Incinerated pottery clay modified ethylene propylene diene copolymer cable material

A technology of EPDM rubber and calcined pottery, which is applied in the field of cable materials to achieve the effects of improving flame retardancy and heat resistance, excellent effect, and good high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

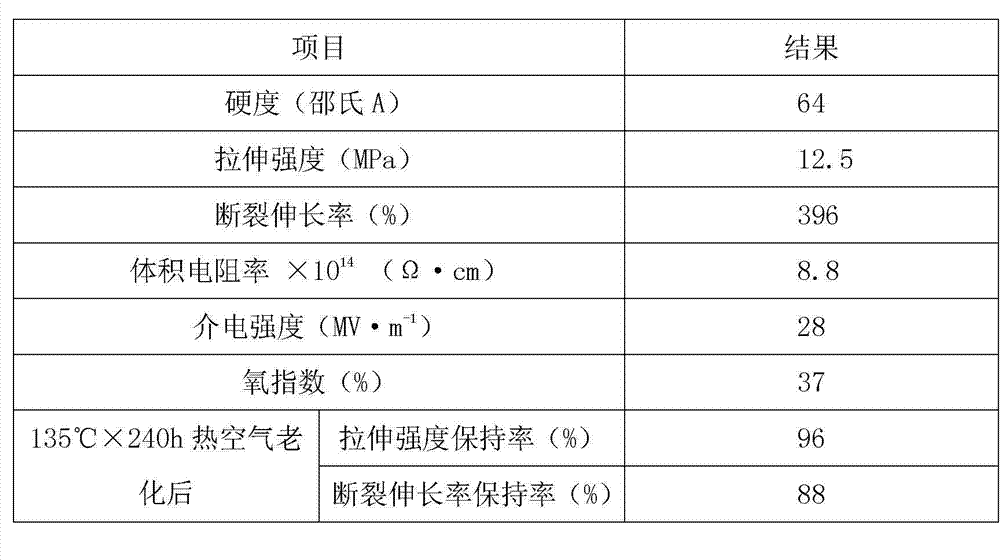

Examples

Embodiment

[0013] A calcined clay-modified EPDM cable material, which is made of the following raw materials in parts by weight: German LANXESS EPDM 3950 108 parts, nitrile rubber N41 24 parts, chlorosulfonated polyethylene rubber CSM2305 12 parts, 15 parts of diisodecyl phthalate, 4 parts of epoxidized triglyceride, 3 parts of triethyl citrate, 6 parts of chlorinated paraffin, 0.8 part of stearic acid, 3 parts of calcium stearate , 1.5 parts of sulfur, 4 parts of zinc oxide, 35 parts of calcined clay, 22 parts of precipitated silica, 8 parts of carbon black N660, 4 parts of zinc borate, 1.6 parts of aluminate coupling agent DL-411, anti-ultraviolet agent UV- 0.6 parts of 531, 1.8 parts of crosslinking agent TAIC, 1.5 parts of 3-aminopropyltrimethoxysilane, 1.2 parts of antioxidant OD, 1.8 parts of antioxidant ODA, 1.5 parts of antioxidant TPPD, 2 parts of accelerator Na-22, accelerator 3 parts of agent DM, 3 parts of modified tree ash.

[0014] Wherein, the modified tree ashes are prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com