Heated aerosol-generating articles comprising improved rods

An aerosol generation and heating technology, which can be used in the preparation of tobacco, paper cigarettes, and cigars, etc., can solve problems such as uneven density and achieve the effect of uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

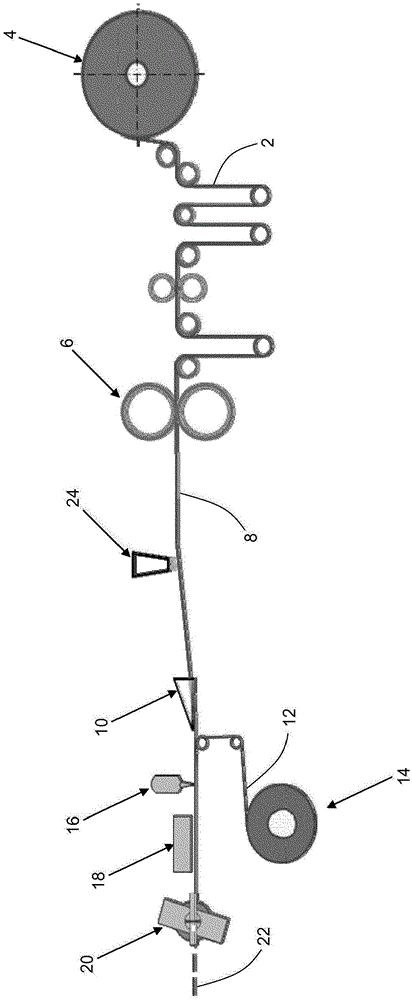

[0125] use figure 1 An apparatus of the type shown in , produces a first rod for use in the present invention comprising a gathered curled sheet of homogeneous tobacco material bounded by a wrapper. A continuous sheet of homogenized tobacco material comprising 12.5 percent by weight glycerin and 12.5 percent by weight lemon on a dry weight basis produced by a casting process for forming rods Acid triethyl ester.

[0126] For comparison purposes, a continuous sheet of homogenized tobacco material comprising 25 percent by weight glycerin on a dry weight basis was used to form a second rod in the same manner.

[0127] A heated aerosol-generating article according to the invention comprising the first strip and a heated aerosol-generating article not according to the invention comprising the second strip were prepared. The sensory properties of heated aerosol-generating articles were evaluated by a panel of consumer experts.

[0128] The panel rated the attributes higher for he...

example 2

[0130] use figure 1 An apparatus of the type shown in , produces a third rod for use in the present invention comprising a gathered curled sheet of homogeneous tobacco material bounded by a wrapper. A continuous sheet of homogenized tobacco material produced by a molding process comprising 9.4 percent by weight sorbitol, 3.1 percent by weight on a dry weight basis, is used to form rods of invert sugar and 7.5 percent by weight of triethyl citrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com