Waterproof coating

A waterproof coating and triethanolamine technology, applied in the coating field, can solve the problems of poor adhesion of water-based waterproof coatings, lipidation of oil-based waterproof coatings, and human and environmental toxicity, and achieve strong adhesion, enhanced waterproof performance, and improved fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

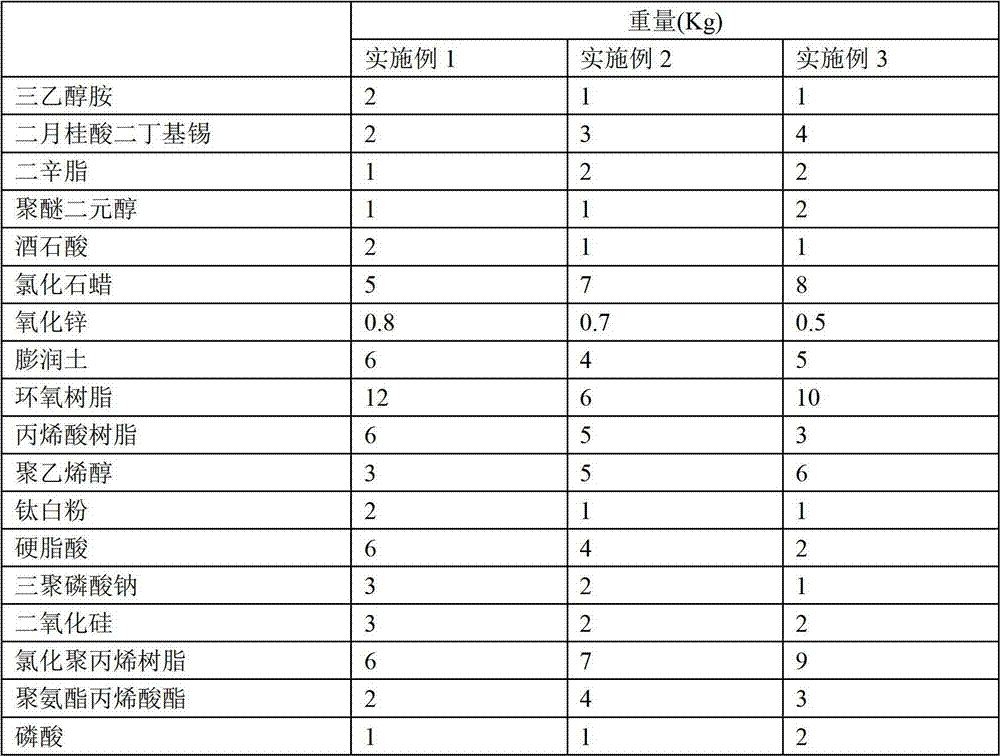

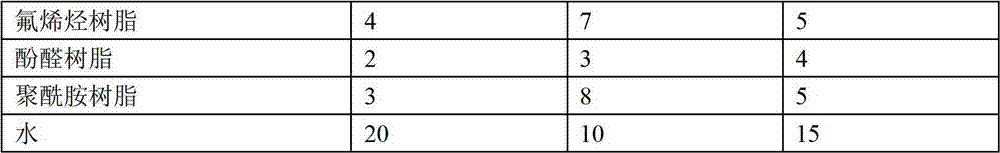

[0016] Each component was weighed according to the weight ratio shown in Table 1.

[0017] The weight proportion of table 1 embodiment 1~embodiment 3

[0018]

[0019]

[0020] The polyether glycol is propylene glycol polyoxypropylene ether.

[0021] Described epoxy resin is bisphenol A type epoxy resin.

[0022] The said titanium dioxide is anatase type titanium dioxide.

[0023] The particle size of the zinc oxide is 10-500 μm.

[0024] The particle size of the silicon oxide is 10-400 μm

[0025] The preparation method of above-mentioned waterproof paint is:

[0026] S1: Mix triethanolamine, dibutyltin dilaurate, dioctyl ester, polyether glycol, tartaric acid, chlorinated paraffin, zinc oxide, bentonite, titanium dioxide, and silicon dioxide, and then stir evenly;

[0027] S2: While stirring, add epoxy resin, acrylic resin, polyvinyl alcohol, stearic acid, sodium tripolyphosphate, chlorinated polypropylene resin, polyurethane acrylate, phosphoric acid, fluoroolefi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com