Elastic support dry-friction damper with intelligent structure

A dry friction damper, intelligent structure technology, applied in spring/shock absorber, vibration suppression adjustment, non-rotation vibration suppression, etc., can solve the problems of unsuitable feedback signal, complex structure, large volume, etc. The effect of stable vibration and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

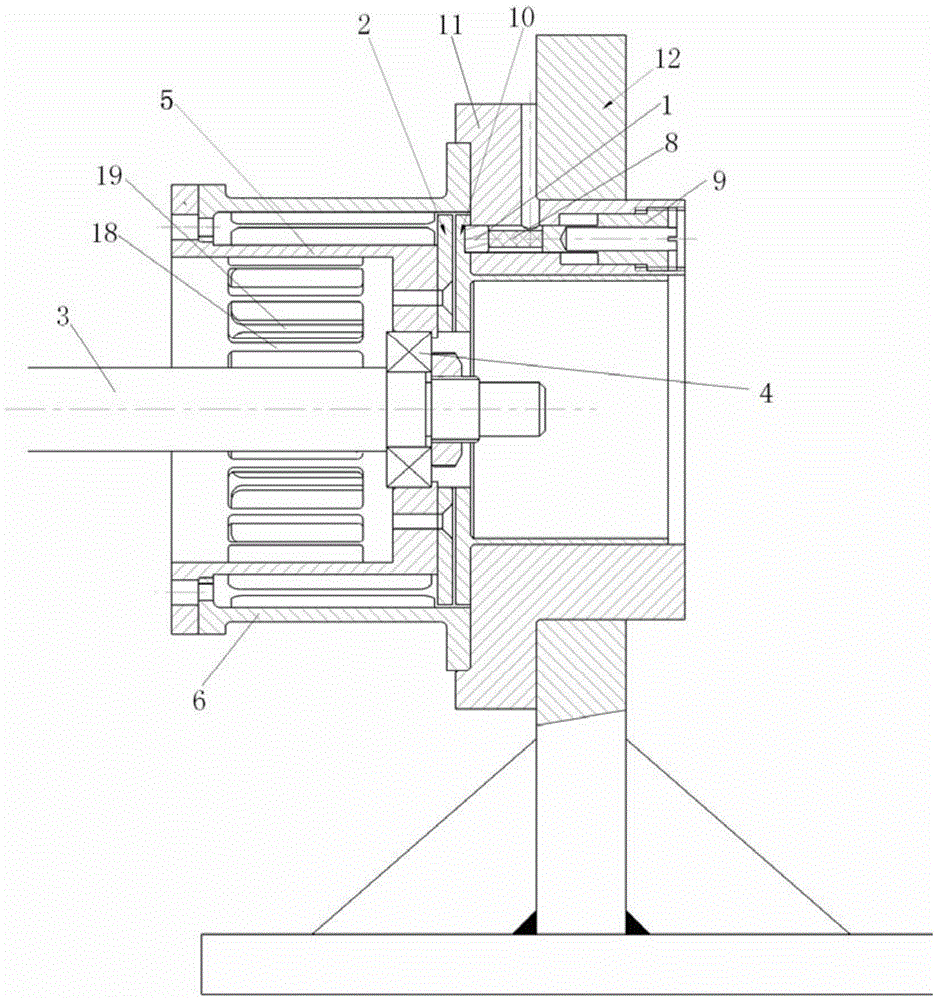

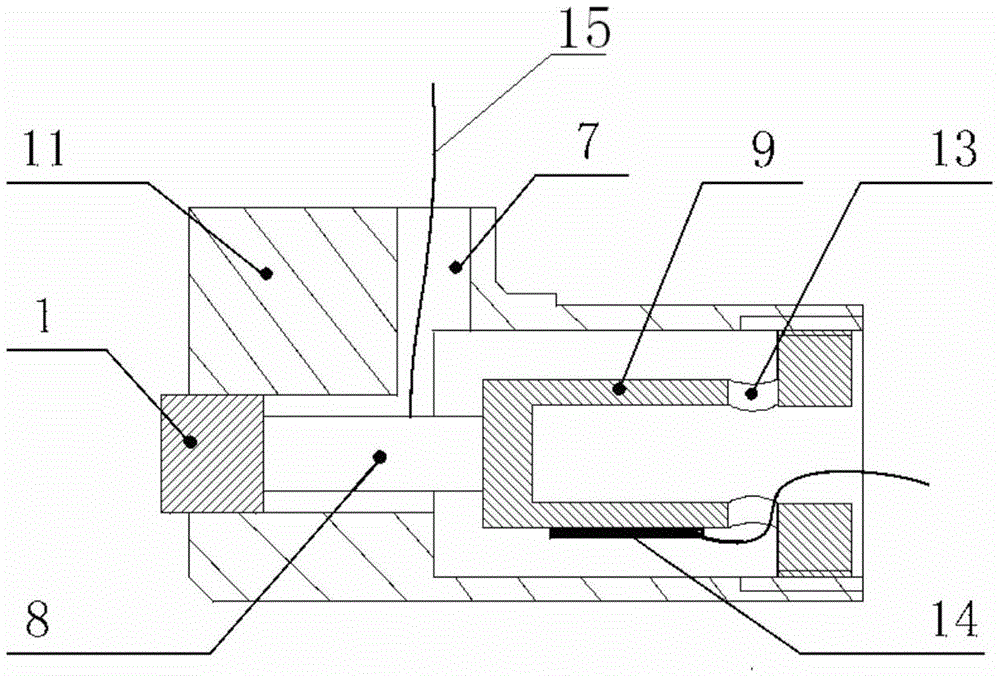

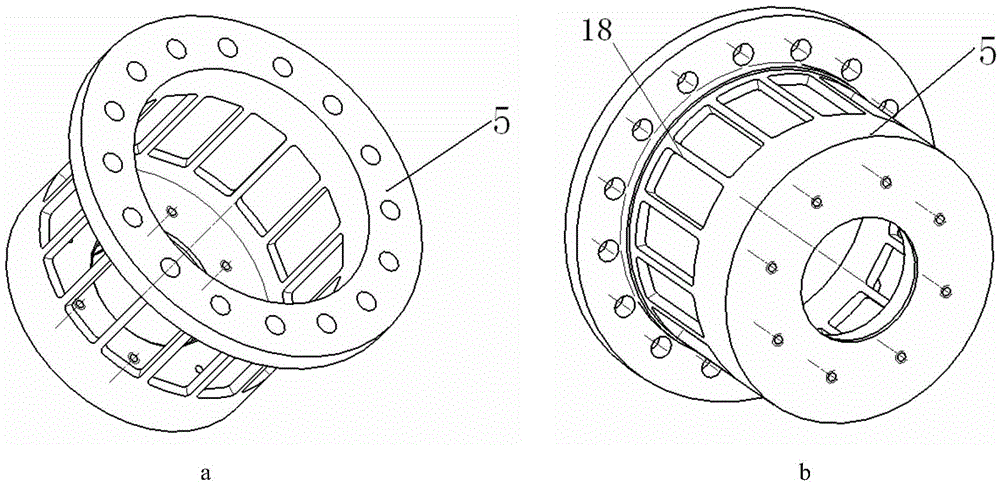

[0028] This embodiment is an intelligent structure spring-supported dry friction damper, which includes a fold-back elastic support, a support base 11, a piezoelectric ceramic 8, a dynamic friction plate 2, a static friction plate 10, and an adjusting bolt 9. The fold-back elastic support includes an inner squirrel cage elastic support 5 and an outer squirrel cage elastic support 6. among them:

[0029] The inner squirrel cage elastic support 5 is mounted on the rotating shaft 3 through a rolling bearing 4. The static friction plate 10 is sleeved on the outer circumference of one end of the rotating shaft 3. The dynamic friction plate 2 is sleeved on the rotating shaft 3 and is located between the end surface of the large diameter end of the static friction plate and the end surface of the inner squirrel cage elastic support 5. The outer squirrel cage elastic support 6 is sleeved on the outer circumference of the inner squirrel cage elastic support 5, and the support seat 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com