Loading test device

A loading test device and loading device technology, which are applied to measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of side loading device stuck and tilted, high manufacturing cost, and high precision requirements, and achieve the loading process. Smooth, high safety and reliability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the embodiments disclosed here are only preferred solutions of the present invention, and the present invention can also be implemented in various other forms besides the disclosed ones.

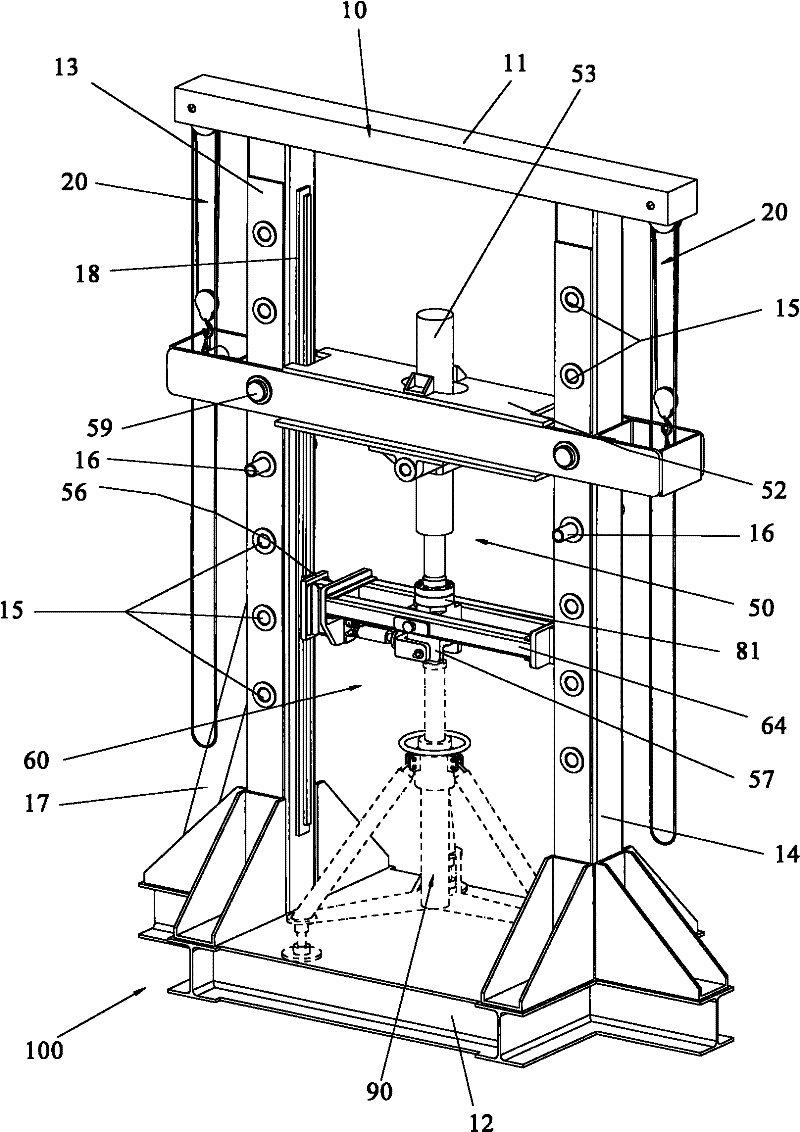

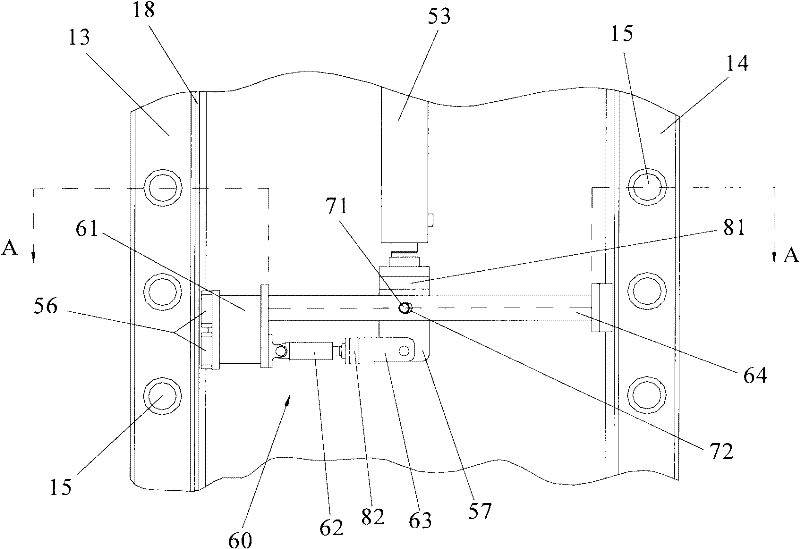

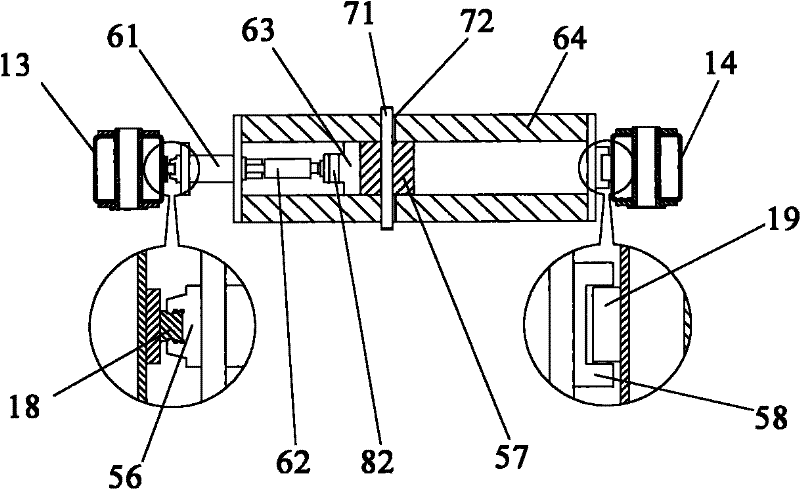

[0029] Such as figure 1 As shown, the loading test device 100 in the preferred embodiment of the present invention mainly includes a support frame 10, a forward loading device 50 and a side loading device 60, and figure 1 The parts shown in dotted line in , that is, the components marked with reference number 90 are the devices under test and are not part of the present invention. It should be noted that although the device to be tested 90 is an aircraft jack in this embodiment, it can be easily changed to other devices depending on the device to be tested.

[0030] The supporting frame 10 mainly includes a top frame 11 , a base 12 and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com