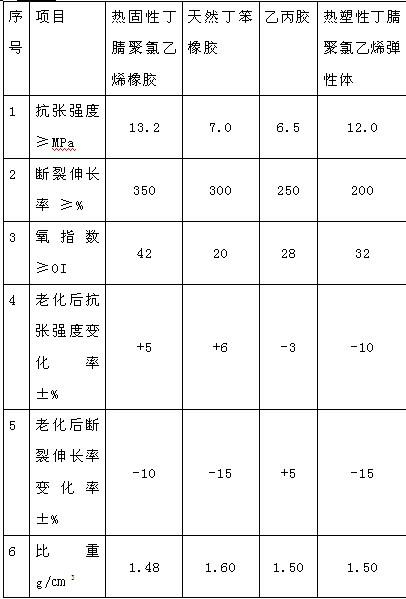

Flame-retardant thermosetting nitrile/polyvinyl chloride (PVC) rubber for wires and cables

A nitrile polyvinyl chloride, wire and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve problems such as melting and loss of insulation performance, and achieve good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 70 parts of powdered nitrile rubber, 30 parts of PVC resin powder, 3 parts of vulcanizing agent DCP, 2.5 parts of accelerator TRA, 1 part of accelerator DM, 6 parts of zinc oxide, 3 parts of stearic acid, 2 parts of coumarone resin, anti-aging 1 part of anti-aging agent RD, 10 parts of chlorinated paraffin, 8 parts of antimony trioxide, 6 parts of zinc borate, 70 parts of aluminum hydroxide, 30 parts of N330 carbon black, and 20 parts of N550 carbon black. The flame-retardant thermosetting nitrile polyvinyl chloride rubber for electric wires and cables of the present invention is obtained.

Embodiment 2

[0023] Take 60 parts of powdered nitrile rubber, 40 parts of PVC resin powder, 2.5 parts of vulcanizing agent DCP, 2 parts of accelerator TRA, 1.5 parts of accelerator DM, 5 parts of zinc oxide, 2.5 parts of stearic acid, and 1.5 parts of coumarone resin , 1.5 parts of anti-aging agent MB, 1.5 parts of anti-aging agent RD, 30 parts of chlorinated paraffin, 10 parts of antimony trioxide, 5 parts of zinc borate, 60 parts of aluminum hydroxide, 25 parts of N330 carbon black, 30 parts of N550 carbon black , The flame-retardant thermosetting nitrile polyvinyl chloride rubber for wire and cable of the present invention is obtained through the above-mentioned preparation method.

Embodiment 3

[0025] Take 50 parts of powdered nitrile rubber, 50 parts of PVC resin powder, 2 parts of vulcanizing agent DCP, 1.5 parts of accelerator TRA, 2 parts of accelerator DM, 4 parts of zinc oxide, 2 parts of stearic acid, 3 parts of coumarone resin, anti-aging 2 parts of agent MB, 1 part of antioxidant RD, 25 parts of chlorinated paraffin, 7 parts of antimony trioxide, 4 parts of zinc borate, 50 parts of aluminum hydroxide, 20 parts of N330 carbon black, 40 parts of N550 carbon black, through the above preparation method The flame-retardant thermosetting nitrile polyvinyl chloride rubber for electric wires and cables of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com