Mucedin-free potato residue baked nang and processing method thereof

A technology of potato dregs and potato dregs powder, which is used in baking, baked food, food preparation and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

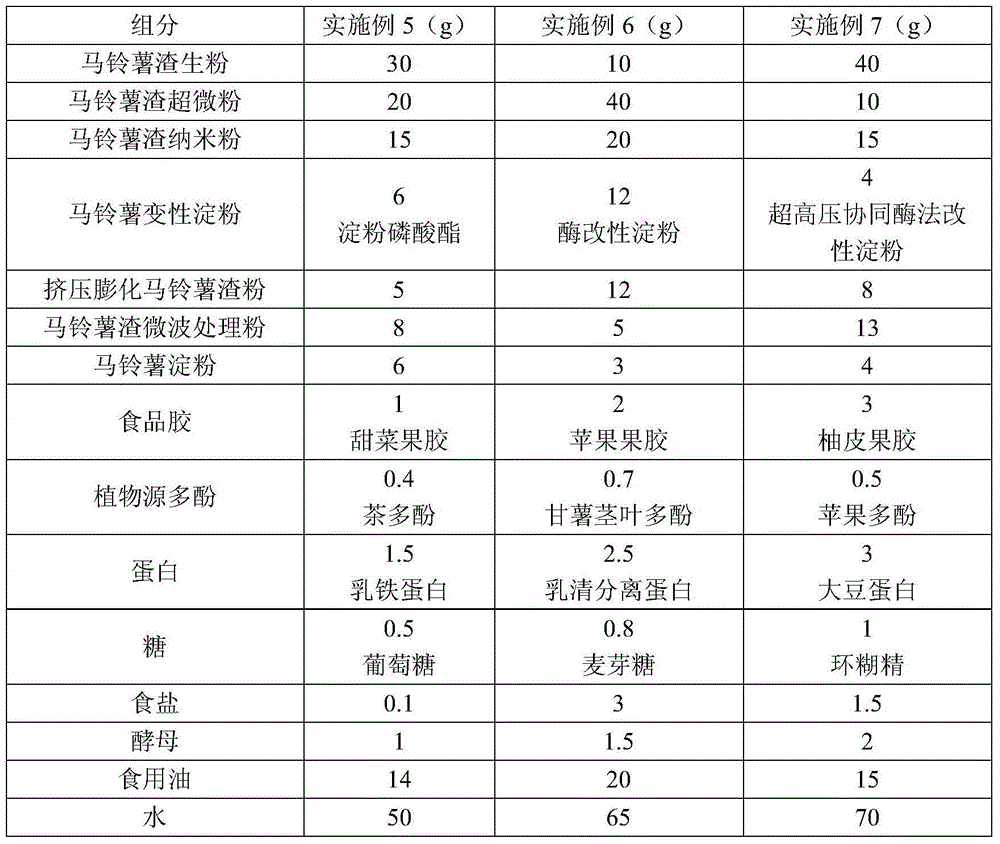

Examples

Embodiment 1

[0041] Embodiment 1: the raw material of potato dregs gluten-free baked naan

[0042] The raw materials of the gluten-free potato dregs baked pancake include potato dregs raw powder, potato dregs superfine powder, potato dregs nanopowder, potato modified starch, extruded potato dregs powder, potato dregs microwave-treated powder, potato starch, citrus pectin , sweet potato stem and leaf polyphenols, rice protein, trehalose, salt, yeast, edible oil and water, the mass ratio of the above ingredients is 25:21:12:8:10:10:5:1.5:0.5:2 :1:0.5:1:18:50.

Embodiment 2

[0043] Embodiment 2: the raw material of potato dregs gluten-free baked naan

[0044] The raw material powder of the gluten-free potato dregs baked pancake consists of potato dregs raw powder, potato dregs superfine powder, potato dregs nano powder, potato modified starch, extruded potato dregs powder, potato dregs microwave-treated powder, potato starch, sweet potato fruit Glue, tea polyphenols, chickpea protein, trehalose, salt, yeast, edible oil and water, the mass ratio of the above ingredients is 25:30:10:8:6:11:2:1.5:0.6:2 :0.6:2:1.5:20:50.

Embodiment 3

[0046] Get the potato slag that embodiment 1 obtains without gluten protein and bake naan raw material, carry out according to the following steps:

[0047] 1) take various raw materials according to embodiment 1;

[0048] 2) Heat the water weighed in step 1) equivalent to 5 times the weight of citrus pectin to 60°C to dissolve the citrus pectin weighed in step 1) to obtain a citrus pectin solution; heat the remaining water to 32°C , dissolving the yeast weighed in step 1) to obtain a yeast solution, and placing it in a constant temperature incubator for activation, the activation time is 10 minutes, and the activation temperature is 32° C.;

[0049] 3) The potato dregs raw powder, potato dregs superfine powder, potato dregs nano powder, potato modified starch, extruded potato dregs powder, potato dregs microwave-treated powder, potato starch, rice protein, and trehalose taken in step 1) , salt and sweet potato stem and leaf polyphenols are poured into the dough mixer, stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com