Flow channel switching valve

A technology of flow path switching and flow port, which is applied in the direction of multi-way valves, valve devices, valve details, etc., can solve the problems of damaging rotor rotation, aggravated cross-contamination, and generation of cutting chips, so as to improve sliding performance and prevent Effects of cross-contamination and wear reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

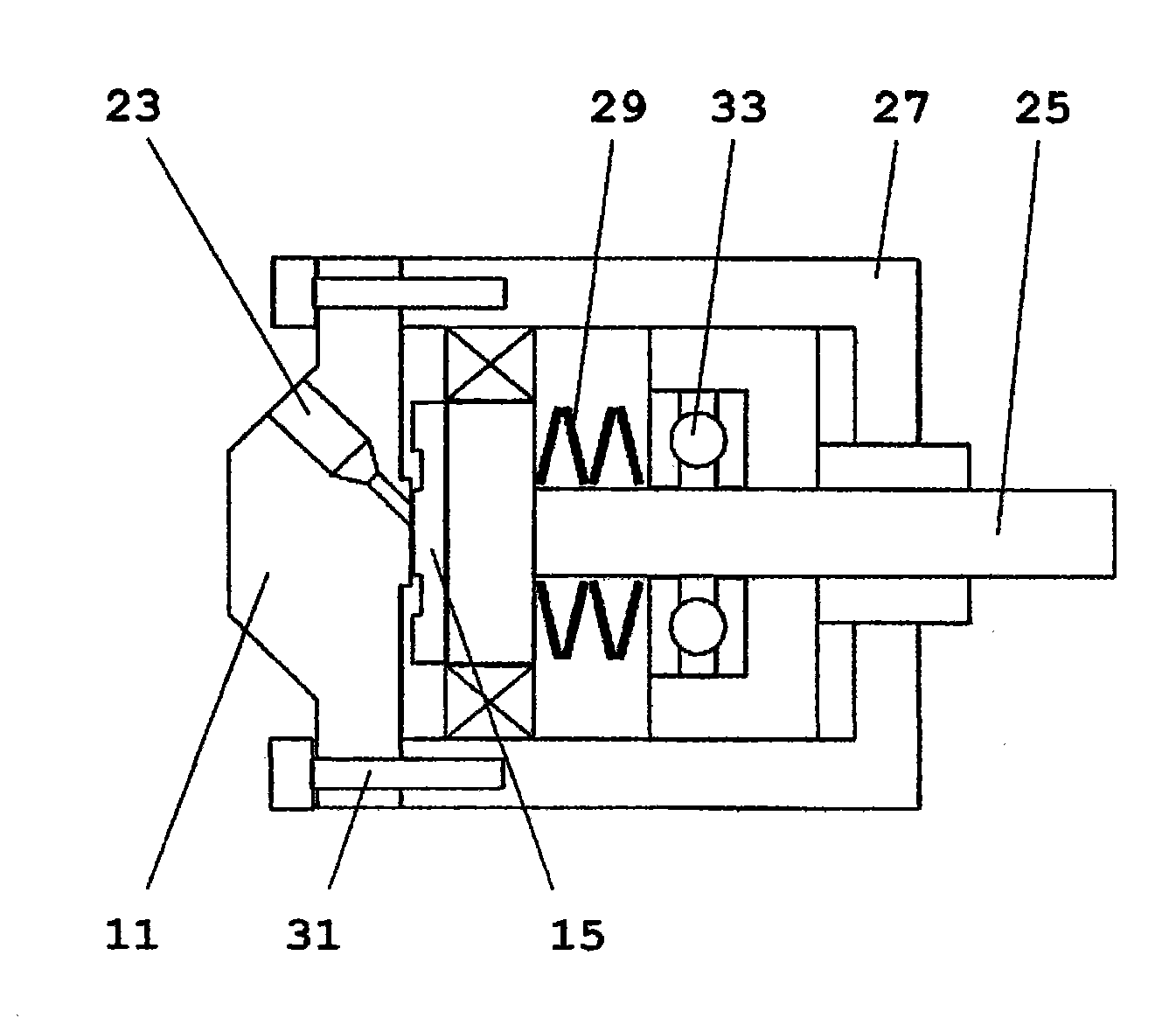

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

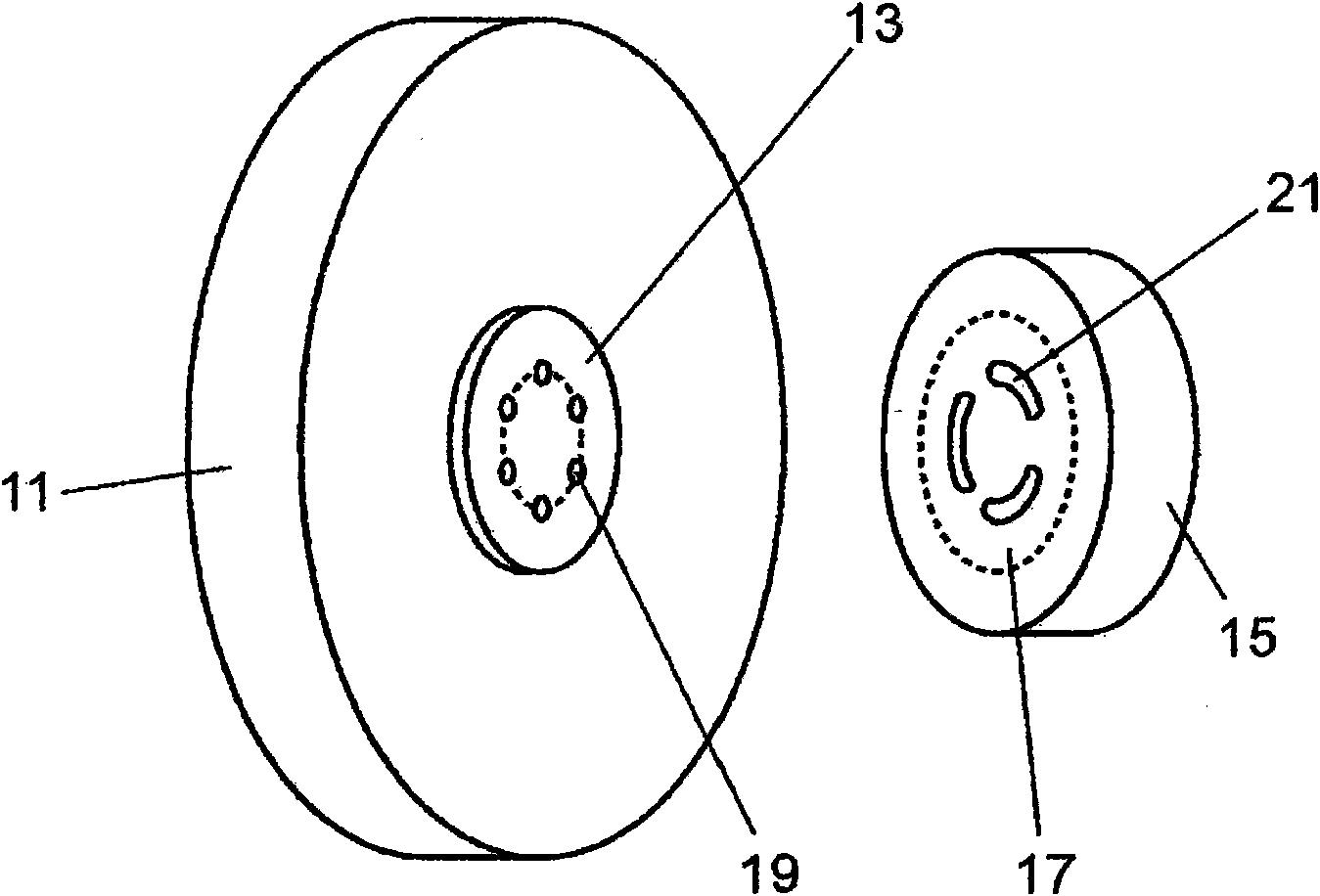

[0030] figure 1 It is a schematic perspective view of the stator and the rotor part of the channel switching valve of one embodiment.

[0031] The stator 11 is made of stainless steel, and is integrally formed with a housing connected to a flow path. The stator sliding surface 13 of the stator 11 is in contact with the rotor sliding surface 17 of the rotor 15 , and the through hole 19 provided on the stator 11 is in communication with the groove 21 provided on the rotor 15 . The rotor 15 is made of resin such as PEEK, and is provided with a plurality of arc-shaped grooves 21 .

[0032] In order to improve sliding properties, it is preferable to grind (mirror finish) the stator sliding surface 13 of the stainless steel stator 11 using diamond abrasive grains (grain diameter: 1 to 3 μm).

[0033] A DLC coating with a thickness of about 2 μm is formed on the sliding su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com