Electric control device of cartridge branch dry damping device

A dry friction damper and electronic control device technology, applied in non-rotation vibration suppression and other directions, can solve problems such as optimal control of friction surface and overheating, and achieve the effects of simple structure, simple control method and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

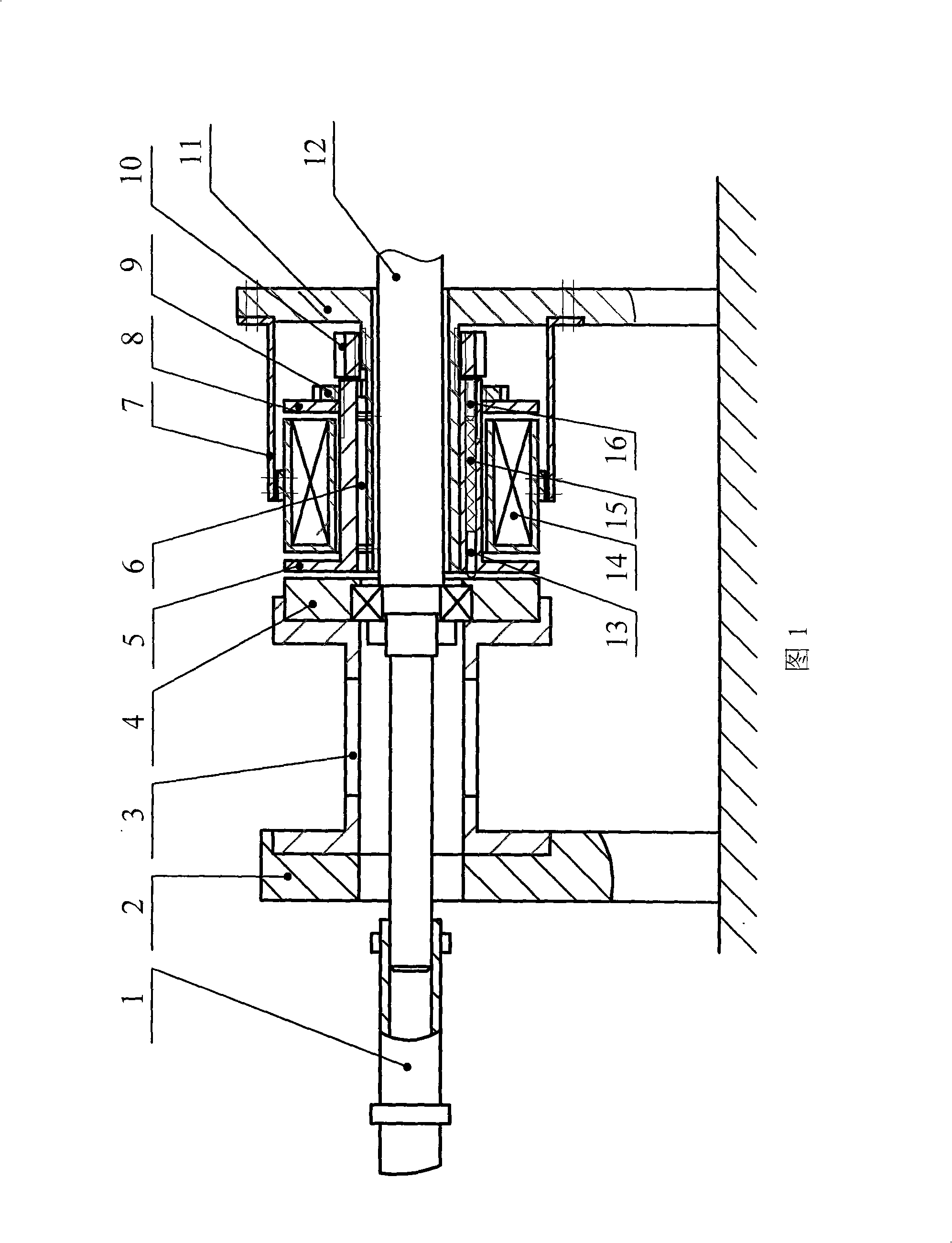

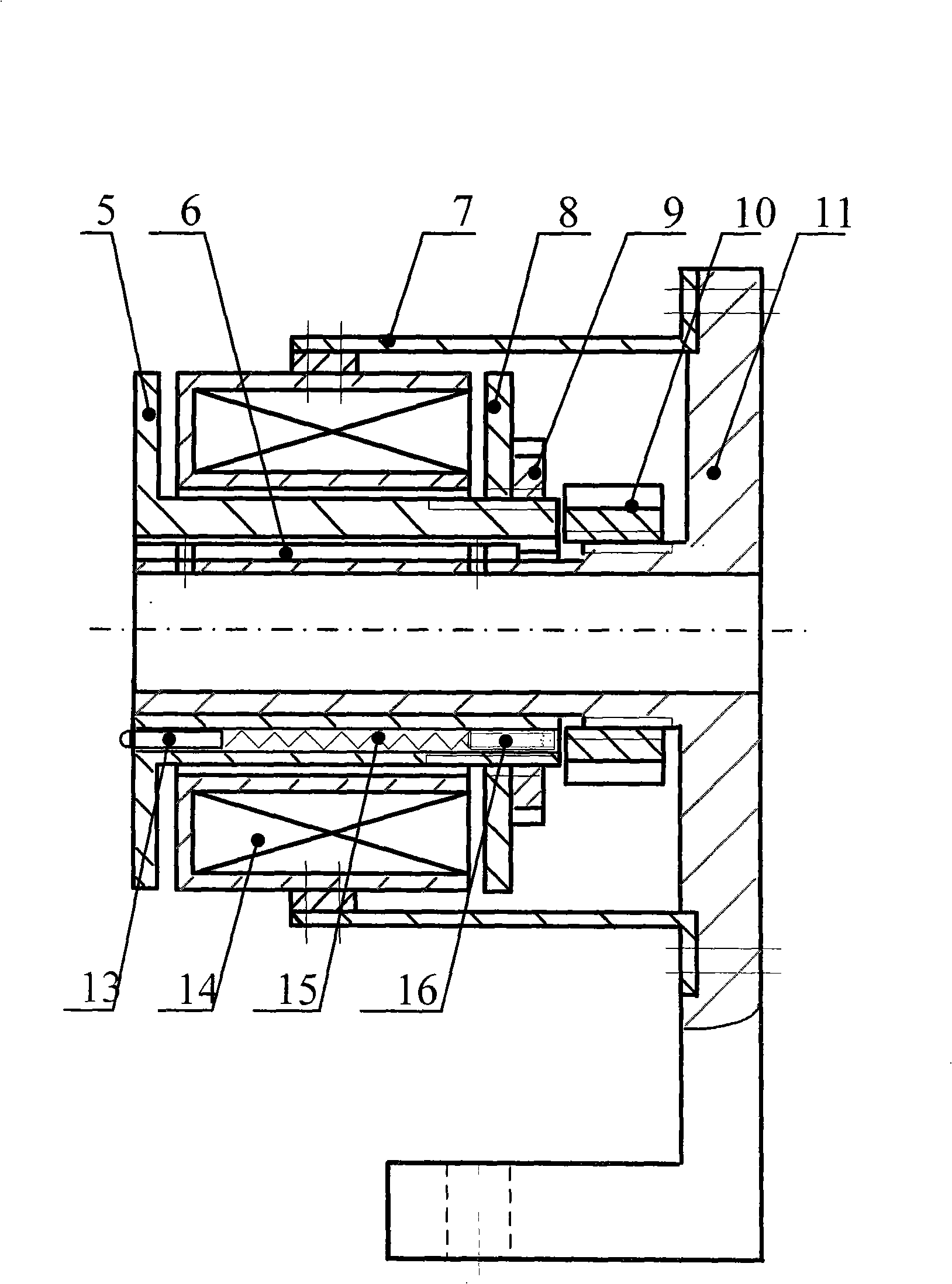

[0032] The structure of the present invention is as figure 2 shown. It consists of static friction plate 5, guide key 6, electromagnet bracket 7, armature 8, armature lock nut 9, static friction plate positioning nut 10, support 11, static friction plate reset guide rod 13, electromagnet 14, reset Spring 15, reset force adjusting bolt 16. in:

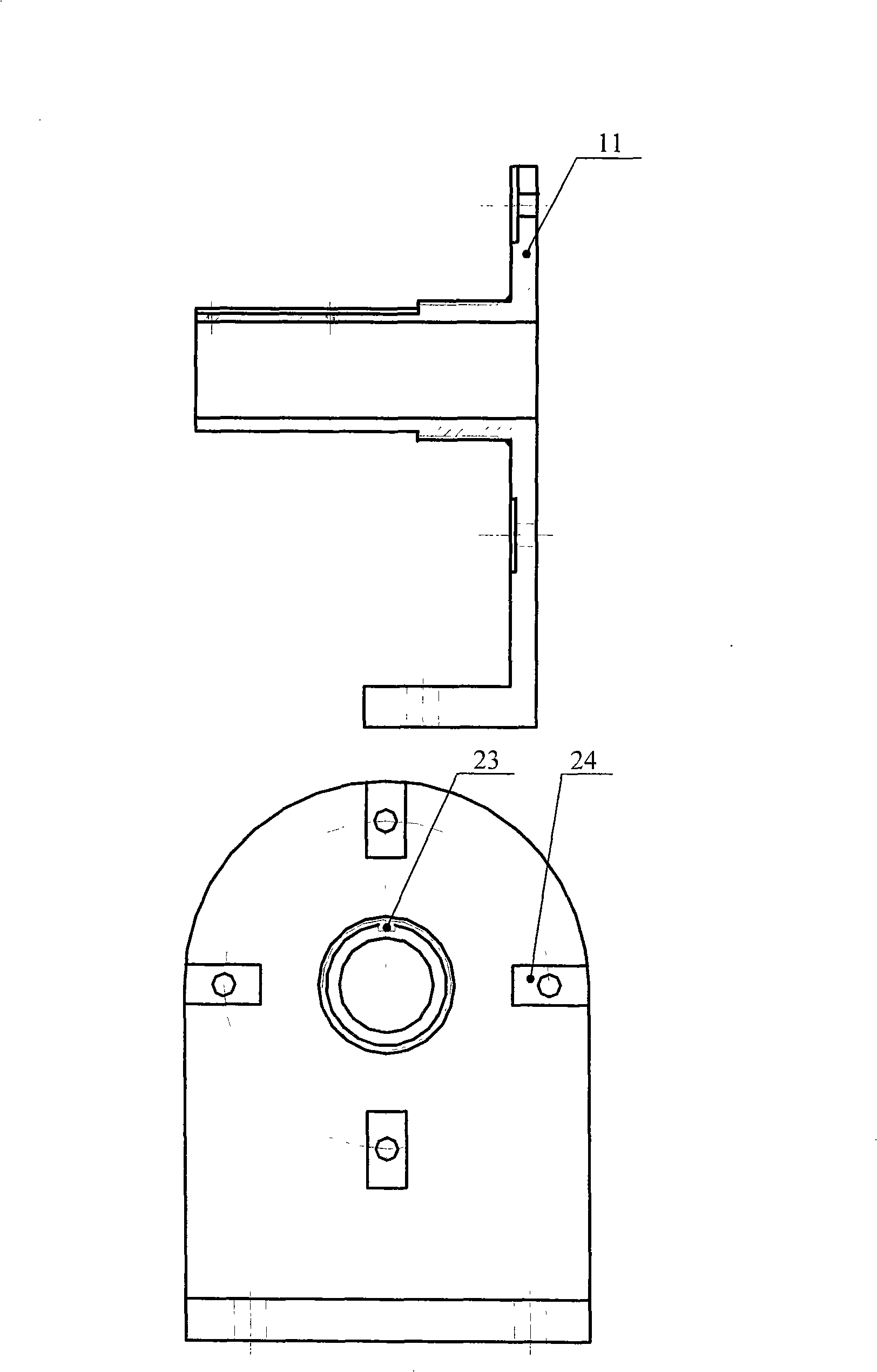

[0033] The support 11 is a circular hollow sleeve with an end cover at one end, the center line of the end cover is a semicircle, and the center line is a rectangle with the same width as the semicircle diameter, and the lower part of the end cover rectangle has an anchor plate, and the anchor plate is passed through the bolt Connected to the foundation; four mounting grooves 24 are evenly distributed on the inner surface of the end cover of the ring support 11, and its shape and size are matched with the support plate of the electromagnet bracket 7; the inner diameter of the sleeve of the support 11 is larger than the shaft The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com