Process for testing capacitance type touch screen

A capacitive touch screen and touch screen testing technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of low test efficiency, not directly giving good and bad products judgment, not suitable for mass production, etc., to achieve test efficiency. High, improve the effect of test accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

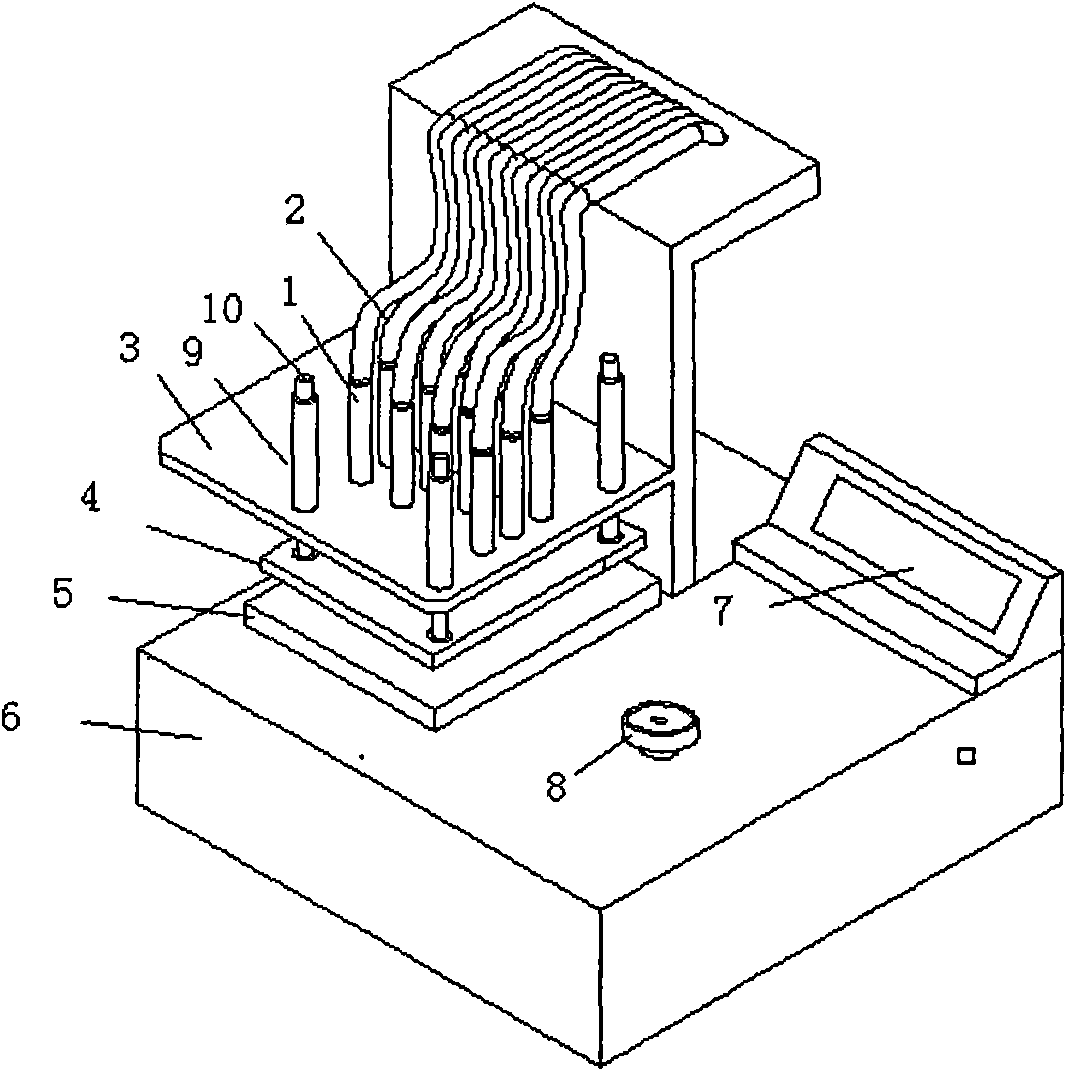

[0018] Such as Figure 1 to Figure 3 As shown, the touch screen tester includes a test chip circuit controlled by a single-chip microcomputer, an instrument casing 6, a pneumatic touch head 1, an air pipe 2, a touch head frame 3, a touch head movable fixture 4, and a touch screen test interface board 5;

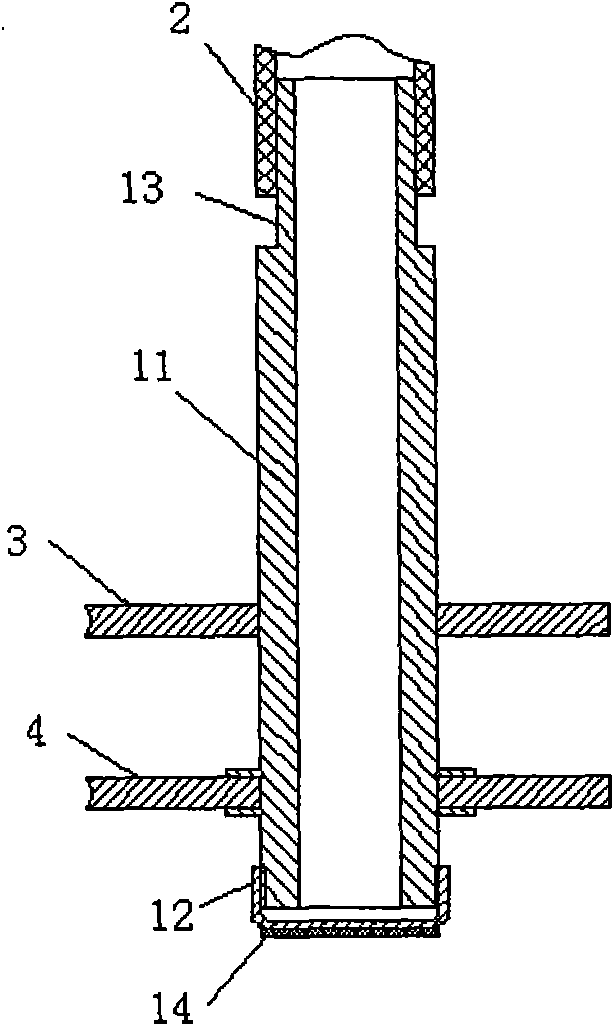

[0019] The pneumatic touch head 1 is composed of a metal tube 11 and a thin metal disc cap 12. The thread at the lower end of the metal tube 11 is screwed into the thin metal disc cap 12. A layer of conductive rubber 14 is pasted on the surface of the thin metal disc cap 12. The end of the metal tube 11 is The upper part processes the trachea interface 13, and the trachea 2 is plugged on the trachea interface 13, and the diameter of the trachea interface 13 is closely matched with the trachea 2 inner diameter.

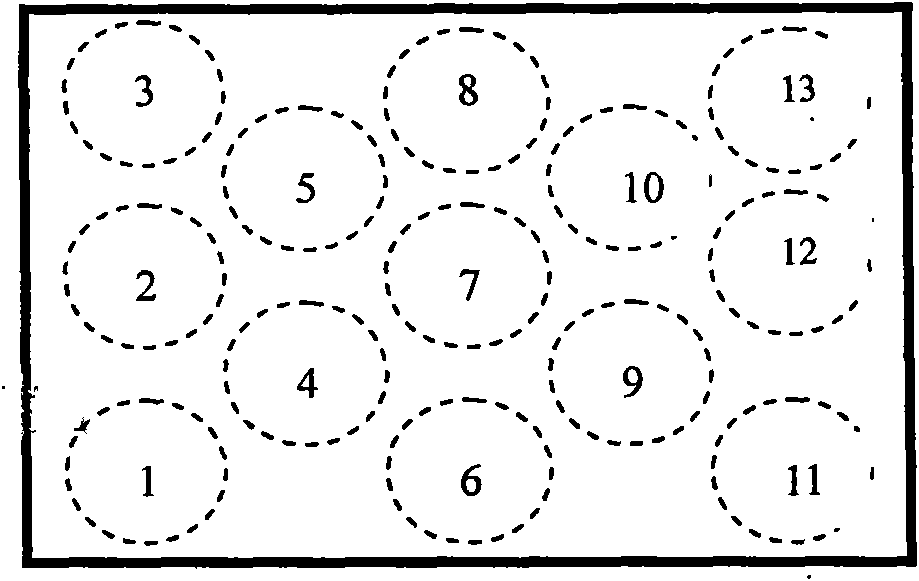

[0020] The instrument case 6 is the support body of the touch head frame 3, and the lower end parts of the metal tubes 11 of 12 pneumatic touch heads pass through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com