Completely biological degradable polylactic coating materials

A coating material and biodegradable technology, applied in coating, paper coating, fiber raw material treatment, etc., can solve the problems of easy processability and low cost limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

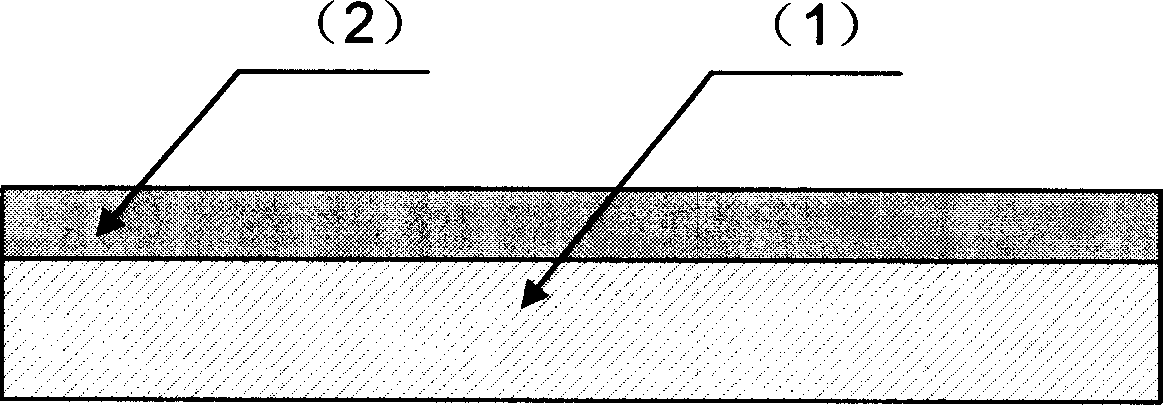

Image

Examples

Embodiment 1

[0015] The composition of the coating material includes 100 parts by weight of non-crystalline polylactic acid, 5 parts by weight of compound plasticizer, and 0.1 part by weight of oleic acid amide. The compound plasticizer contains 2 parts of polyethylene glycol and 3 parts of triethyl citrate. The polylactic acid, compound plasticizer and additives of the above composition are mixed by mechanical stirring, melted, extruded and granulated by a twin-screw extruder to obtain a plasticized polylactic acid composition, which is coated by extrusion coating with a T-shaped die The equipment extrudes the plasticized polylactic acid composition into a film or sheet and presses it on the paper layer to form a completely biodegradable polylactic acid coating material.

Embodiment 2

[0017] The composition of the coating material includes 100 parts by weight of non-crystalline polylactic acid and 30 parts by weight of a compound plasticizer. The composite plasticizer contains 20 parts of triacetin and 10 parts of poly-1,3-butylene sebacate, and the preparation method of the materials is the same as in Example 1.

Embodiment 3

[0019] The composition of the coating material includes 100 parts by weight of crystalline polylactic acid, 70 parts by weight of a compound plasticizer, and 5 parts by weight of diatomite. The compound plasticizer contains 20 parts of triacetin, 20 parts of poly(1,3-butylene adipate) and 30 parts of acetyl triethyl citrate. The preparation method of the materials is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com