Method for in-situ synthesis of composite TiC-DLC coating on surface of titanium

A composite coating and in-situ synthesis technology, which is applied in metal material coating process, coating, vacuum evaporation plating, etc., can solve the problems of various types of reaction gases, unfavorable large-scale application, complicated experimental process, etc., and achieve good results. The effect of application prospect, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

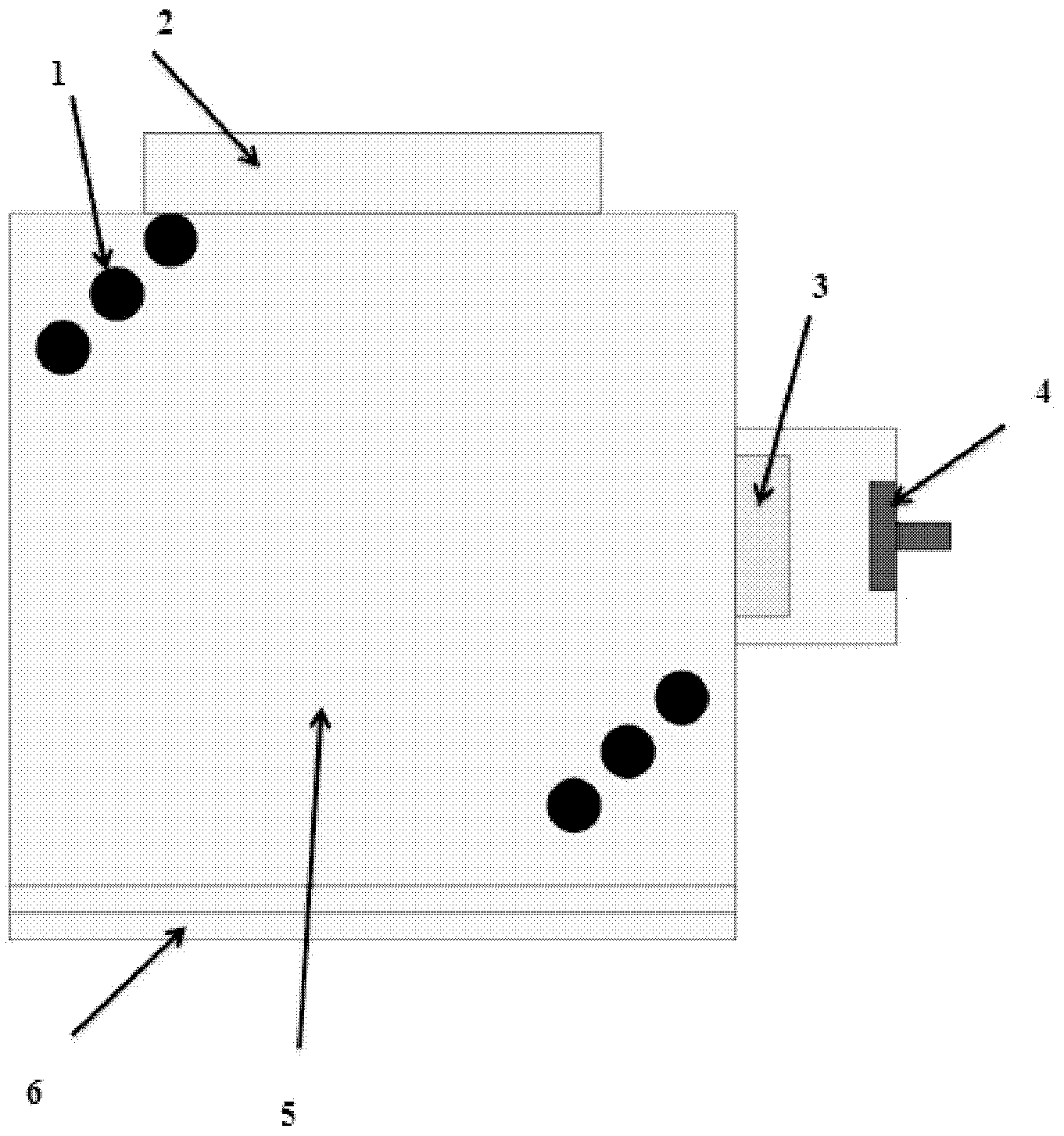

Method used

Image

Examples

Embodiment 1

[0039] Acetylene gas is introduced into the coating chamber, and the high ionization rate of arc ion plating is used to evaporate Ti ions from the Ti target. At the same time, the strong plasma generated by arc discharge is used to ionize the acetylene passed into the vacuum chamber and dissociate the acetylene into C ions. And H ion. The C ions and Ti ions react on the surface of the Ti target to generate TiC; due to the strong affinity between Ti and C, finally the DLC phase will be formed between the TiC phases, thereby obtaining a titanium carbide-doped diamond-like film.

[0040] In this embodiment, the number of Ti target is one, it is disc-shaped, the bottom diameter is 100mm, and the thickness is 7.5mm; the flow rate of acetylene gas is 50sccm, 100sccm, 200sccm, 300sccm, 400sccm and 500sccm. The cathode discharge conditions of the Ti target are 1~3Pa, current is 50 amperes; synthesis time is 20 minutes, synthesis temperature is 150~300℃.

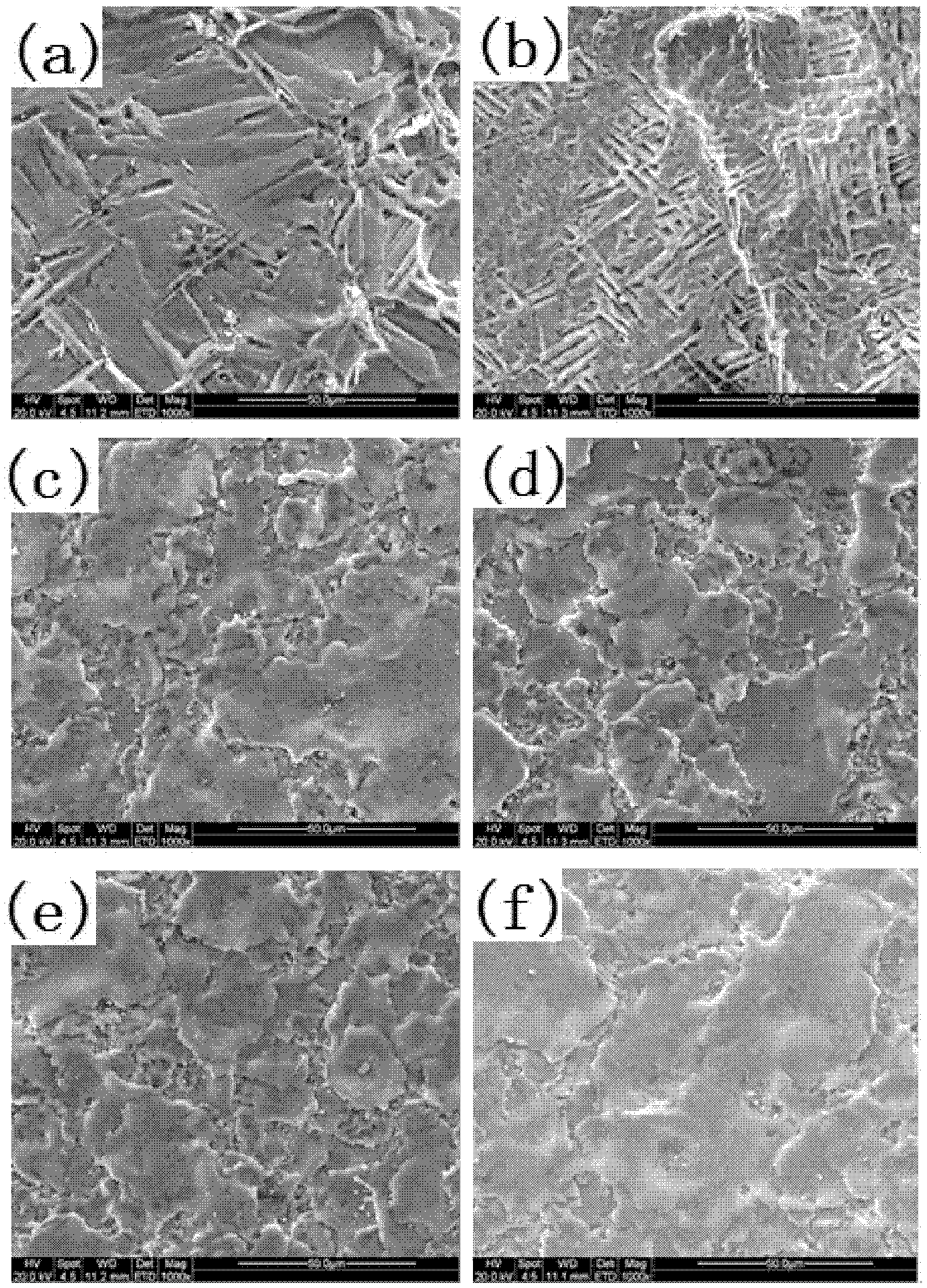

[0041] The surface SEM image and ...

Embodiment 2

[0048] Acetylene gas is introduced into the coating chamber, and the high ionization rate of arc ion plating is used to evaporate Ti ions from the Ti target. At the same time, the strong plasma generated by arc discharge is used to ionize the acetylene passed into the vacuum chamber and dissociate the acetylene into C ions. And H ion. The C ions and Ti ions react on the surface of the Ti target to generate TiC; due to the strong affinity between Ti and C, finally the DLC phase will be formed between the TiC phases, thereby obtaining a titanium carbide-doped diamond-like film.

[0049] In this embodiment, the number of Ti target is one, it is disc-shaped, the bottom diameter is 100mm, the thickness is 7.5mm; the flow rate of acetylene gas is 400sccm; the cathode discharge condition of Ti target is 1~3Pa, the current is 50A; synthesis time Respectively 20, 30, 40, 50 and 60 minutes, the synthesis temperature is 150-300℃.

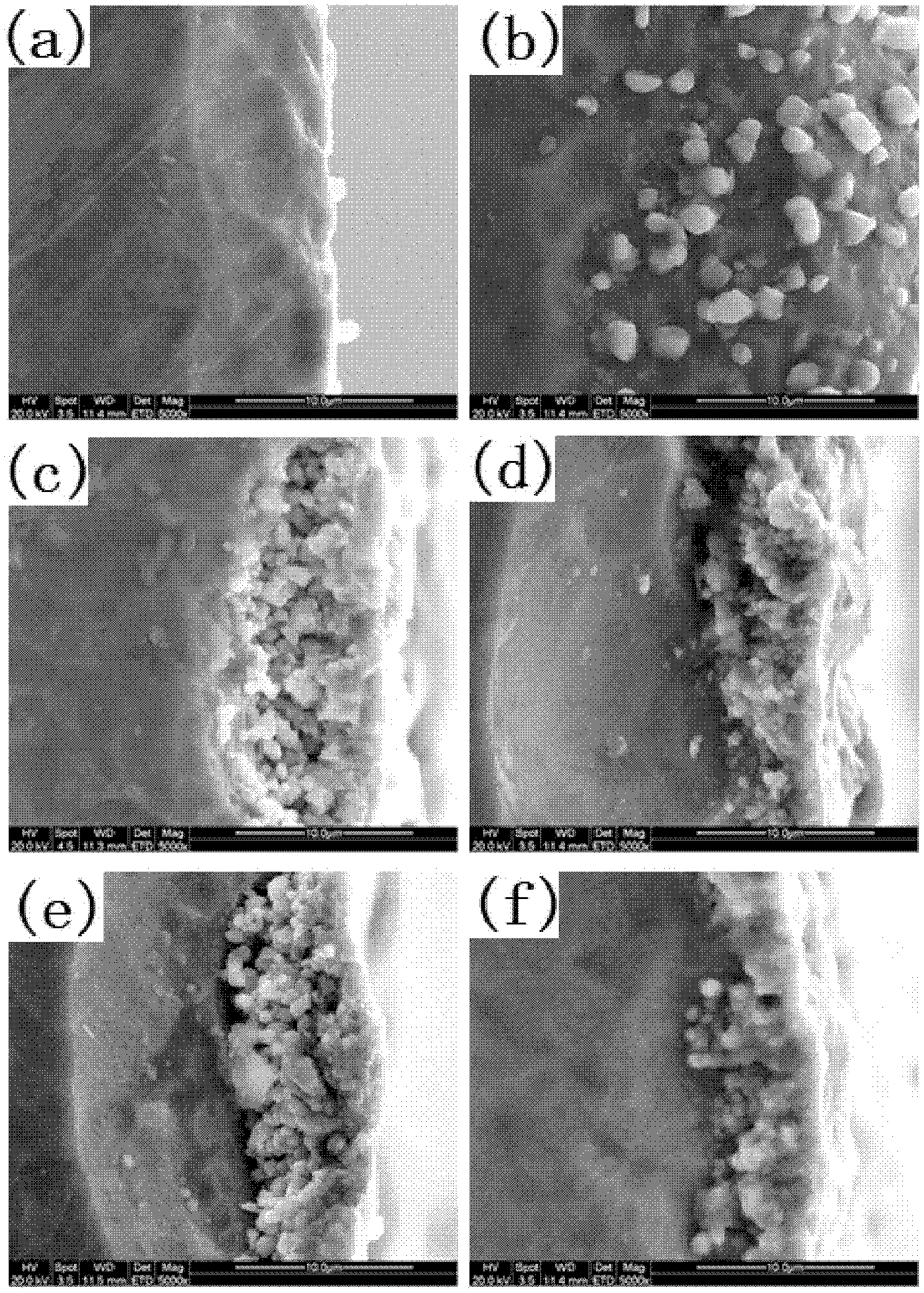

[0050] The surface SEM image of the TiC-DLC composite coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com