A vertical gas distribution device of an aerobic composting bin and a gas distribution method thereof

An aerobic composting and air distribution device technology, applied in fertilization devices, organic fertilizers, climate change adaptation and other directions, can solve the problems of uneven local ventilation, blocking of organic materials, poor ventilation effect, etc., and achieve stable and lasting ventilation effect. , reduce energy consumption and production costs, the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

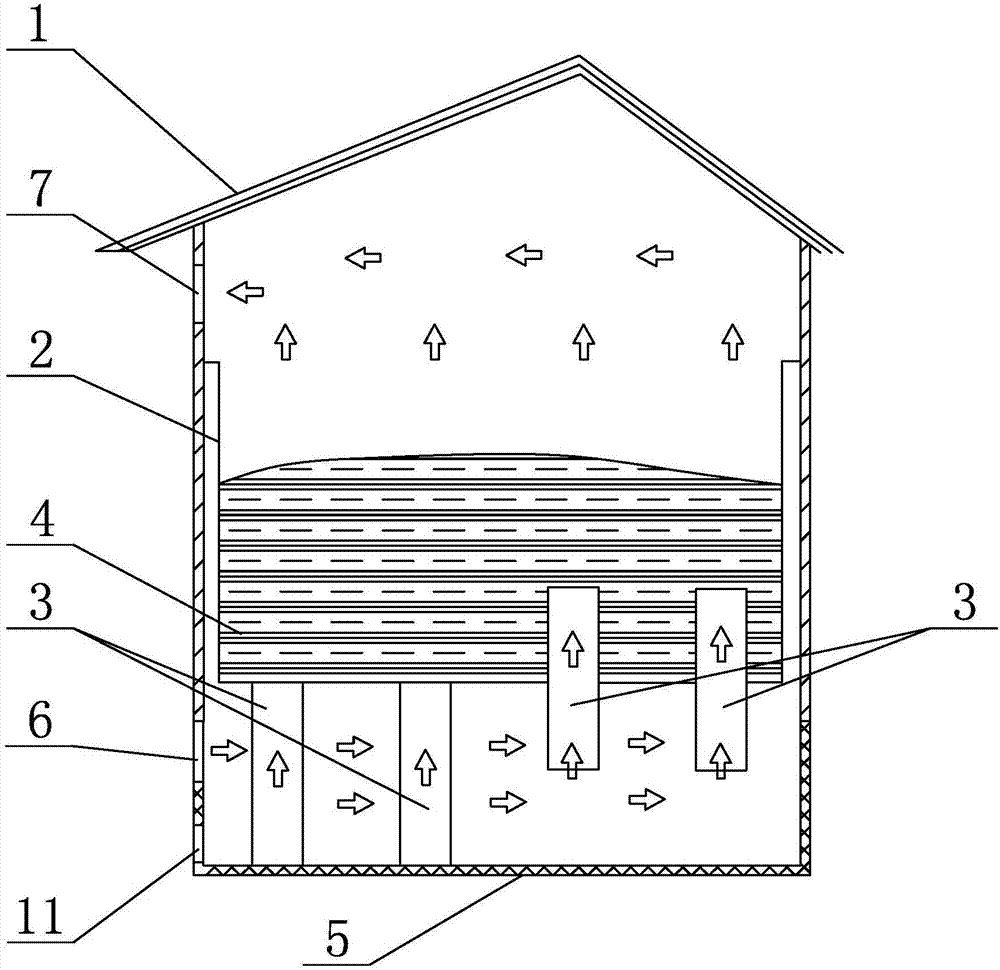

[0024] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment comprises composting room 1, compost bin 2, manure heap 4, leachate pool 5 and several distribution air pipes 3, and described several distribution air pipes 3 are arranged at the bottom of composting room 1, every A distribution air pipe 3 makes a reciprocating lifting movement along the height direction of the composting room 1. The leachate pool 5 is located at the bottom of the composting room 1 and is directly below several distribution air pipes 3. The side wall of the leachate pool 5 is processed There is an air inlet 6, and an air outlet 7 is processed on the side wall of the composting room 1. The interior of the composting room 1 is a composting bin 2, and a fertilizer pile 4 is arranged in the composting bin 2;

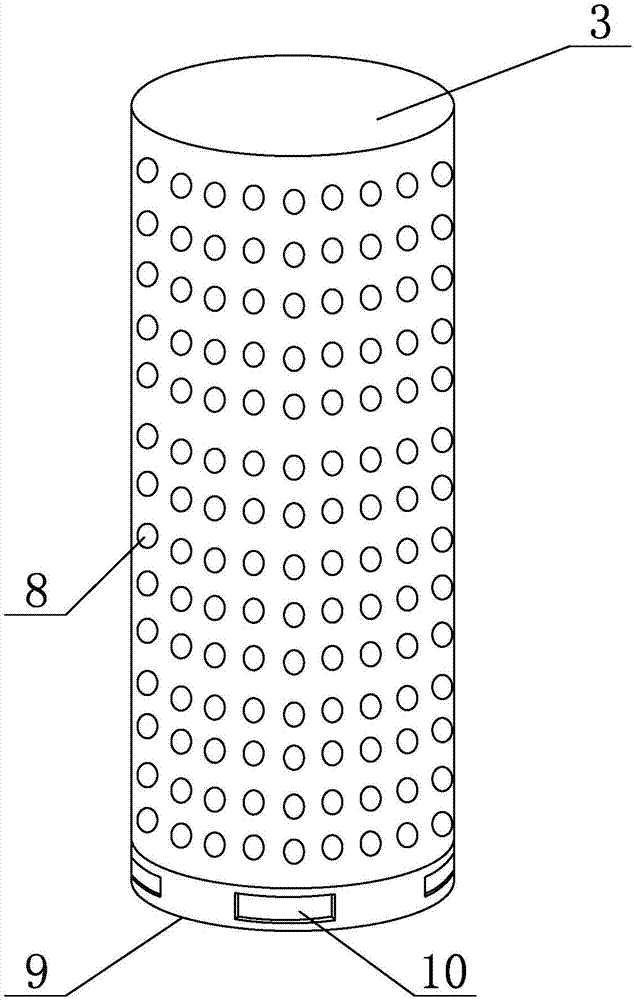

[0025] The top of each distribution air pipe 3 is a sealed end, and several air holes 8 are processed on the side wall of each distribution ai...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 2 Describe this embodiment, in this embodiment, the vent hole 8 is a tapered hole, the small mouth end of the vent hole 8 is arranged on the outer wall of the distribution air pipe 3, and the large mouth end of the ventilation hole 8 is arranged on the inner wall of the distribution air pipe 3. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. In this embodiment, each distribution air pipe 3 makes a reciprocating lifting motion along the height direction of the composting room 1 driven by the lifting mechanism.

[0028] In this embodiment, the lifting mechanism is an existing product. The lifting mechanism is that the meshing of the motor, the bevel gear set and the leading screw drive each distribution air pipe 3 to move up and down along the leading screw or the lifting mechanism is a pneumatic piston type telescopic rod to drive the distribution air pipe 3 to move up and down. Other existing lifting mechanisms that can realize manual or electric control are all all right.

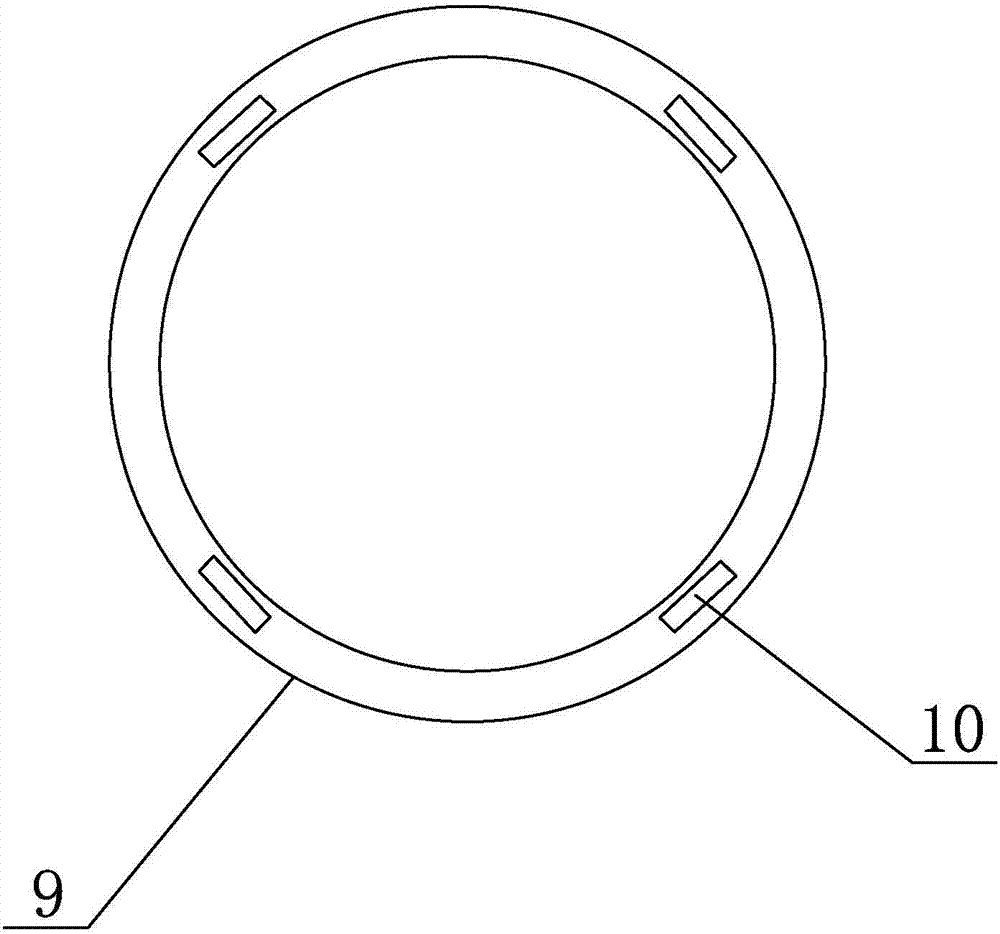

[0029] Specific implementation mode four: combination image 3 Describe this embodiment, in this embodiment, the bottom of each distribution air pipe 3 is correspondingly provided with a bottom ring 9, and each bottom ring 9 is coaxially arranged with its corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com