Process for producing acet-tributyl citrate

A technology of acetyl tributyl citrate and tributyl citrate, which is applied in the production process field of acetyl tributyl citrate, can solve the problems of long reaction cycle, large equipment investment and high production cost, and achieve short production cycle, The effect of less investment in equipment and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

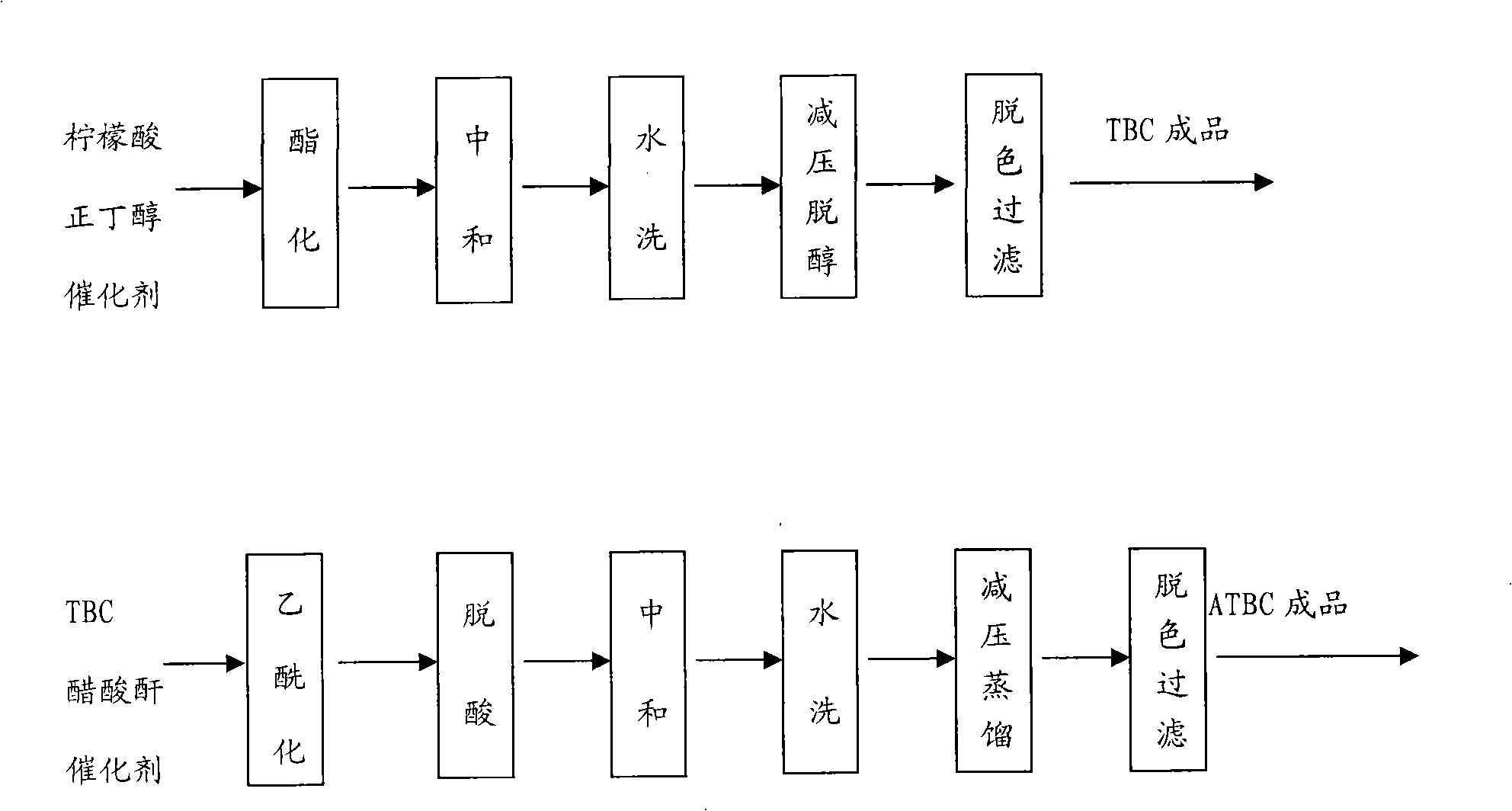

Method used

Image

Examples

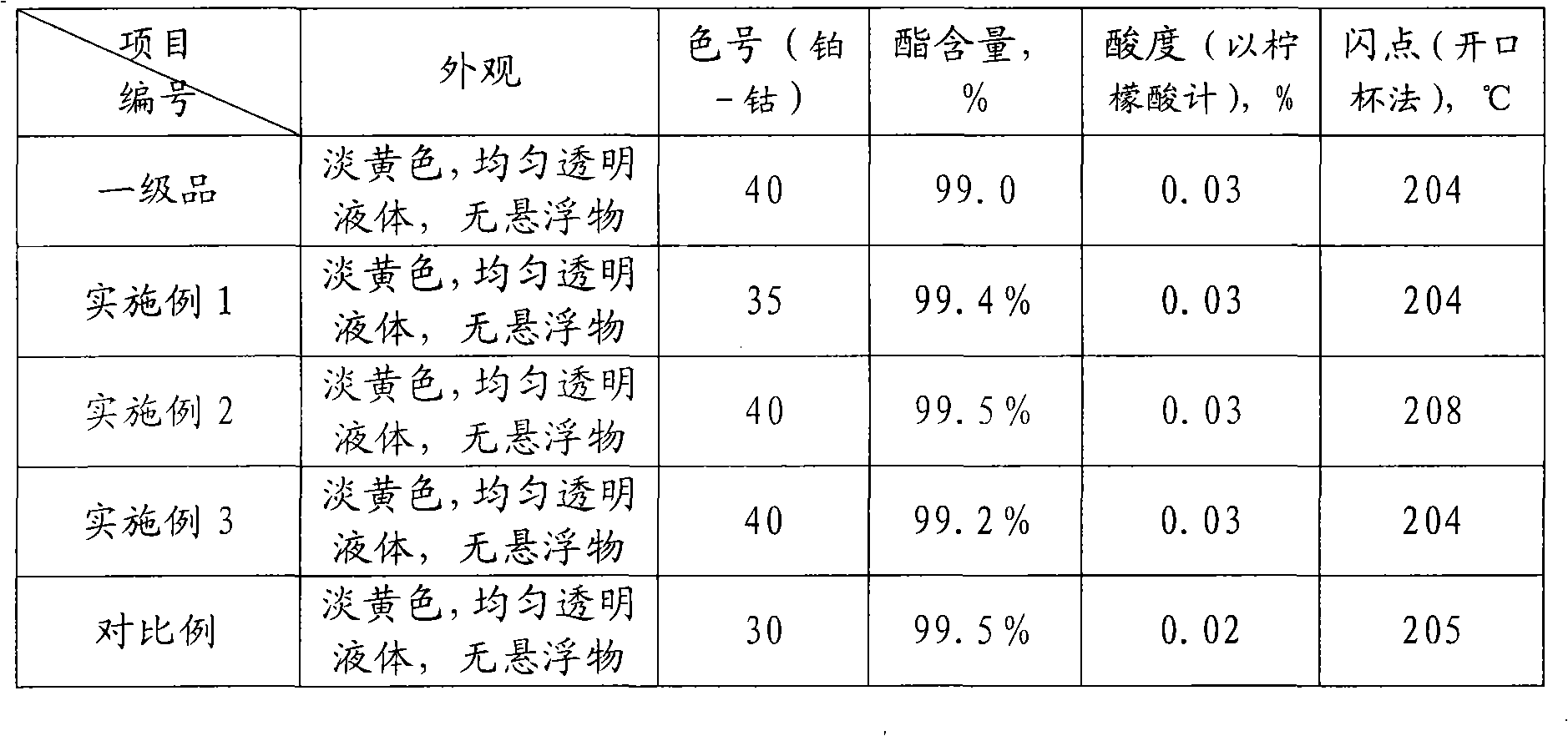

Embodiment 1

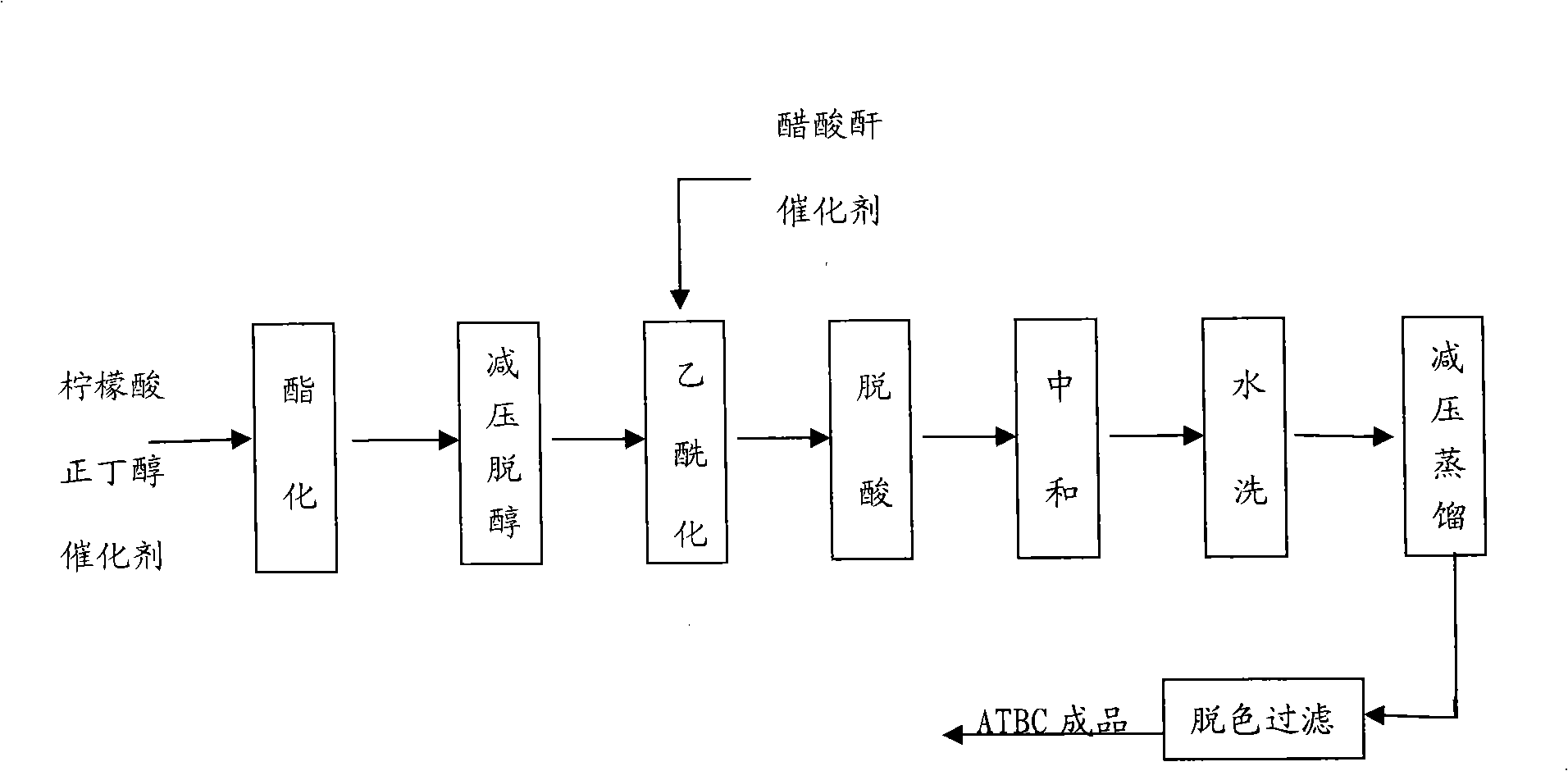

[0015] like figure 2 As shown in the process flow: using citric acid and n-butanol as raw materials, the esterification reaction is carried out under the action of a catalyst. After the esterification reaction is complete, the waste heat is directly used to dealcoholize under reduced pressure to obtain the crude product of tributyl citrate, and then add acetic acid The anhydride is acetylated with a catalyst, and finally deacidified, neutralized, washed with water, distilled under reduced pressure, decolorized and filtered to obtain the acetyl tributyl citrate.

[0016] at 10m 3 Add 4t of citric acid, 5240kg of n-butanol and 40Kg of 30% sulfuric acid solution to the reaction kettle in sequence, add the remaining 760kg of n-butanol in batches, and react under reflux at 120-150°C for about 5 hours under stirring, and take samples to measure the acid value , The esterification is completed below the acid value of 2.3mgKOH / g in the middle control, and then the waste heat is used...

Embodiment 2

[0018] The quality that adds acetic anhydride is 2.11t, other is with embodiment 1.

Embodiment 3

[0020] The quality that adds acetic anhydride is 2.88t, and other is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com