Negative electrode for lithium metal battery and lithium metal battery including the same

A lithium metal battery, lithium metal electrode technology, applied in the direction of battery electrodes, lithium batteries, electrode current collector coating, etc., can solve the problems of lithium secondary batteries to reduce cycle characteristics and stability, and achieve increased charge-discharge cycle , The effect of improving cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0084] According to an exemplary embodiment, R in the silsesquioxane of the cage structure 1 -R 8 It can be eight isobutyl. For example, the cage-structure silsesquioxane may be octaisobutyl-t8-silsesquioxane.

[0085] The inorganic particles and / or organic-inorganic particles may have various shapes. For example, the inorganic particles and / or organic-inorganic particles may have a spherical shape, an elliptical shape, a cubic shape, a tetrahedral shape, a pyramidal shape, an octahedral shape, a cylindrical shape, a polygonal columnar shape, a conical shape, a columnar shape, a tube shape , spiral, funnel, dendritic, or any of a variety of ordinary regular and irregular shapes.

[0086] The inorganic particles and / or organic-inorganic particles may be present in an amount of about 10 parts by weight to about 200 parts by weight, such as about 50 parts by weight to about 100 parts by weight, based on about 100 parts by weight of the first polymer. While not wishing to be b...

Embodiment 1

[0226] Embodiment 1: the preparation of negative electrode

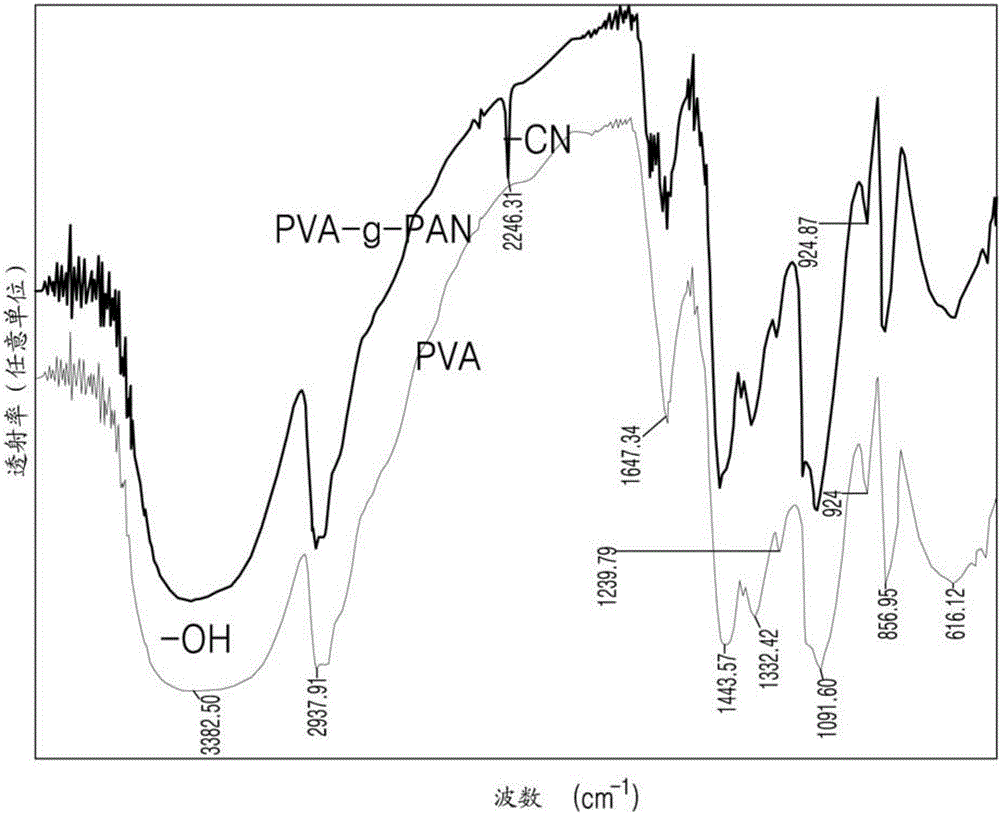

[0227] 10 grams (g) of polyvinyl alcohol (with 93.5×10 3 A weight-average molecular weight in Daltons (Da), a degree of saponification of about 99 mole percent (mol%), and a degree of polymerization of 1,700) was dissolved in 10 g of acrylonitrile and 100 milliliters (ml) of dimethyl sulfoxide (DMSO). Then 0.01 g of potassium persulfate was added thereto, and a stirring process was performed at about 60° C. for 5 hours to carry out a graft reaction of polyvinyl alcohol and acrylonitrile.

[0228] After completion of the reaction, unreacted acrylonitrile remained by separating from the reaction product by dissolving the reaction product with dimethylformamide several times, followed by adding water and dimethylformamide to obtain a precipitate and purifying the precipitate. The resulting product was dried at 40° C. for 34 hours to obtain a polyvinyl alcohol acrylonitrile graft copolymer. The amount of acrylonitrile ...

Embodiment 2

[0231] Embodiment 2: the preparation of negative electrode

[0232] An anode was prepared in the same manner as in Example 1, except that the protective film forming composition was diluted about 10 times and the protective film had a thickness of about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com