Flame-retardant low-smoke-density gel coat and preparation method thereof

A technology of smoke density and gel coat, used in coatings, fire-retardant coatings, polyester coatings, etc., can solve the problems of inability to balance the fire resistance and mechanical properties of gel coats, and the mechanical properties of fire-resistant additives. Inexpensive, simple to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

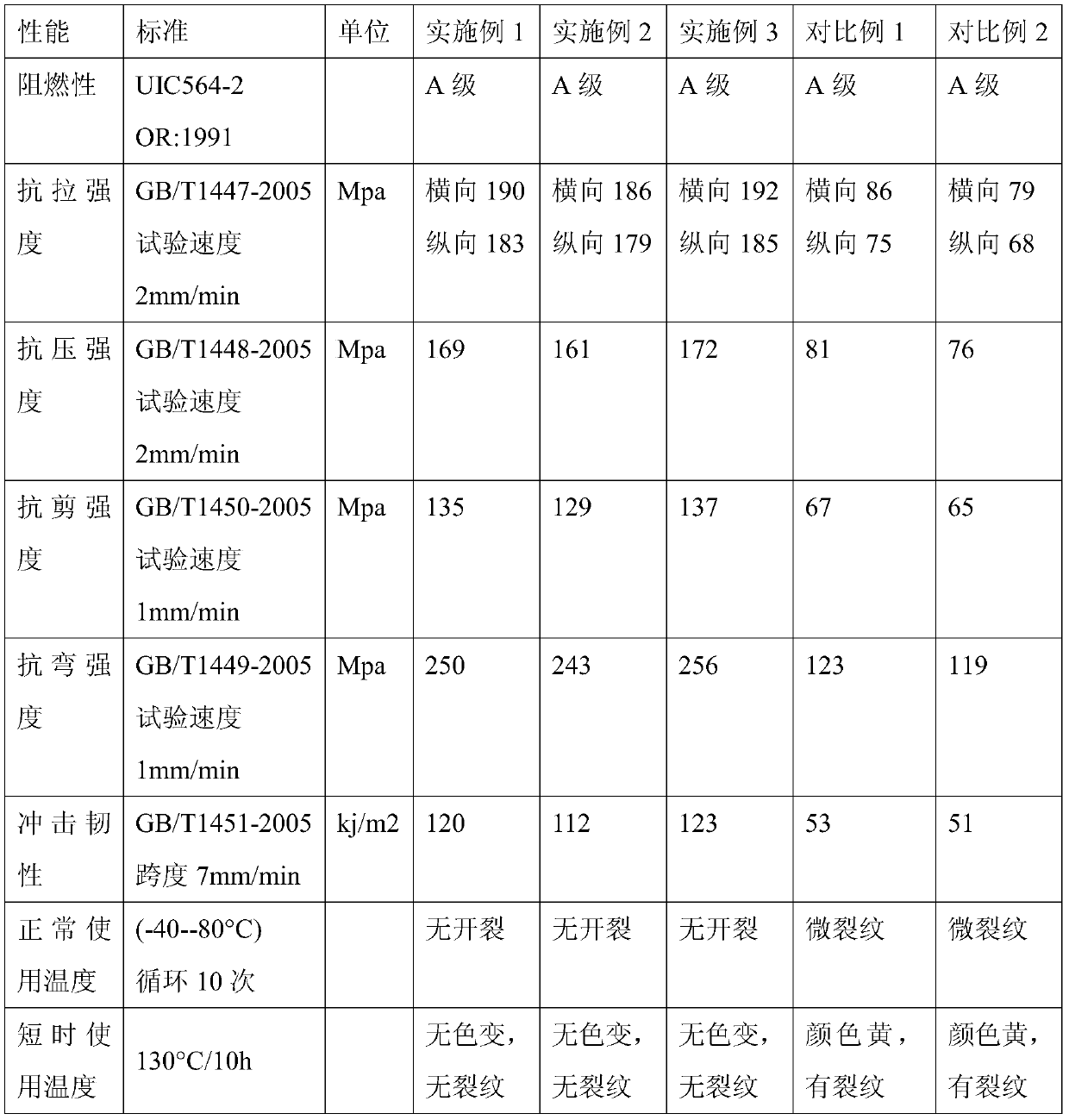

Examples

Embodiment 1

[0025] The raw material components of a flame retardant low smoke density gel coat include: 38% unsaturated polyester resin, 2% silicon dioxide, 10% titanium dioxide, 0.5% defoamer, 0.5% leveling agent, 0.5% antioxidant %, UV absorber 0.5%, composite viscosity reducer 4% and aluminum hydroxide powder 1500 order 44%, and described percentage is mass percent.

Embodiment 2

[0027] The raw material components of a flame-retardant low-smoke density gel coat include: 35% of unsaturated polyester resin, 2% of silicon dioxide, 10% of titanium dioxide, 0.5% of defoamer, 0.5% of leveling agent, and 0.5% of antioxidant %, 0.5% of ultraviolet absorber, 5% of composite viscosity reducer and 46% of aluminum hydroxide powder 1500 orders, and described percentage is mass percent.

Embodiment 3

[0029] The raw material components of a flame retardant low smoke density gel coat include: 40% unsaturated polyester resin, 2% silicon dioxide, 10% titanium dioxide, 0.5% defoamer, 0.5% leveling agent, 0.5% antioxidant %, UV absorber 0.5%, composite viscosity reducer 4% and aluminum hydroxide powder 1500 order 42%, described percentage is mass percent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com