Method for preparing organic acid glycerin fatty acid ester

A technology of glycerol fatty acid ester and organic acid glycerol, which is applied in the field of organic chemical synthesis to achieve the effects of high conversion rate, good emulsifying performance and improving tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

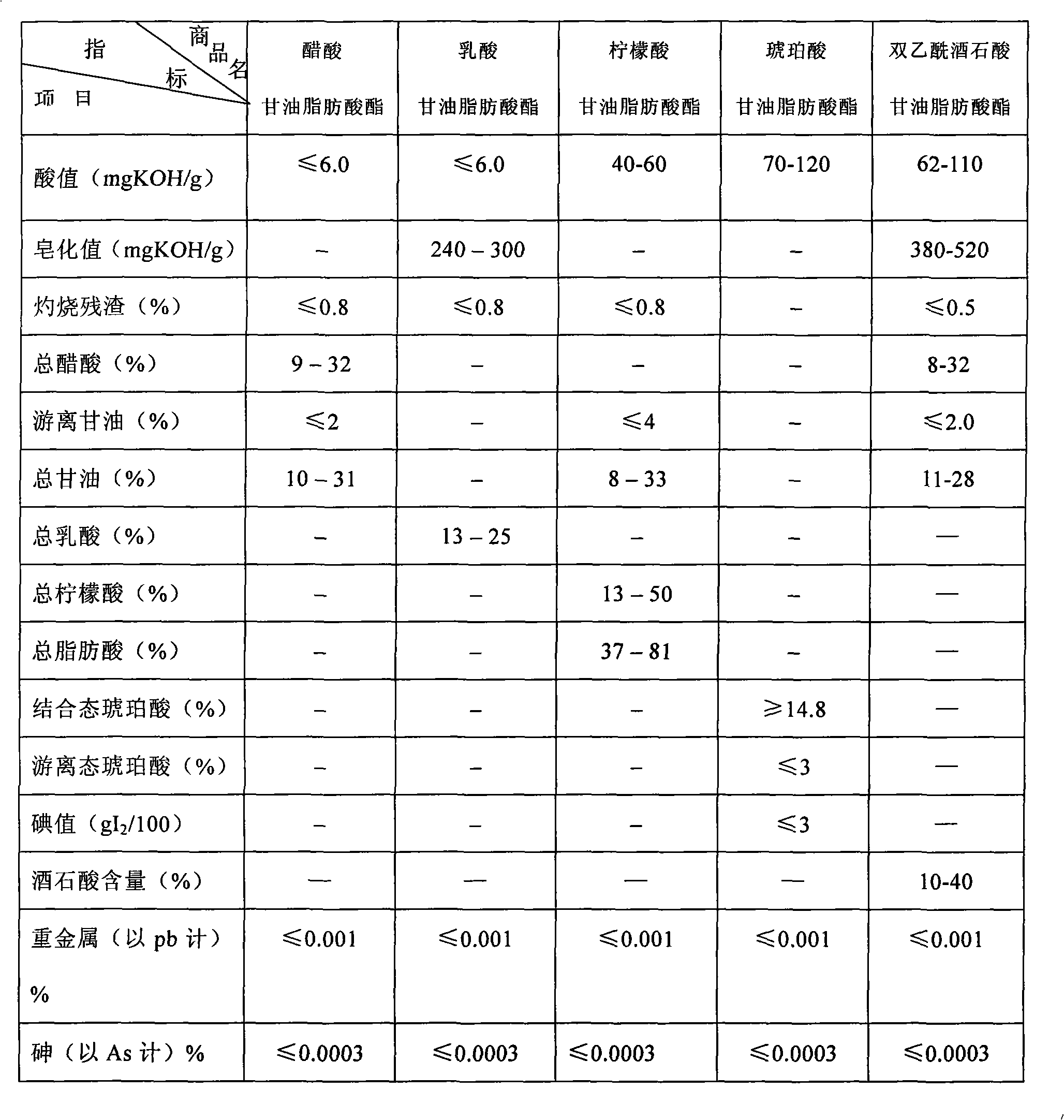

Image

Examples

Embodiment 1

[0018] Add 186Kg of acetic anhydride, 1050Kg of glycerol stearate, and 1.2Kg of catalyst phosphoric acid into the reaction kettle, heat to 130-145°C for acetylation reaction for 1-1.5 hours, continue to heat up to 160°C, and then cool down to 100°C, then evacuate and heat up to 165°C for 30 minutes until no acid is extracted. After the acid value is less than 6.0 mg KOH / g, cool down to 60°C and refine to obtain glyceryl acetate stearate. The total acetic acid in the product accounts for 9.2%, and the total glycerin accounts for 25.6%.

Embodiment 2

[0020] Add 408Kg of acetic anhydride, 550Kg of glycerol laurate, and 0.8Kg of catalyst sulfuric acid into the reaction kettle, heat to 130-145°C for acetylation reaction for 1-1.5 hours, continue to heat up to 160°C, and then cool down to 100°C after no acid ℃, then evacuate and heat up to 165 ℃ for 30 minutes until no acid is drawn out. After the acid value is less than 6.0 mg KOH / g, cool down to 60 ℃ and refine to obtain glyceryl acetate laurate. The total acetic acid in the product accounts for 31.8%, the total glycerin accounts for 24.7%

Embodiment 3

[0022] Add 248Kg of lactic acid into the reaction kettle, add 805Kg of glycerol stearate and 4.3Kg of catalyst phosphoric acid under stirring, and heat to 180-190°C for esterification reaction for 10 hours under vacuum. After the acid value is less than 6.0 mg KOH / g, cool down to Refined at 60°C to obtain lactic acid glyceryl stearate. The total lactic acid in the product accounts for 24.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com