Heatproof anti-wear self-lubrication material and preparation method thereof

A self-lubricating material, heat-resistant technology, applied in the field of powder metallurgy, can solve the problems of long process route, self-lubricant burning loss is not well solved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

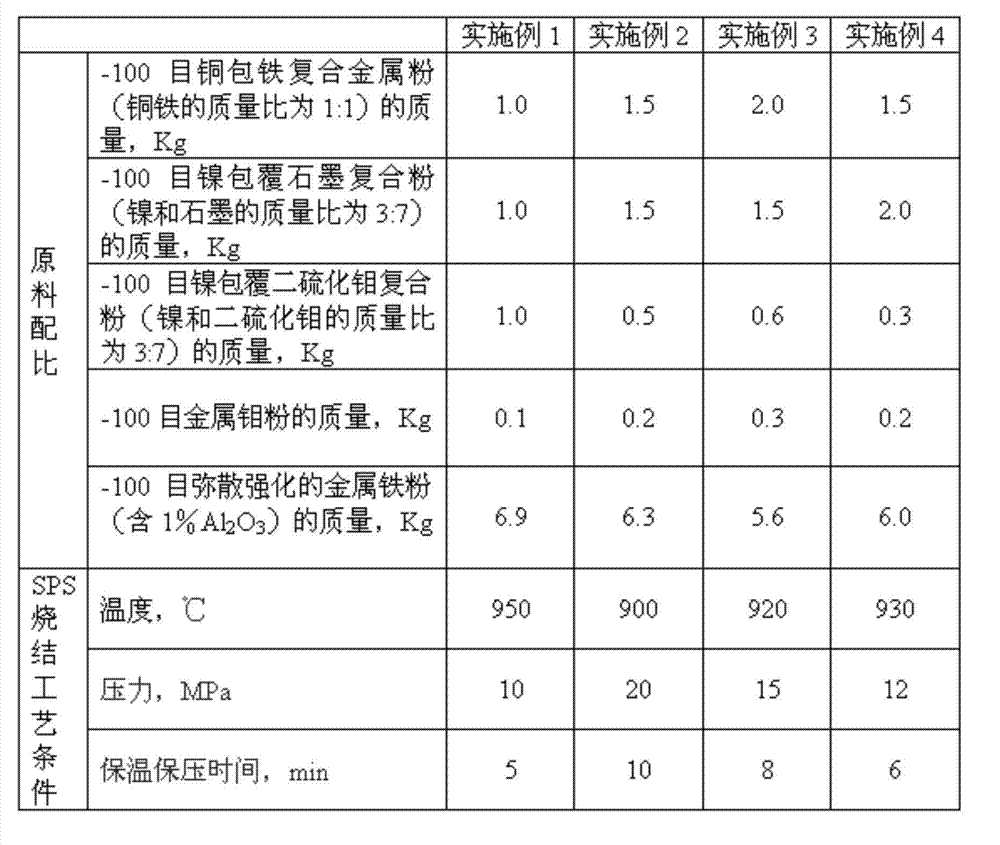

[0016] First weigh 1Kg of copper-clad iron composite metal powder (mass ratio of copper to iron is 1:1), 1Kg of nickel-coated graphite composite powder (mass ratio of nickel to graphite is 3:7), 1Kg of nickel-coated molybdenum disulfide composite powder (The mass ratio of nickel and molybdenum disulfide is 3:7) 1Kg, metal molybdenum powder 0.1Kg, dispersion strengthened metal iron powder 7Kg (containing 1% Al 2 o 3 ), the particle size of the above powders is -100 mesh, and then they are added to the V-shaped mixer for thorough mixing, the mixed powder is put into the mold, and finally the mold filled with the powder is put into the spark plasma sintering equipment (SPS ), using the following process conditions for sintering: temperature 950°C, pressure 10MPa, heat preservation and pressure holding time 5 minutes. After the sintering was completed, it was released when it was cooled below 200°C. The physical and mechanical properties of the prepared self-lubricating material ...

Embodiment 2~4

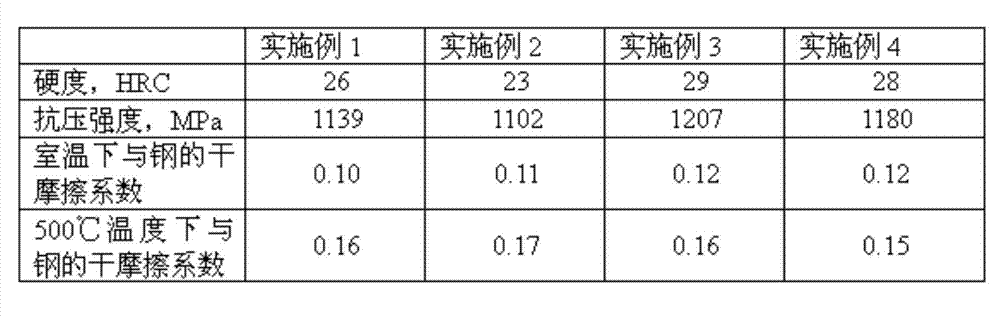

[0018] The process is the same as in Example 1, except that the ratio of raw materials and the SPS sintering process conditions are changed, and the specific parameters are shown in Table 2. The physical and mechanical performance test results of the self-lubricating materials prepared accordingly are shown in Table 1.

[0019] Table 1 Physical and Mechanical Properties of Examples 1-4 Samples

[0020]

[0021] Table 2 Raw material ratio and SPS sintering process conditions of Examples 1-4

[0022]

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com