Micro-component transfer device, transfer method, manufacturing method, device, and electronic device

A transfer device and transfer method technology, applied in semiconductor/solid-state device manufacturing, measuring devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

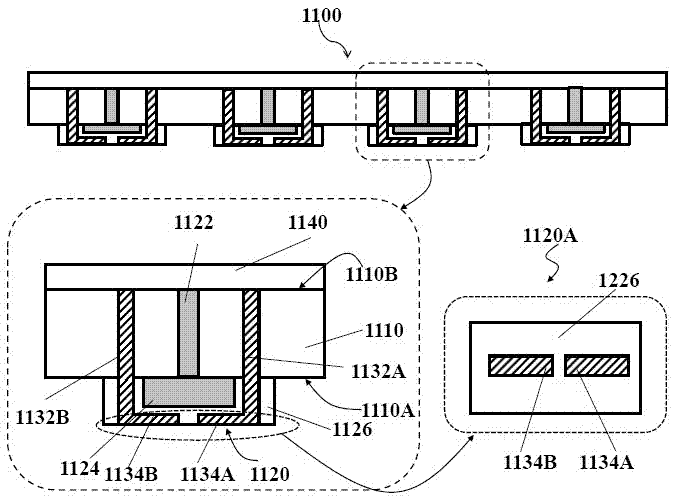

[0086] figure 1 A cross-sectional side view of a transfer device according to a first preferred embodiment of the present invention is shown. The transfer device 1100 includes: a base substrate 1110 , an array of pick-up heads 1120 , a testing circuit and a CMOS integrated circuit 1140 . Specifically, the base substrate 1110 is used to provide a supporting function, and may be formed of various materials, such as silicon, ceramics, and polymers. The pick-up heads 1120 are arranged in an array on the first surface 1110A of the base substrate 1110, with a size ranging from 1 μm to 100 μm, for example, 50 μm to 20 μm, and a pitch of (1 μm to 100 μm)×(1 μm to 100 μm), for example 10μm x 10μm or 50μm x 100μm pitch. The array of pick-up heads 1120 is disposed on the first surface 1110A of the base substrate 1100 for picking up micro-components by various adsorption forces (such as electrostatic force, vacuum pressure, van der Waals force, magnetic force, etc.) to achieve the funct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com