Physiological active buck peptide by compound proteinase catalysis and use of products thereby

A composite protease, physiologically active technology, applied in the direction of peptide/protein components, medical preparations containing active ingredients, drug combinations, etc., can solve problems such as reducing application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

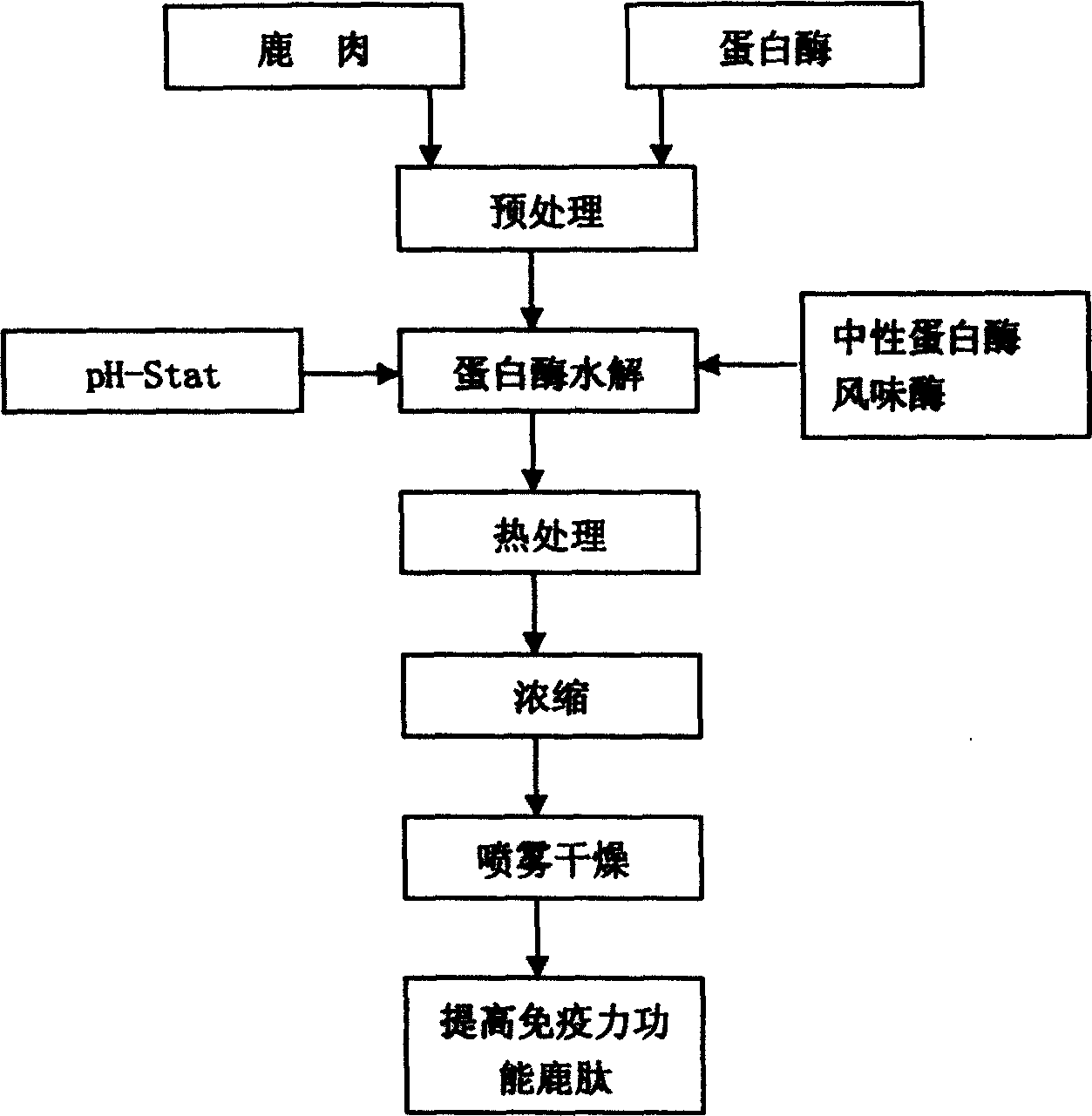

[0101] Example 1: The technological process refers to the attached figure 1

[0102] Put 80 kilograms of pretreated venison pulp into the reaction tank, stir and heat to 50° C., and adjust the pH value to 7.0. During stirring (rotating speed 120rpm / min), first add the neutral protease dissolved in ice water, control the reaction process with standard NaOH solution, and make the degree of protein hydrolysis reach 28%, then add the flavor enzyme dissolved in ice water to continue the hydrolysis reaction to make the protein When the degree of hydrolysis reaches 38%, the temperature of the enzymolysis solution is kept at 115°C for 15 minutes, and then the temperature is quickly lowered to room temperature. Concentrate under reduced pressure to a solid content of 25%, and then freeze-dry. Promptly obtain about 8 kilograms of deer peptides with the physiological function of improving immunity (the protein recovery rate is about 70%).

example 2

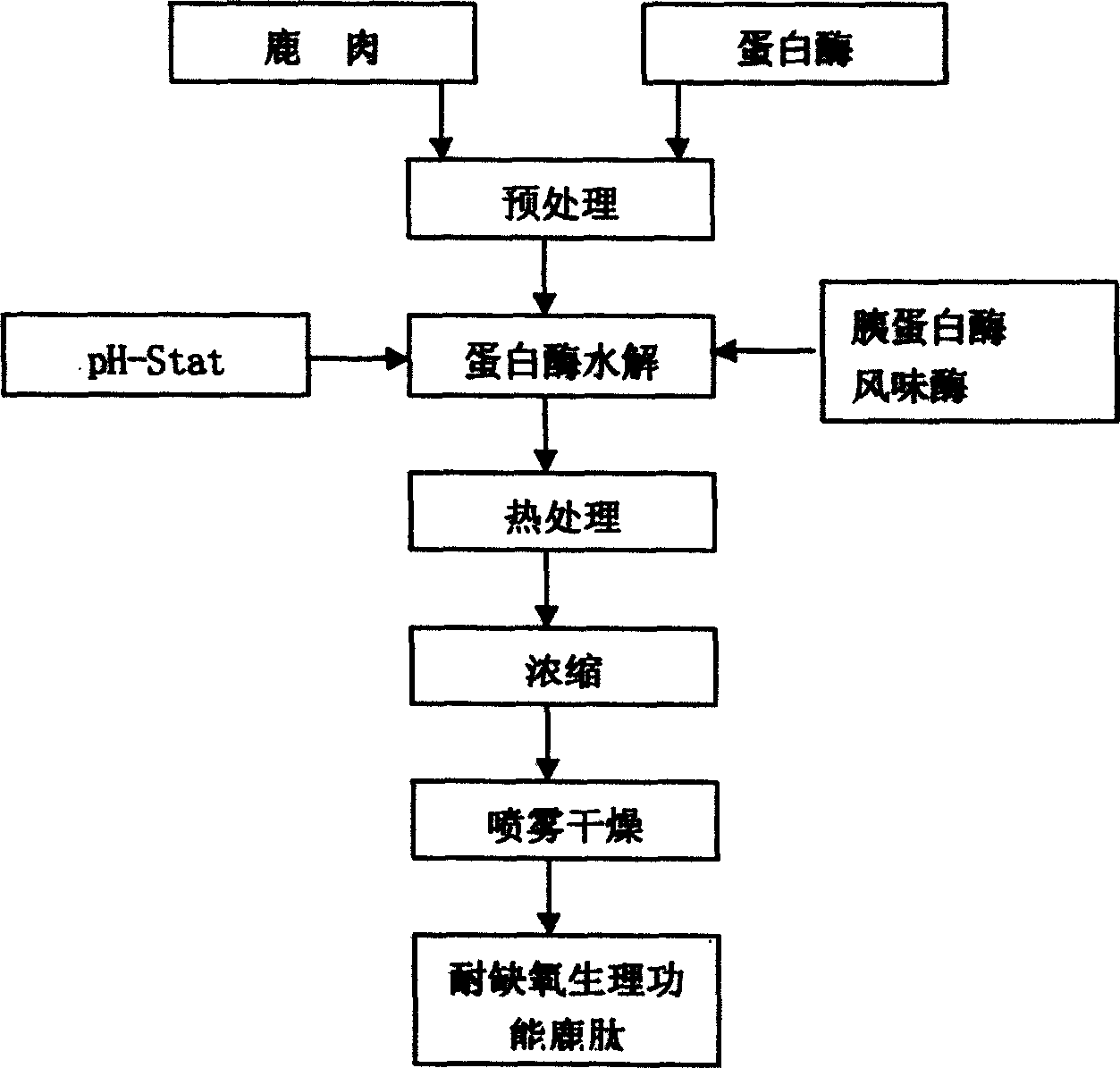

[0103] Example 2: The technological process refers to the attached figure 2

[0104] Put 80 kilograms of pretreated venison pulp into the reaction tank, stir and heat to 50° C., and adjust the pH value to 7.0. During stirring (rotating speed 120rpm / min), first add the trypsin dissolved in ice water, control the reaction process with standard NaOH solution, make the degree of protein hydrolysis reach 33%, then add the flavor enzyme dissolved in ice water to continue the hydrolysis reaction, so that the protein When the degree of hydrolysis reaches 41%, the temperature of the enzymolysis solution is kept at 115°C for 15 minutes, and then the temperature is quickly lowered to room temperature. Concentrate under reduced pressure to a solid content of 25%, and then freeze-dry. Promptly obtain about 8.5 kilograms of deer peptides with hypoxia resistance (the protein recovery rate is about 72%).

example 3

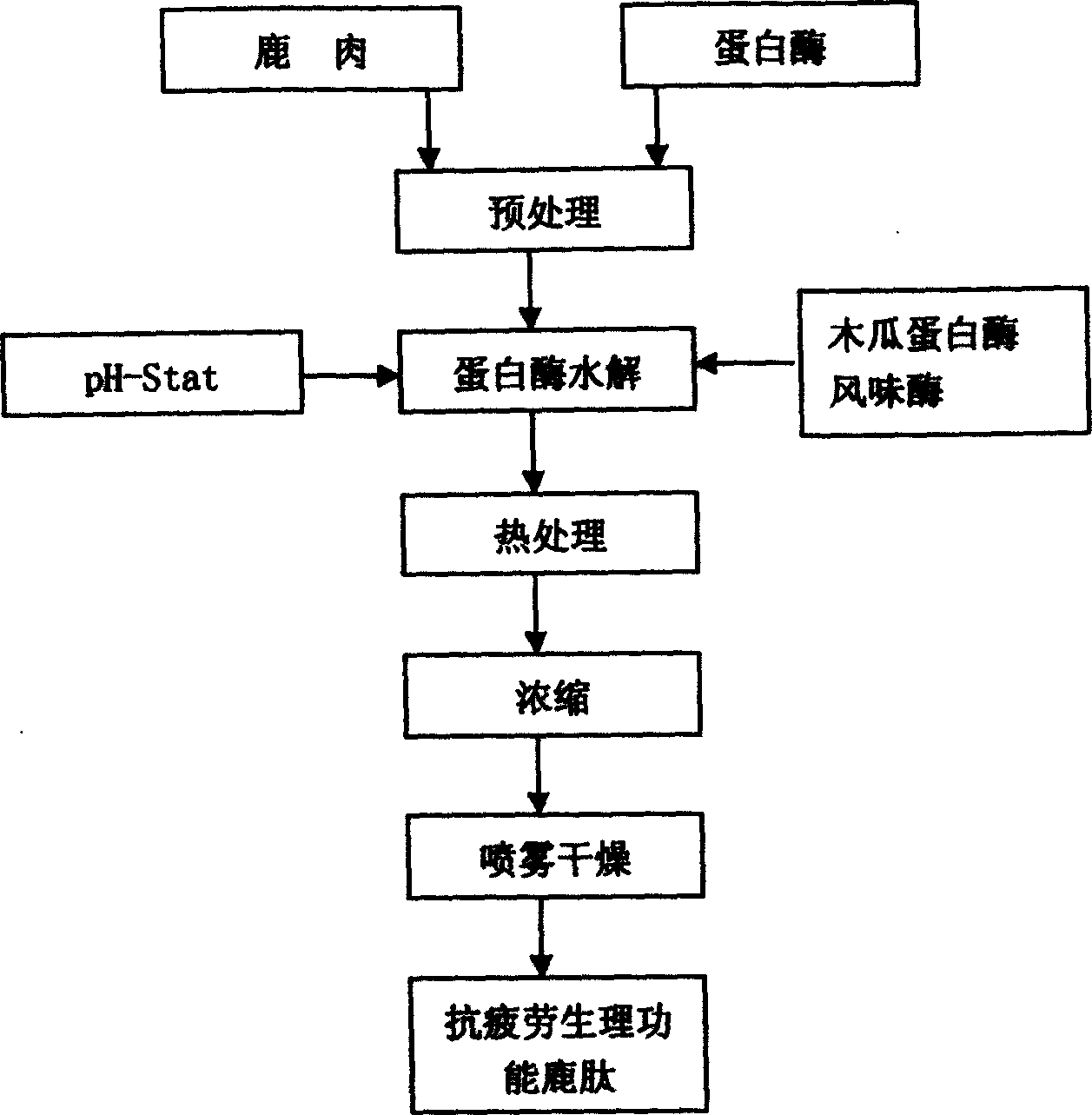

[0105] Example 3: The technological process refers to the attached image 3

[0106] Put 80 kg of pretreated venison pulp into the reaction tank, stir and heat to 50°C, and adjust the pH value to 7.0±0.1. During stirring (rotating speed 120rpm / min), first add the papain dissolved in ice water, control the reaction process with standard NaOH solution, make the degree of protein hydrolysis reach 31%, then add the flavor enzyme dissolved in ice water to continue the hydrolysis reaction, so that the protein When the degree of hydrolysis reaches 42%, the temperature of the enzymolysis solution is kept at 115° C. for 15 minutes, and then the temperature is quickly lowered to room temperature. Concentrate under reduced pressure to a solid content of 25%, and then freeze-dry. Promptly obtain about 8 kilograms of deer peptides with anti-fatigue physiological function (the protein recovery rate is about 70%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com