Production technology of composite water permeable brick

A preparation process and technology of permeable bricks, which are applied in the direction of manufacturing tools, forming indenters, ceramic molding machines, etc., can solve the problems that composite permeable bricks cannot be efficiently and automatically prepared, and multiple bricks cannot be formed at one time, so as to avoid pressure. No head pollution, save labor costs, and ensure the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

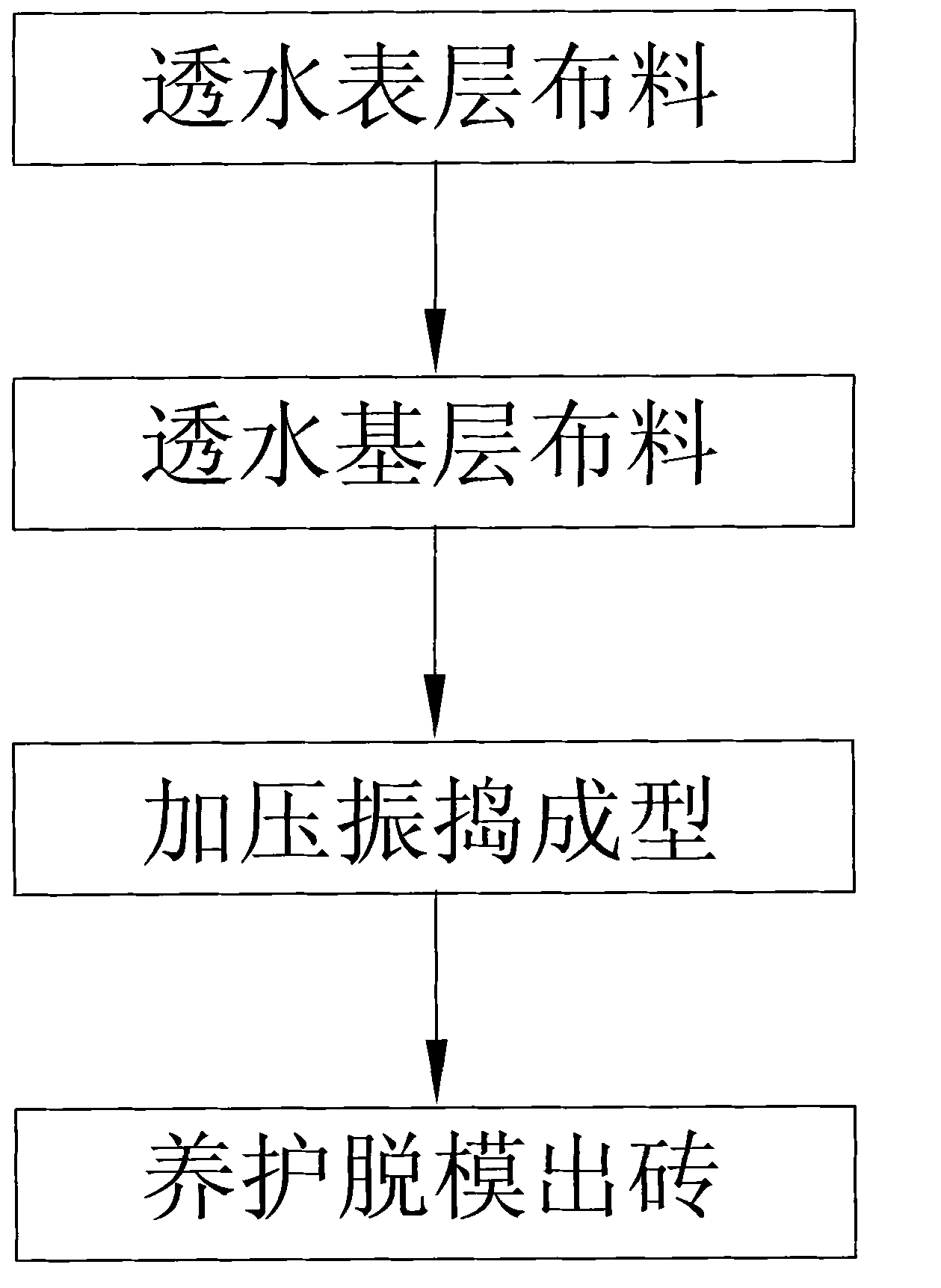

[0042] The composite permeable brick prepared by using the mold of the present invention includes a permeable surface layer and a permeable base layer, and the permeable surface layer and the permeable base layer are closely integrated into one; Aggregate-coated binder; the binder in the water-permeable surface layer at least contains a hydrophilic binder, and the binder in the water-permeable surface layer can be either all hydrophilic binders or partially Hydrophilic binder.

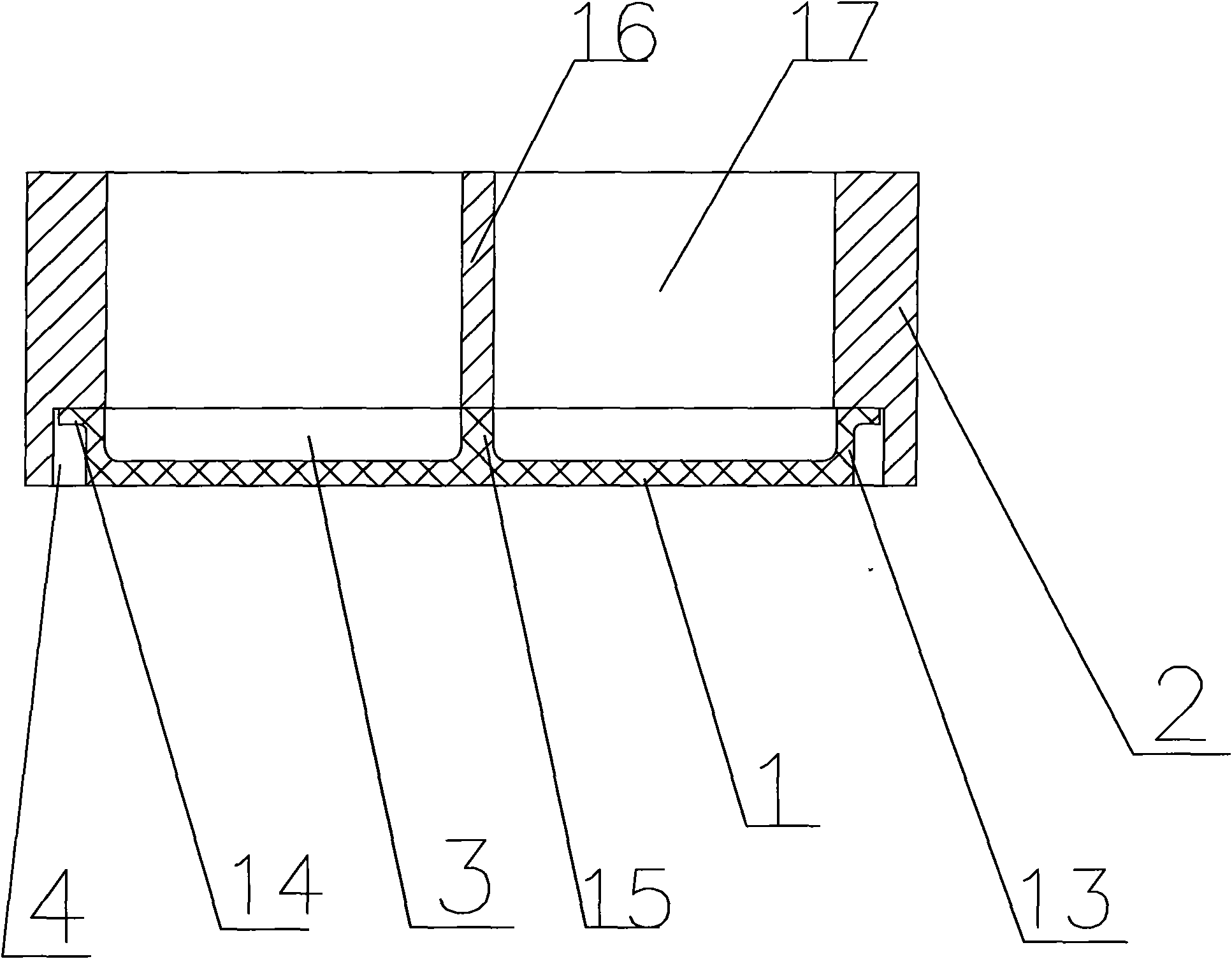

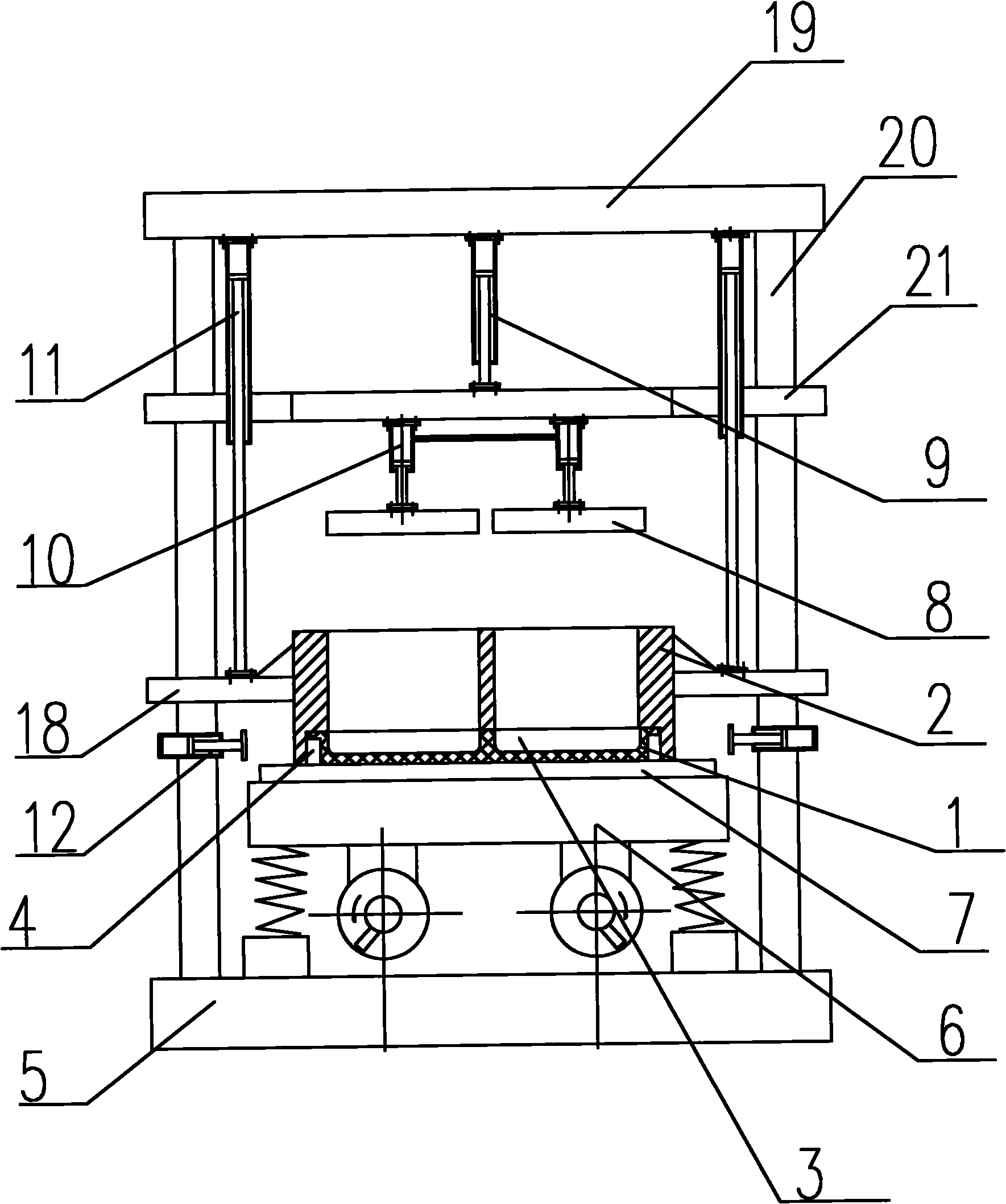

[0043] like figure 1 As shown, the mold used in the present invention includes a bottom mold 1 and an upper mold 2 arranged above the bottom mold 1. The bottom mold 1 and the upper mold 2 are split structures, and the bottom mold 1 and the upper mold 2 both have The mold cavities cooperate with each other to form a mold cavity; the height of the bottom mold cavity 3 is smaller than the height of the upper mold cavity 17 . The bottom mold cavity 3 has the same cross section as the upper mold cavity 17...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com