Downhole oilfield apparatus comprising a diamond-like carbon coating and methods of use

a technology of diamond-like carbon coating and oilfield apparatus, which is applied in the direction of fluid removal, earth drilling and mining, borehole/well accessories, etc., can solve the problem that the prior art of oilfield has been restricted to dlc us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

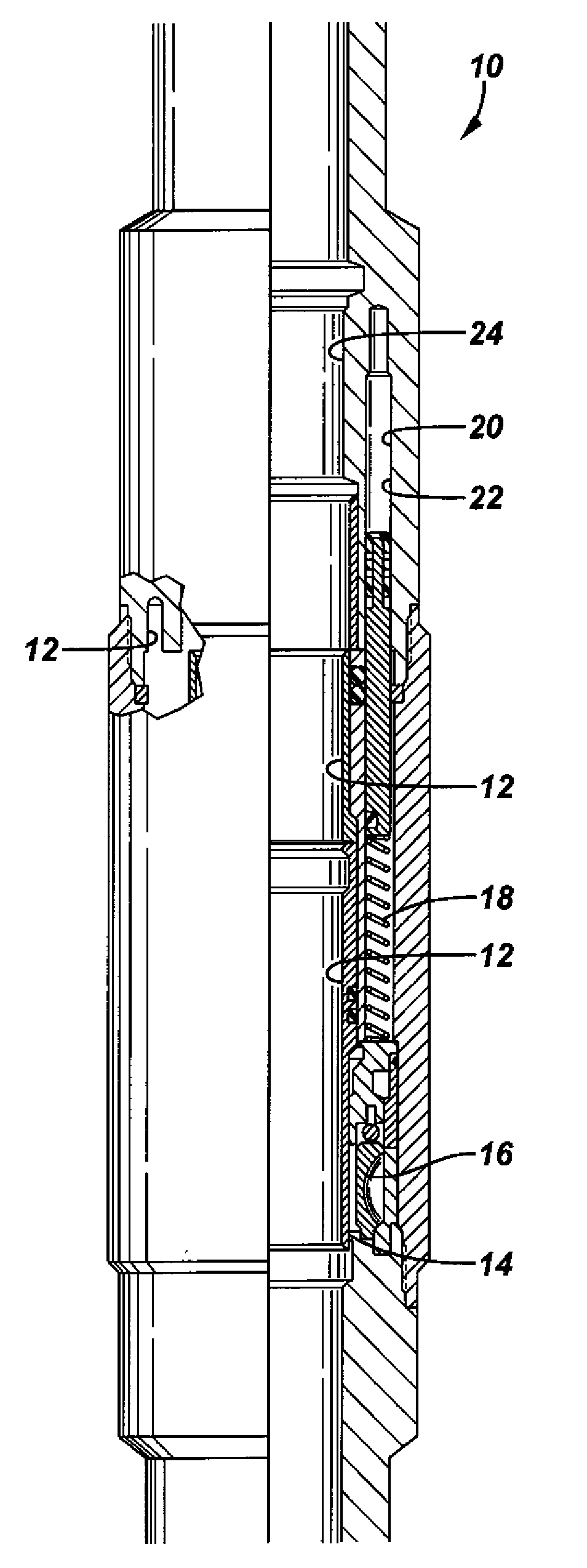

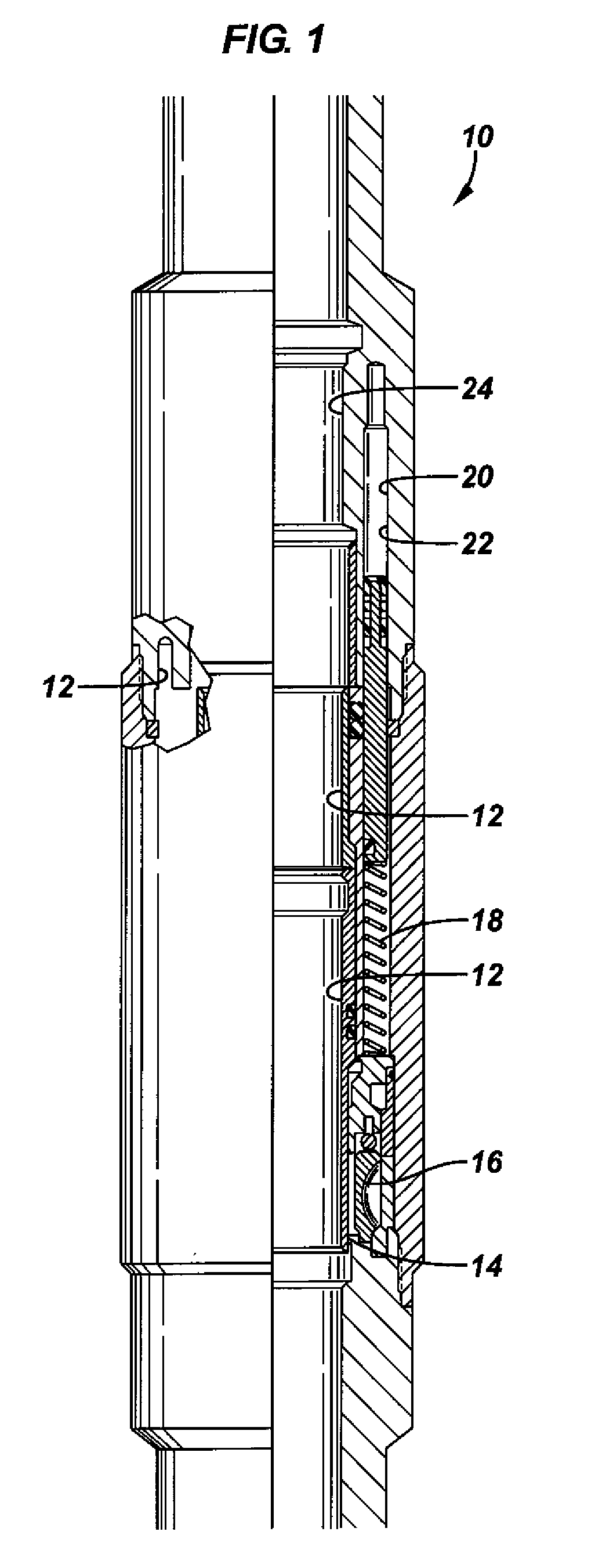

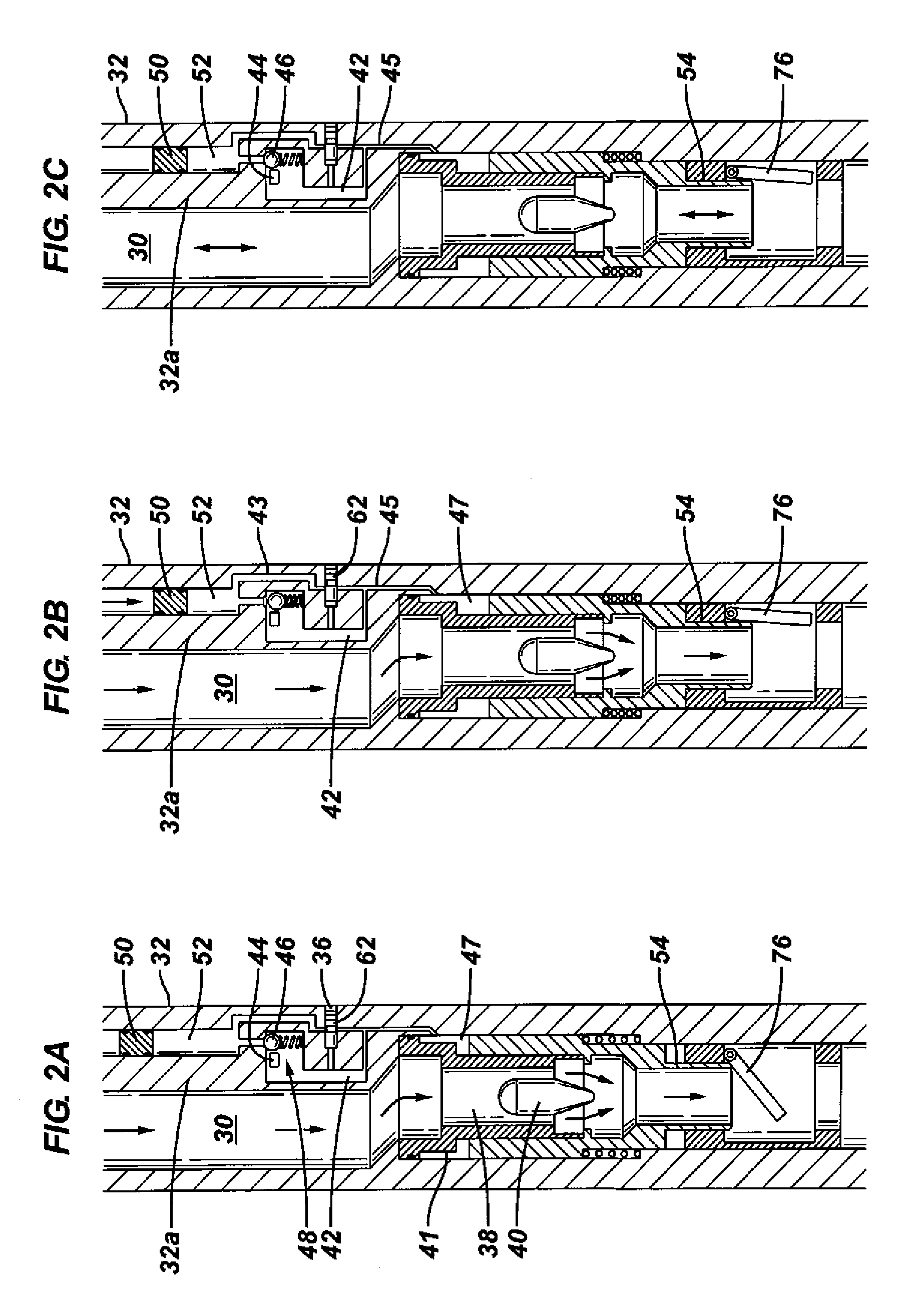

Image

Examples

examples

[0069]Diamond-like coatings were tested in aqueous environments with various hydronium ion concentrations, or PH, with temperatures ranging from room temperature to water boiling. The DLC coatings were applied on the internal surface of a 410 stainless steel (13 Cr-type) cylindrical piece (see FIGS. 9, 10A and 10B). Table 1 lists the visible results of the DLC coating after exposure for 24 hours. DLC coatings were produced using the “Sub-One” process (Sub-One Technology, Pleasanton, Calif.) hollow cathode plasma immersion ion processing (HCPIIP).

TABLE 1DLC Exposure testingConditionsResultsWater PH = 9 24 hrsNo effect on DLCWater PH = 7 24 hrsNo effect on DLCWater PH = 3 24 hrsNo effect on DLCPure HCl (10 min)No effect on DLCWater PH = 0; 10%No effect on DLCNaClHeavilyNo effect on DLCconcentratedNaOH in water

[0070]FIG. 11 shows a drawing of a seal testing device, wherein an internal cylindrical surface is coated with a DLC coating and a piston is moved cyclically from one side to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com