Latent-curing single-component color polyurethane waterproofing paint and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of complex screening process, difficult formulation design, etc., to achieve good flexibility, strong market competitiveness, adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

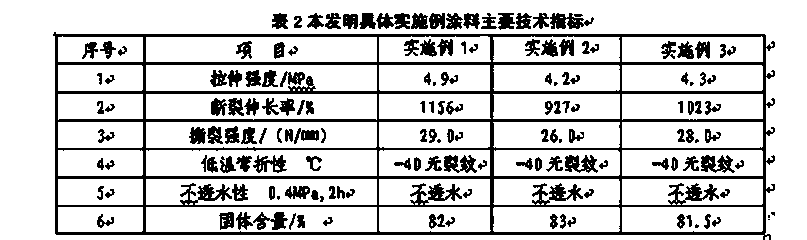

Embodiment 1

[0053] A latent curing one-component color polyurethane waterproof coating comprises the following components by weight:

[0054] Polyether 2000 20

[0055] Polyether 330N 6

[0056] Chlorinated paraffin 20

[0057] Powder 30

[0058] Dispersant 1

[0059] MDI-50 8

[0060] Catalyst 1

[0061] latent curing agent 4

[0062] Chain extender 4

[0063] solvent 6.

[0064] Among them, the dispersant is F-108 dispersant, the powder is light calcium carbonate, the chain extender is 1,4-butanediol, the latent curing agent is oxazolidine latent curing agent (208), and the catalyst is organotin T -12 (alias dibutyltin dilaurate).

Embodiment 2

[0066] A latent curing one-component colored polyurethane waterproof coating comprises the following components in parts by weight:

[0067] Polyether 2000 18

[0068] Polyether 330N 5

[0069] Chlorinated paraffins 18

[0070] Powder 28

[0071] Dispersant 0.8

[0072] MDI-50 6

[0073] Catalyst 0.8

[0074] latent curing agent 3

[0075] Chain extender 3

[0076] solvent 6.

[0077] Among them, the dispersant is F-108 dispersant, the powder is talcum powder, the chain extender is an amine chain extender, the latent curing agent is an amine latent curing agent, and the catalyst is organotin T-12.

Embodiment 3

[0079] A latent curing one-component colored polyurethane waterproof coating comprises the following components in parts by weight:

[0080] Polyether 2000 22

[0081] Polyether 330N 7

[0082] Chlorinated paraffins 22

[0083] Powder 32

[0084] Dispersant 1.2

[0085] MDI-50 10

[0086] Catalyst 1.2

[0087] latent curing agent 5

[0088] Chain extender 5

[0089] Solvent 8.

[0090] Among them, the dispersant is F-108 dispersant, the powder is carbon black, the chain extender is 1,4-butanediol, the latent curing agent is oxazolidine latent curing agent (208), and the catalyst is organotin T-12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com