P-N junction 4pi light emitting high-voltage light emitting diode (LED) and LED lamp bulb

A LED light bulb, P-N technology, applied in the direction of semiconductor devices, light sources, electric light sources, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

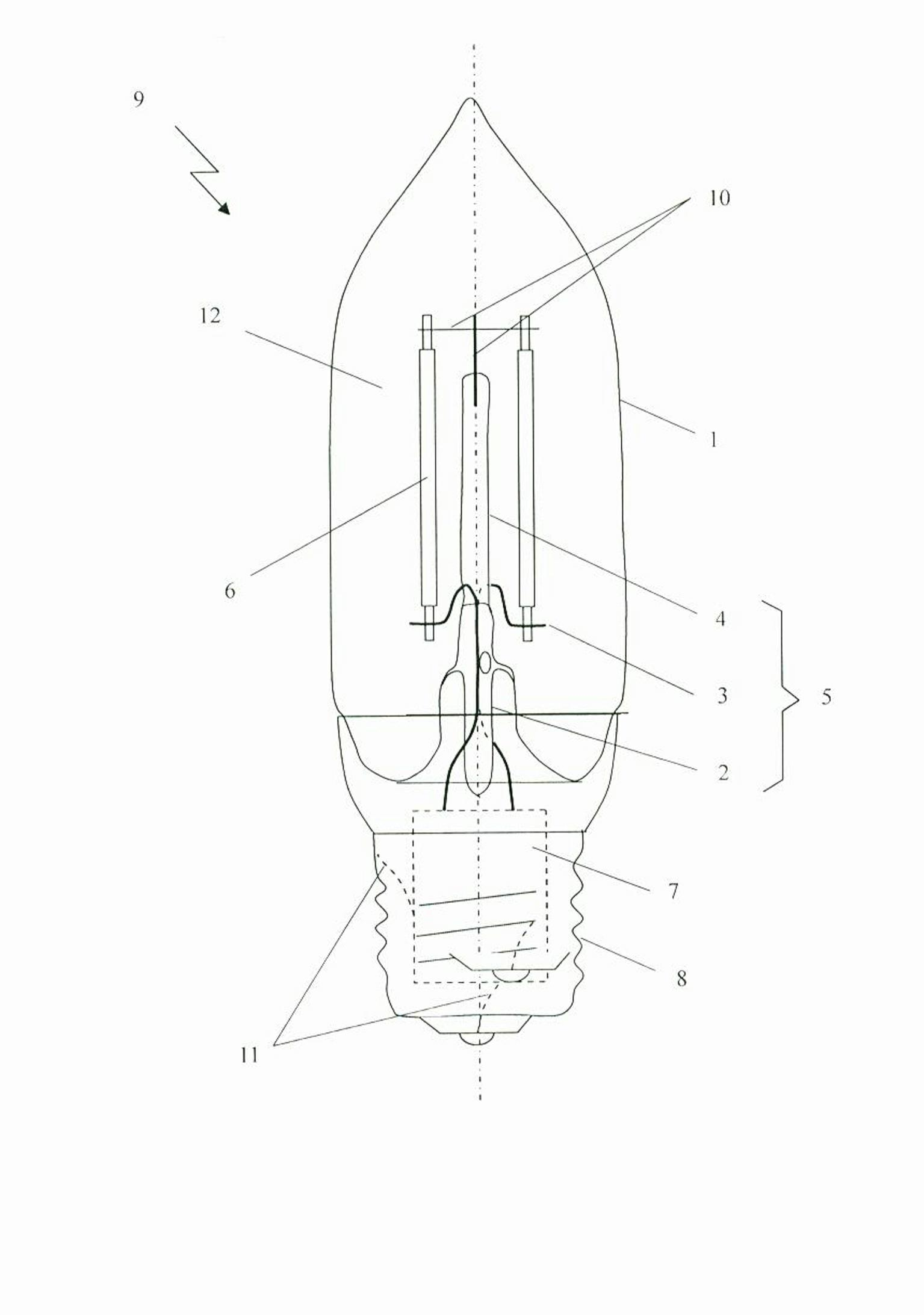

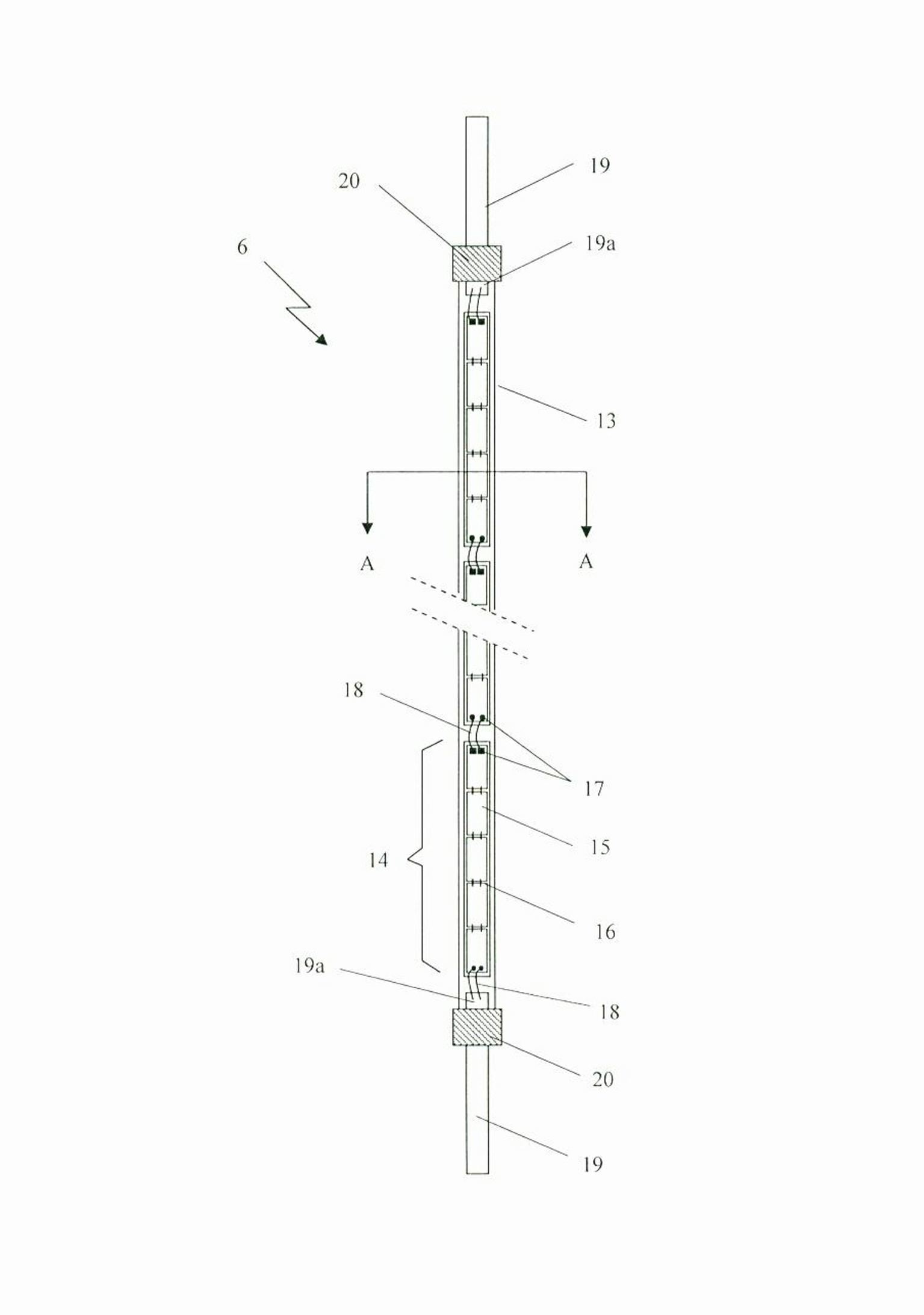

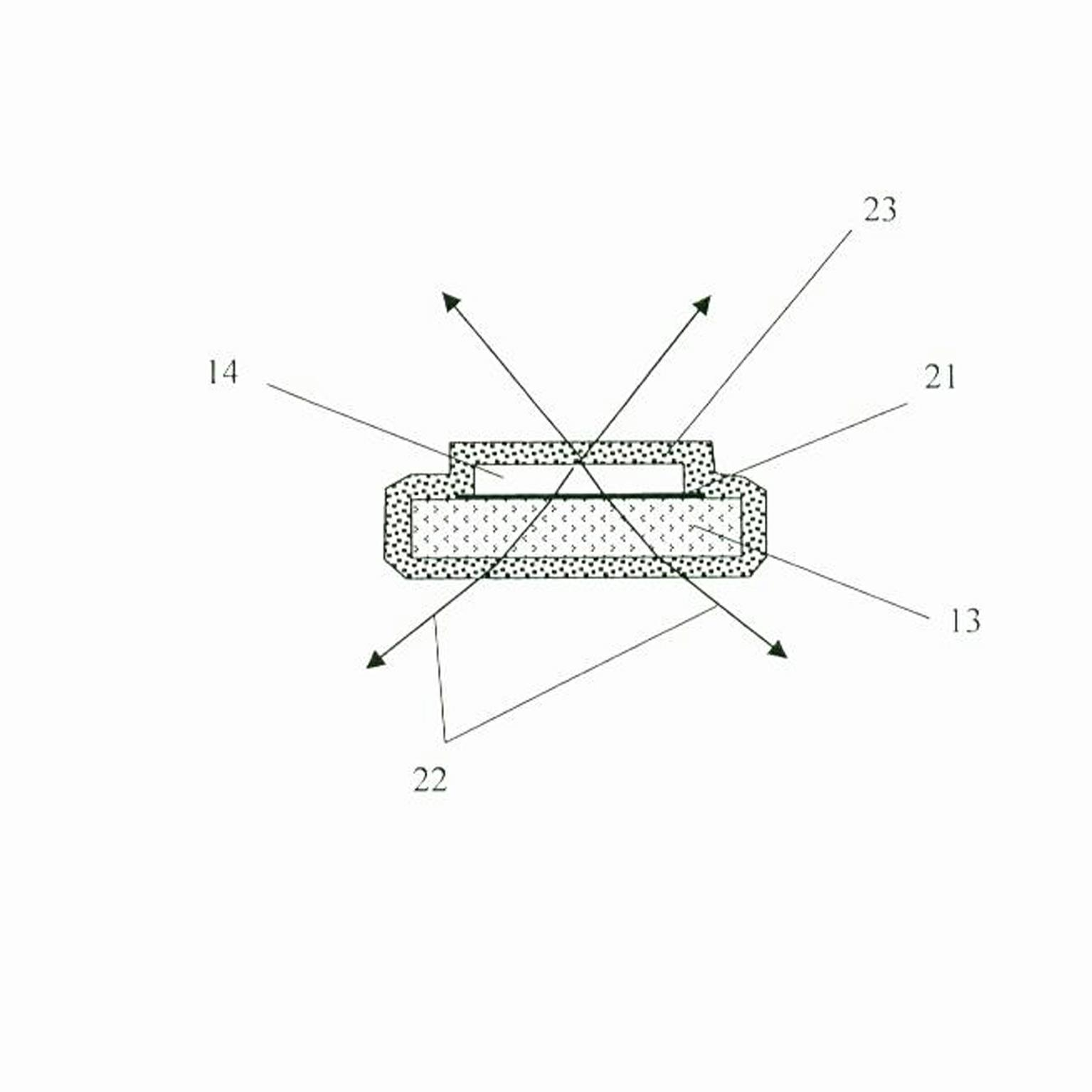

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of an embodiment of a high-efficiency LED light bulb composed of a high-voltage LED with a P-N junction 4π emitting light in the present invention. The high-efficiency LED light bulb includes a light-transmitting bulb 1, a stem 5 with an exhaust pipe 2, an electrode lead wire 3 and a support 4, at least one high-voltage LED 6 that emits light from a P-N junction 4π, a driver 7, An electrical connector 8 ; the light-transmitting bulb 1 , stem 5 , high-voltage LED 6 , driver 7 and electrical connector 8 are interconnected to form a whole lamp 9 . The high-voltage LED 6 is fixed on the stem 5 by the electric lead-out wire 3 of the stem and the fixed metal wire 10 on the pillar, and its electrodes pass through the electric lead-out 3 of the stem, the driver 7, the connection wire 11 and the electrical connector 8 connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com