Vibration testing device of damping mistuning blade-turbine disk with damping block structure

A technology of vibration testing and damping blocks, which is applied in the field of experimental devices, can solve the problems of insufficient research on mechanism and little understanding of performance, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

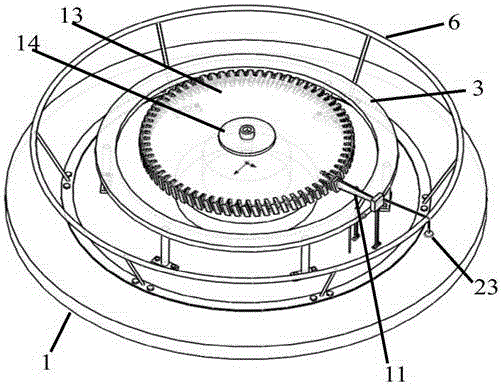

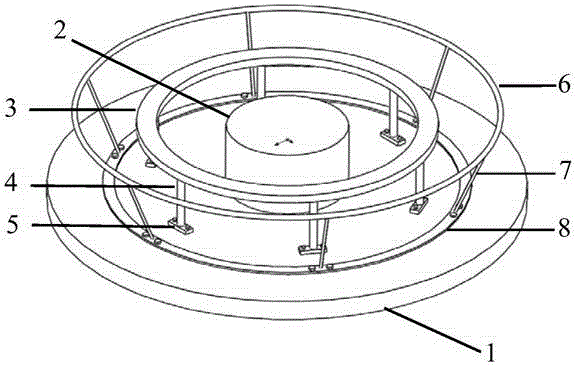

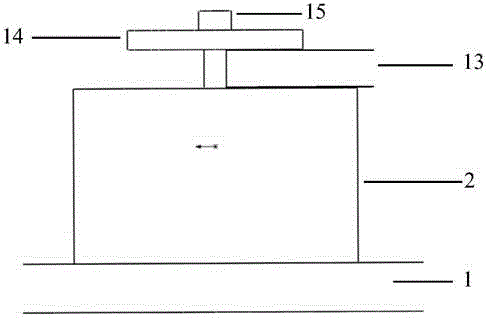

[0030] The present invention will be further explained below in conjunction with the drawings.

[0031] See figure 1 , The present invention is a damping detuned blade-wheel vibration testing device with a damping block structure, which includes a base stand, a wheel disk fixing device, a blade root fixing device, a centrifugal force loading device, an exciting vibration generating device and a measuring device.

[0032] See figure 2 , First introduce the turbine blades in the experiment. The turbine blade is composed of a shroud 9, a damping block 10, a blade body 11 and a blade root 12. In the working state, due to the centrifugal force, on the one hand, the blade root 12 and the wheel disc 13 are in close contact with and pressed against the tooth surface of the corresponding wheel groove; on the other hand, the blade body 11 is twisted and restored, so that the adjacent blade shroud 9 Touch and press tightly. Under the action of the airflow excitation force, relative slippag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com