Automatic weighing and packaging system of strip-shaped materials

An automatic weighing and packaging system technology, which is applied in the system field of strip materials, feeding, weighing, bag making, filling and packaging, and can solve problems such as adhesion, uneven material layer thickness, and inaccurate material weighing and measurement. , to achieve the effect of uniform thickness and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

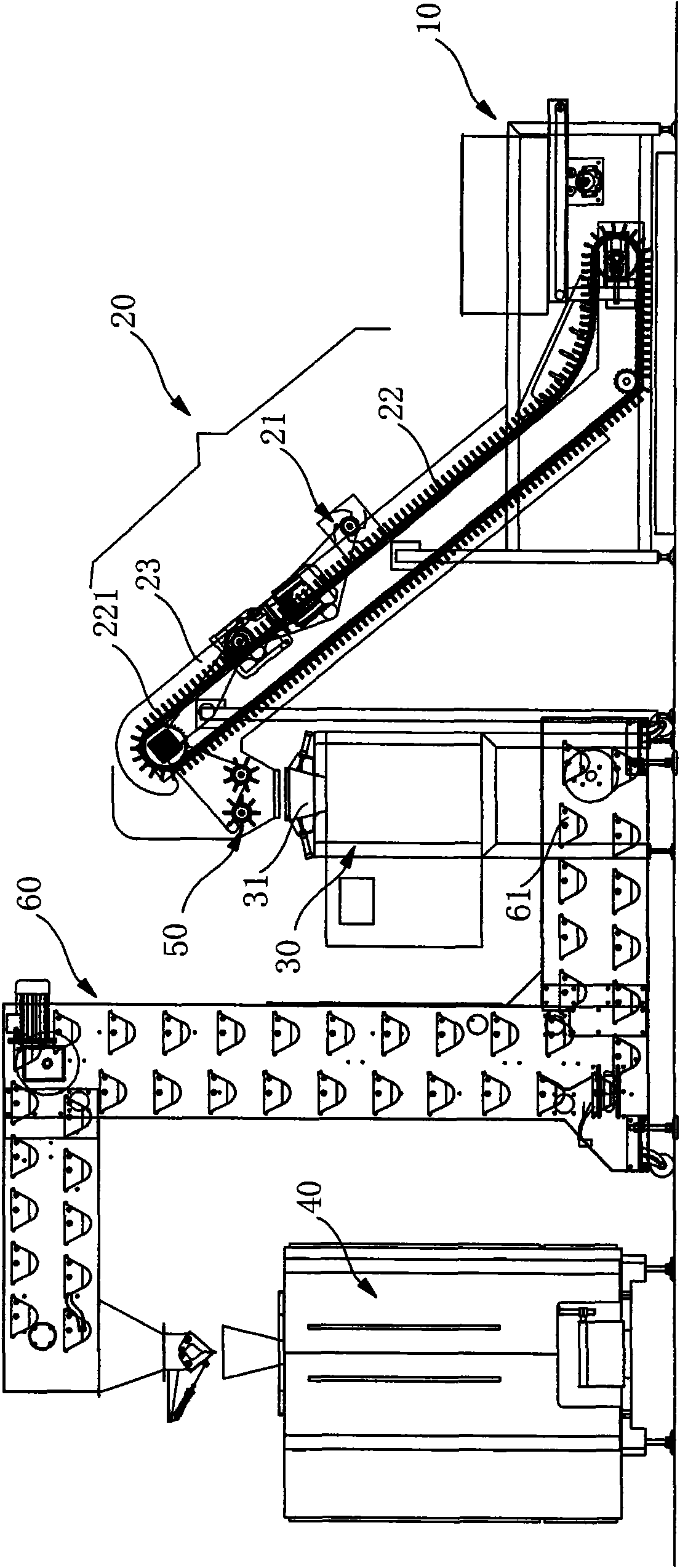

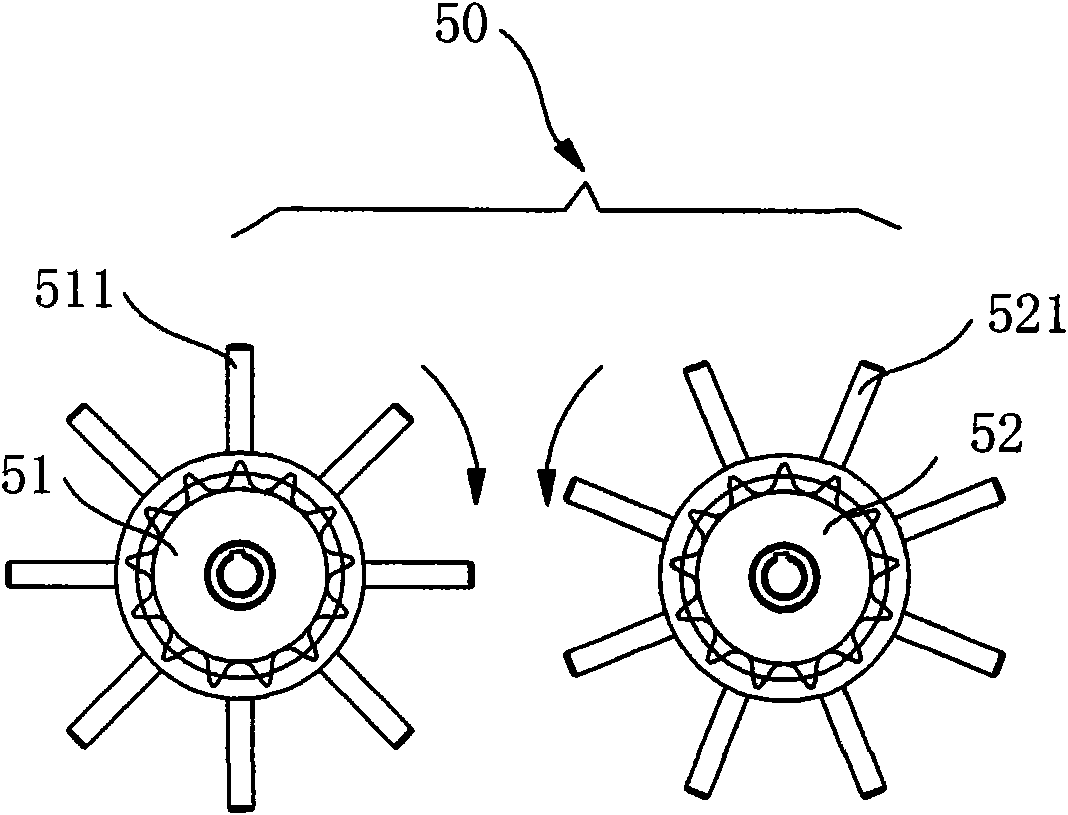

[0013] Such as figure 1 A material automatic weighing and packaging system is shown. The material is sent to the lifting device 20 through the feeding device 10, then weighed by the weighing device 30, and then quantitatively transported to the packaging device 40 through the conveying device 60. The lifting device 20 is equipped with There is a carding mechanism 21 .

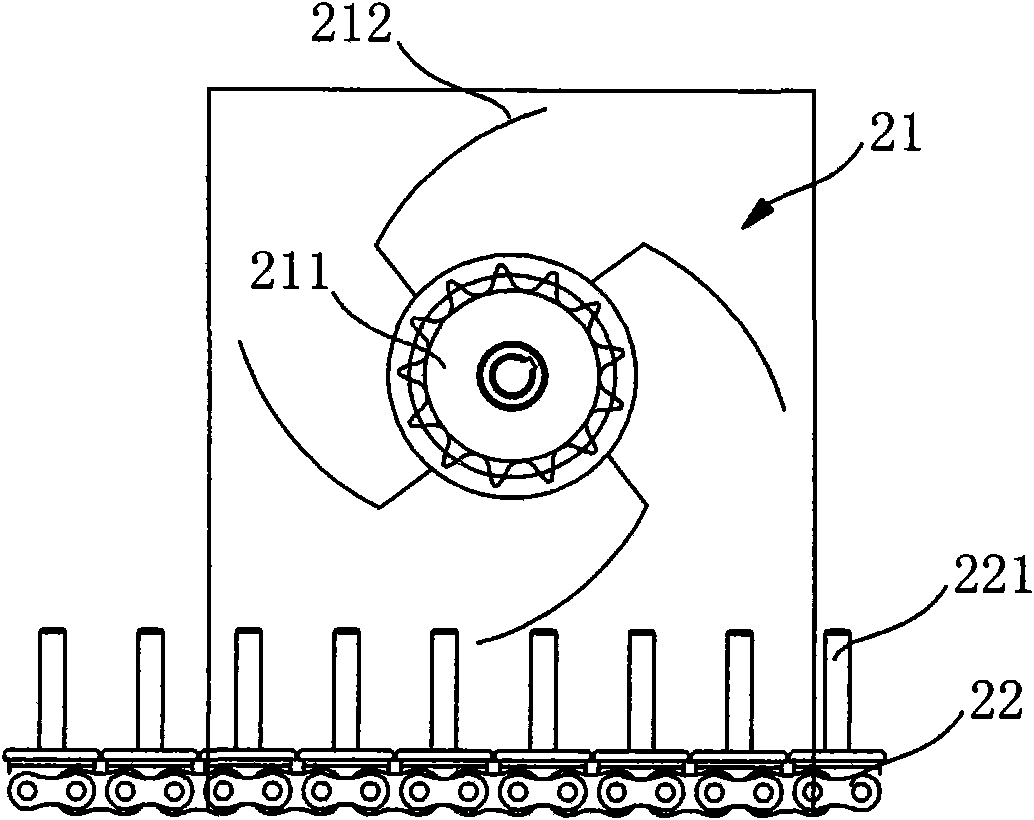

[0014] Such as figure 1 , figure 2 As shown, the lifting device 20 is a chain plate type hoist, and its chain plate belt 22 is evenly provided with rods 221 perpendicular to the surface of the chain plate belt 22. The distance, height and diameter of the rods 221 are the same, and the chain plate belt 22 The two sides of the baffle plate 23 are provided with, and the baffle plate 23 is arranged along the extending direction of the chain plate belt 22; The plate 23 is fixed with it, and the wheel surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com