A high-flame-retardant, high-life, high-load, low-smoke, halogen-free building cloth wire and its preparation process

A high-load, high flame-retardant technology, applied in the direction of cable/conductor manufacturing, circuit, insulated cables, etc., can solve the problems of complex wiring process, equipment paralysis, high construction cost, etc., achieve halogen-free flame retardant performance, improve roundness The effect of high degree and convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

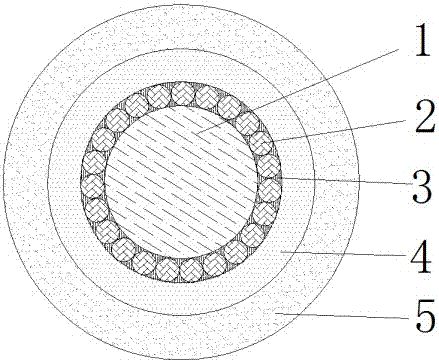

[0025] see figure 1 , the present invention provides a technical solution: a high-flame-retardant, high-life, high-load, low-smoke, halogen-free building cloth wire, including a copper conductor layer 1, a conductor winding layer 2, a semiconducting dielectric coating 3, an inner insulating layer 4 and an outer Insulation layer 5, the outer side of the copper conductor layer 1 is coated with a plurality of conductor winding layers 2 formed by winding thin copper wires, the outer side of the conductor winding layer 2 is provided with an inner insulating layer 4, and the conductor winding layer 2 and the inner insulating layer 4 The gap is filled with a semiconducting dielectric coating 3 , and the outer surface of the inner insulating layer 4 is fixedly provided with an outer insulating layer 5 .

[0026] The copper conductor layer 1 is made of pure copper with a copper content ≥ 99.99%. The inner insulation layer 4 is an extruded irradiated polyolefin insulation layer, which ...

Embodiment 2

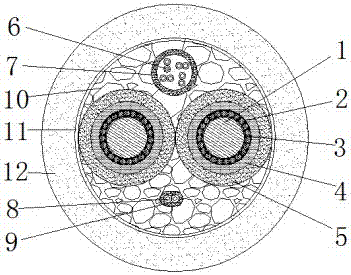

[0035]On the basis of Example 1, to meet the needs of integrated wiring in the building, the two-core high-flame-resistance, high-life, high-load, low-smoke, halogen-free architectural wiring is integrated with network cables and telephone lines. like figure 2 As shown, a network cable unit 6 is added, and the outside of the network cable unit 6 is wrapped with a network cable inner sheath 7 . The inner sheath 7 of the network cable is an extruded irradiated polyolefin material. According to the GB / T2406 test, the oxygen index of this material can reach 39, which has the precondition of high flame retardancy; Good processing performance is guaranteed; the service life of the material after crosslinking can reach 60-70 years, which is about 50% longer than that of conventional polyolefin materials. The cable thermal aging life test is carried out according to IEC 60216-1:2001: 90 The heat-resistant life at ℃ is 60.5 years, and the activation energy of the insulating material ...

Embodiment 3

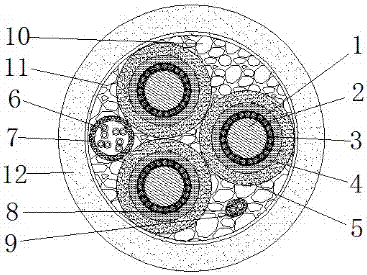

[0050] On the basis of Example 1, in response to the integrated wiring requirements in the building, the three-core high-flame-resistance, high-life, high-load, low-smoke, halogen-free architectural wiring is integrated with network cables and telephone lines. like image 3 As shown, a network cable unit 6 is added, and the outside of the network cable unit 6 is wrapped with a network cable inner sheath 7 . The inner sheath 7 of the network cable is an extruded irradiated polyolefin material. According to the GB / T2406 test, the oxygen index of this material can reach 39, which has the precondition of high flame retardancy; Good processing performance is guaranteed; the service life of the material after crosslinking can reach 60-70 years, which is about 50% longer than that of conventional polyolefin materials. The cable thermal aging life test is carried out according to IEC 60216-1:2001: 90 The heat-resistant life at ℃ is 60.5 years, and the activation energy of the insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| cover factor | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com