Method for evenly mixing wet gluten with alkali liquor

A uniform mixing and wet gluten technology, applied in the field of hydrolyzed wheat protein production, can solve the problems of equipment damage, unsatisfactory mixing effect, unstable operation, etc., and achieve the effect of easy operation, good mixing effect and convenient large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below by specific embodiment, further illustrate advantage of the present invention:

[0015] A method for uniformly mixing wet gluten and lye, the method is realized by a wet gluten and lye mixing device.

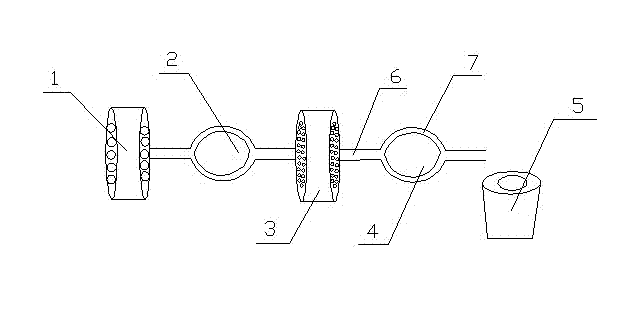

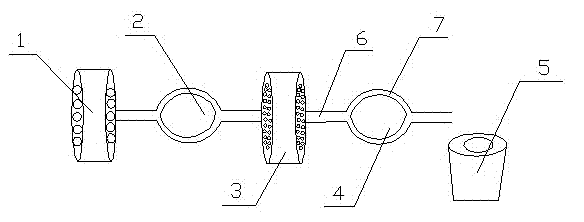

[0016] Such as figure 1 As shown, the wet gluten and lye mixing device comprises a large-aperture perforated plate 1, a pipeline mixer one 2, a small-aperture perforated plate 3, a pipeline mixer two 4 and a homogenizer 5, and the large-aperture perforated plate 1, Pipeline mixer one 2, small-aperture perforated plate 3, pipeline mixer two 4 are connected successively, and described pipeline mixer one 2 and pipeline mixer two 4 are all provided with conveying pipe 6 and separating pipe 7, and described conveying pipe 6 and separating Tube 7 is fixedly connected.

[0017] Using the wet gluten and lye mixing device, let the wet gluten and lye prepared in a certain proportion first pass through the large-aperture perforated plate 1; then mix through the pipeline mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com