Patents

Literature

126results about How to "Increase breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Under-pressure chamber opening method for shield tunneling machine in coarse-grain soil stratum

ActiveCN103967498AReduce penetrationReduce air permeabilityUnderground chambersTunnel liningSoil scienceSlurry

The invention discloses an under-pressure chamber opening method for a shield tunneling machine in a coarse-grain soil stratum. The under-pressure chamber opening method comprises the steps of preparing thin mud, and making the thin mud permeate into the stratum to form a stable permeation band to reduce permeability of the stratum; replacing the thin mud with thick and high-density mud to form a tight mud type of mud membrane on the surface of the stratum to reduce breathability of the stratum; setting a pressure value of under-pressure chamber opening by testing a airtightness value of the mud membrane through an indoor test and airtightness effect through an in situ test; reducing the liquid level of mud of a pressure chamber to the position below a maintenance surface, and performing under-pressure chamber opening under protection of local pressure by means of the airtightness of the mud membrane; repairing the mud membrane on an excavation face by ascending and descending the liquid level of the mud of the pressure chamber during chamber opening. By means of the under-pressure chamber opening method for the shield tunneling machine, under-pressure chamber opening of the shield tunneling machine is achieved safely and quickly in the coarse-grain soil stratum with high water pressure and strong permeability. Furthermore, the under-pressure chamber opening method for the shield tunneling machine is simple in operation, economical and suitable for current national conditions in China.

Owner:HOHAI UNIV

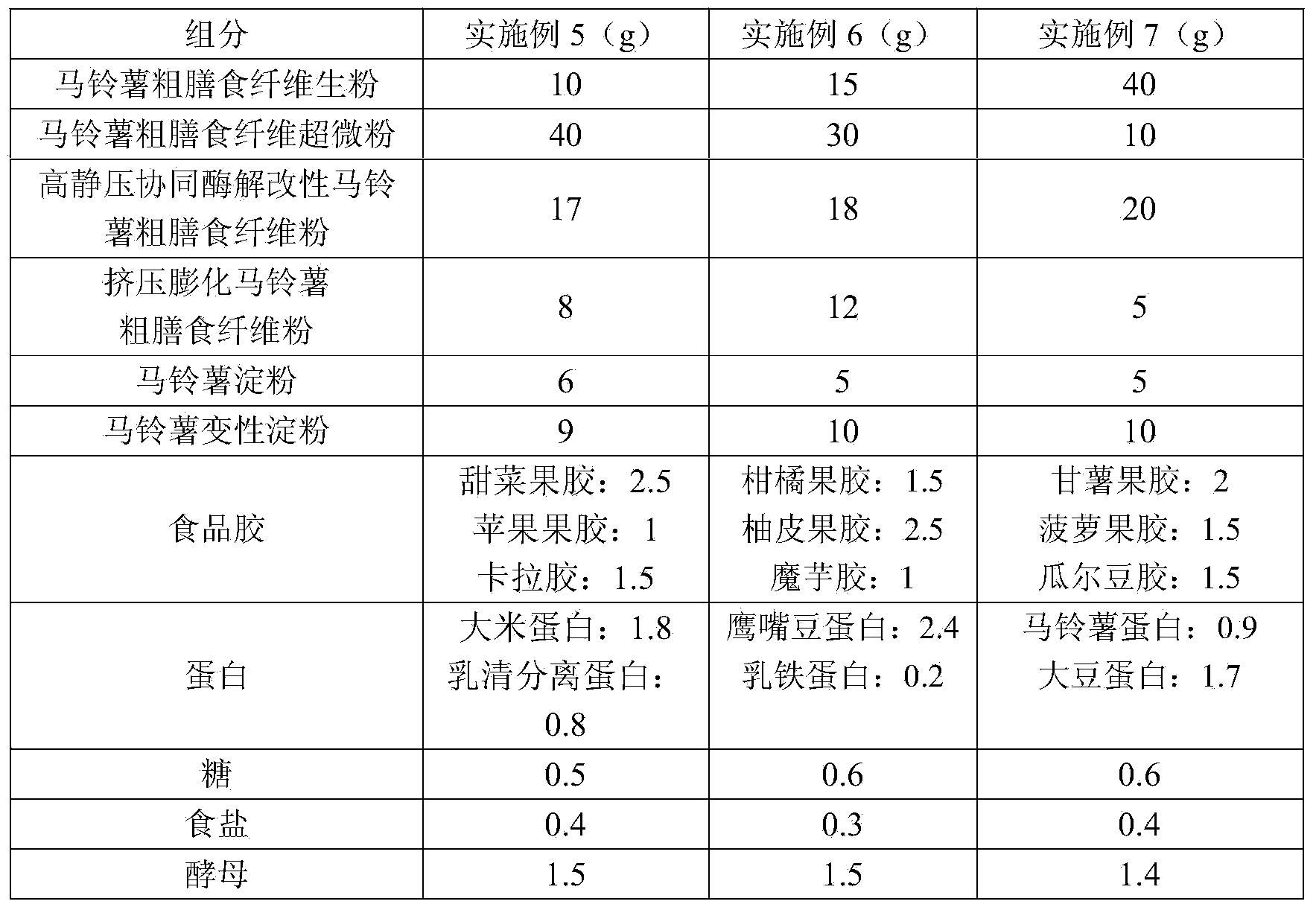

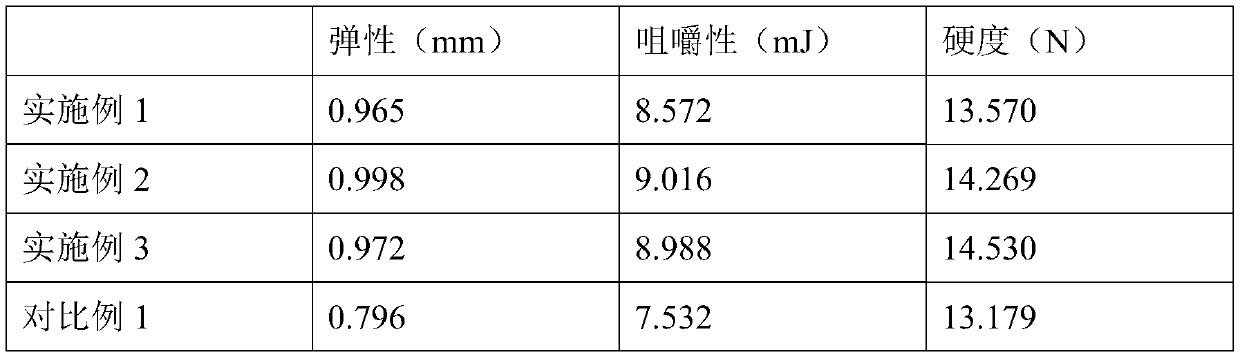

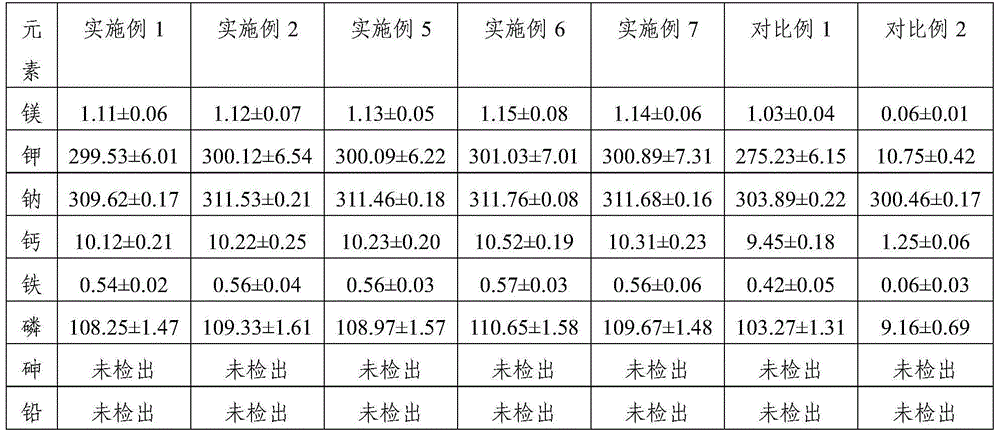

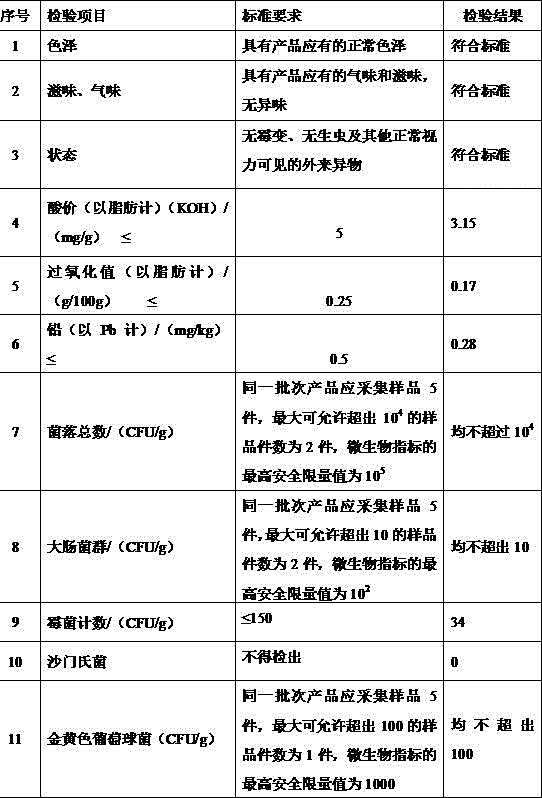

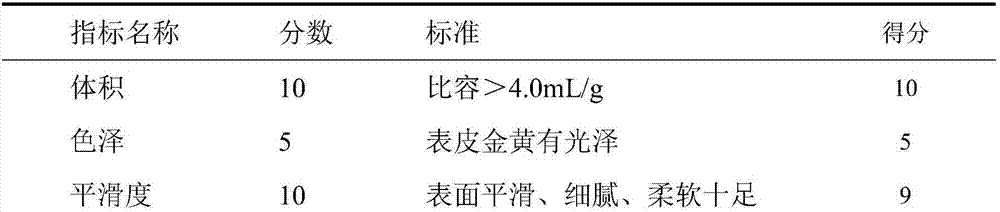

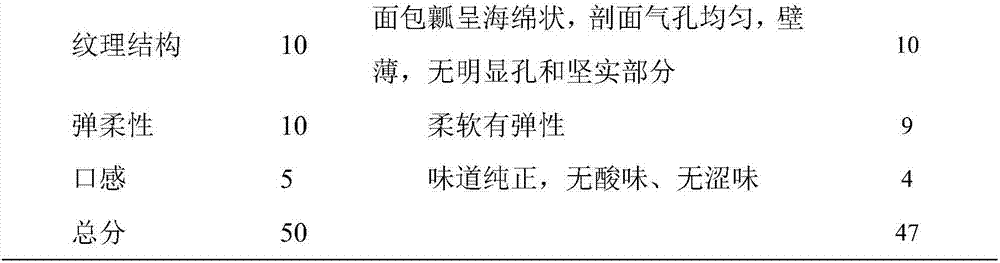

Potato dietary fiber bread and making method of potato dietary fiber bread

ActiveCN104365733AOvercoming the low proportion of ingredientsOvercoming low nutritional valueDough treatmentModified nutritive productsPotato starchAntioxidant

The invention relates to the field of foods, in particular to potato dietary fiber bread and a making method of the potato dietary fiber bread. The potato dietary fiber bread comprises, by mass, 10 parts to 40 parts of potato coarse dietary fiber starch, 10 parts to 40 parts of potato coarse dietary fiber submicron powder, 10 parts to 20 parts of high-hydrostatic-pressure synergetic enzymatic hydrolysis modified potato coarse dietary fiber powder, 4 parts to 12 parts of extrusion potato coarse dietary fiber powder, 5 parts to 12 parts of potato starch, 5 parts to 13 parts of potato modified starch, 2 parts to 6 parts of food gum, 1 part to 3 parts of egg white, 0.5 part to 3 parts of sugar, 0 part to 1 part of salt and 1 part to 3 parts of yeast. The potato dietary fiber bread does not contain gluten, the contents of protein, mineral substances, dietary fibers, vitamins and antioxidants are obviously higher than the contents of protein, mineral substances, dietary fibers, vitamins and antioxidants in existing wheat bread, and the potato dietary fiber bread is suitable for being eaten by the crowd allergic to wheat or celiac disease patients.

Owner:北京中农探味科技有限公司

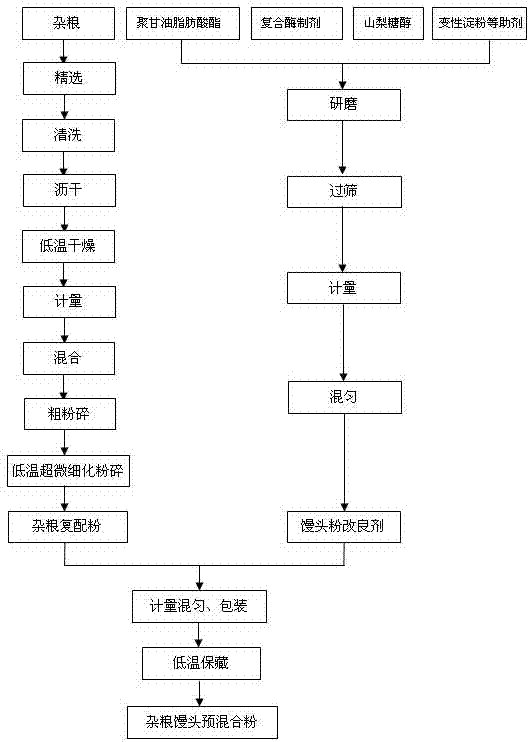

Premixed powder for preparing whole coarse cereal steamed bun

The invention relates to premixed powder for preparing whole coarse cereal steamed bun. The premixed powder for preparing the whole coarse cereal steamed bun is prepared by mixing and processing the following materials in parts by weight: 20-40 parts of corn flour, 5-10 parts of small red bean flour, 5-10 parts of black bean flour, 5-10 parts of kidney bean flour, 5-10 parts of mung bean flour, 5-10 parts of soybean flour, 5-10 parts of black rice flour, 5-10 parts of small yellow rice flour, 5-10 parts of broomcorn flour, 5-10 parts of coix seed flour, 5-10 parts of buckwheat, 1-5 parts of sesame flour, 0.1-0.5 part of polyglycerol fatty acid ester, 0.001-0.015 part of a complex enzyme preparation, 0.1-1 part of sorbitol, 0.5-1 part of active dry yeast, 0.1-0.5 part of baking powder, 0.001-0.003 part of tricalcium phosphate and 0.5-2 parts of cross-linked pre-gelatinized carboxymethyl starch. According to the premixed powder disclosed by the invention, about 12 kinds of different types of varicolored coarse cereal flour (having five colors) of which the function and the nutrient are optimized and complementary to one another are scientifically and reasonably selected to completely replace wheal flour so as to comprehensively balance nutrient demands of human bodies, is good in taste of prepared steamed bun, and greatly simplifies the steamed bun production procedures.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

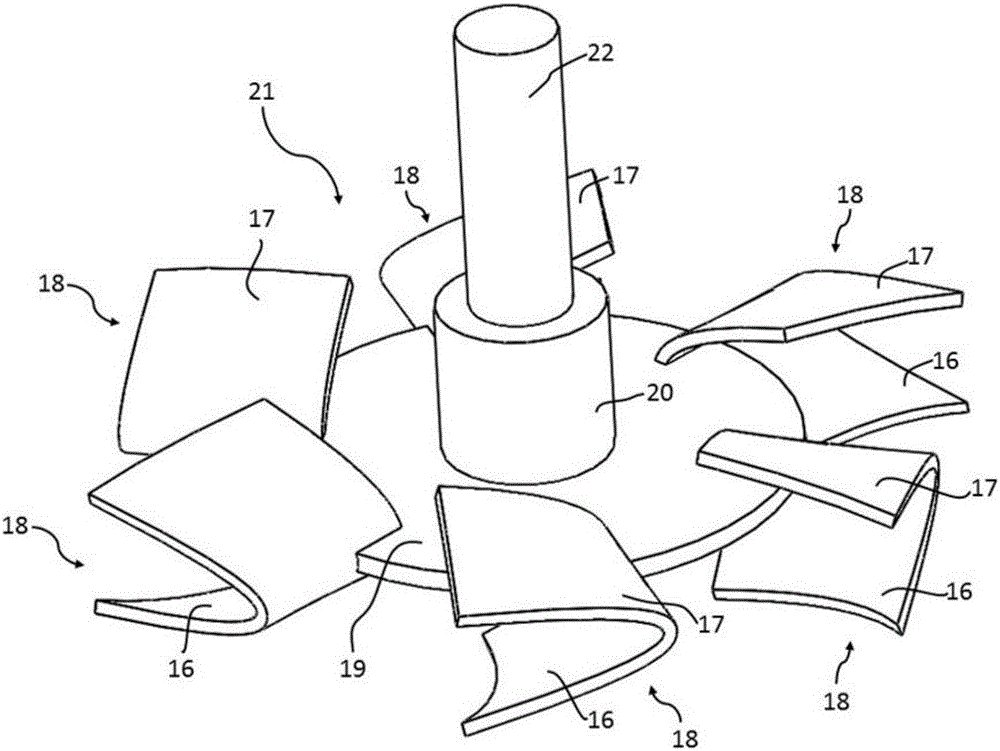

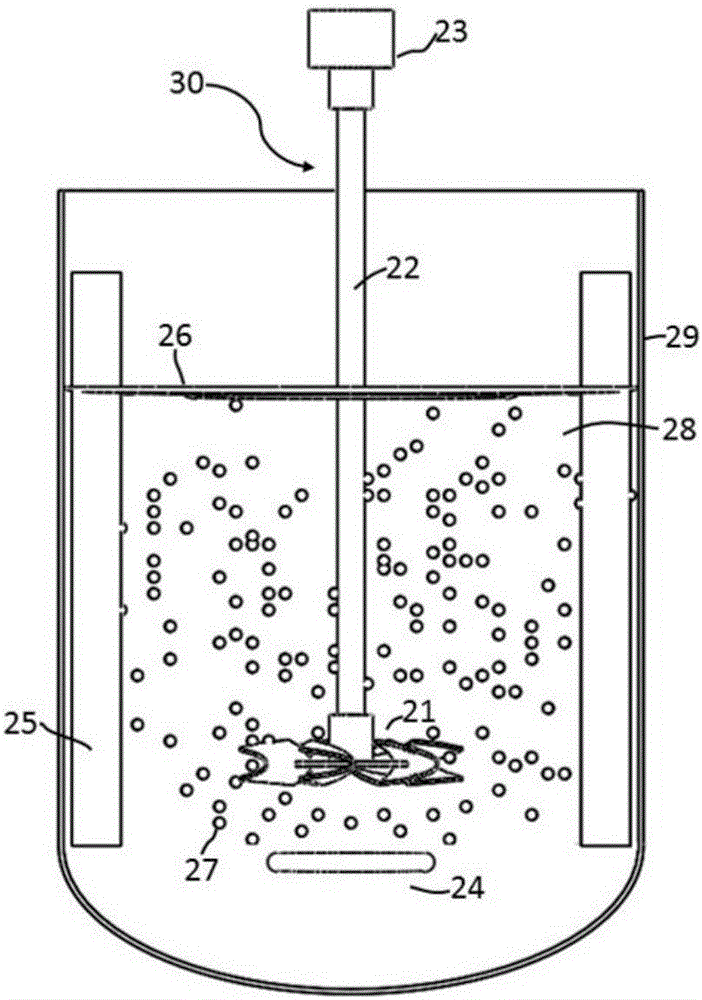

Gas-liquid dispersing and stirring device

ActiveCN106268579AEasy to captureReduce consumptionRotary stirring mixersTransportation and packagingCircular discEngineering

The invention discloses a gas-liquid dispersing and stirring device and belongs to the technical field of fluid mixing. Every blade of the gas-liquid dispersing and stirring device consists of a radially extending and highly shrinking concave, the vertex of the concave is positioned at the intersection position of the concave and a disk plane and extends perpendicularly along the tangential direction. The upper half and the lower half of an inner margin curve of every concave are asymmetric, the upper half extension length is greater than the lower half extension length, but the upper half and the lower half of an outer margin curve of the concave are symmetric; the vertical height of the inner margin of the concave is greater than that of the outer margin thereof, but the tangential extension length of the outer margin of the concave is greater than that of the inner margin thereof. The inner sides of the blades are beneficial to catching ascending bubbles and making the same disperse into a liquid phase, and in an outward extension process of the blades, the vertical height of every blade decreases gradually. The gas-liquid dispersing and stirring device has the advantages of low power consumption, high gas-liquid dispersion efficiency and mixing performance and capability of dispersing gas into a liquid phase system or liquid-solid system in an efficient energy-saving way.

Owner:ZHENJIANG EAST BIOTECH EQUIP & TECH +1

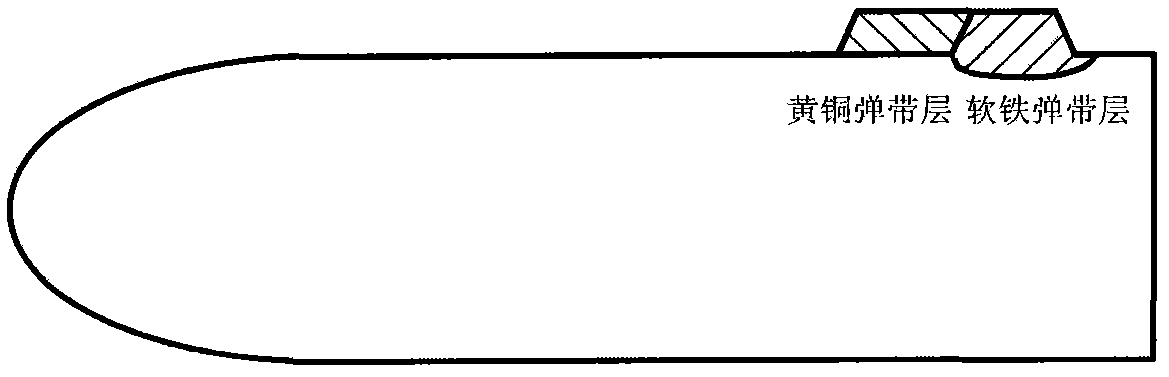

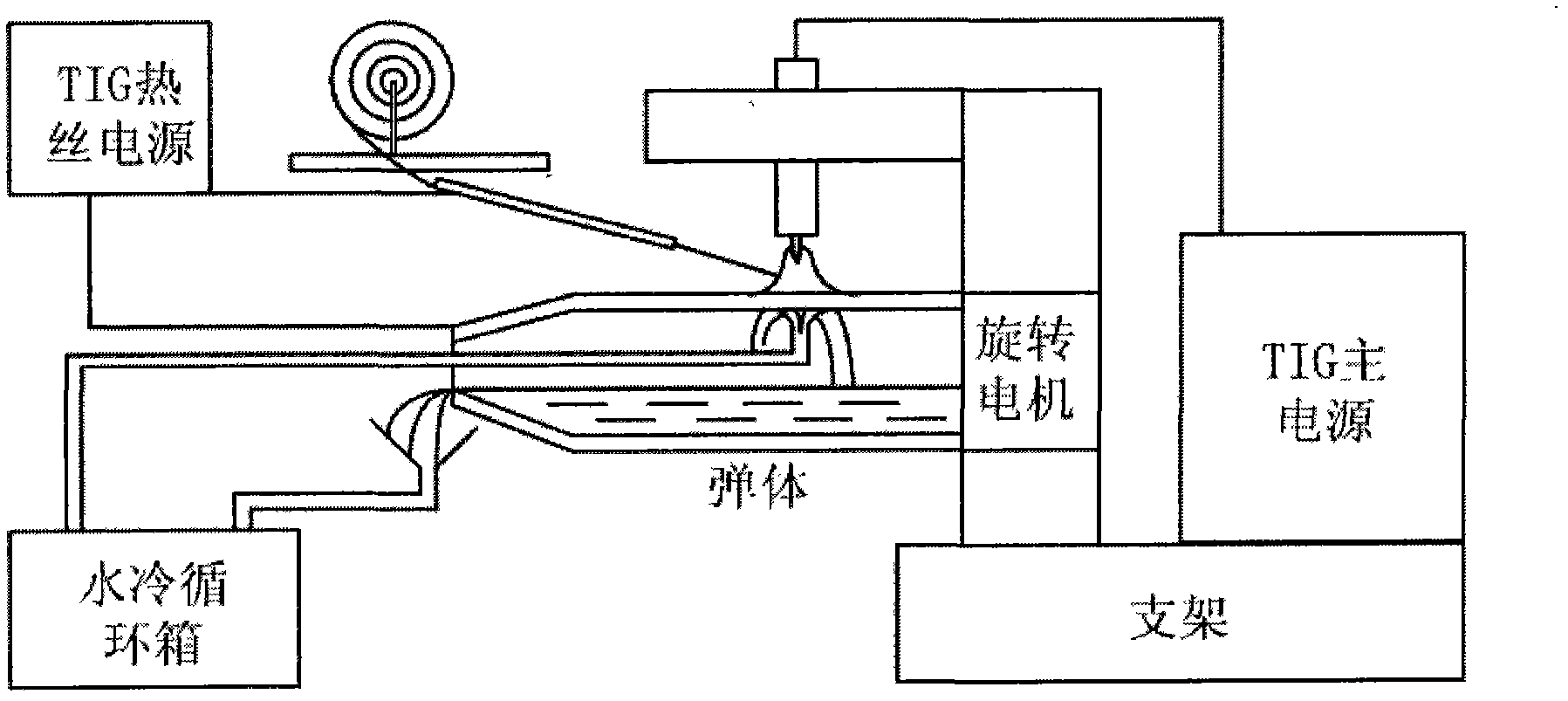

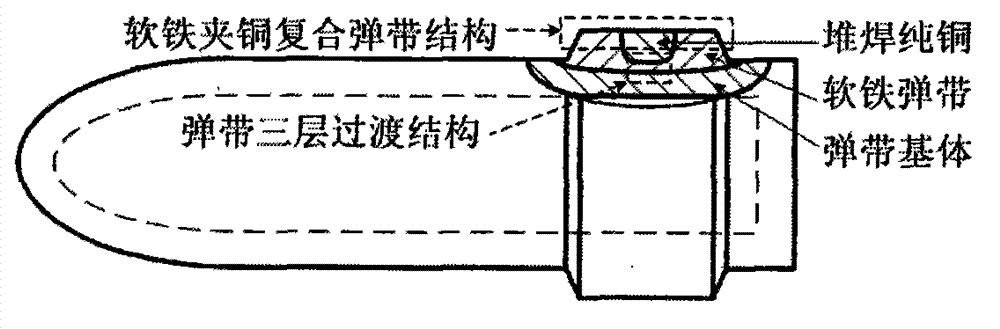

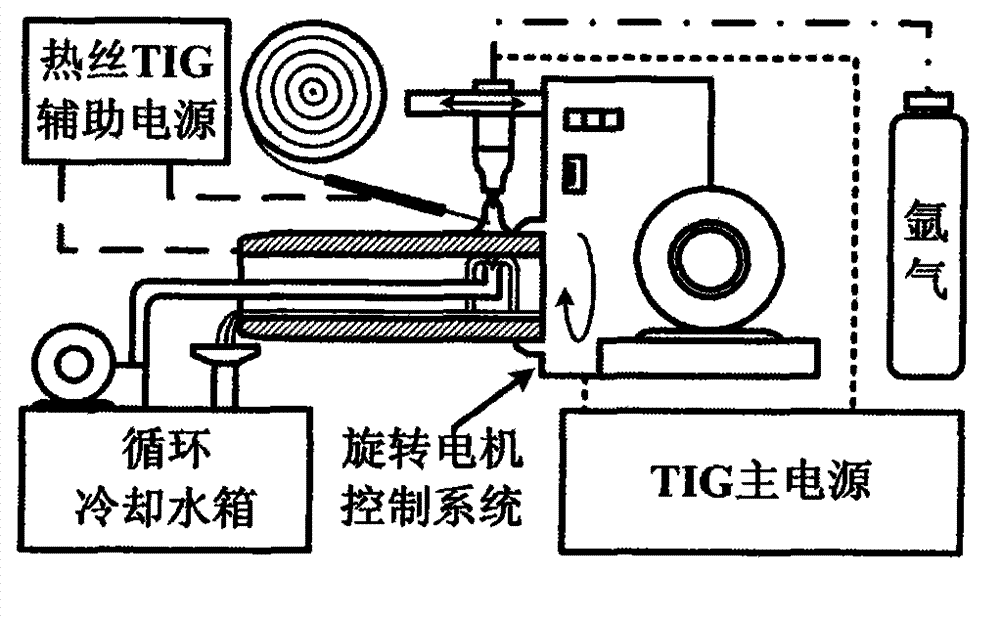

Soft iron-brass composite band structure and welding method thereof

InactiveCN102636084AHigh strengthIncrease stiffnessAmmunition projectilesArc welding apparatusHardnessUltimate tensile strength

The invention provides a soft iron-brass composite band structure and a welding method thereof. The soft iron-brass composite band structure uses two materials of soft iron and brass to overlay on the surface of an elastic body; the soft iron is located at the back of a band; and a brass part is located at the front part of the band. The welding method comprises the following steps of: firstly, welding a soft iron part; overlaying the brass part after cutting and machining to be flat; and finally, secondarily machining to form the entire band meeting design requirements. According to the soft iron-brass composite band structure and the welding method thereof provided by the invention, the properties and functions of the band can be improved by using own characteristics of the brass and the soft iron to complement the advantages of the brass and the soft iron. The characteristic of good air closeness of a soft iron band is maintained by using the composite band, so as to achieve a wider cannonball firing range. Compared with a brass band, the composite band only has the advantage that a half amount of the brass is used, so that the manufacturing cost is lowered. The composite band has the advantage of larger flexibility. Compared with the brass band, the soft iron band has the advantages of high strength, high rigidity and better air closeness. The rigidity, air closeness and the like of the band can be adjusted by adjusting the ratio of the soft iron and the brass in the band.

Owner:HARBIN INST OF TECH

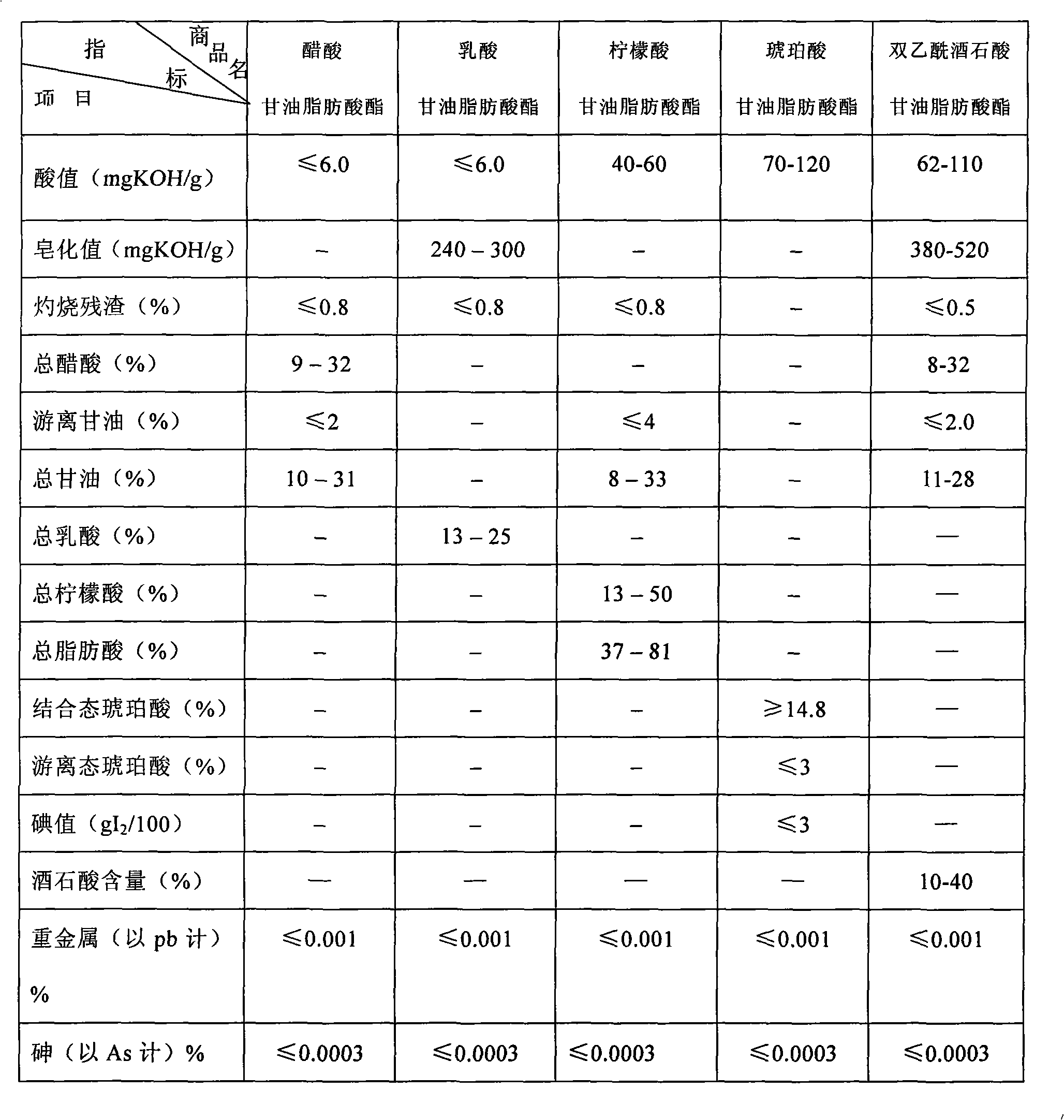

Method for preparing organic acid glycerin fatty acid ester

ActiveCN101633617ASimple structureIncrease elasticityPreparation by ester-hydroxy reactionMetal/metal-oxides/metal-hydroxide catalystsOrganic acidChemical synthesis

The invention discloses a method for preparing organic acid glycerin fatty acid ester, belonging to the technical field of organic chemistry synthesis. The method comprises: heating organic acid and glycerin fatty acid ester to 130-190 DEG C to have reaction in vacuum for 3-10h under the action of catalyst sodium hydroxide, potassium hydroxide, sulfuric acid or phosphoric acid, and obtaining the organic acid glycerin fatty acid ester. The synthesis method is simple and feasible as well as convenient for industrialized production, and has high conversion rate reaching 90%. The synthesized organic acid glycerin fatty acid ester can be used for food emulsifying agent, so as to lead the volume of food such as bread, cake and the like to be increased; furthermore, the organic acid glycerin fatty acid ester can improve the organization structure, enhance the elasticity, the toughness and the gas-holding performance of dough, and lead grease, plant fat cream and the like to have good emulsifying property.

Owner:河南正通食品科技有限公司

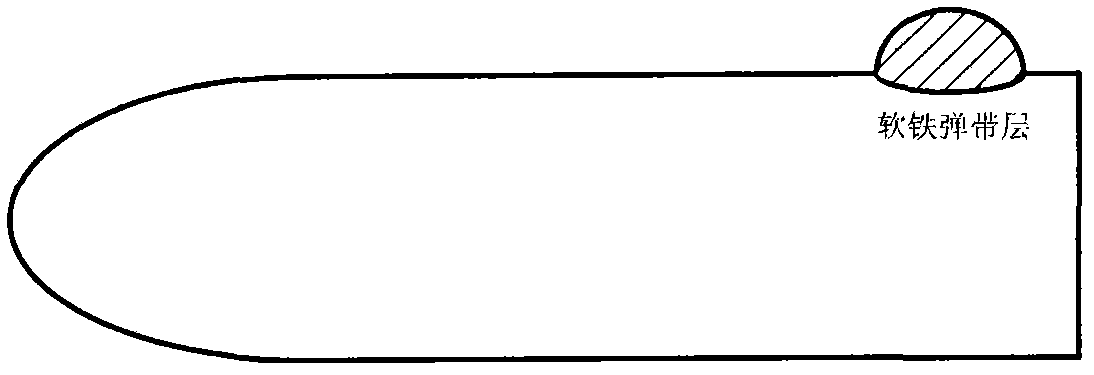

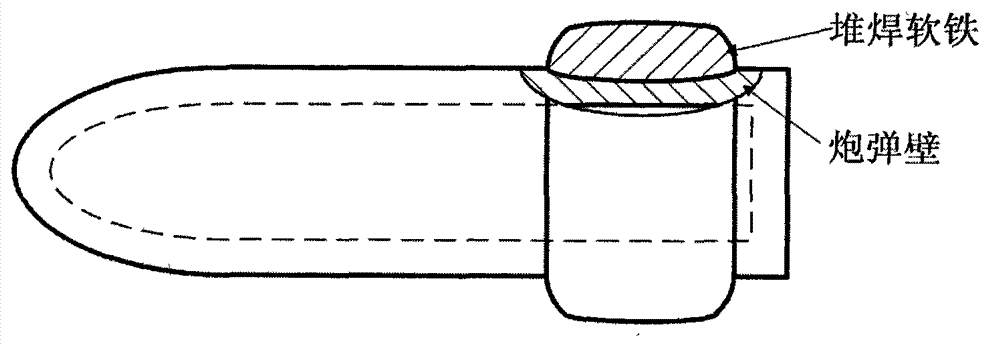

Method for welding composite bearing band of soft iron mixed with pure copper, and structure of composite bearing band

InactiveCN103071891AHigh strengthIncrease stiffnessAmmunition projectilesArc welding apparatusCarbon coatingHardness

The invention relates to a method for welding a composite bearing band of soft iron mixed with pure copper, and a structure of the composite bearing band. A bearing band is formed at the surface of a projectile body by overlaying of the soft iron and the pure copper; the soft iron part is welded firstly when the bearing band is surfaced on the surface of the projectile body; a middle open slot of the leveled soft iron bearing band is processed in a cutting manner; then the pure copper part is surfaced inside a groove; secondary cutting and processing are carried out, and finally the intact composite bearing band is formed. The ratio of the copper bearing band to the soft iron bearing band in the composite bearing band in the entire bearing band structure can be flexibly adjusted; and carbon coating and alloying of the bearing band in the welding process are better controlled, so as to adjust the strength, the hardness and the air-tightness of the bearing band. The method can adapt with different service conditions and application scenes. The traditional band-receiving structure is changed fundamentally; the wall of the projectile is thinned; and the charge mass is increased, so that the firing range of a shell is longer.

Owner:HARBIN INST OF TECH

High wheat bran dietary fiber steamed bread flour

The invention discloses high wheat bran dietary fiber steamed bread flour, belonging to the technical field of flour processing. The high wheat bran dietary fiber steamed bread flour is prepared from 65 to 85 parts of wheat flour, 10 to 25 parts of wheat bran fiber flour, 2 to 10 parts of wheat protein powder and 0.2 to 0.5 part of modifier. The modifier is prepared from Vc, glucose oxidase, lipase, sodium stearyl lactate, cellulose and xylanase; the wheat bran fiber flour is prepared by taking wheat bran as a raw material, and adopting a specific enzymolysis technology. A finished product of steamed bread prepared by adopting the high wheat bran dietary fiber steamed bread flour disclosed by the invention is good in leaven, soft in structure and good in palatability, and has unique leaven fragrance. According to the steamed bread contains more dietary fiber, particularly, the dietary fiber is processed through a unique technology, water-soluble dietary fiber therein is obviously increased, is complementary with non-soluble dietary fiber mutually, and is more beneficial to human health.

Owner:徐伟

Corn bread flour

The invention discloses corn bread flour which is prepared by mixing pure corn flour, frozen corn flour, puffed corn flour, raw soybean flour, glutelin flour, sodium carboxymethylcellulose, sodium pyrophosphate and yeast at a mass ratio of (25-35): (15-25): (5-15): (5-15): (25-35): (0.08-0.12): (0.02-0.03): (0.01-0.03). The bread prepared from the bread flour has soft and delicate mouthfeel, golden color and rich corn flavor; and in the processing, the bread can be steamed or baked after short time of fermentation.

Owner:铁岭市千水农产品加工有限责任公司

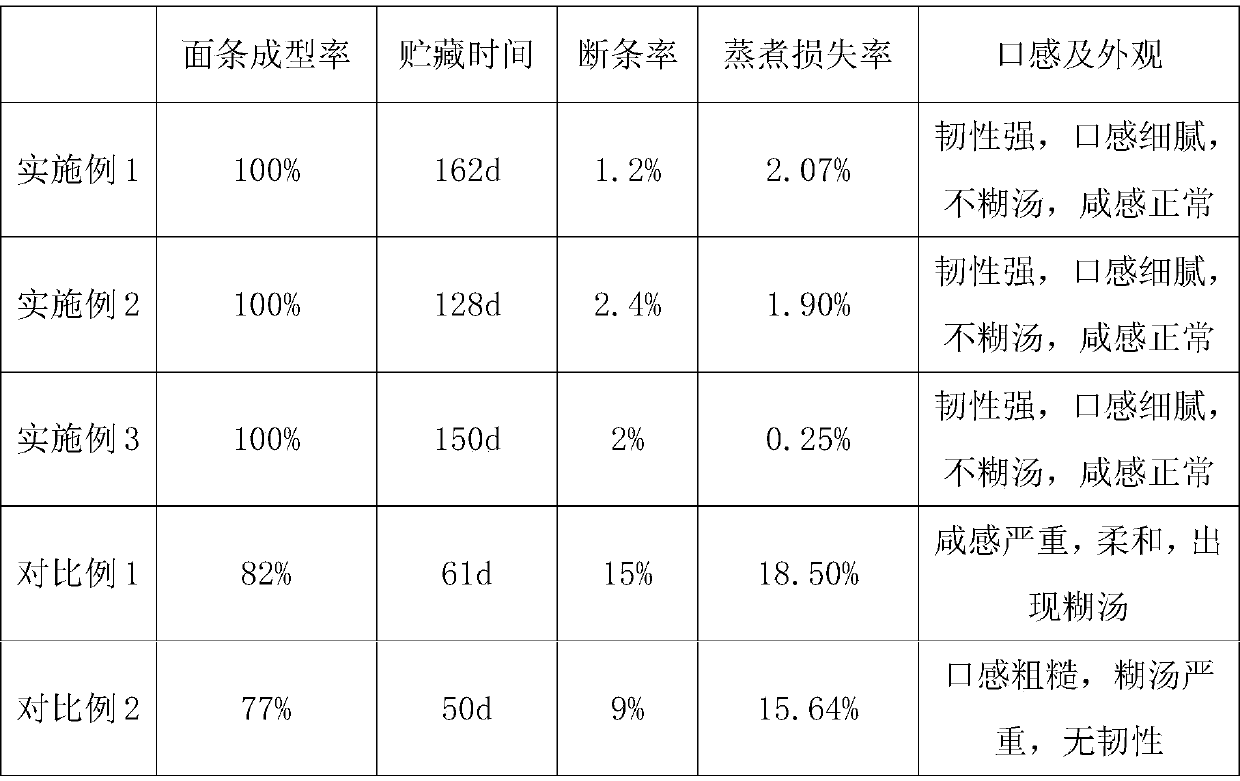

Convenient instant fresh wet noodle and preparation method thereof

The invention discloses a convenient instant fresh noodle and a preparation method thereof, and relates to the field of food processing. The convenient instant fresh wet noodle is mainly composed of high-gluten wheat flour, modified starch, vital gluten and salt. The addition of additives reduces indicator degradation of color, texture and microorganisms during storage. The noodle adopts an extrusion molding curing process to ensure long shelf life by pickling, modified atmosphere packaging and irradiation sterilization.

Owner:湖北戴氏食品科技股份有限公司

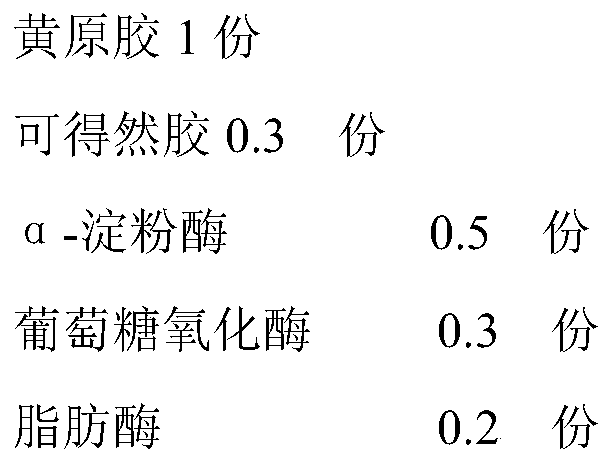

Quality modifier for compound multi-grain bread powder

InactiveCN102754673AEnhance gluten network structureEnhanced rheological stabilityDough treatmentSodium stearylXanthan gum

The invention relates to a quality modifier for compound multi-grain bread powder. The quality modifier comprises, by weight, 20-40 parts of wheat gluten, 7-11 parts of xanthan gum, 3-4 parts of guar gum and 3-4 parts of sodium stearyl lactate. The wheat gluten is also known as vital wheat gluten or gluten powder, the xanthan gum and the guar gum are thickening agents, and the sodium stearyl lactate is an emulsifier. The usage amount of the quality modifier accounts for 3.1-5.9% of the weight of the bread powder. The quality modifier is designed according to rheological property of the bread powder and quality promotion, the synergistic stabilizing effect of the natural wheat gluten, the xanthan gum and the guar gum is utilized, the emulsifier is added simultaneously, so that rheological parameters of the multi-grain bread powder are greatly improved, and simultaneously the optimized modifier enables storage stability of a final finished product and sensory quality of bread to be improved.

Owner:HEFEI UNIV OF TECH

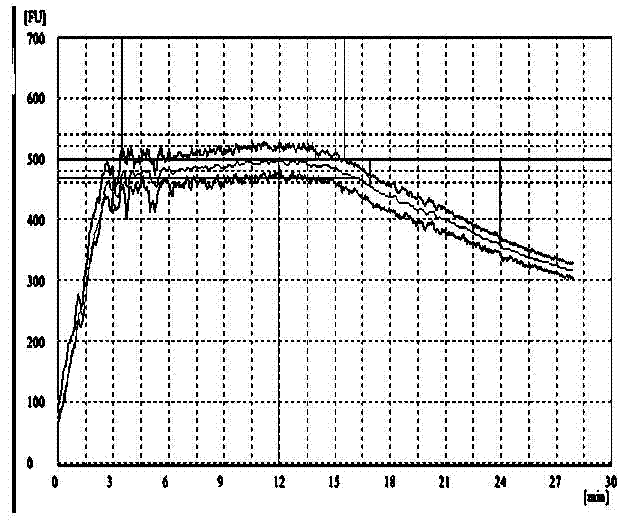

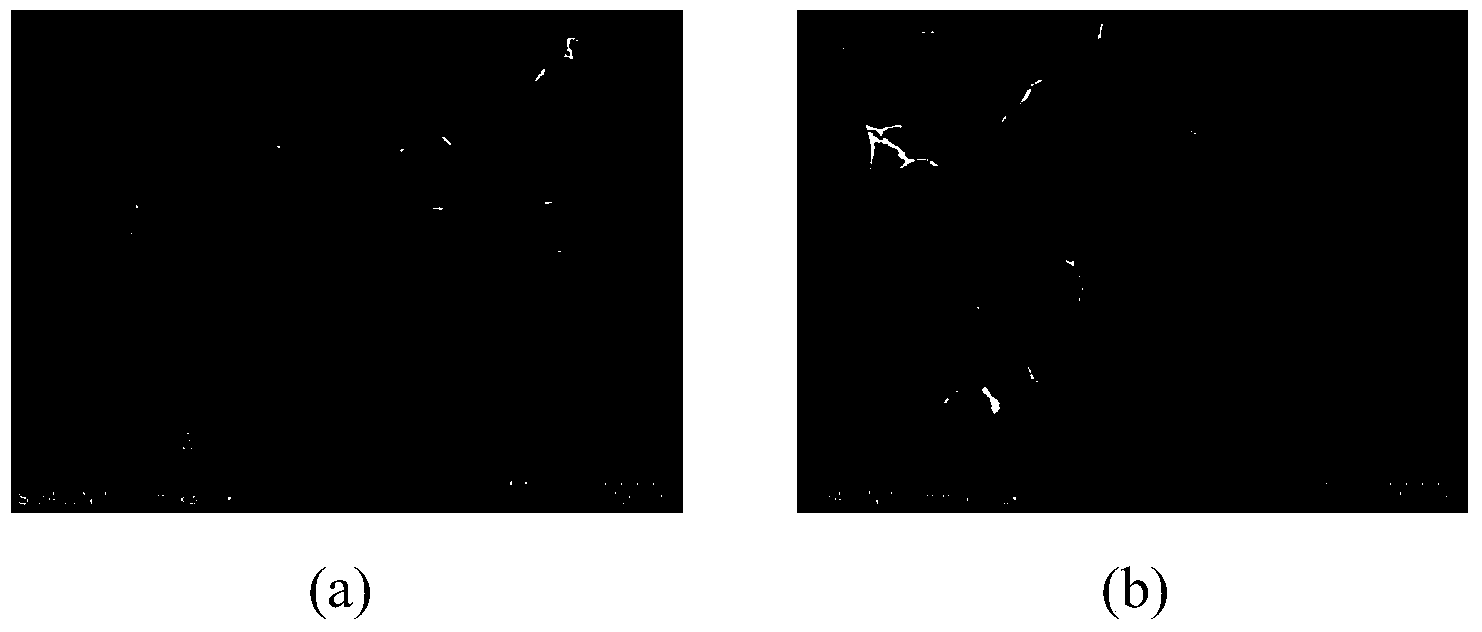

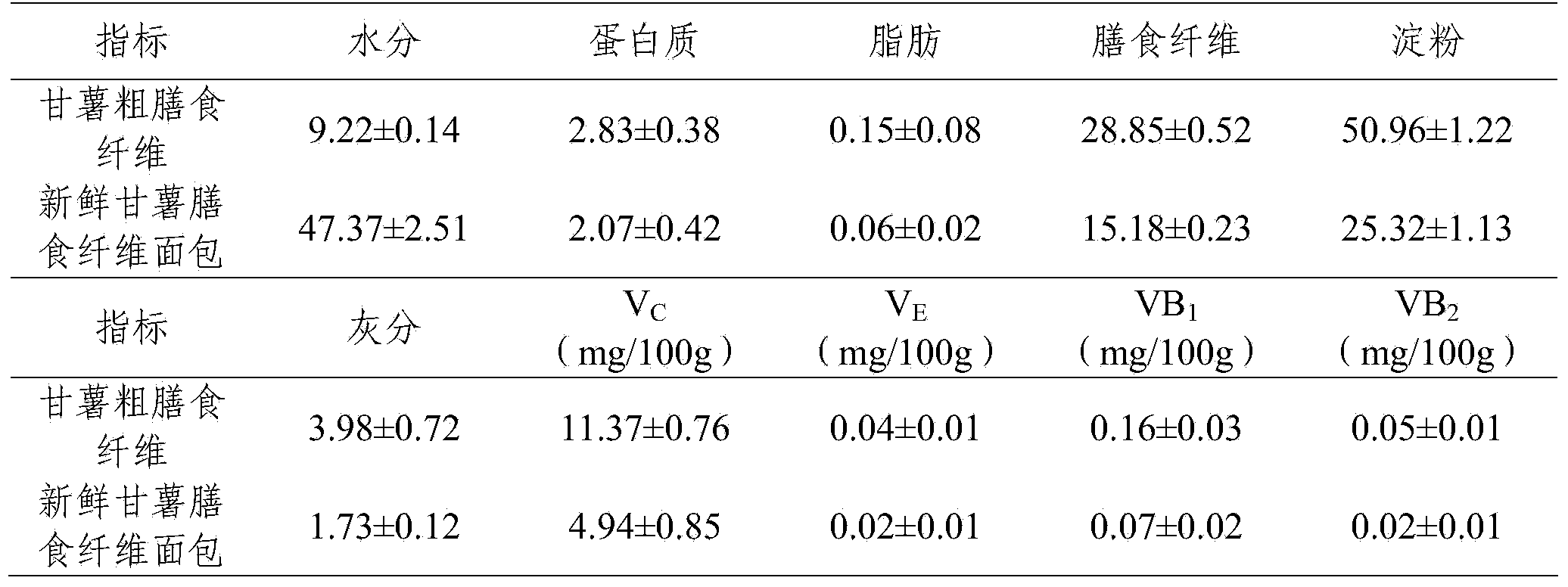

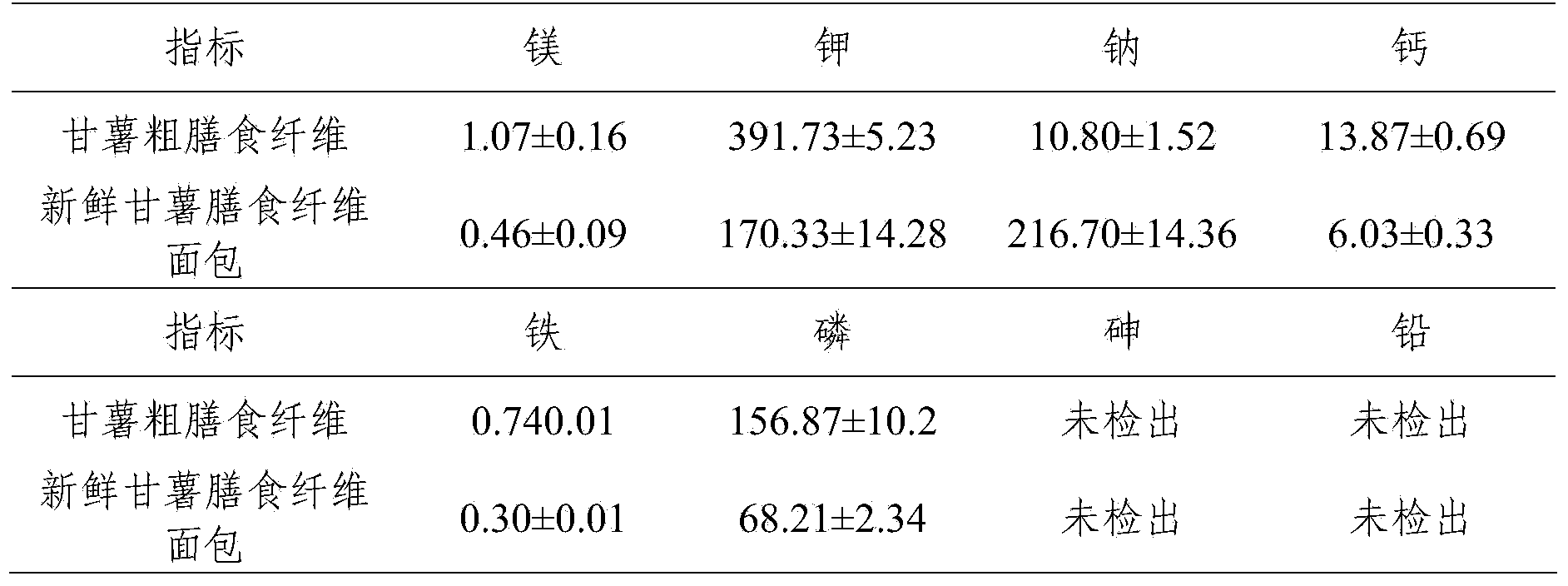

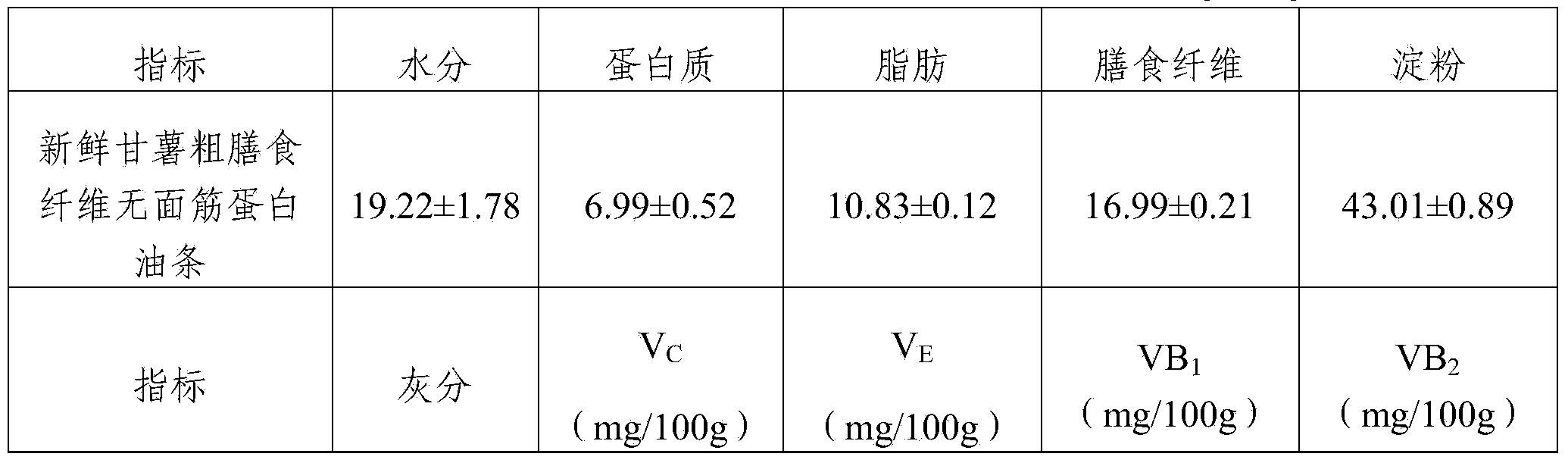

Bread rich in sweet potato dietary fiber and manufacturing method thereof

InactiveCN104365732AIncrease specific volumeIncrease in sizeDough treatmentModified nutritive productsFlavorYeast

The invention provides bread rich in sweet potato dietary fiber and a manufacturing method of the bread. The raw materials used for manufacturing the bread rich in sweet potato dietary fiber include, by mass, 10-40 percent of sweet potato rough dietary fiber starchy flour, 10-40 percent of sweet potato rough dietary fiber ultra-fine powder, 10-20 percent of high hydrostatic pressure synergy enzymolysis modified sweet potato rough dietary fiber powder, 4-12 percent of extrusion sweet potato rough dietary fiber powder, 5-12 percent of sweet potato starch, 5-13 percent of sweet potato modified starch, 0.2-6 percent of food gum, 1-3 percent of egg white, 0.5-3 percent of sugar, 0.1-1 percent of salt, 0.5-3 percent of yeast and the like. When the bread rich in sweet potato dietary fiber is manufactured, the weight ratio of the raw materials and water is 100:70-110. According to the method, the manufactured bread rich in sweet potato dietary fiber is large in specific volume, and has the unique flavor of sweet potatoes, the chewy taste is achieved, the color is slightly yellow, and the good nutrition and healthcare effects are achieved.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

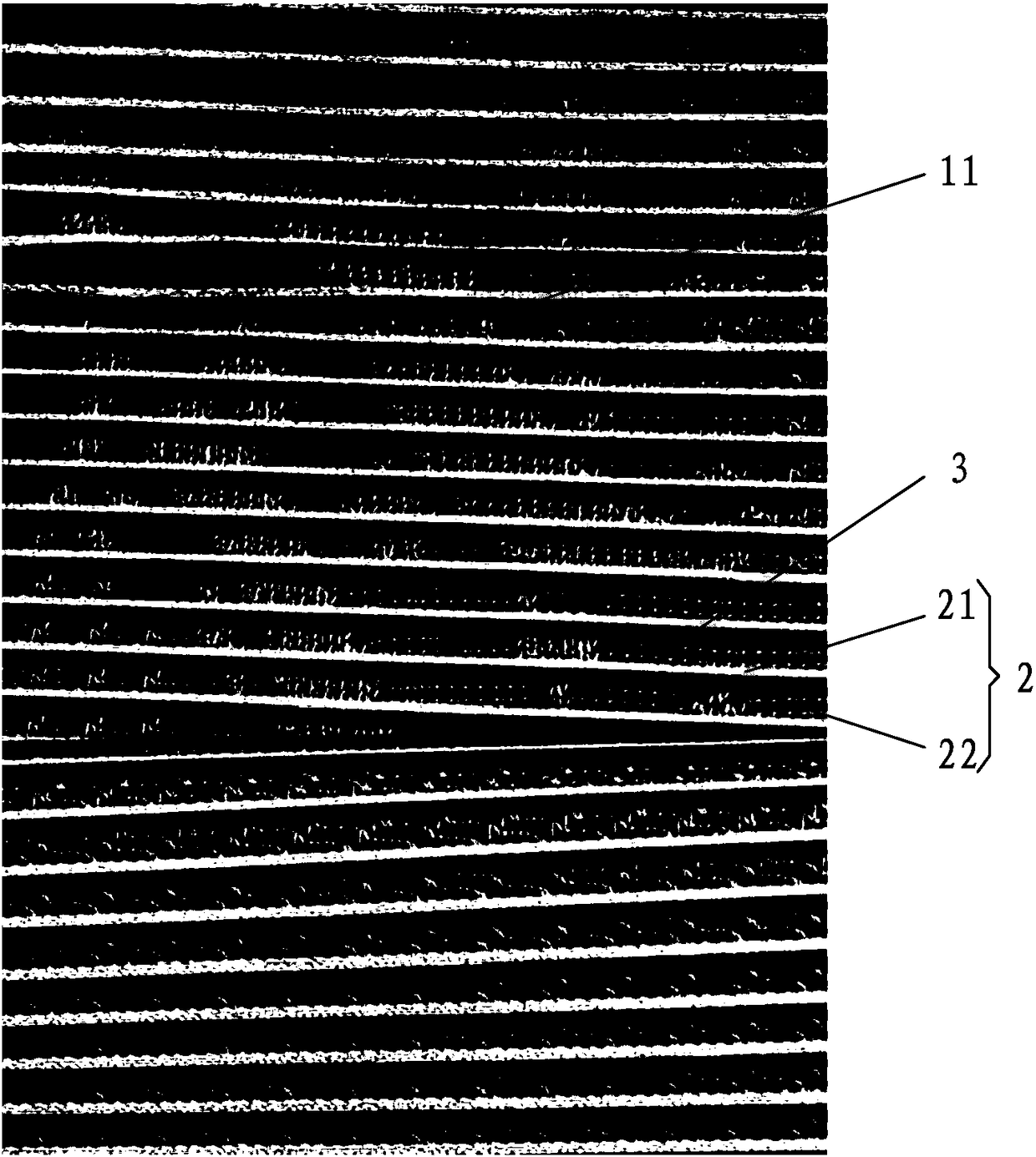

Jacquard fabric with color changing function and preparation method thereof

PendingCN108277574AImprove the three-dimensional effectIncrease breathabilityWarp knittingYarnEngineering

The invention provides jacquard fabric with a color changing function. The jacquard fabric comprises a jacquard bottom layer on which patterns are knitted and multiple flow guiding posts which are arranged on the jacquard bottom layer side by side, wherein the bottom part of each flow guiding post is connected to the jacquard bottom layer; all the flow guiding posts are distributed at intervals; aflow guiding groove is formed between two adjacent flow guiding posts; each flow guiding post comprises a first bulge and a second bulge which are in different colors and are connected in a width direction of the flow guiding post. The invention also provides a preparation method of the jacquard fabric with the color changing function. Two sides of the flow guiding posts are in different colors,so that the front surface of the jacquard fabric can be in varied integral colors in different angles. An abundant color changing effect can be expressed as the color of yarn per se can be changed under different angles, a corresponding color changing structure of the jacquard fabric is stable, the jacquard fabric is not easy to damage, and the defects brought by addition of a color changing material can be avoided.

Owner:SINCETECH FUJIAN TECH CO LTD

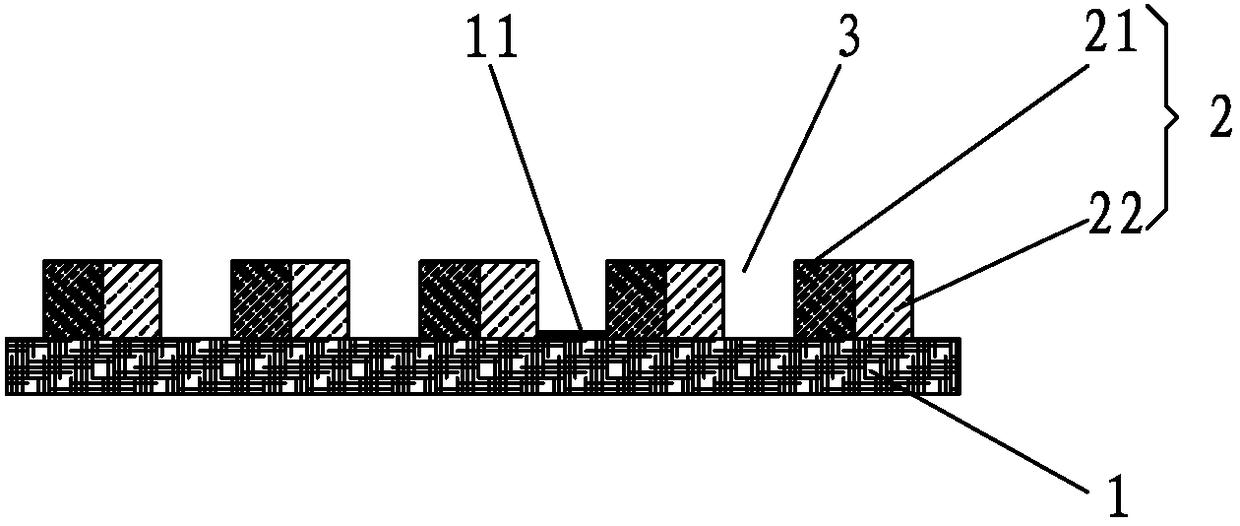

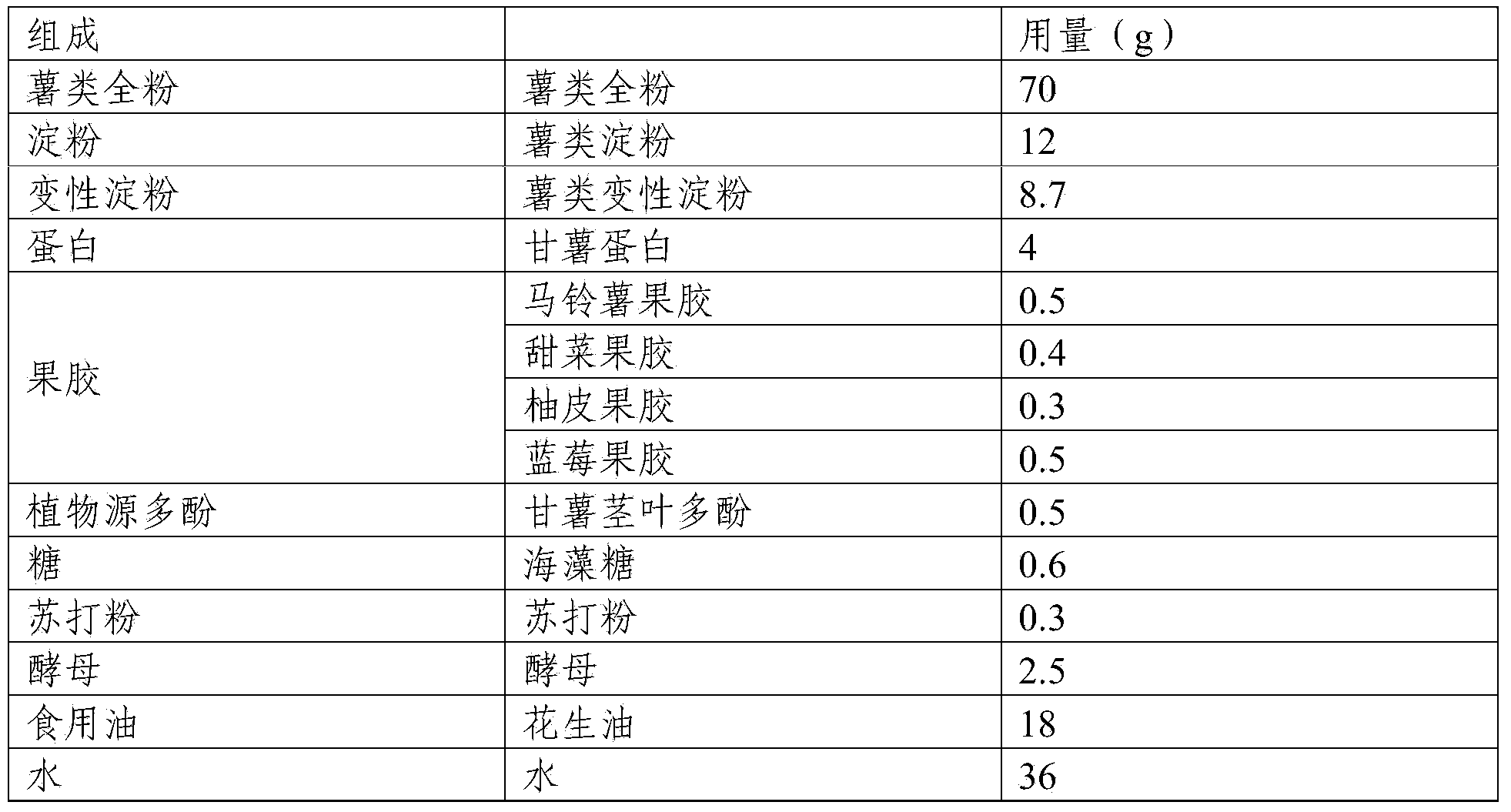

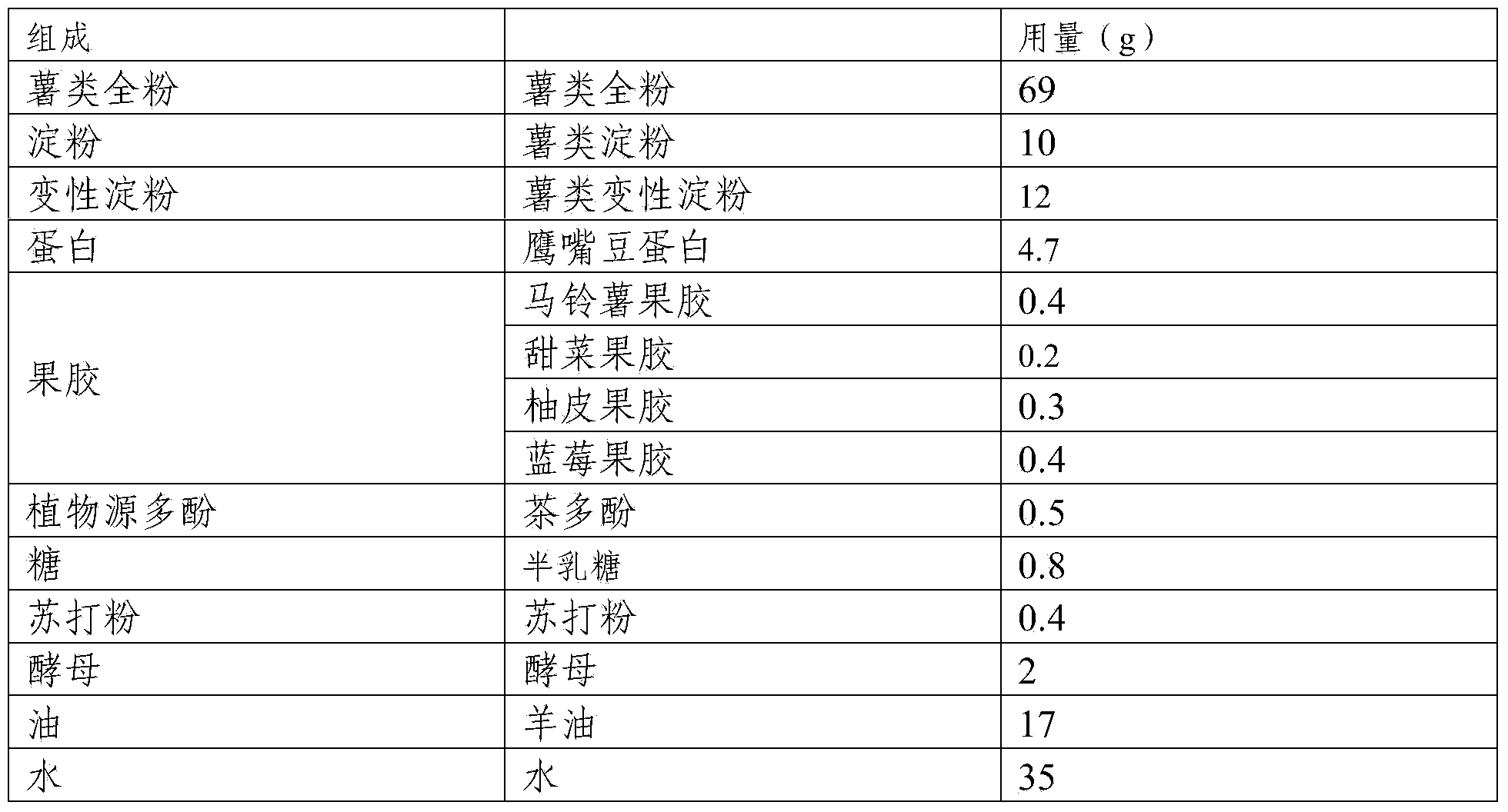

Baked pancake prepared from whole potatoes and preparation method thereof

ActiveCN104366378AIncrease specific volumeImprove featuresSugar food ingredientsFood preparationAdditive ingredientPotato starch

The invention provides a baked pancake prepared from whole potatoes and a preparation method of the baked pancake. Raw materials of the baked pancake comprise the following ingredients: whole potato flour, potato starch, modified potato starch, protein, pectin, plant-derived polyphenol, sugar, soda ash, yeast, edible oil and water. The baked pancake prepared from whole potatoes disclosed by the invention overcomes the shortcoming of a common wheat baked pancake that allergy of some people is caused due to existence of gluten protein, and the prepared baked pancake is suitable for people allergic to wheat or patients of celiac disease; moreover, the baked pancake has unique flavors of potato and sweet potato, is crisp in taste, contains rich ingredients such as protein, dietary fiber, vitamin and mineral elements, and has good nutrition and health efficacies.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Thermal insulation waterproof paint

The invention discloses thermal insulation waterproof paint which consists of the following raw materials in parts by weight: 70-76 parts of silicone acrylic emulsion, 0.7-1 part of triterpenoid saponin, 2-3 parts of hexafluorobutyl acrylate, 1-2 parts of ammonium polyphosphate, 0.7-1 part of N-hydroxymethyl acrylamide, 0.1-0.3 part of polybenzimidazole, 1.3-2 parts of hydrogenated castor oil, 3-4 parts of ceramic powder, 1-2 parts of diacetone alcohol, 0.1-0.2 part of molybdenum boride, 1-2 parts of saturated stearamide, 0.8-1 part of dibutyl maleate, 6-8 parts of quartz sand, 0.5-1 part of ammonium trimolybdate, 6-8 parts of coalescing agents and 10-30 parts of deionized water. The waterproof paint has high fluidity and adhesiveness; and due to the addition of the ammonium trimolybdate and ceramic powder, the gas tightness, elasticity and wear resistance of the film can be effectively improved, and the water resistance of the film is further enhanced.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

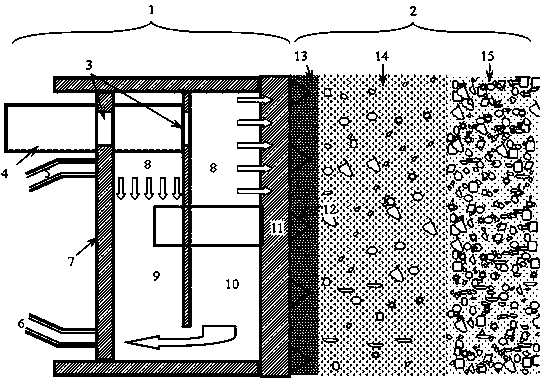

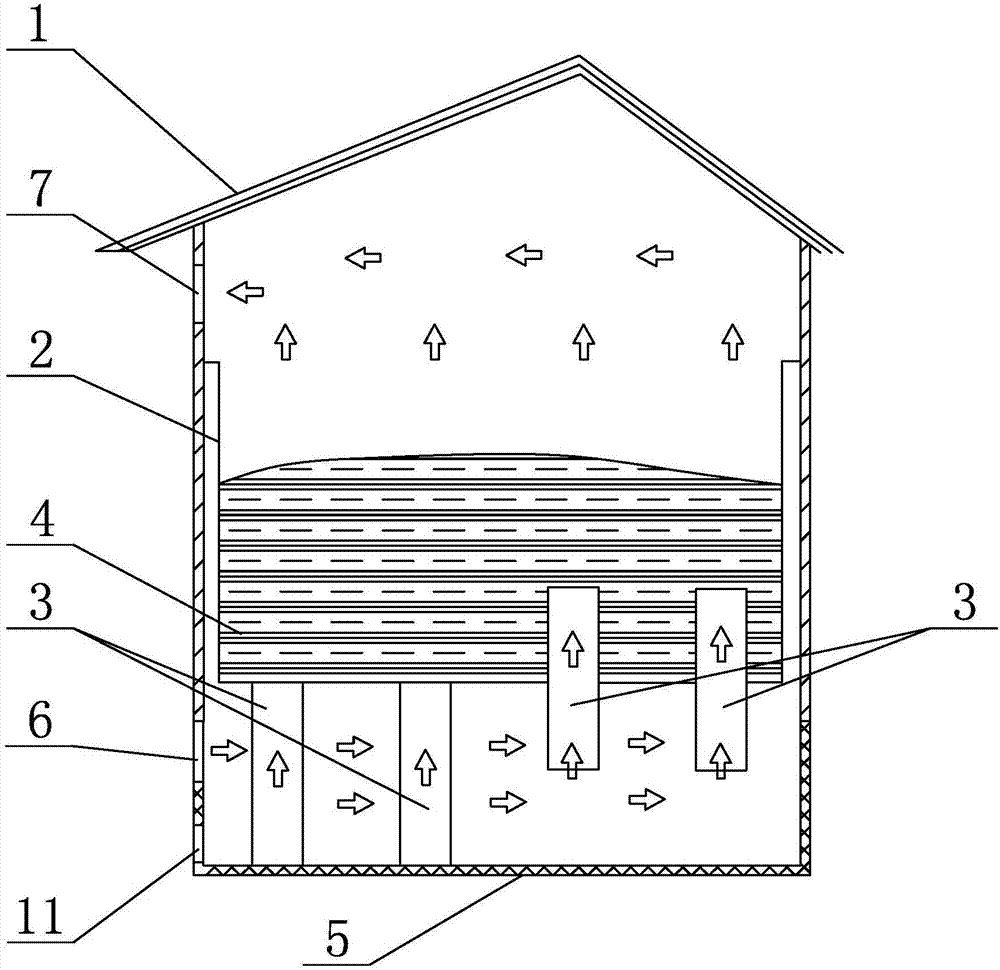

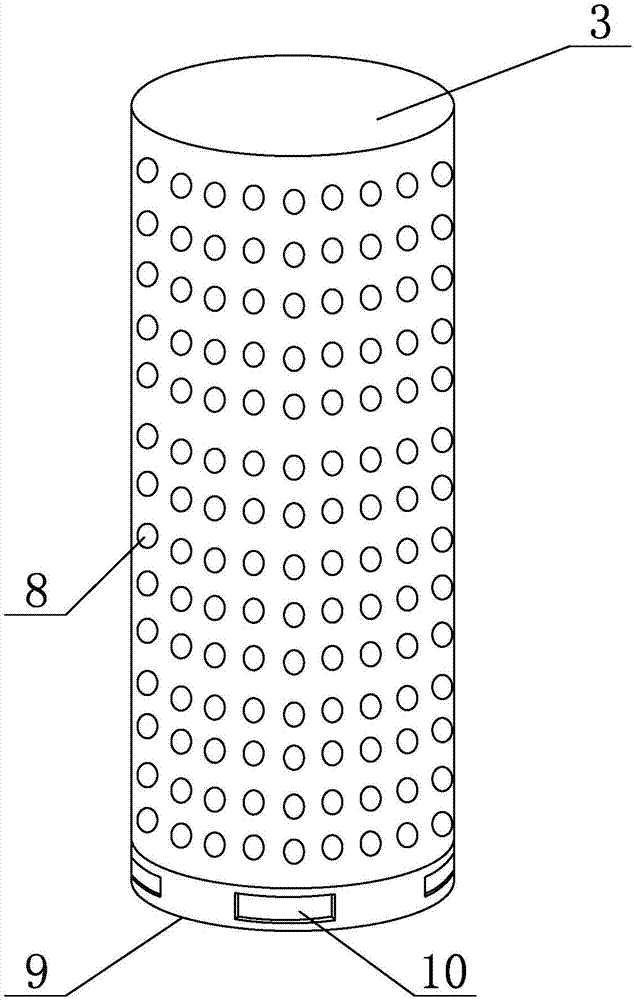

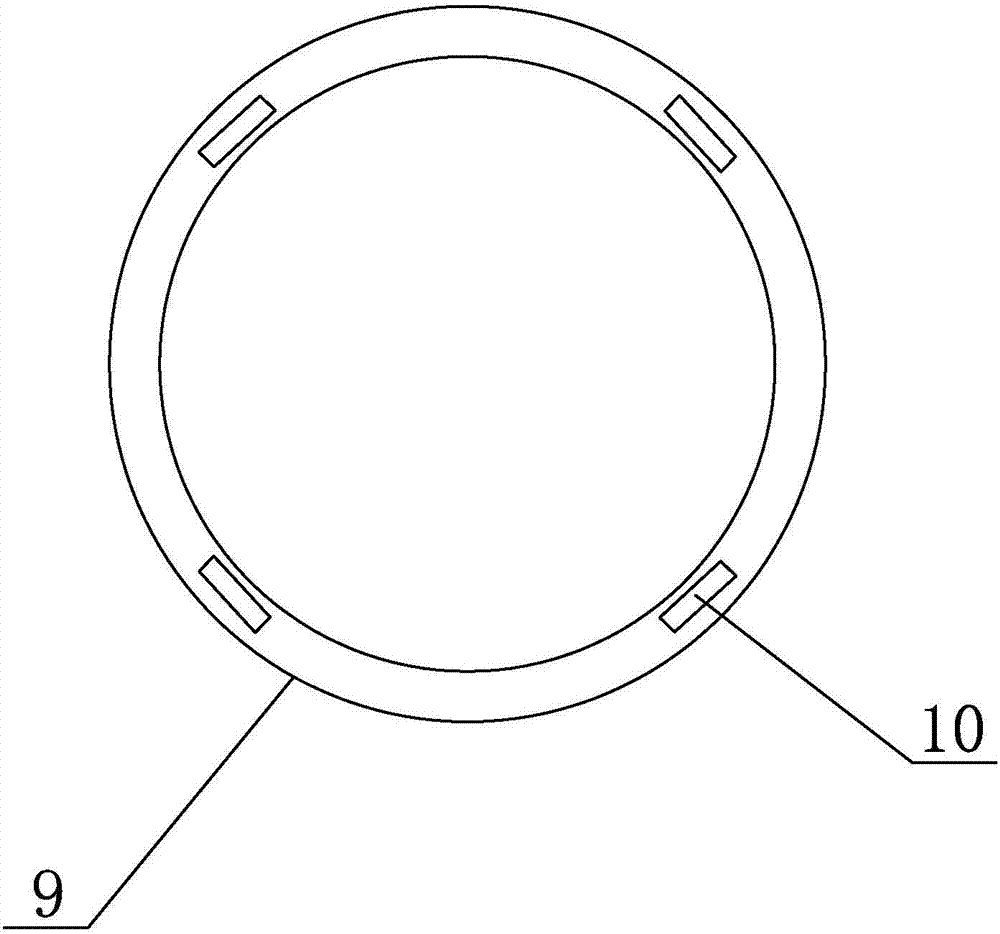

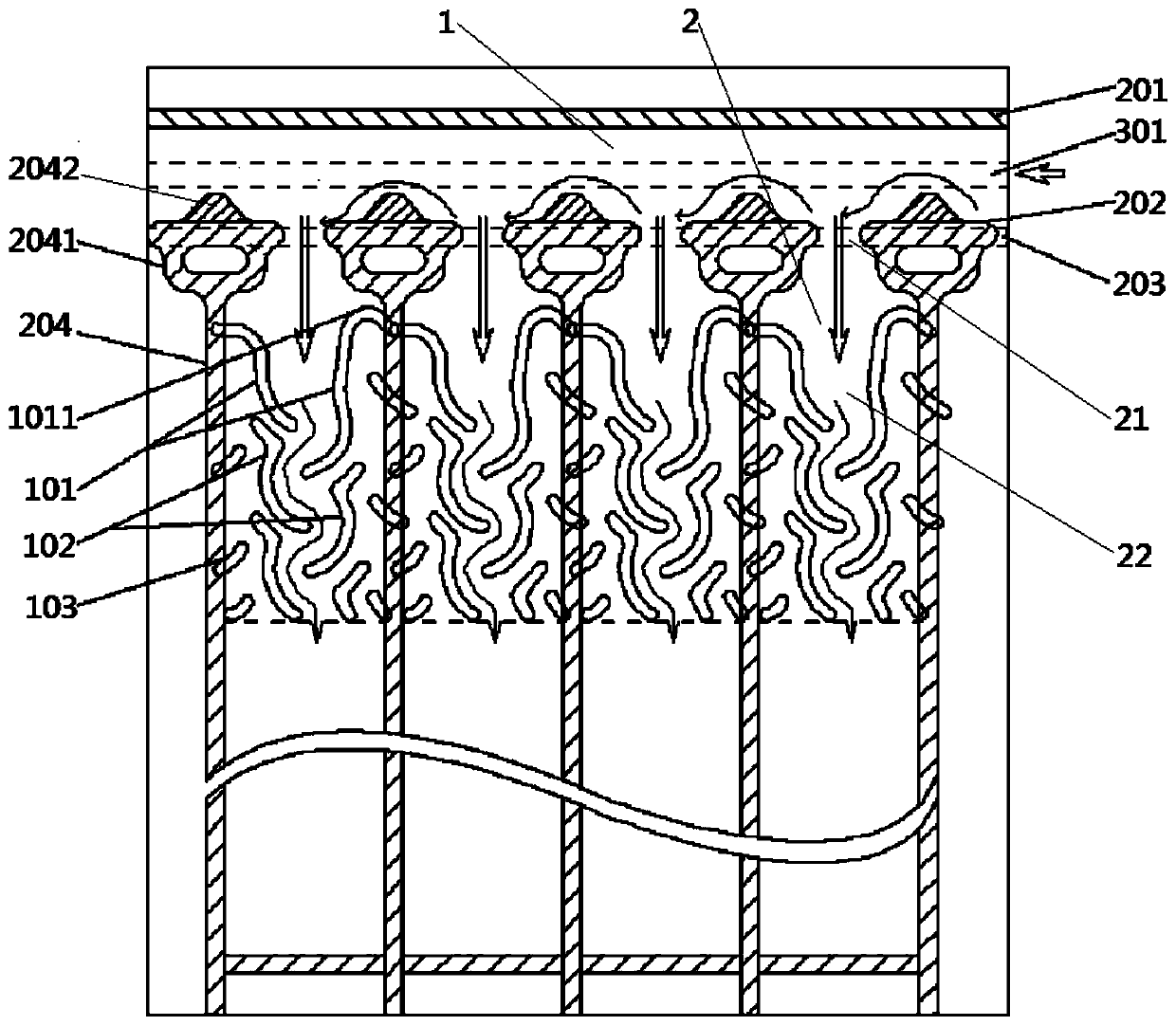

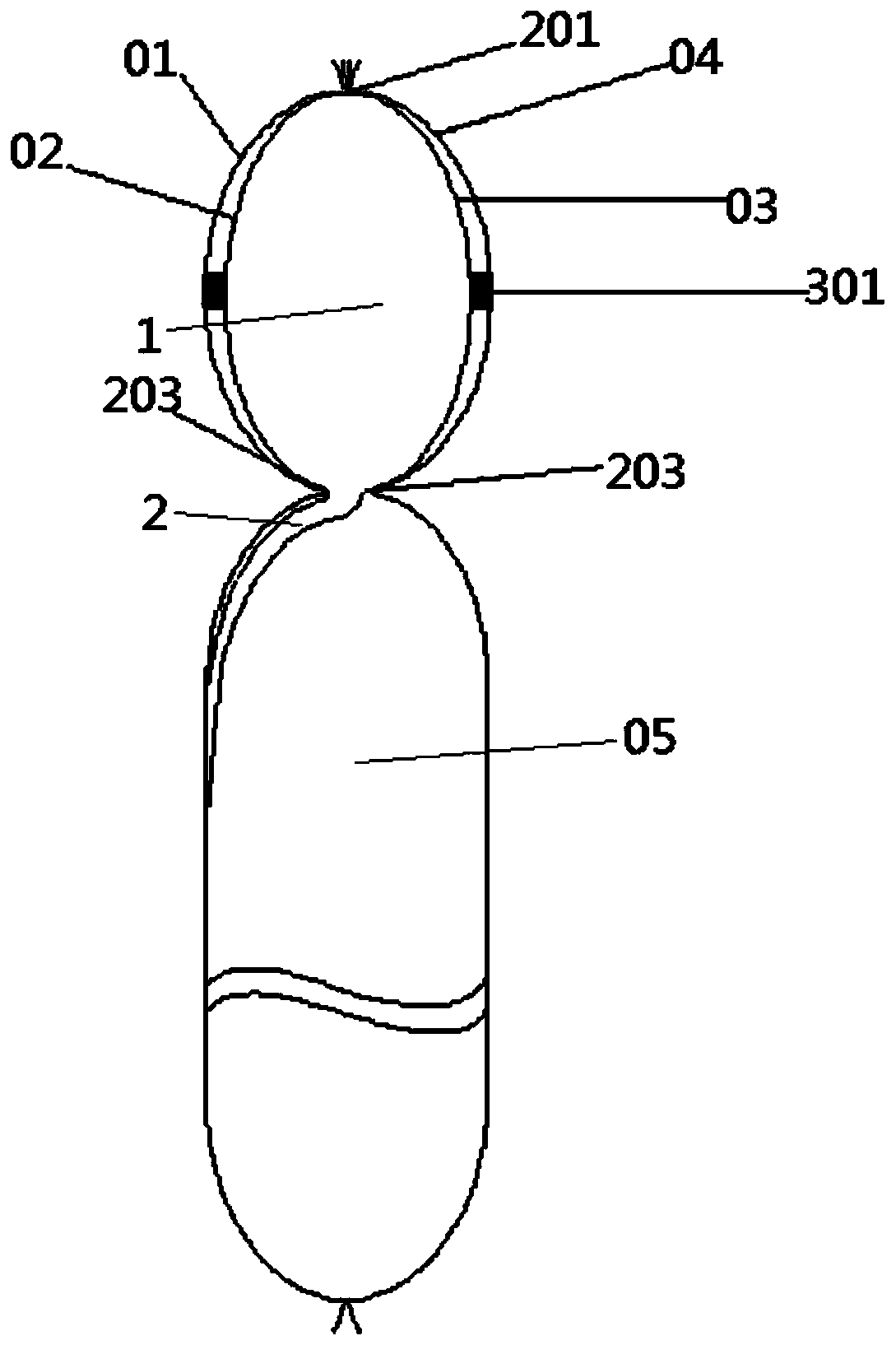

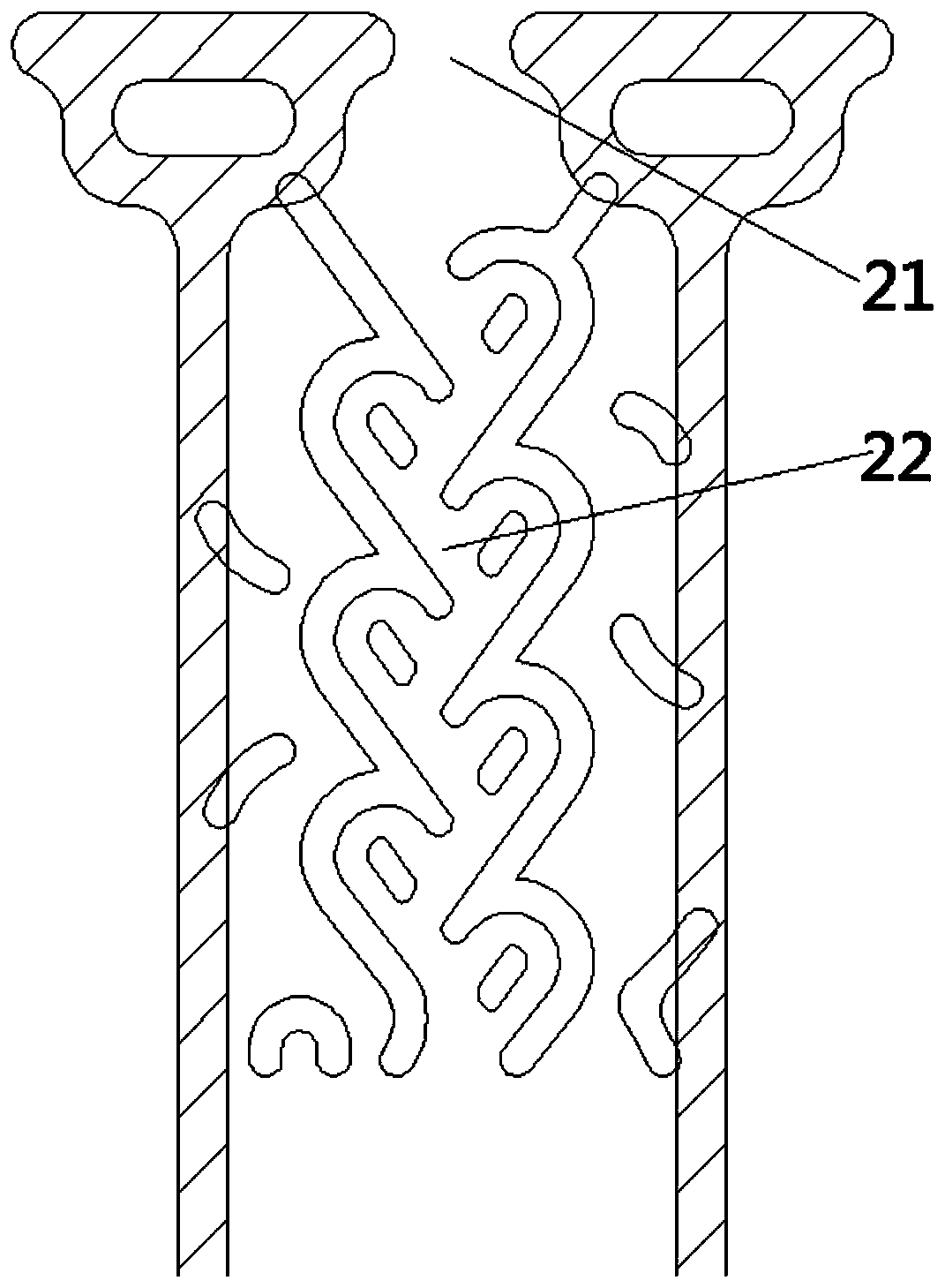

A vertical gas distribution device of an aerobic composting bin and a gas distribution method thereof

ActiveCN107200613AIncrease breathabilityStable and long-lasting ventilationProductsBio-organic fraction processingDistribution methodCompost

The invention relates to an arrangement device and method for composting, particularly a vertical gas distribution device of an aerobic composting bin and a gas distribution method thereof. At present, gas distribution pipes ventilated by force are liable to be blocked by organic materials so that local ventilation is nonuniform, cleaning is difficult and ventilation effects are poor. The device includes a composting room, a composting bin, a compost heap, a percolate tank and a plurality of branch gas distribution pipes. The plurality of branch gas distribution pipes are arranged at the bottom of the composting room. Each branch gas distribution pipe reciprocates along the height direction of the composting room. The percolate tank is at the bottom of the composting room and is right under the plurality of branch gas distribution pipes. The side wall of the percolate tank is provided with an air feeding port. The side wall of the composting room is provided with a gas outlet. The inside of the composting room is the composting bin. The compost heap is in the composting bin. The top of each branch gas distribution pipe is a sealed end. The side wall of each branch gas distribution pipe is provided with a plurality of vent holes. The bottom end of each branch gas distribution pipe is communicated with the percolate tank. The device and the method are used for ventilation during composting.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

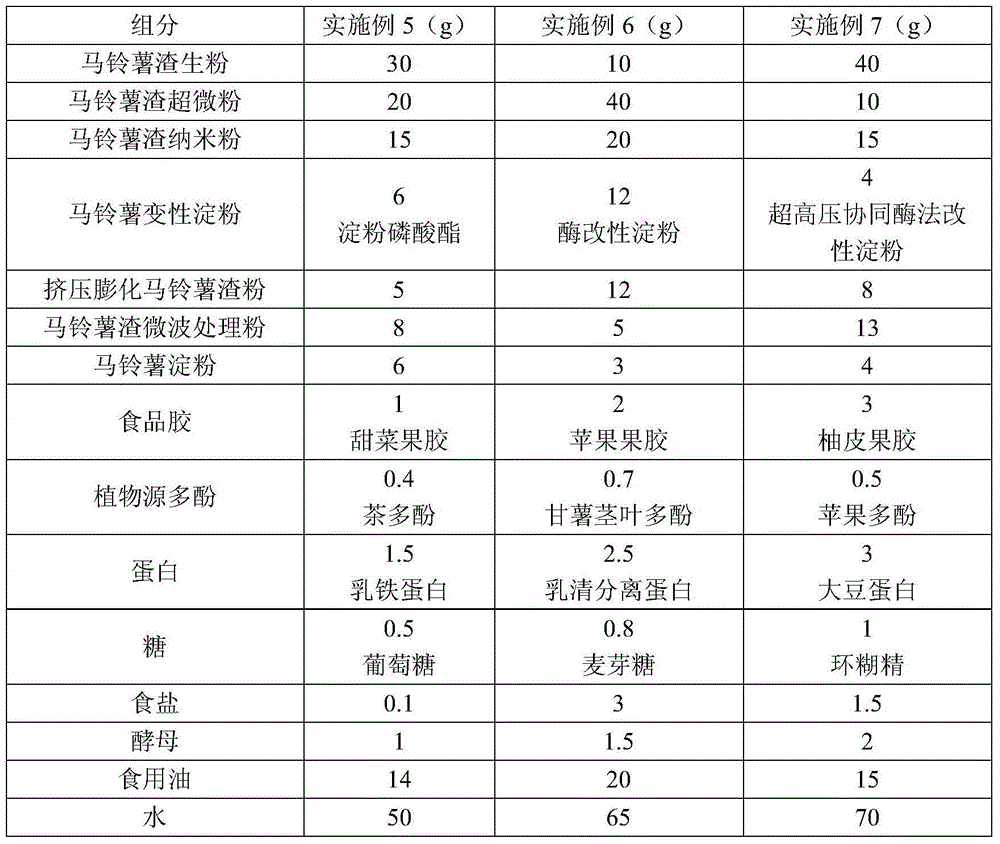

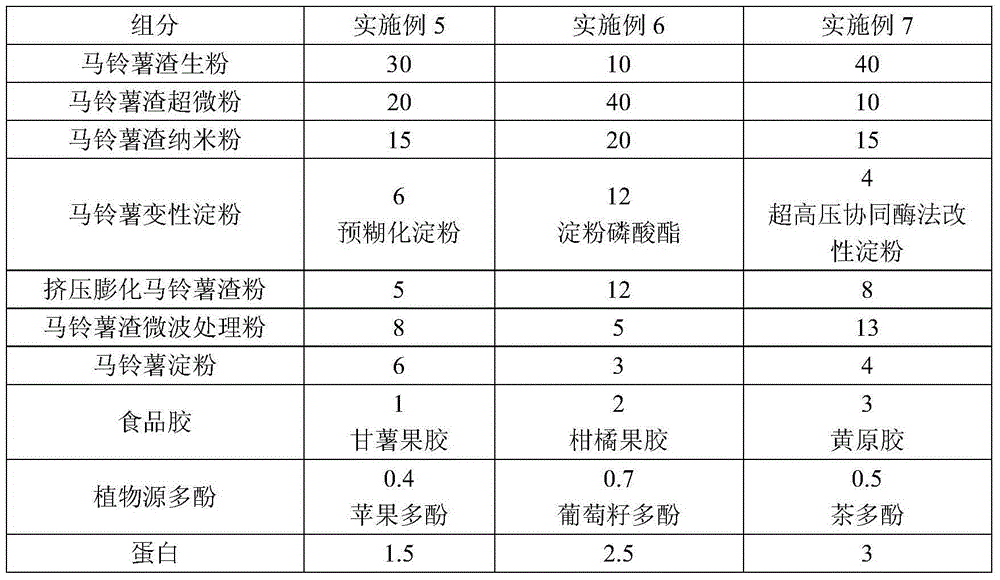

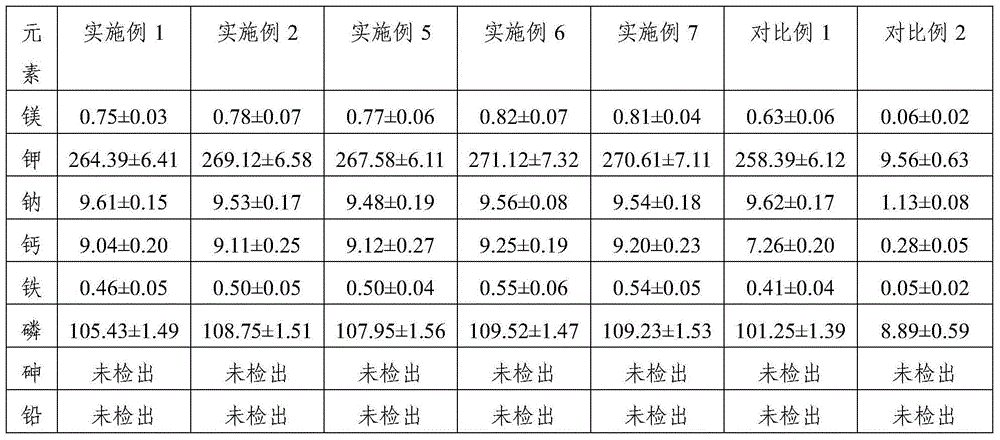

Mucedin-free potato residue baked nang and processing method thereof

ActiveCN104431883AIncrease in sizeHigh nutritional valueBakery productsFood preparationChemistryEdible oil

The invention relates to the field of foods and particularly relates to a mucedin-free potato residue baked nang and a processing method thereof. The mucedin-free potato residue baked nang comprises the following raw materials in parts by weight: 10-40 parts of potato residue flour, 10-40 parts of potato residue superfine powder, 10-20 parts of potato residue nanometer powder, 4-12 parts of potato modified starch, 5-12 parts of extruded potato residue powder, 5-13 parts of potato residue microwave processing powder, 1-6 parts of potato starch, 0.1-3 parts of salt, 1-2 parts of yeast, 14-34 parts of edible oil and 20-69 parts of water. Component analysis results show that the contents of protein, minerals, dietary fibers, vitamins and antioxidant substances in the mucedin-free potato residue baked nang provided by the invention are obviously higher than those in the existing wheat baked nang.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

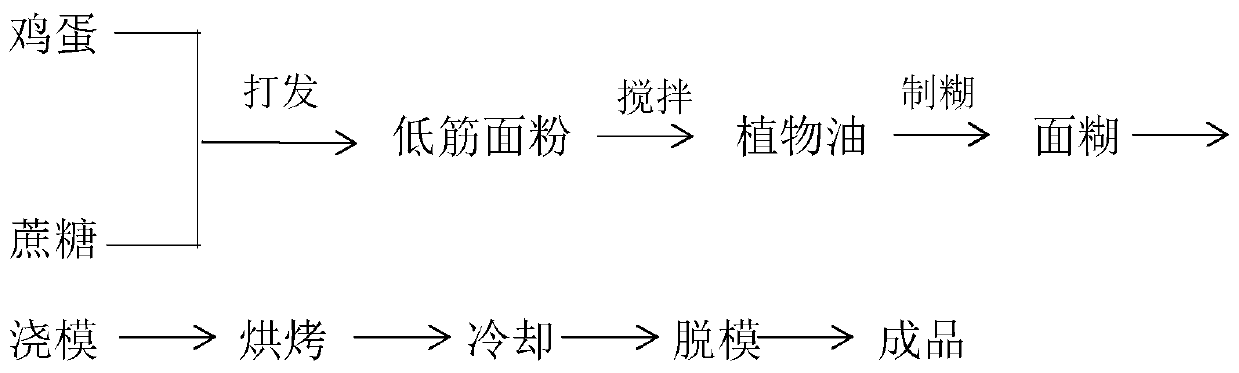

Making technology of rice flour sponge cake

InactiveCN106305941AHigh selectivityIncrease industrial conversion rateBakery productsSponge cakeRice flour

The invention relates to a making technology of a rice flour sponge cake, relates to a making technology of a sponge cake and aims to solve the problem of high probability of allergy caused by cakes prepared from wheat flour. The making technology comprises the following steps: 1, rice flour, precooked and gelatinized rice flour, water, soft sugar, an egg liquid, baking powder and sugar-free milk powder are weighed; 2, the egg liquid, the sugar-free milk powder and the soft sugar are mixed, sugar grains are dissolved, the mixture is agitated at a low speed and then agitated at a high speed until the mixture becomes milky foam; 3, precooking and gelatinization are performed; 4, the baking powder is added and agitated; 5, the rice flour is added in separate times and agitated until the rice flour and the egg liquid are uniformly mixed, and cake paste is obtained; 6, the paste is injected into a mold; 7, baking is performed; 8, the cake is taken out of an oven and cooled. The wheat flour used in traditional bakery is replaced with the gluten-free rice flour, and part of the wheat flour is precooked and gelatinized, so that the viscosity and air holding capacity of the cake paste are improved. A finished product has mild taste, high digestibility and extremely low allergy. The making technology is used for making the sponge cake.

Owner:HARBIN UNIV OF COMMERCE

High-fiber bread capable of prolonging ageing time and preparation method thereof

InactiveCN107396950AGreat tastePromote absorptionDough treatmentPre-baking dough treatmentFiberYeast

The invention discloses a kind of high-fiber bread capable of prolonging ageing time. The high-fiber bread is prepared by the materials including, by weight, 3-5 parts of oat powder, 3-5 parts of buckwheat powder, 3-5 parts of sorghum rice flour, 2-4 parts of red bean powder, 2-4 parts of red-skinned millet flour, 80-120 parts of high gluten wheat flour, 4-6 parts of active dry yeast, 2-4 parts of bread improver, 12.5-17.5 parts of soft white sugar, 0.8-1.5 parts of salt, 8-12 parts of eggs, 8-12 parts of butter, 6-10 parts of plant oil, 0.4-0.6 parts of soya bean lecithin, 0.002-0.004 parts of ascorbic acid, 0.001-0.003 parts of alpha-amylase, and 40-60 parts of water. The preparation method of the high-fiber bread comprises the steps of pretreatment of raw materials; dough mixing; primary fermentation; segmenting and shaping; proofing; baking; and cooling and packaging. The bread is high in dietary fiber content and long in aging time, bread kinds are enriched, and the preparation technology of the bread is simple.

Owner:XUZHOU UNIV OF TECH

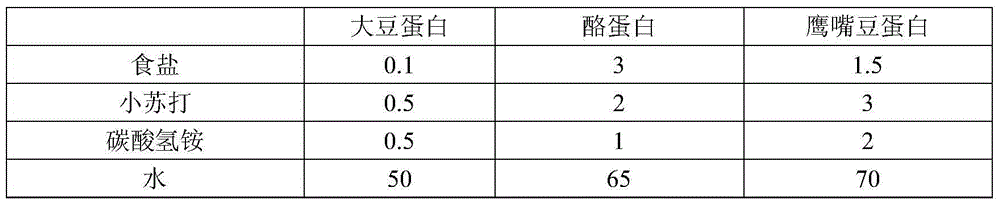

Potato residue no-mucedin fried bread stick and making method thereof

ActiveCN104381922AImprove featuresImprove sensory qualityFood ingredient for microbe protectionFood preparationSodium bicarbonateAmyris

The invention relates to the field of food and particularly relates to potato residue no-mucedin fried bread stick and a preparation method thereof. The fried bread stick comprises the following raw materials in parts by weight: 10-40 parts of potato-residue raw powder, 10-40 parts of potato-residue ultrafine powder, 10-20 parts of potato-residue nano powder, 4-12 parts of potato-residue modified starch, 5-12 parts of extruded and puffed potato-residue powder, 5-13 parts of potato-residue microwave-treated powder, 0-6 parts of potato starch, 0-3 parts of food gum, 0-0.7 parts of plant-source polyphenol, 1-10 parts of protein, 0-3 parts of salt, 0.5-3 parts of sodium bicarbonate, 0.5-3 parts of ammonium bicarbonate and 20-69 parts of water. The fried bread stick is crispy and tasty in mouthfeel, and the contents of protein, mineral, dietary fiber, vitamin and antioxidant substance are obviously superior to the content of the existing wheat flour fried bread stick.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

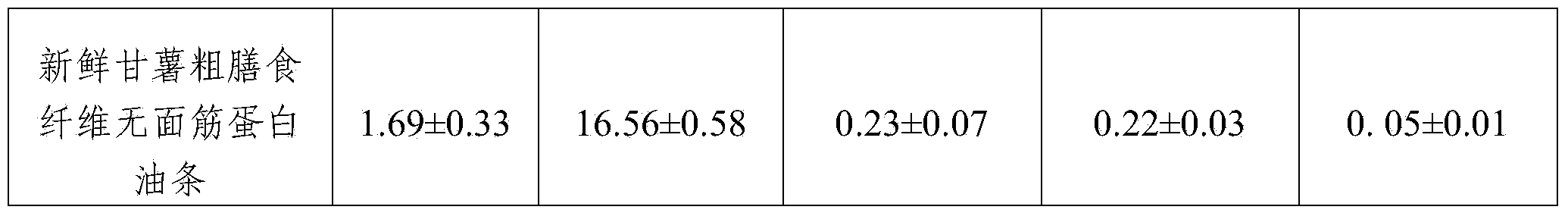

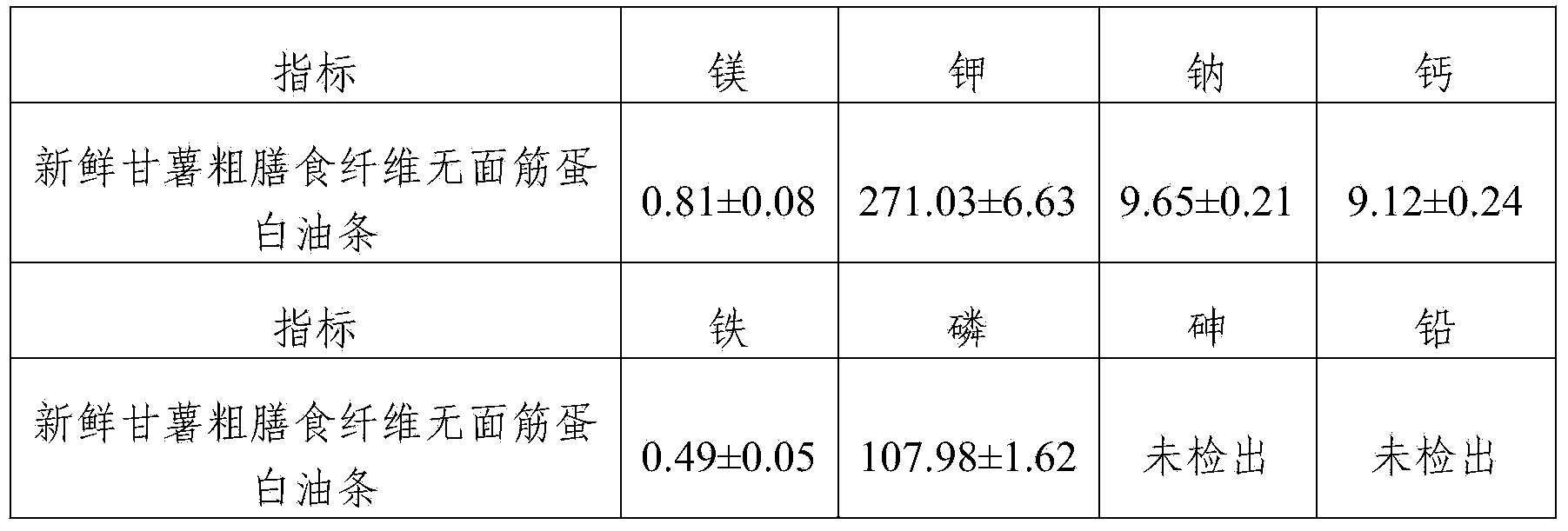

No-gluten fried bread stick made from sweet potato crude dietary fiber and preparation method thereof

InactiveCN104365735AImprove featuresImprove sensory qualityDough treatmentDeep-fried productsFiberPotato starch

The invention provides a no-gluten fried bread stick made from sweet potato crude dietary fiber and a preparation method of the fried bread stick. The raw materials used for making the no-gluten fried bread stick comprise, by weight, 10-40 parts of sweet potato crude dietary fiber potato starch, 10-40 parts of sweet potato crude dietary fiber super micropowder, 10-20 parts of sweet potato crude dietary fiber nanometer powder, 4-12 parts of sweet potato modified starch, 5-12 parts of extrusion sweet potato crude dietary fiber powder, 5-13 parts of sweet potato crude dietary fiber microwave processing powder, 0.5-6 parts of sweet potato starch, 0.1-3 parts of food gum, 0.1-0.7 part of plant source polyphenols, 1-10 parts of protein, 0.1-3 parts of salt, 0.5-3 parts of baking soda, 0.5-3 parts of ammonium bicarbonate, 20-69 parts of water and the like. The no-gluten fried bread stick made with the method has the unique taste of sweet potato, is crisp, tasty and refreshing, looks golden in color, is rich in the ingredients of protein, dietary fiber, vitamin, mineral elements and the like, and has good nutrition and health care efficacy.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

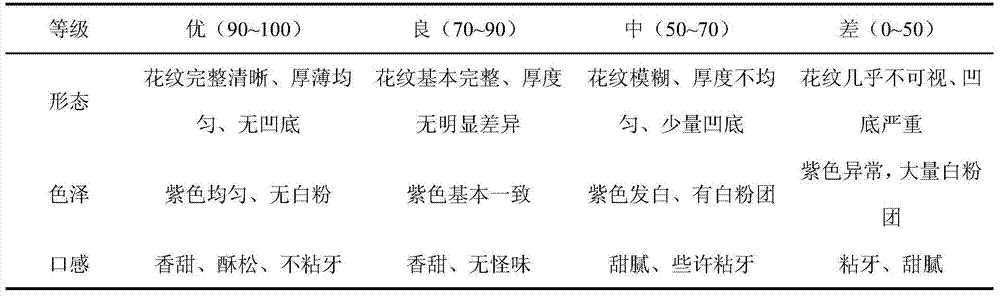

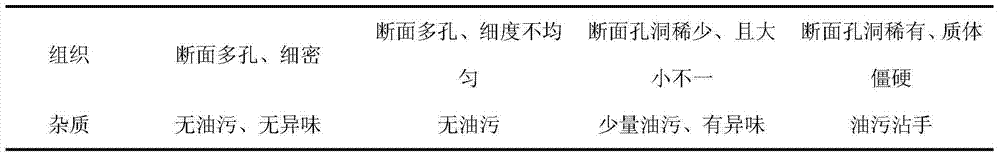

Purple-potato biscuit and small bun and preparation methods of purple-potato biscuit and small bun

ActiveCN104489035AReduced muscle strengthIncrease elasticityDough treatmentBakery productsVegetable oilSodium Caseinate

The invention discloses a purple-potato biscuit and a small bun and preparation methods of the purple-potato biscuit and the small bun. The purple-potato biscuit and the small bun are prepared from the flowing raw materials in parts by weight: 65-70 parts of high-gluten flour, 30-35 parts of whole purple-potato powder, 2-2.5 parts of soybean protein foam powder, 1.5-2 parts of rice protein foam powder, 1-1.5 parts of peanut protein foam powder, 5-10 parts of maltodextrin, 0.3-0.5 part of xanthan gum, 3-4 parts of xylitol, 0.1-0.12 part of proteoglycan, 0.1-0.2 part of salt, 0.1-0.15 part of tartaric acid, 0.3-0.5 part of sodium caseinate, 0.2-0.3 part of lecithin, and 3-5 pars of vegetable oil. The raw materials mixed, kneaded, formed, baked and cooling so as to obtain the purple-potato biscuit and the small bun. The purple-potato biscuit and small bun, disclosed by the invention are crisp, keep the color of natural purple potatoes, taste sweet, are not easy to be stuck to teeth, and are easy accept by consumers.

Owner:湖南国饼世家农业发展有限公司

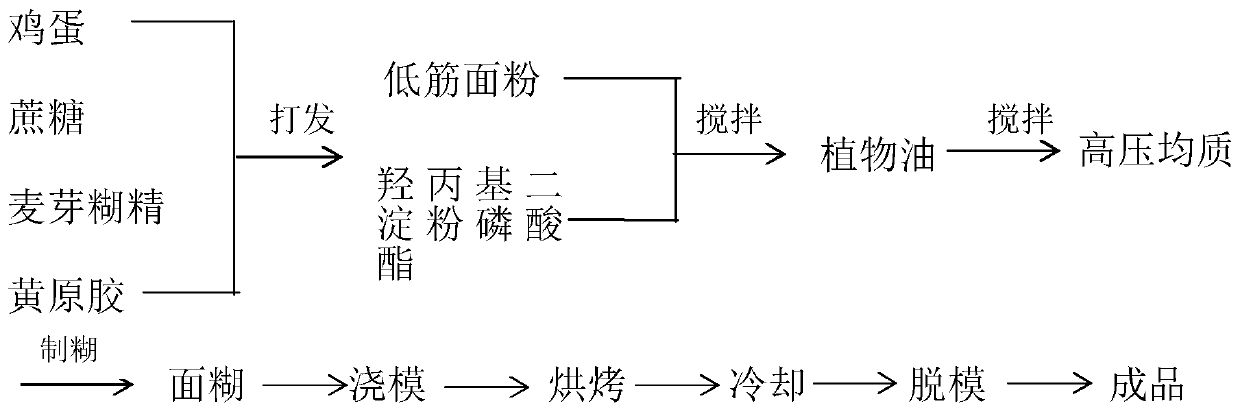

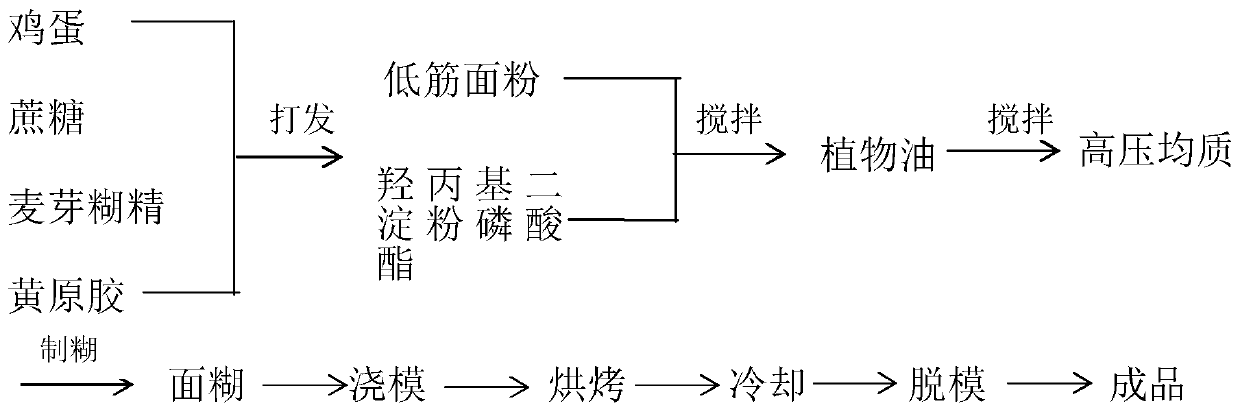

Making method of low-temperature resistant ageing resistant cakes

InactiveCN109699708ANot easy to retractStable structureDough treatmentModified nutritive productsCooking & bakingVegetable oil

The invention discloses a making method of low-temperature resistant ageing resistant cakes. The making method comprises the steps of (1) uniformly mixing maltodextrin with xanthan gum in proportion to obtain a maltodextrin and xanthan gum mixture, weighing cane sugar, egg liquid and the maltodextrin and xanthan gum mixture, performing placing in a stirrer, and performing stirring, to obtain milkywhite foam; (2) adding low-gluten flour and hydroxypropyl distarch phosphate, and performing whipping to obtain paste, so that the flour and egg paste are thoroughly mixed; (3) adding vegetable oil to the stirred cake paste, and performing whipping to obtain paste emulsified for the first time; (4) brushing a layer of the vegetable oil to a cake mold, and then pouring the paste into the cake mold; (5) putting the mold loaded with the paste in an oven for baking; and (6) taking out the thoroughly-cooked cakes, performing natural cooling to room temperature, and performing removing from the mold, so as to obtain cake products. According to the making method, the low-temperature storage properties of the made cakes are improved, the ageing resistance is improved, the cakes are good in tissuestructure stability, the mouth feel of the cakes is improved, and the specific volume of the cakes is increased.

Owner:ZHEJIANG XINDIJIAHE FOOD CO LTD

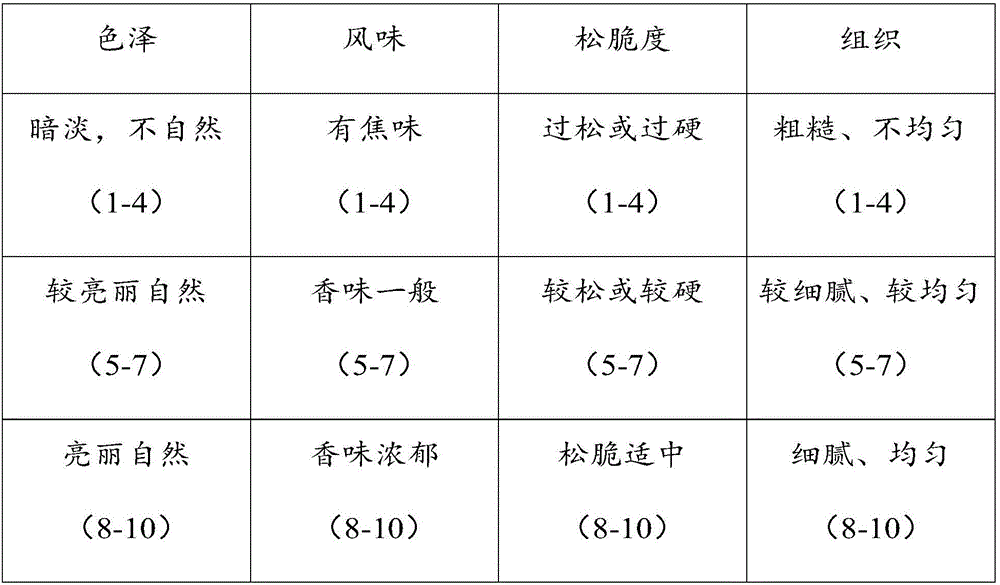

Compounded enzyme preparation of tough biscuit and preparation method of compounded enzyme preparation

InactiveCN106614888AStructuredClear structureDough treatmentPre-baking dough treatmentFood additiveMonoglyceride

The invention relates to a compounded enzyme preparation of a tough biscuit and a preparation method of the compounded enzyme preparation, and belongs to the field of food additives. The compounded enzyme preparation is prepared by mixing a compounded enzyme and an auxiliary material, wherein the compounded enzyme comprises the following components in parts by weight: 1-15 parts of neutral protease, 0.1-5 parts of papain, 1-8 parts of glucamylase, 2-9 parts of fungus alpha-amylase; and the auxiliary material comprises the following components in parts by weight: 5-30 parts of diacetate monodiglyceride, 5-30 parts of molecular distillation monoglycerides and 40-60 parts of distarch phosphate. The preparation method is simple, and the processes are environmentally friendly. Sodium pyrosulfite can be replaced with the compounded enzyme preparation for the processing process of the tough biscuit, adverse effects caused by use of the sodium pyrosulfite can be avoided, the biscuit is bright and natural in color and luster and crisp and delicate in taste, the breakage rate and hidden cracks of the biscuit are reduced and the yield is improved, thereby achieving the effects of improving the nutrient value and the quality of the biscuit and reducing the production energy consumption is reduced.

Owner:WUHAN SUNHY BIOLOGICAL

Nutrition and health care cake with effects of invigorating spleen and whetting appetite and preparation method thereof

InactiveCN107811010AFull of nutritionReasonable collocationDough treatmentBakery productsMaltitolFruit juice

The invention discloses a nutrition and health care cake with effects of invigorating spleen and whetting appetite and a preparation method thereof. The nutrition and health care cake comprises the following raw materials: wheat flour, oat powder, flos abelmoschus manihot powder, potato powder, xylitol, maltitol, honey, eggs, an emulsifier, fruit juice, salad oil, essence, Chinese yam, hawthorn, liquorice, cinnamon, almond, donkey-hide gelatin and orange peel. According to the nutrition and health care cake with the effects of invigorating spleen and whetting appetite and the preparation method thereof provided by the invention, by optimizing the formula and the preparation process thereof, the obtained cake is rich in nutrition, delicious in taste and long in quality guarantee period, hasthe effects of enriching blood, promoting blood circulation, invigorating spleen and whetting appetite, detoxifying and beautifying, tonifying middle-Jiao and qi and the like and also has an excellent health effect.

Owner:合肥市绿之林农业开发有限公司

Air column bag and air way for buffer air column

InactiveCN111439484AReduce backflow velocityPrevent leakageContainers to prevent mechanical damageEnvironmental engineeringAirflow

The invention discloses an air way for a buffer air column. The air way comprises a first air way and multiple second air ways. The first air way is used for allowing external air to be inflated in and transversely flow. The second air ways communicate with the first air way and are used for allowing the air to flow to an air storage chamber to form the air column. Any second air way comprises anair guide passageway and an air guide opening for allowing the air in the first air way to flow to the air guide passageway, wherein the air guide opening and the air guide passageway can adjust the speed and the pressure of airflow in order to avoid air leakage. The invention further discloses an air column bag with the air way for the buffer air column. By means of the air way for the buffer aircolumn, the air retaining time can be greatly prolonged, the air inflow speed and the reflux speed of the air in the air column can be reduced, impact force of the air for an external film is reduced, thus, the quality of products can be more reliable, and the air closing effect is better.

Owner:RUILI PACKAGING (CHONGQING) CO LTD

Coarse grain bread flour and production method thereof

InactiveCN105794900ADelicate tasteImprove liver and kidney nourishmentDough treatmentLiver and kidneyAdditive ingredient

The present invention discloses coarse grain bread flour and a production method thereof. The coarse grain bread flour is prepared by blending the following raw materials in parts by weight: 25-35 parts of sorghum flour, 35-50 parts of buckwheat flour, 5-15 parts of black rice, 5-15 parts of corn flour, 15-25 parts of sorghum puffed flour, 10-15 parts of soybean meal, 1-3 parts of walnut kernels, 1-2 parts of Chinese wolfberry fruits, 1-3 parts of pine nut kernels, 0.8-1.2 parts of wheat gluten, 0.05-0.08 part of sodium carboxymethyl cellulose, 0.02-0.03 part of sodium pyrophosphate, 0.01-0.02 part of yeast and 0.5-0.8 part of artemisia carvifolia. The coarse grain bread flour is prepared by mixing all the nutrients in coarse grains and has advantages of being more comprehensive in nutrition and more delicate in consumption mouthfeel. The Chinese wolfberry fruits, walnut kernels and other ingredients are added into the traditional coarse grain ingredients, so that nutrient proportioning is optimized and the bread flour has efficacies of improving organism immunity, nourishing liver and kidneys, preventing aging, etc.

Owner:张凌斌

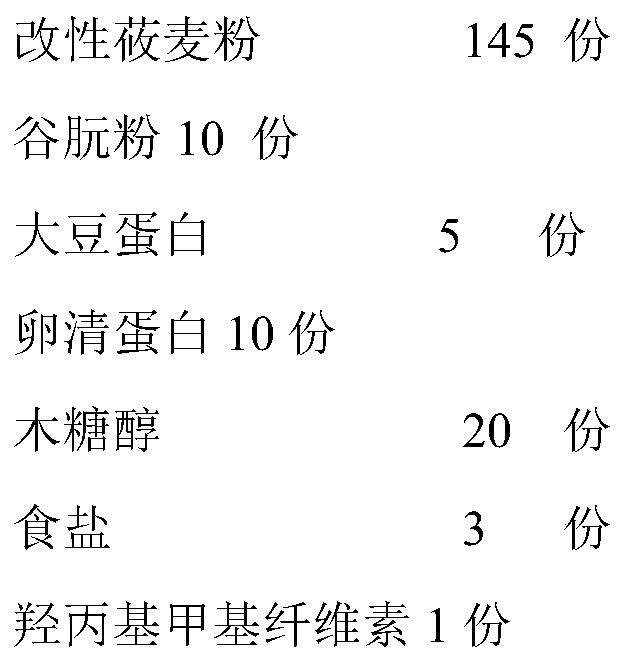

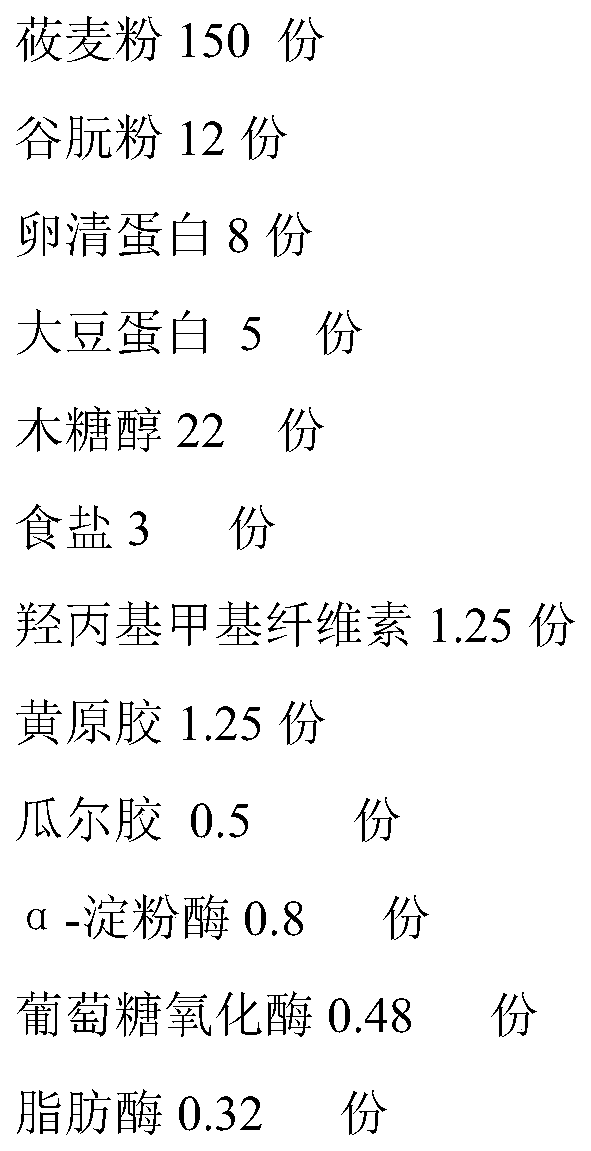

Low GI hulless oat premix powder without adding flour and preparation method thereof

The invention discloses a low GI hulless oat premix powder without adding flour and a preparation method thereof, which belongs to the technical field of food processing. The hulless oat premix powdercomprises modified hulless oat flour, exogenous protein, TG enzyme, compound hydrocolloid, a compound enzyme preparation and a seasoning auxiliary. The hulless oat premix powder comprises the following components in parts by weight: 145 to 155 parts of modified hulless oat flour, 15 to 25 parts of exogenous protein, 1 to 3 parts of compound hydrocolloid, 0.8 to 1.5 parts of a compound enzyme preparation, and 14 to 25 parts of a seasoning auxiliary material, wherein the modified hulless oat flour is modified by using ultra-high pressure and radio frequency composite enzyme. The oat flour breadmade by the method of the invention has dense gluten network, good gas-holding performance, golden color, uniform pores, fine tissue, soft taste and non-sticking, elasticity, and special oat flour fragrance, and has a low glycemic generation index and is capable of eating by people with diabetics and obesity.

Owner:JIANGNAN UNIV

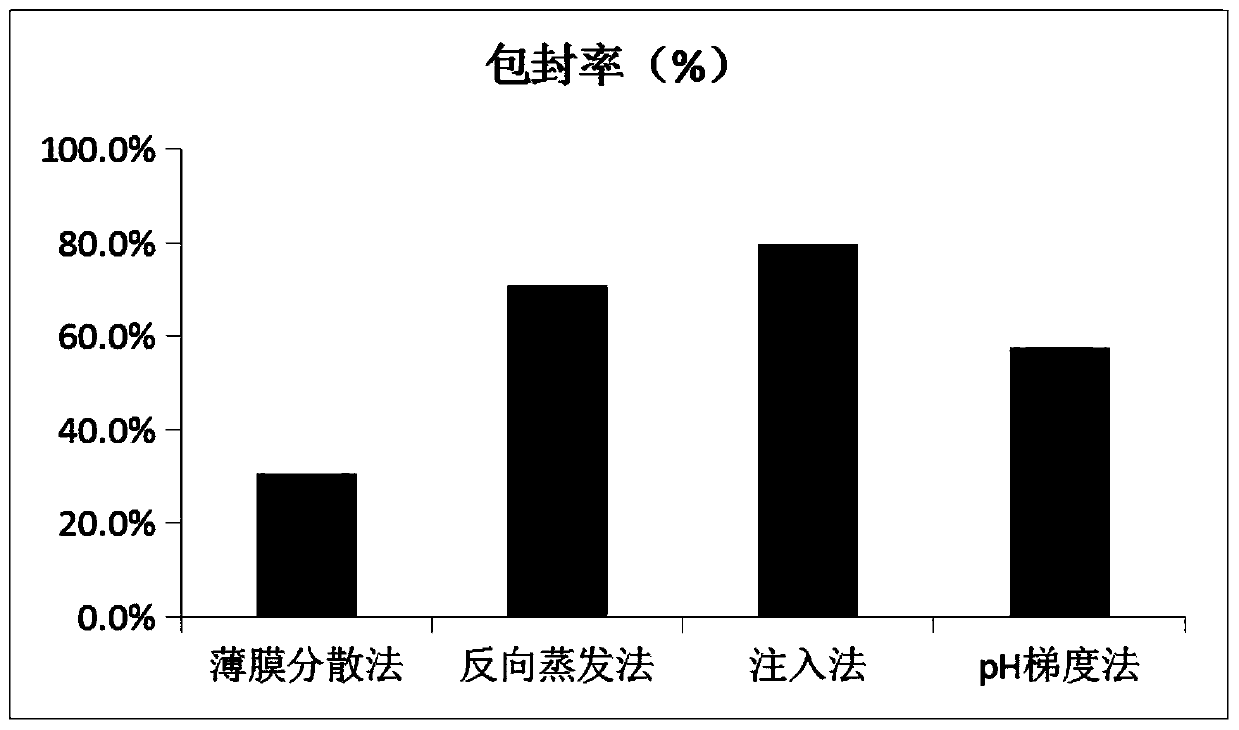

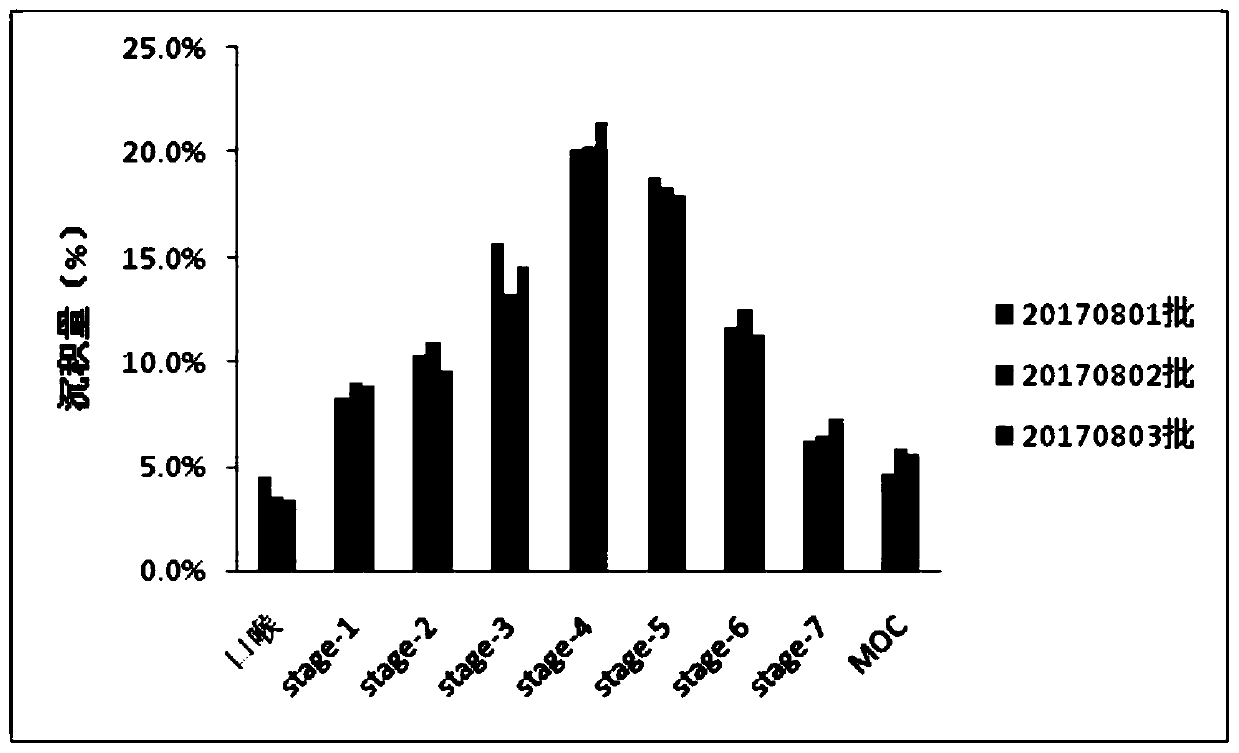

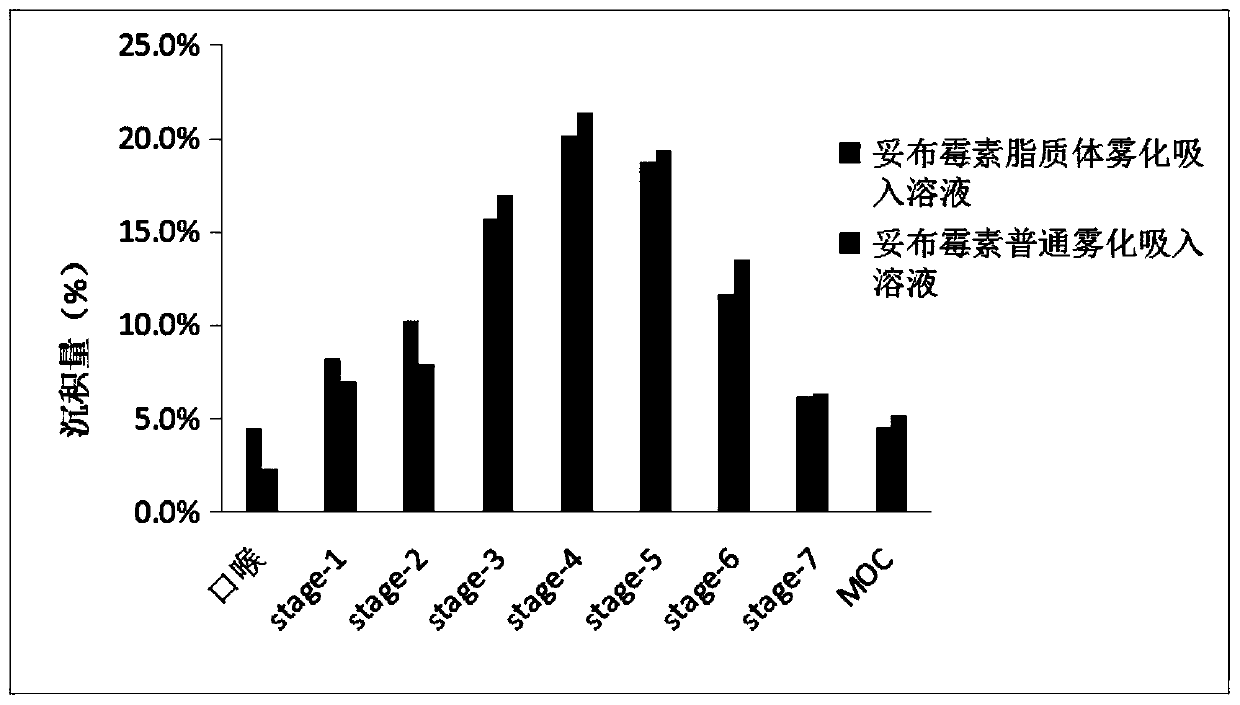

Tobramycin liposome used for aerosol inhalation and production method thereof

ActiveCN111228243AGood compatibilityImprove bioavailabilityAntibacterial agentsOrganic active ingredientsPhospholipidLiposome

The invention discloses a tobramycin liposome used for aerosol inhalation. The tobramycin liposome used for aerosol inhalation is composed of the following components: 0.1%-15.0% of tobramycin, 0.5%-36.0% of a phospholipid, 0.05%-20.0% of a stabilizer, 0.01%-10.0% of a charge modifier, 0.01%-5.0% of an antioxidant, 5.0%-50.0% of an organic-phase medium and the balance an aqueous-phase medium. According to the tobramycin liposome used for aerosol inhalation, the aerosol inhalation technology is used, relative to oral administration, the aerosol inhalation technology has the advantages that a medicine can be directly delivered to a respiratory tract, is absorbed fast, and takes effect quickly, and a medicine concentration of the respiratory tract is increased; the bioavailability and the stability are high, and the tobramycin liposome used for aerosol inhalation has good safety; and a production process is simple, easy and reasonable, and the performance is stable, so that conditions arecreated for achieving industrial productization.

Owner:ZHUHAI ESSEX BIO PHARMA

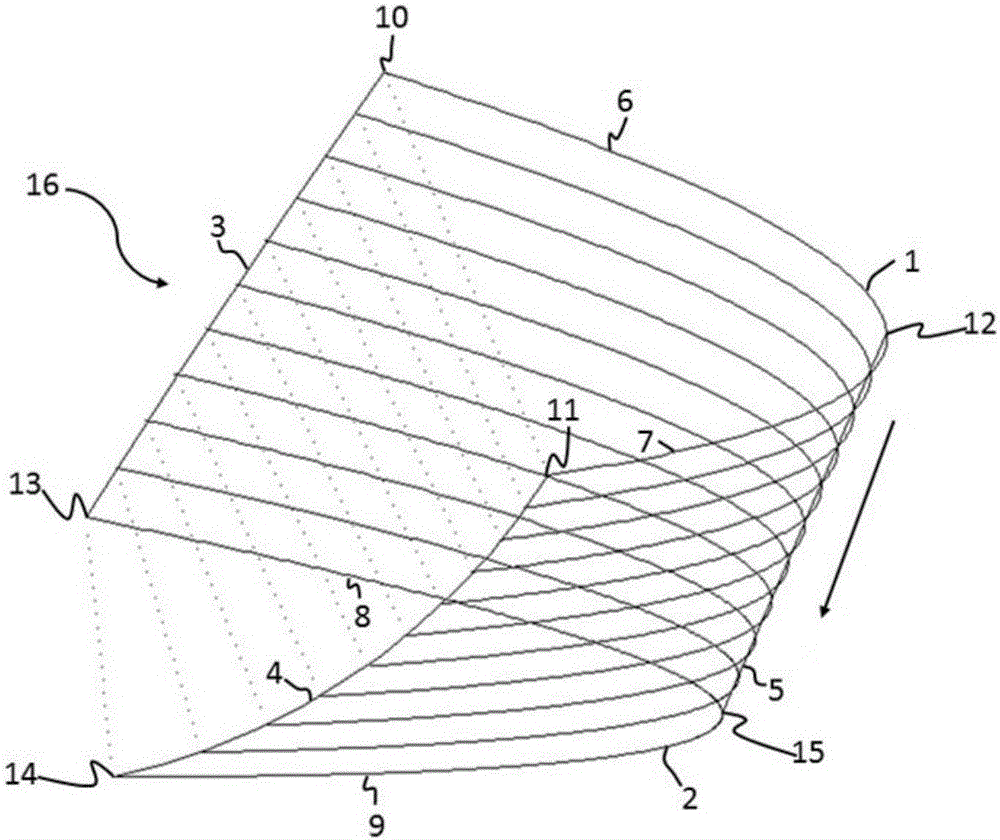

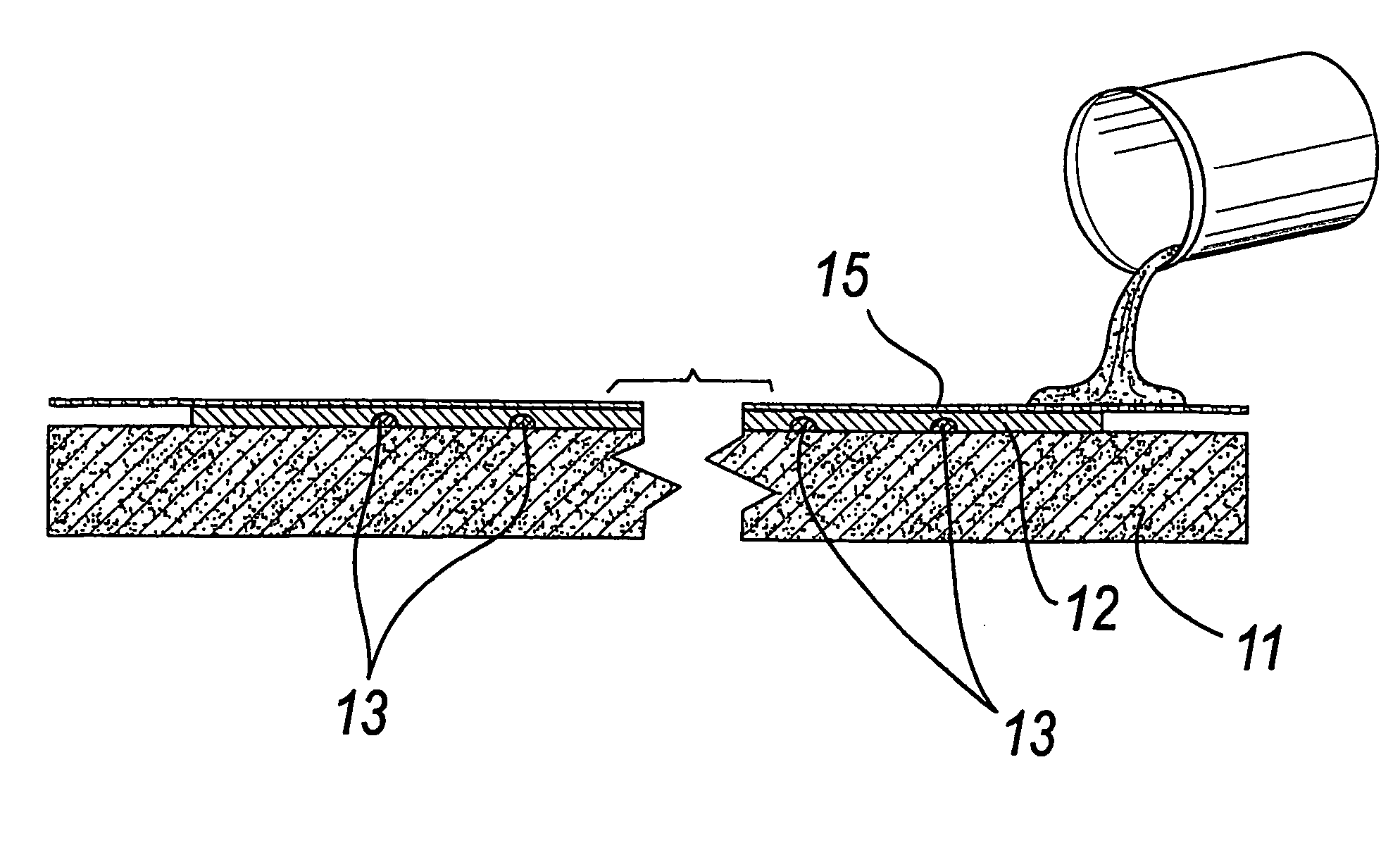

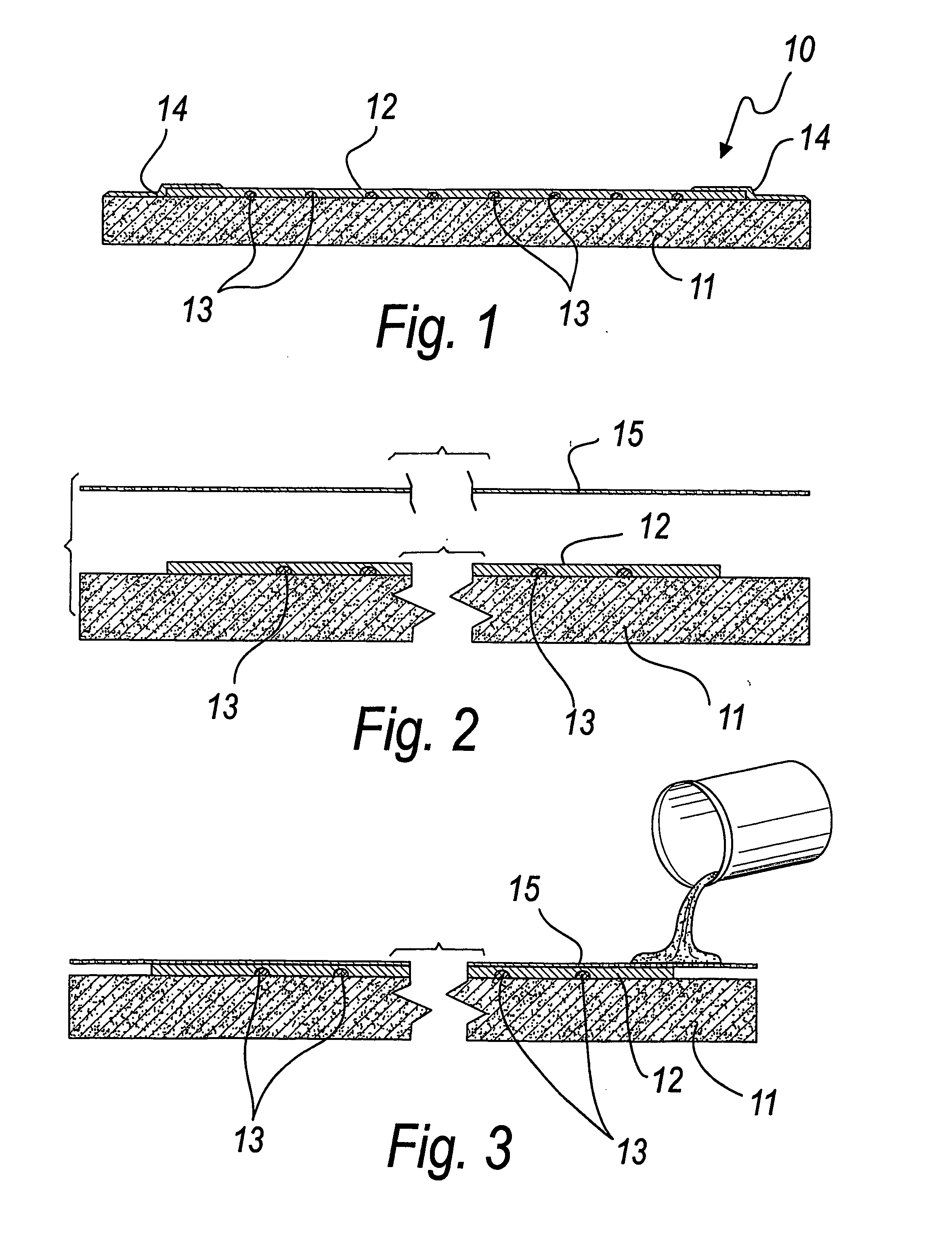

Waterproofed and breathable sole for shoes and manufacturing method thereof

ActiveUS20050268486A1Increase breathabilityHigh flexibilitySolesWear-resisting attachmentsMembrane configurationBiomedical engineering

A waterproofed and breathable sole (10) for shoes, characterized in that it comprises a tread (11) made of leather or similar breathable and water-permeable material, which is coverad at least partially in an upward region by a membrane (12) made of a material that is breathable and waterproof and is joined perimetrically to the tread (11) by means of a screen-printed sealing ring (14).

Owner:GEOX SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com