Ammonia desulfurization method for effectively removing chlorine and fluorine ions and heavy metal ions

A heavy metal ion, ammonia desulfurization technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as device corrosion, excessive heavy metal content, soil heavy metal pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

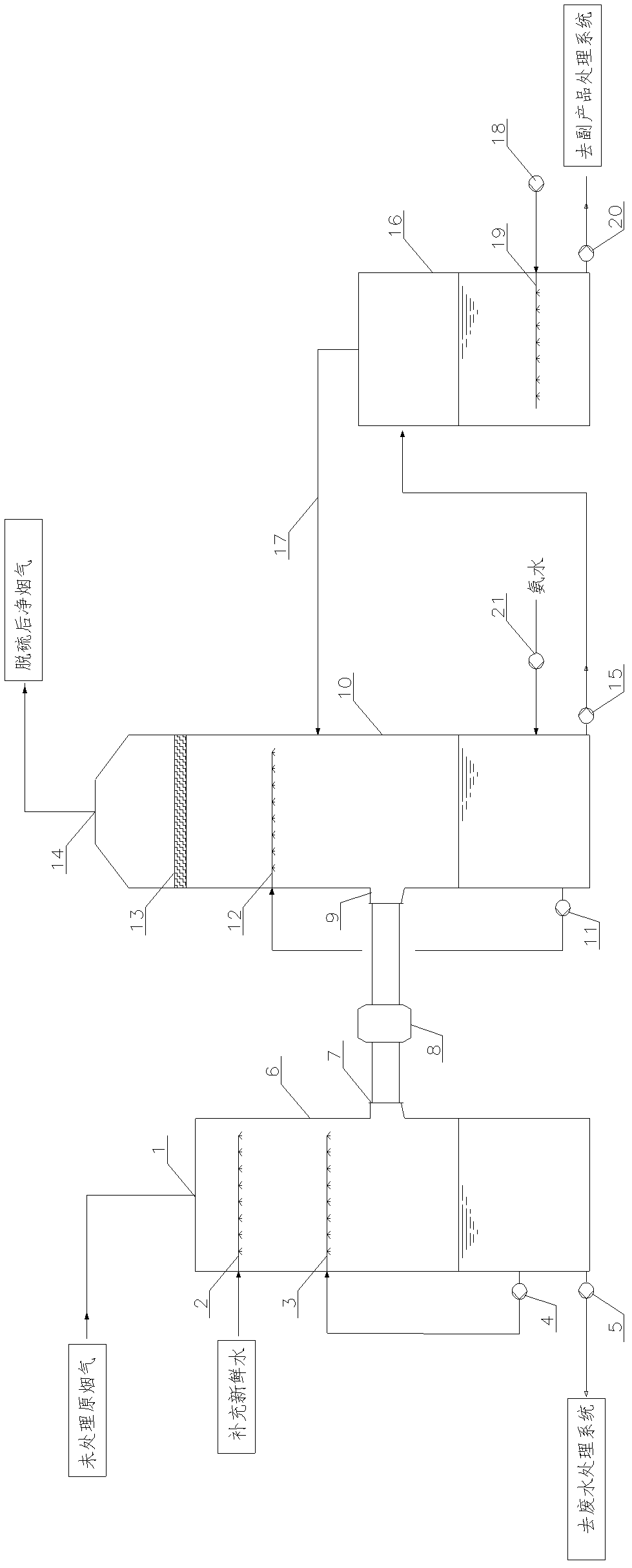

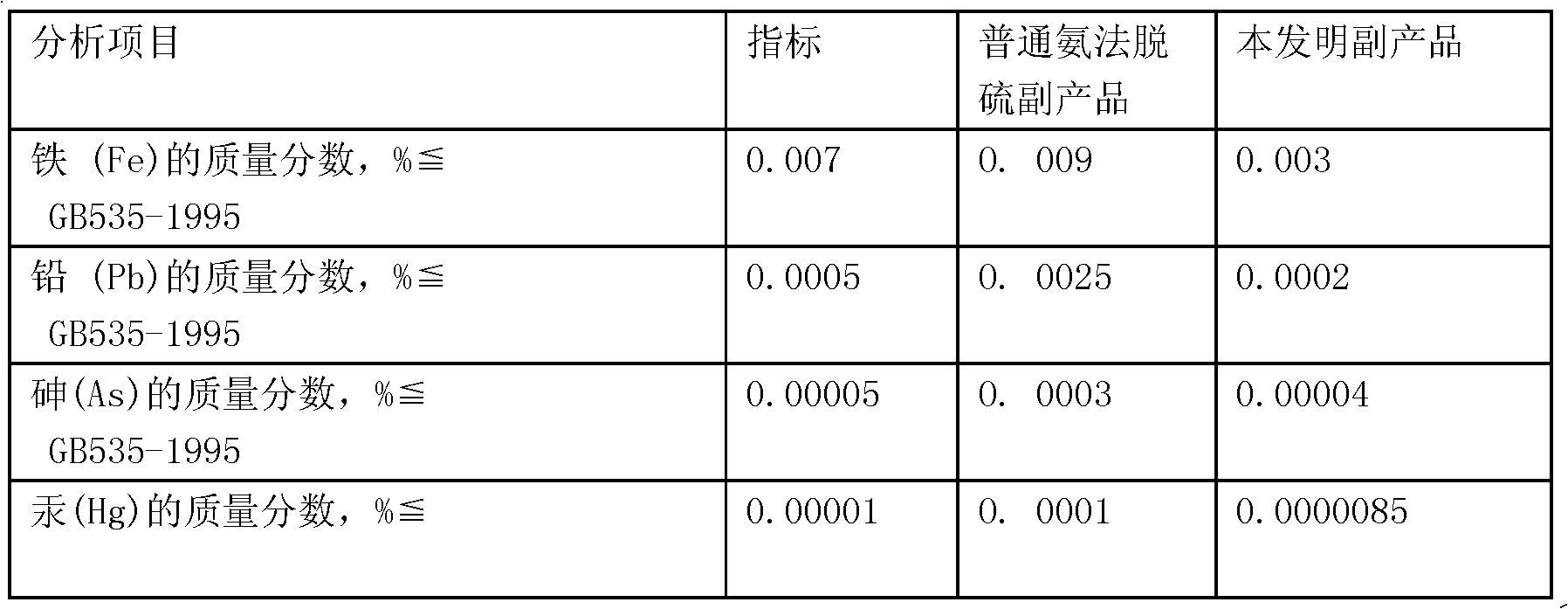

[0033] like figure 1 As shown, the flue gas from the boiler at a temperature of 130°C has a flow rate of 1.2×10 6 Standard cubic meters per hour, the concentration of sulfur dioxide in the flue gas is 3000mg / Nm 3 , the dust content is 100mg / Nm 3 . The flue gas enters the pre-washing tower 6 from the flue gas inlet 1 of the pre-washing tower, sprays fresh water through the fresh water spray pipe 2 and sprays it to cool down to 80°C, and the flue gas in the pre-washing tower 6 circulates and sprays with the pre-washing tower The scrubbing solution sprayed by pipe 3 is fully contacted, the temperature of the flue gas drops to 56°C, and the Cl in the flue gas - , F - 95% is removed, soluble metal ions such as: Fe 3+ , Hg 2+ , Pb 2+ 70%-80% is removed, 70%-80% of dust is removed, and most of Cl is washed away - , F - and most Fe 3+ , Hg 2+ , Pb 2+ The flue gas of soluble metal ions and dust leaves the pre-washing tower 6 from the pre-washing tower flue gas outlet 7, and...

Embodiment 2

[0042] The flow process of embodiment 2 is exactly the same as that of embodiment 1, the difference is that the flue gas is from the sintering machine of the iron and steel plant, the temperature is 120 ℃, and the flue gas flow rate is 1.6×10 6 Standard cubic meters per hour, the concentration of sulfur dioxide in the flue gas is 1300mg / Nm 3 , the dust content is 100mg / Nm 3 ;

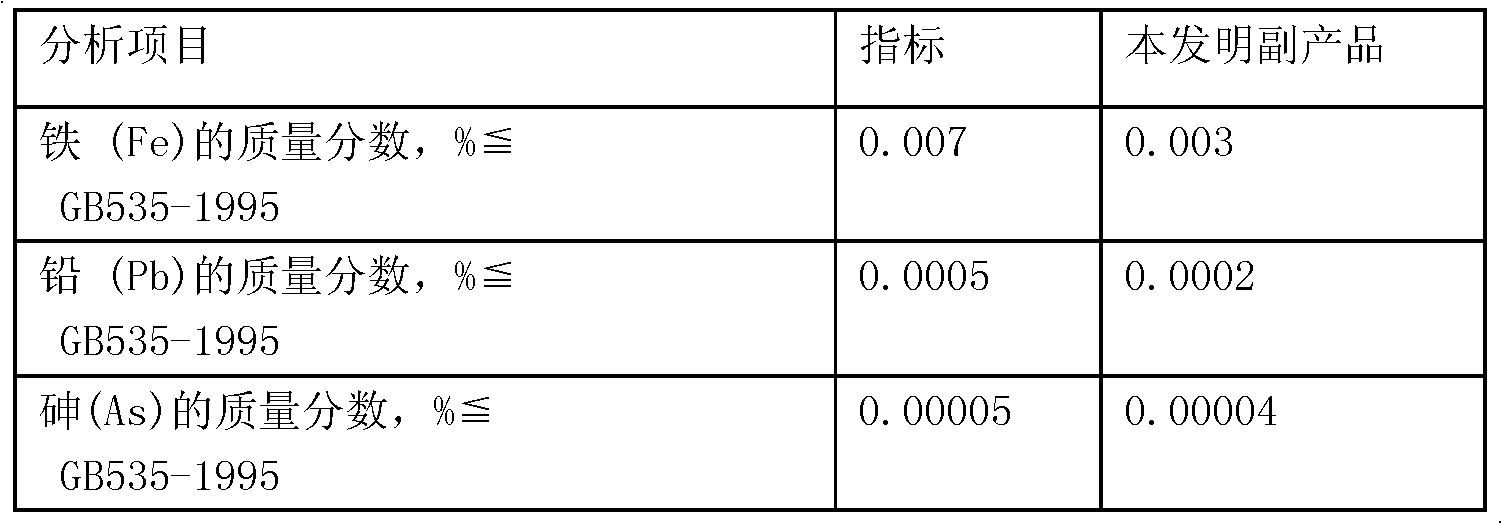

[0043] The concentration of sulfur dioxide in the clean flue gas discharged after desulfurization by the desulfurization tower 10 is 65mg / Nm 3 , the dust content is 20mg / Nm 3 . The measurement results of impurities in finished fertilizers are:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com