Method for preparing diglyceride through enzyme catalysis

A technology of catalyzed esterification of diacylglycerol, which is applied in the field of food science, can solve the problems of deacidification of by-products and difficult control of hydrolysis, and achieve the effects of avoiding excessive hydrolysis, reducing production costs, and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of edible diglyceride provided by the invention comprises the following steps:

[0024] (1) Partial hydrolysis of oil: the edible oil is partially hydrolyzed by enzymatic hydrolysis, and the hydrolyzate is obtained after dehydration, so that the content of diglyceride in the hydrolyzate is between 30.0wt% and 35.0wt%, and the free fatty acid content Between 26.0wt% and 30.0wt%; the enzyme used is a lipase with a specific activity between 1,000,000U / g and 1,100,000U / g, and the added amount is 0.3%-1.5% of the mass of the edible oil.

[0025] The enzyme-catalyzed hydrolysis reaction conditions are as follows:

[0026] The oil-water ratio is 1:1.5-2.9g / mL, the reaction temperature is 35.0-60.0°C, and the reaction time is 3.0-10.0h.

[0027] (2) Re-esterification: Add glycerol with 2.5 times to 4 times its mass to the hydrolyzate obtained in step (1), use enzyme-catalyzed esterification to carry out esterification reaction to synthesize diglyceride, ...

Embodiment 1

[0035] A preparation method of edible diglycerides, comprising the following steps:

[0036] (1) Partial hydrolysis of oil: the commercially available rapeseed oil is partially hydrolyzed by an enzyme-catalyzed hydrolysis method, and the hydrolyzate is obtained after dehydration. The specific steps are as follows:

[0037] Add LipozymeTLIM, whose specific activity is 1,050,000 U / g, the amount of enzyme added is 0.43% of the edible oil mass, and placed in a constant temperature shaker at a temperature of 55.8° C. for 4.2 hours.

[0038] The content of diglyceride in the hydrolyzate is 33.08%, and the content of free fatty acid is 28%.

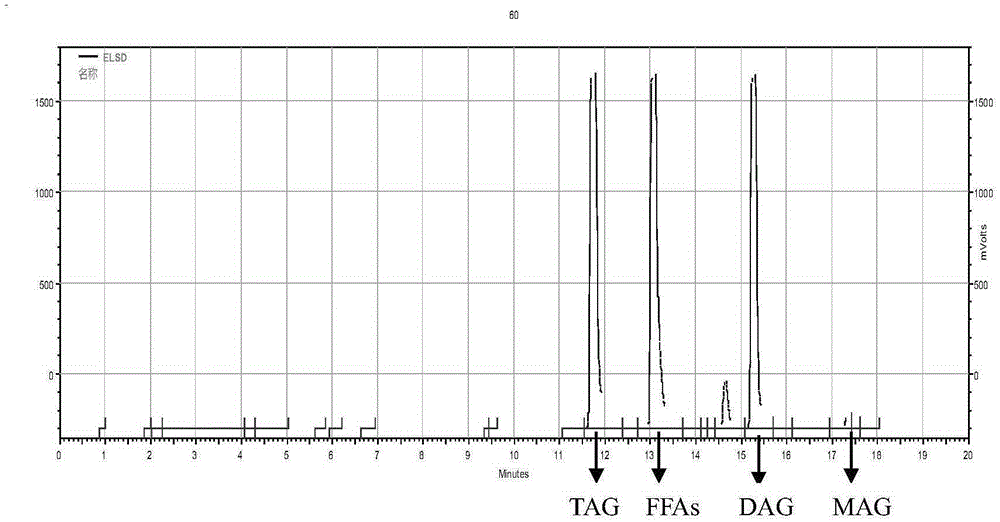

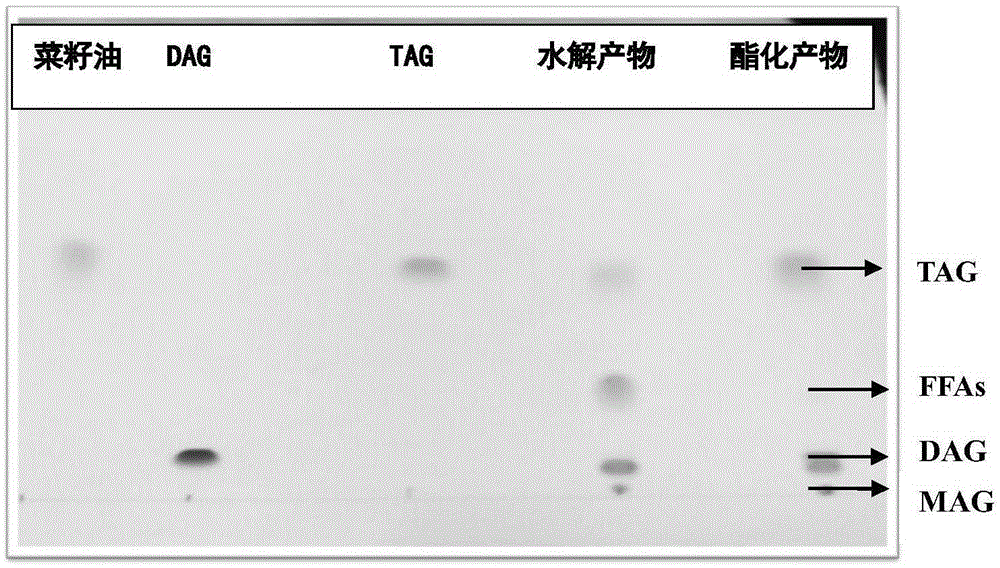

[0039] The reaction product was detected by HPLC-ELSD, and the results were as follows: figure 1 Shown, each component and its content, triglyceride (TAG): 38.715%, free fatty acid (FFAs): 23.252%, diglyceride (DAG): 32.256%, monoglyceride (MAG): 2.770%.

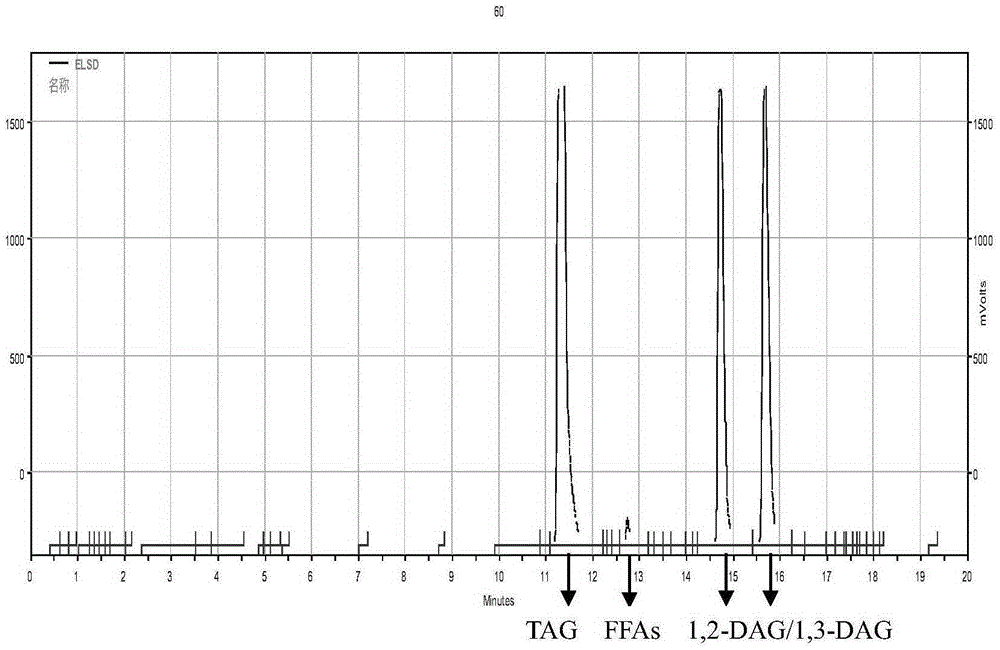

[0040] (2) Re-esterification: Add glycerin with 2.85 times its mass to the hydrolyzate o...

Embodiment 2

[0046] A preparation method of edible diglycerides, comprising the following steps:

[0047] (1) Partial hydrolysis of oil: The commercially available soybean oil is partially hydrolyzed by an enzyme-catalyzed hydrolysis method, and the hydrolyzate is obtained after dehydration. The specific steps are as follows:

[0048] Add LipozymeTLIM, whose specific activity is 1,080,000 U / g, the amount of enzyme added is 0.3% of the edible oil mass, and placed in a constant temperature shaker at a temperature of 60° C. for 10 hours.

[0049] The content of diglyceride in the hydrolyzate is 35.0wt%, and the content of free fatty acid is 26.0wt%.

[0050] (2) Re-esterification: Add glycerin 4 times its mass to the hydrolyzate obtained in step (1), use enzyme-catalyzed esterification to carry out esterification reaction to synthesize diglyceride, and obtain the edible diglycerides. The enzyme used is lipase Novozyme435 with a specific activity of 114,562 U / g, and the added amount is 0.6% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com