Aqueous ultrathin steel structure fire-retardant coating and preparation method thereof

A fire retardant coating, ultra-thin technology, applied in fire retardant coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of low expansion ratio, poor coating fineness, difficult to grind, etc., to achieve foaming and Excellent fire resistance, convenient and environmentally friendly construction, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of a water-based ultra-thin steel structure fireproof coating has the following steps:

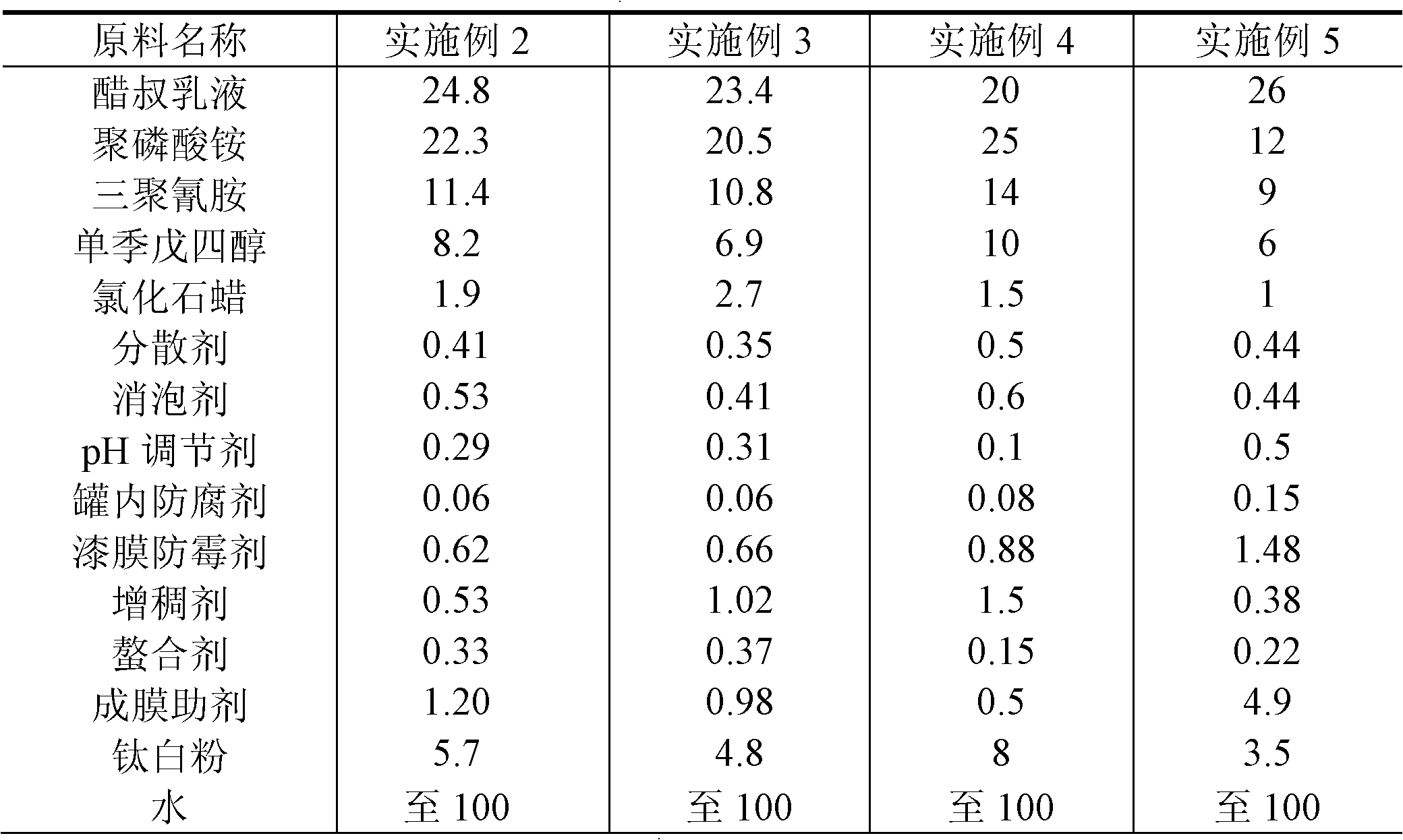

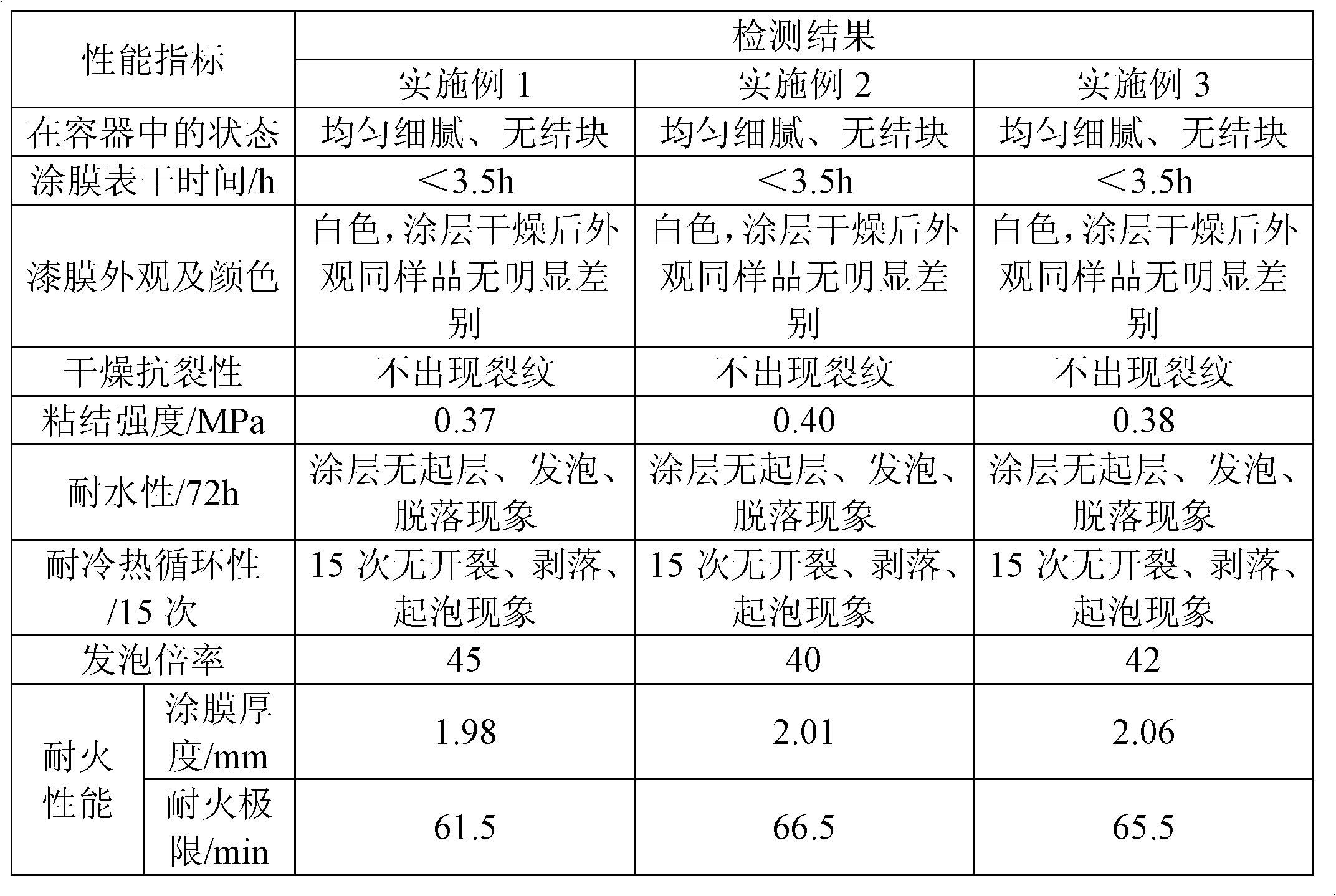

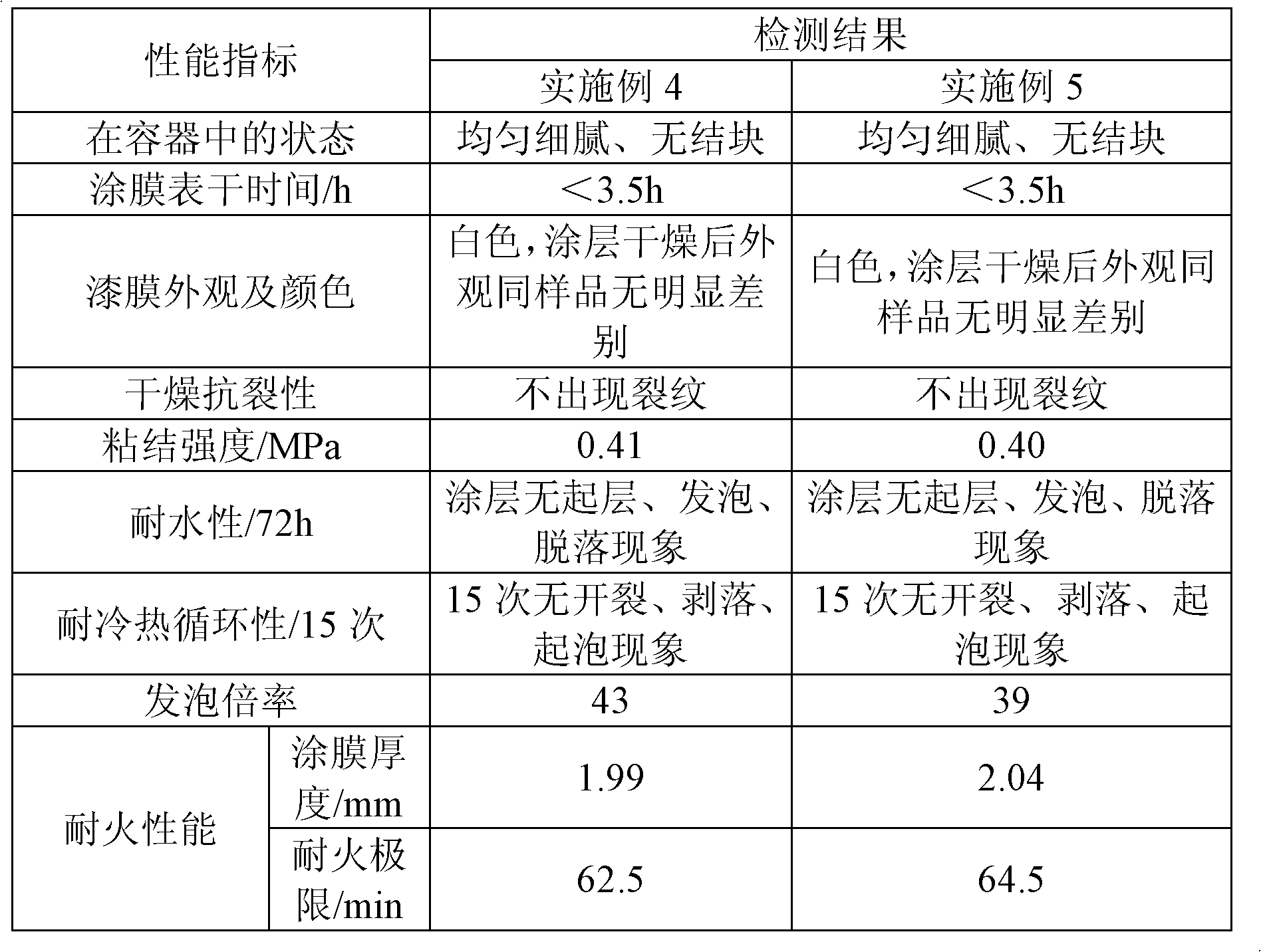

[0022] (1) According to the mass percent of each component: 22.5% of tertiary vinegar emulsion, 2.4% of chlorinated paraffin, 21.8% of ammonium polyphosphate, 7.8% of monopentaerythritol, 13.7% of melamine, 0.3% of defoamer, 0.3% of dispersant, 0.4% thickening agent, 0.2% chelating agent, 0.2% pH regulator, 0.8% film-forming aid, 0.05% preservative in tank, 0.5% antifungal agent for paint film, 6.6% titanium dioxide, and the balance is water. Prepare materials ; First, crush the monopentaerythritol through a powder crusher to crush the hard crystals into powder, so as to reduce the subsequent sanding time and improve production efficiency;

[0023] (2) Dispersant, thickener, half of defoamer, paint film antifungal agent, preservative in tank, half of pH regulator, chelating agent, ammonium polyphosphate, melamine, powdered monopentaerythritol, Titanium dioxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fire resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com