Low-smoke anti-aging cross-linked elastomer and preparation method thereof

A cross-linked elastomer, aging-resistant technology, applied in the field of thermoplastic elastomers, can solve the problems of difficult processing, deterioration of the mechanical properties of the flame retardant material matrix, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

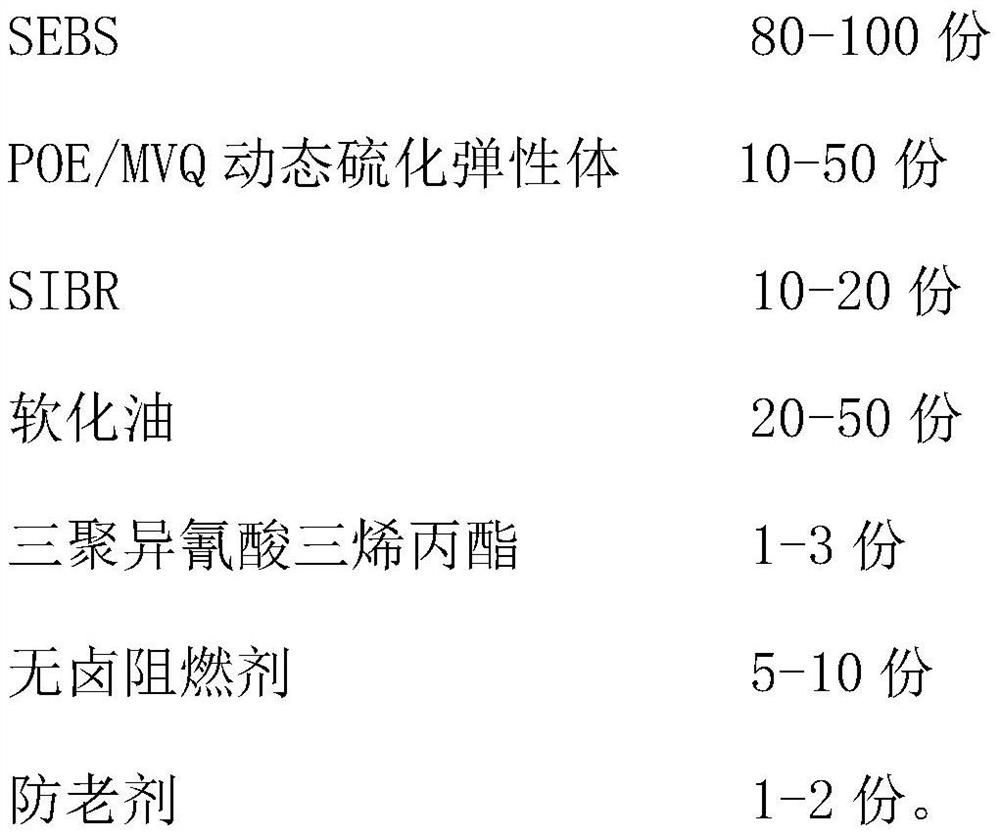

[0044] A low-smoke and aging-resistant cross-linked elastomer, comprising the following components (unit: g):

[0045]

[0046] Its preparation method comprises the following steps:

[0047] Step 1. Prepare each raw material according to the weight;

[0048] Step 2, mix SEBS with softening oil and stir evenly, let it stand for 20 hours to obtain pre-softened elastomer;

[0049] Step 3, passing the pre-softened elastomer obtained in step 2 and the remaining components through a high-speed mixer, and mixing uniformly to obtain a mixed material;

[0050] Step 4. Put the mixed material into a twin-screw extruder for melt kneading and extrusion. The extrusion temperature is 250° C., and the screw speed is 500 rpm;

[0051] Step 5, cooling the molten output extruded from the extruder die, and then irradiating and cross-linking through ultraviolet radiation equipment to obtain a low-smoke and anti-aging cross-linked elastomer and a preparation method thereof.

Embodiment 2

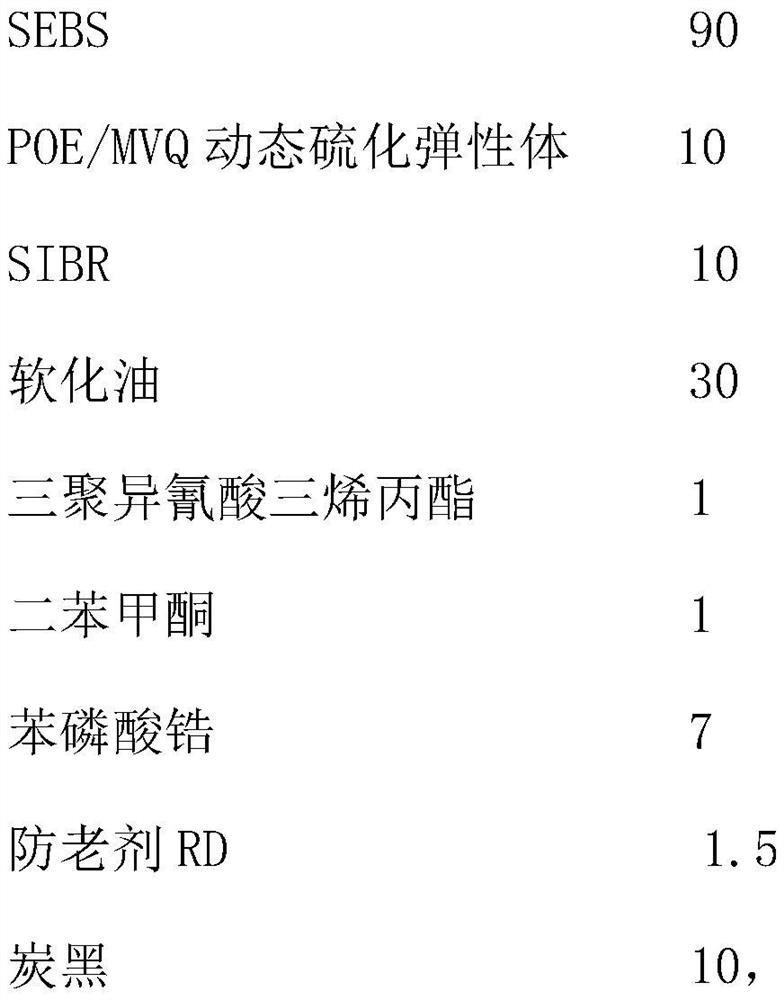

[0053] A low-smoke and aging-resistant cross-linked elastomer, comprising the following components (unit: g):

[0054]

[0055] Its preparation method comprises the following steps:

[0056] Step 1. Prepare each raw material according to the weight;

[0057] Step 2, mix SEBS with softening oil and stir evenly, let it stand for 40 hours to obtain pre-softened elastomer;

[0058] Step 3, passing the pre-softened elastomer obtained in step 2 and the remaining components through a high-speed mixer, and mixing uniformly to obtain a mixed material;

[0059] Step 4. Put the mixed material into a twin-screw extruder for melt kneading and extruding. The extrusion temperature is 260° C., and the screw speed is 550 rpm;

[0060] Step 5, cooling the molten output extruded from the extruder die, and then irradiating and cross-linking through ultraviolet radiation equipment to obtain a low-smoke and anti-aging cross-linked elastomer and a preparation method thereof.

Embodiment 3

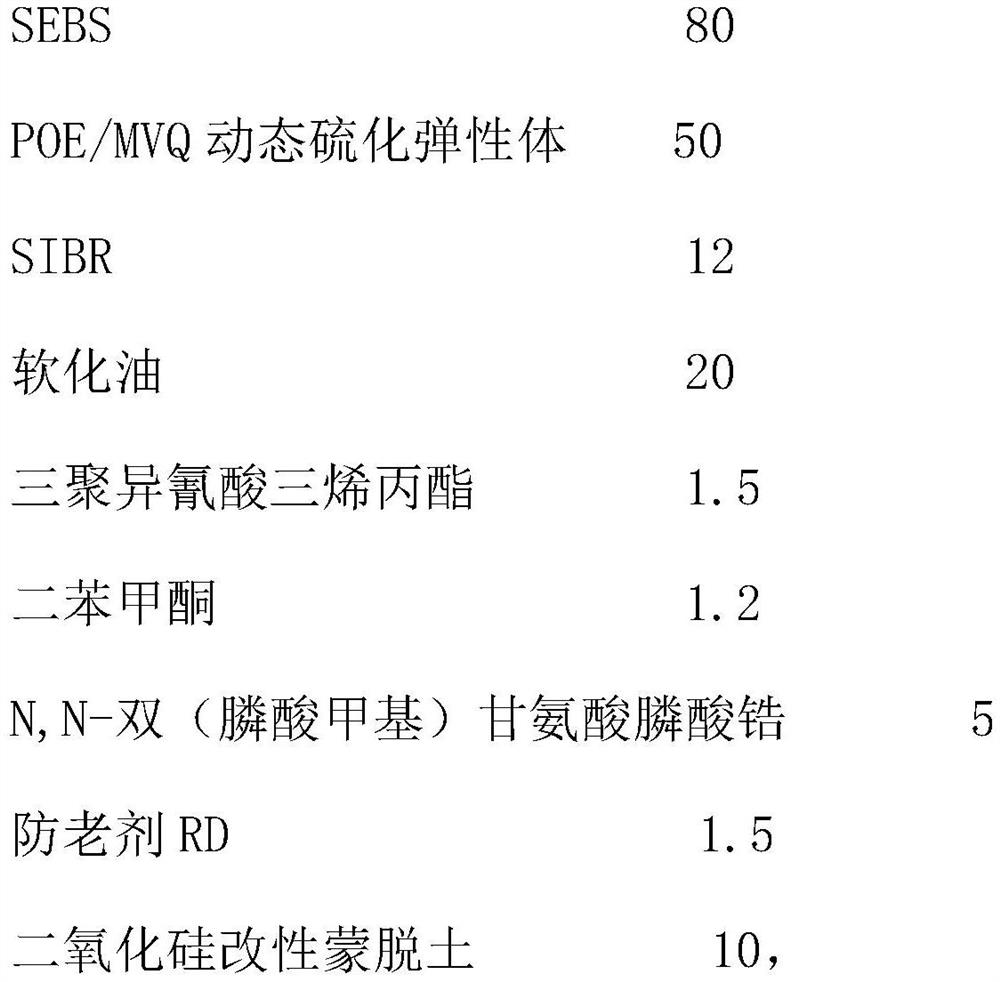

[0062] A low-smoke and aging-resistant cross-linked elastomer, comprising the following components (unit: g):

[0063]

[0064] Its preparation method comprises the following steps:

[0065] Step 1. Prepare each raw material according to the weight;

[0066] Step 2, mix SEBS with softening oil and stir evenly, let it stand for 25 hours to obtain pre-softened elastomer;

[0067] Step 3, passing the pre-softened elastomer obtained in step 2 and the remaining components through a high-speed mixer, and mixing uniformly to obtain a mixed material;

[0068] Step 4. Put the mixed material into a twin-screw extruder for melt kneading and extrusion, the extrusion temperature is 240°C, and the screw speed is 500rpm;

[0069] Step 5, cooling the molten output extruded from the extruder die, and then irradiating and cross-linking through ultraviolet radiation equipment to obtain a low-smoke and anti-aging cross-linked elastomer and a preparation method thereof.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com