Novel heat sink and production method thereof

A heat dissipation device, a new type of technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of LED light attenuation, high cost, heat conduction and heat dissipation performance decline, etc., to achieve good market promotion value, The effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

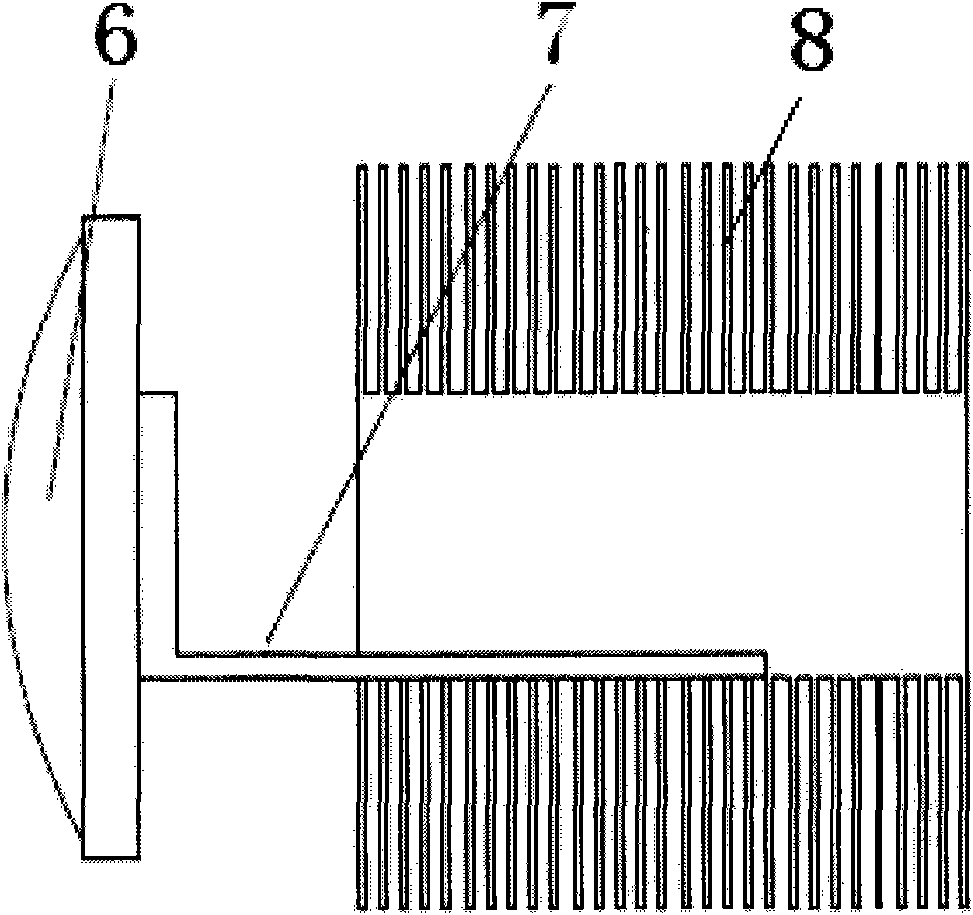

[0022] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

[0023] refer to figure 1 The new heat dissipation device of the preferred embodiment of the present invention includes: a heat conduction element 7 abutted against the heat source 6 and a heat dissipation fin 8 affixed to the heat conduction element 7, and the heat dissipation fin 8 can be replaced by other common heat dissipation devices. Such as thermal glue, heat pipe and the like.

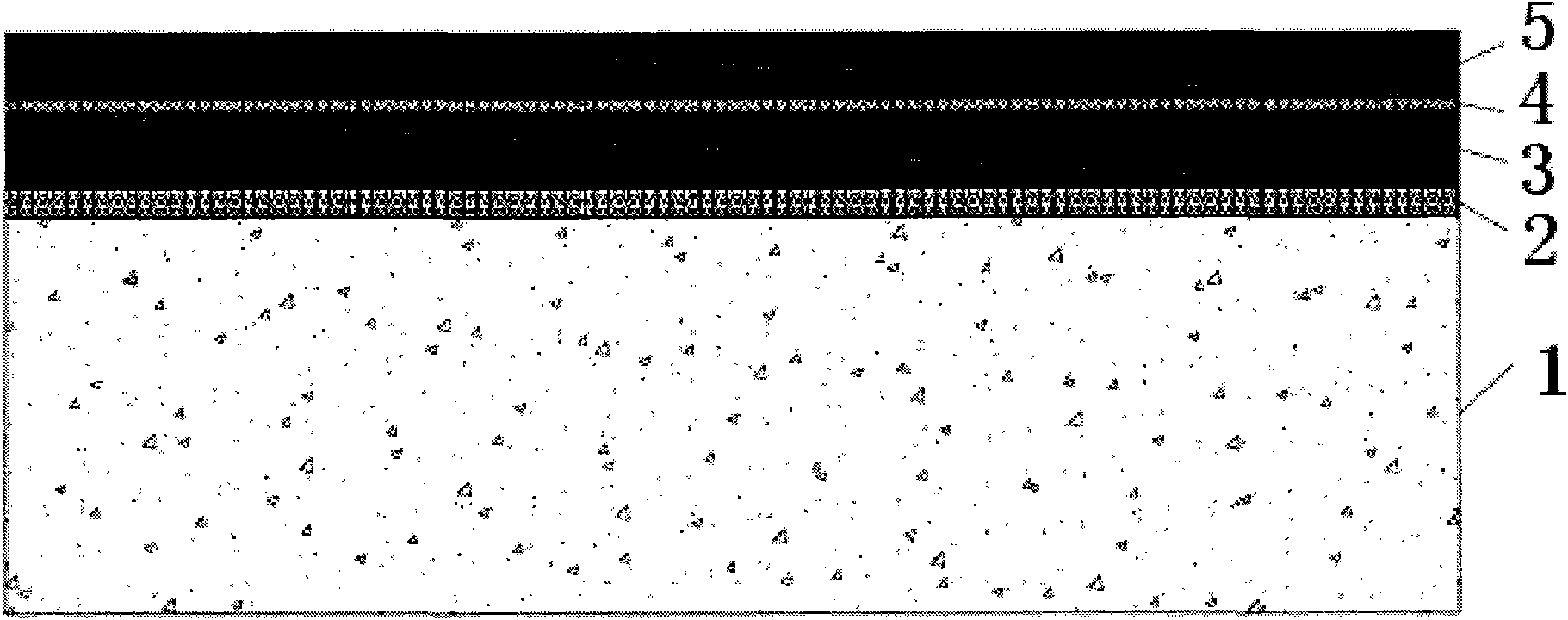

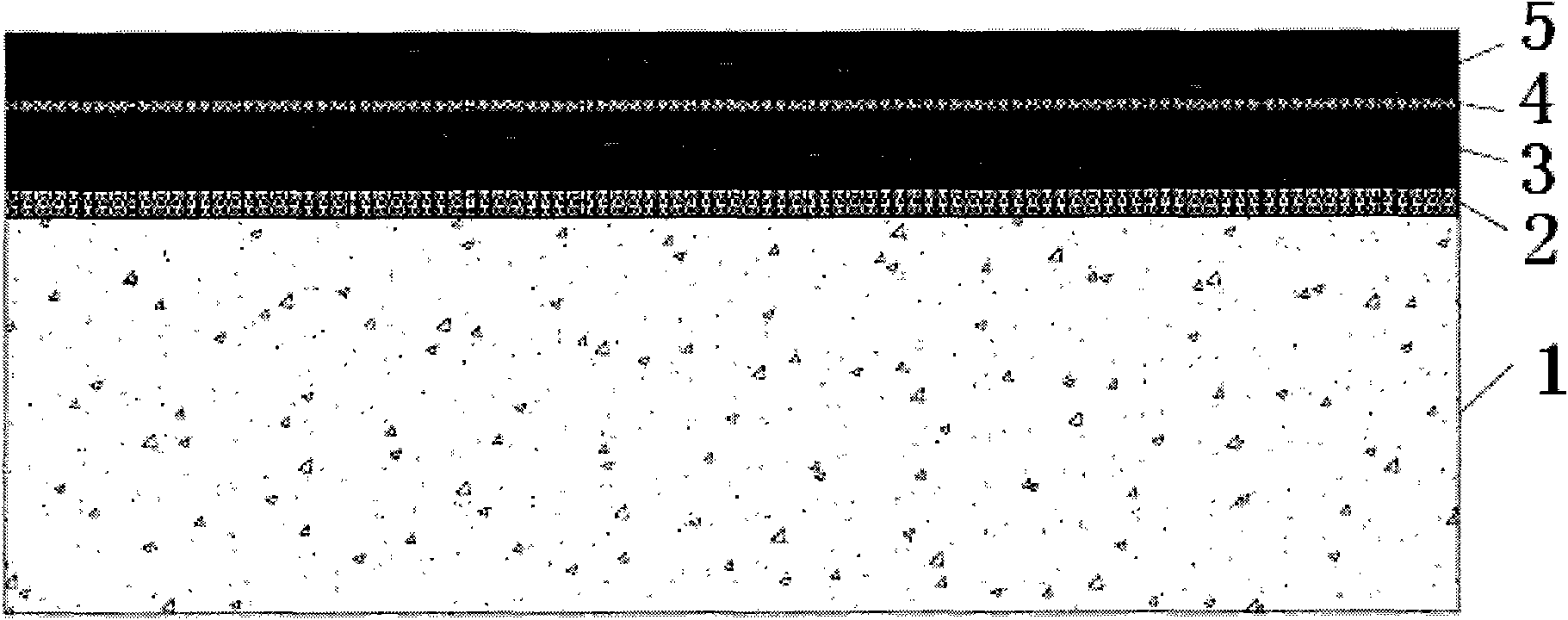

[0024] The heat conducting element 7 is composed of a metal substrate 1 and a high thermal conductivity coating deposited on the metal substrate, and the metal substrate is copper, or aluminum alloy, or stainless steel.

[0025] refer to figure 2 , the high thermal conductivity coating comprises two layers of diamond-like coatings, the first layer of diamond-like coatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com