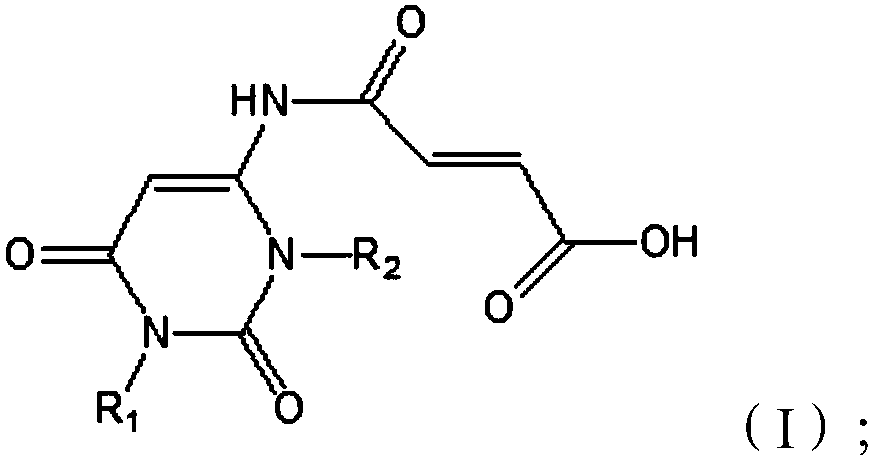

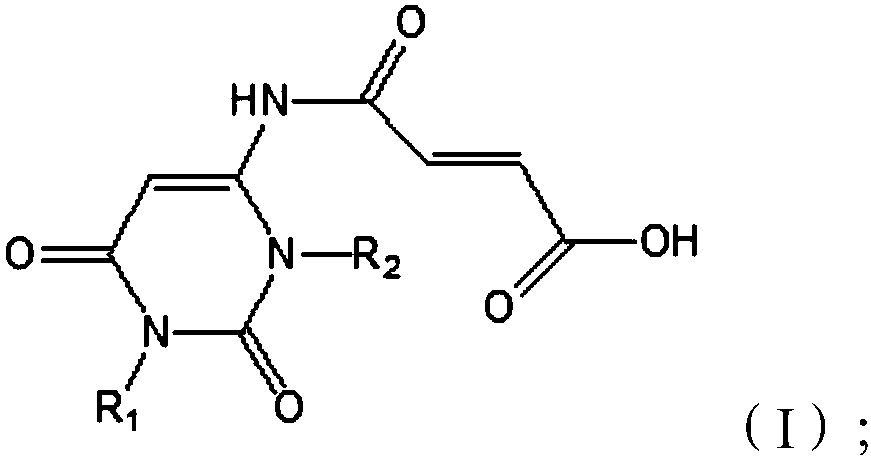

Aminouracil maleamic acid as well as preparation method thereof and polyvinyl chloride heat stabilizer

A technology of aminouracil and maleamic acid, which is applied in organic chemistry and other fields, and can solve the problems of poor PVC compatibility, easy frosting and precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Preparation of aminouracil maleamic acid

[0032] After pouring maleic anhydride (MAH) into the flask, heat and stir and blow nitrogen, then add aminouracil compounds, raise the temperature to 70°C, and react for 8 hours to obtain the product.

[0033] Wherein, the reaction ratio of maleic anhydride and semi-uracil compounds is 1:1; semi-uracil compounds are selected as 1,3-dialkyl-6-amino-uracil.

[0034] 2. Preparation of polyvinyl chloride (PVC) material

[0035] Formula: 100 parts of PVC, 3 parts of aminouracil maleamic acid, 2 parts of calcium stearate, 1 part of zinc stearate, 1 part of stearic acid, 4 parts of calcium carbonate, 4 parts of dioctyl phthalate (DOP), parts are parts by weight.

[0036] Weigh the raw materials according to the formula, and mix them evenly with a stirrer to obtain PVC material 1. Then, detect the performance of PVC material 1 with reference to national standard GB / T2917.1-2002. Among them, the Congo red experiment commonly used...

Embodiment 2

[0038] 1. Preparation of aminouracil maleamic acid

[0039] After pouring maleic anhydride (MAH) into the flask, heat and stir and blow nitrogen, then add aminouracil compounds, raise the temperature to 90°C, and react for 5 hours to obtain the product.

[0040] Wherein, the reaction ratio of maleic anhydride and aminouracil compounds is 1:1.2.

[0041] 2. Preparation of polyvinyl chloride (PVC) material

[0042] Formula: 100 parts of PVC, 2 parts of aminouracil maleamic acid, 2 parts of calcium stearate, 1 part of zinc stearate, 1 part of stearic acid, 4 parts of calcium carbonate, 4 parts of dioctyl phthalate (DOP), parts are parts by weight.

[0043] Weigh the raw materials according to the formula, and mix them evenly with a stirrer to obtain PVC material 2. Then, check the performance of PVC material 2 with reference to national standard GB / T2917.1-2002. Among them, the Congo red experiment commonly used in the PVC product industry is used to characterize the static t...

Embodiment 3

[0045] 1. Preparation of tin aminouracil maleamate

[0046] After pouring maleic anhydride (MAH) into the flask, heat and stir and blow nitrogen, then add aminouracil compounds, raise the temperature to 120°C, and react for 2 hours to obtain the product.

[0047] Wherein, the reaction ratio of maleic anhydride and semi-uracil compound is 1:1.5.

[0048] 2. Preparation of polyvinyl chloride (PVC) material

[0049]Formula: 100 parts of PVC, 3 parts of aminouracil maleamic acid, 2 parts of calcium acetylacetonate, 1 part of zinc acetylacetonate, 1 part of stearic acid, 4 parts of calcium carbonate, 4 parts of dioctyl phthalate (DOP ), the parts are parts by weight.

[0050] Weigh the raw materials according to the formula, and mix them evenly with a stirrer to obtain PVC material 3. Then, check the performance of PVC material 3 with reference to national standard GB / T2917.1-2002. Among them, the Congo red experiment commonly used in the PVC product industry is used to charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com