Preparation method of skim polypeptide cow milk

A technology of peptide milk and neutral protease, applied in the production method and application field of polypeptide milk, can solve the problems of low consumption, high cost, and few varieties, and achieve the goal of improving nutritional status, anti-osteoporosis, and high degree of hydrolysis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

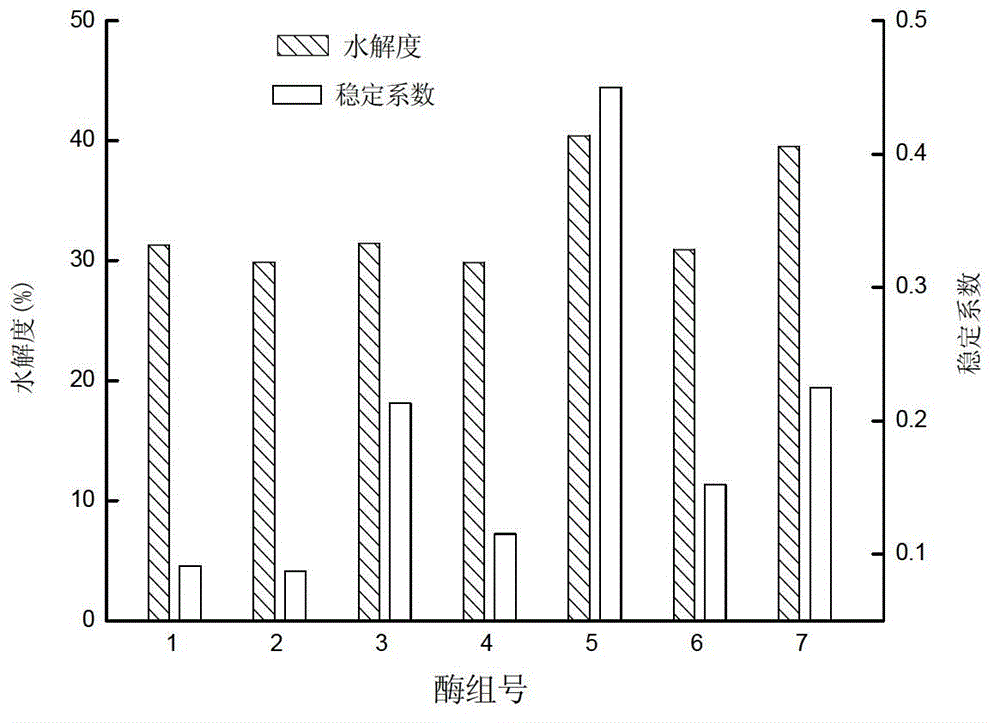

[0026] The screening of embodiment 1 defatted polypeptide milk key protease system

[0027] 1. Heat treatment: heat-treat skim milk with a fat content of 0.1% at 75°C for 5 minutes, pre-sterilize it and moderately denature the milk protein to ensure maximum enzymatic hydrolysis of the milk protein.

[0028] 2. Enzymatic hydrolysis: the product of step 1 is hydrolyzed with complex enzymes to hydrolyze skim milk, the amount of enzyme added is 750U / g protein, and the skim milk is hydrolyzed at 50°C for 15 minutes. The complex enzymes are single enzymes composed of papain, flavor protease and neutral protease System, dual enzyme system (1U:1U) and triple enzyme system (1U:1U:1U).

[0029] 3. Enzyme inactivation and sterilization: the product of step 2 is subjected to an enzyme inactivation and sterilization treatment at 65°C for 30 minutes (ie, LTLT method), and then cooled rapidly. Determination of the degree of hydrolysis and stability of enzymolyzed milk (results such as f...

Embodiment 2

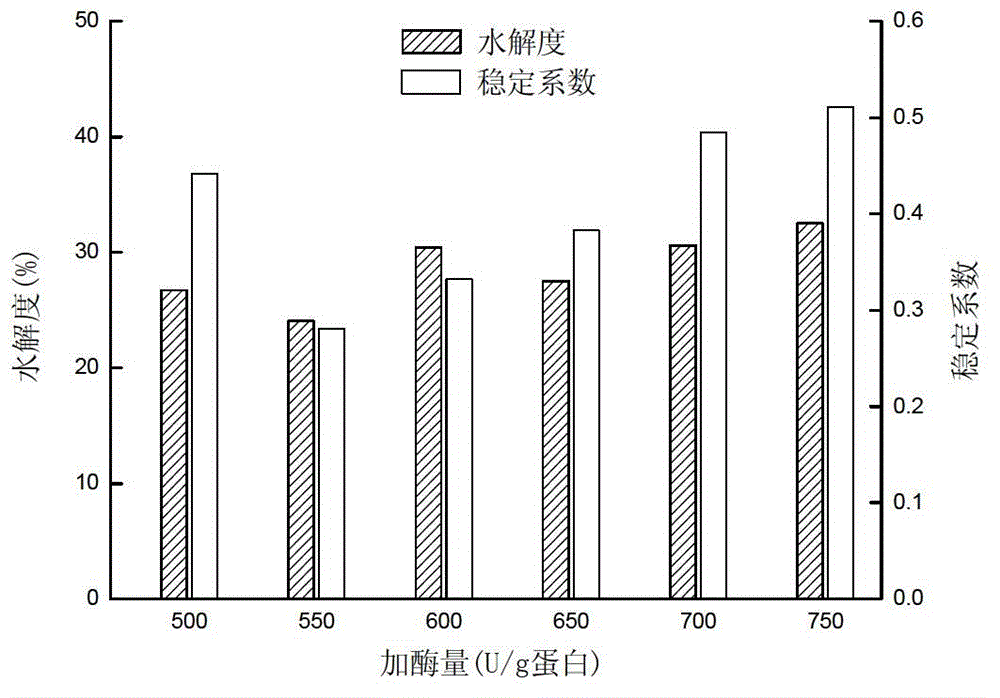

[0031] Embodiment 2 Effects of different enzyme dosages on the enzymatic hydrolysis effect of defatted polypeptide milk

[0032] 1. Heat treatment: heat-treat skim milk with a fat content of 0.1% at 75°C for 5 minutes.

[0033] 2. Enzymolysis: the product of step 1 is hydrolyzed with a compound enzyme to hydrolyze skim milk, the compound enzyme is papain: neutral protease is combined at 1U:1U, and the ratio of enzyme to protein is 500U / g protein, 550U / g protein, 600U respectively The total amount of enzyme added per g protein, 650U / g protein, 700U / g protein, and 750U / g protein was used to hydrolyze skim milk at 50°C for 15 minutes.

[0034] 3. Enzyme inactivation and sterilization: the product of step 2 is then subjected to an enzymatic inactivation treatment at 65°C for 30 minutes (that is, the LTLT method), and the degree of hydrolysis and stability of the enzymolyzed milk are measured. The results are as follows: figure 2 .

[0035] figure 2 It shows that with the i...

Embodiment 3

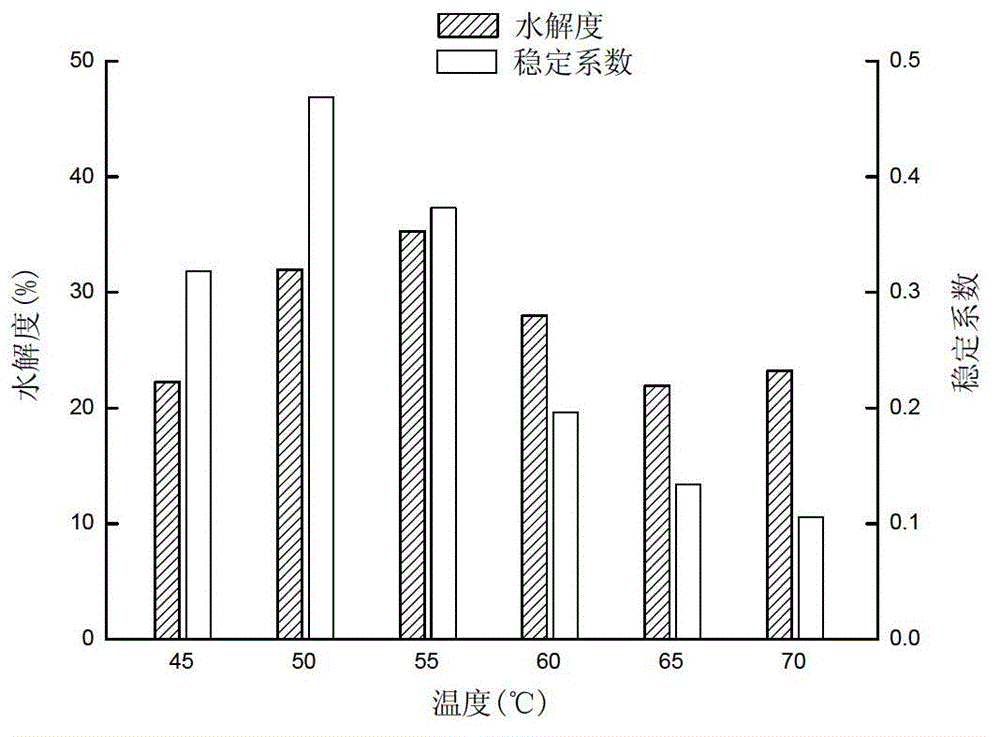

[0036] Embodiment 3 Effects of different temperatures on the enzymatic hydrolysis effect of defatted polypeptide milk

[0037] 1. Heat-treat skim milk with a fat content of 0.1% at 75°C for 5 minutes.

[0038] 2. Enzymolysis: the product of step 1 is hydrolyzed with a compound enzyme to hydrolyze skim milk, the compound enzyme is papain: neutral protease is combined with the same enzyme amount, and the total enzyme amount is 750U / g protein, respectively at 45°C, 50°C, The skim milk was hydrolyzed for 15 minutes at 55°C, 60°C, 65°C, and 70°C.

[0039] 3. Enzyme inactivation: the product of step 2 is subjected to an enzymatic inactivation treatment at 65°C for 30 minutes (ie, LTLT method), and its degree of hydrolysis and stability are measured. The results are as follows: image 3 .

[0040] Depend on image 3 It can be seen that when the enzymatic hydrolysis temperature is 50°C, the stability coefficient of milk is the highest, that is, the stability is the best; although t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com