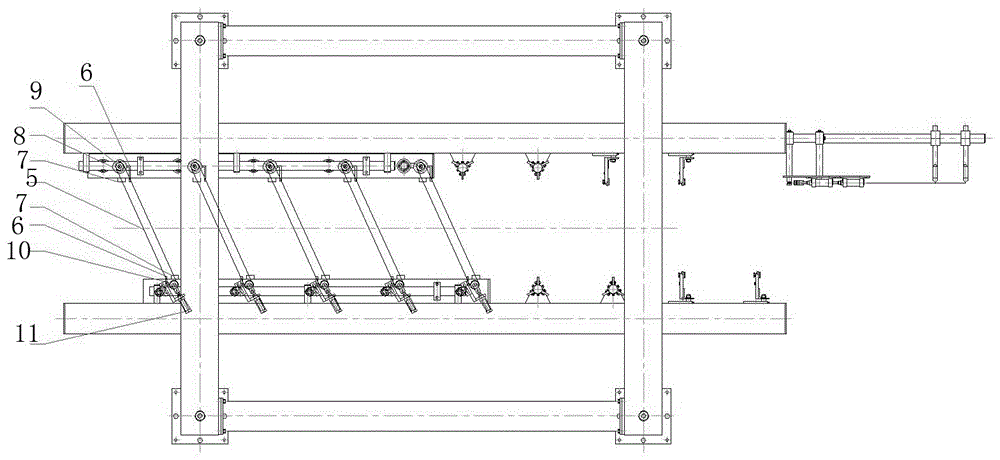

[0022] exist figure 1 A cross-sectional view of an air-entrained concrete cutting device is shown in . Before cutting the aerated concrete block body, the aerated concrete block body 1 is produced through processes such as batching, stirring, pouring, resting and the like. In the preparation process, when the slurry is poured, the concave side plate 2 and the mold box are usually combined to form a box with an upper opening and a lower closed box. Separate from the mold box together, and then put it on the cutting trolley 3 for cutting. After the cutting is completed, the side plate 2 and the aerated concrete block body 1 are placed on the steam curing trolley together, and the three enter the steam curing kettle together Carry out steaming. That is, in the subsequent autoclaving and curing process, due to the hydrothermal synthesis reaction, the hydration product extends and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com