Acid-soluble peanut protein and preparation method and application thereof

A technology of peanut protein and peanut protein powder, applied in the application, protein food processing, vegetable protein processing and other directions, can solve the problems of affecting taste, stratification or precipitation, failure to obtain and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

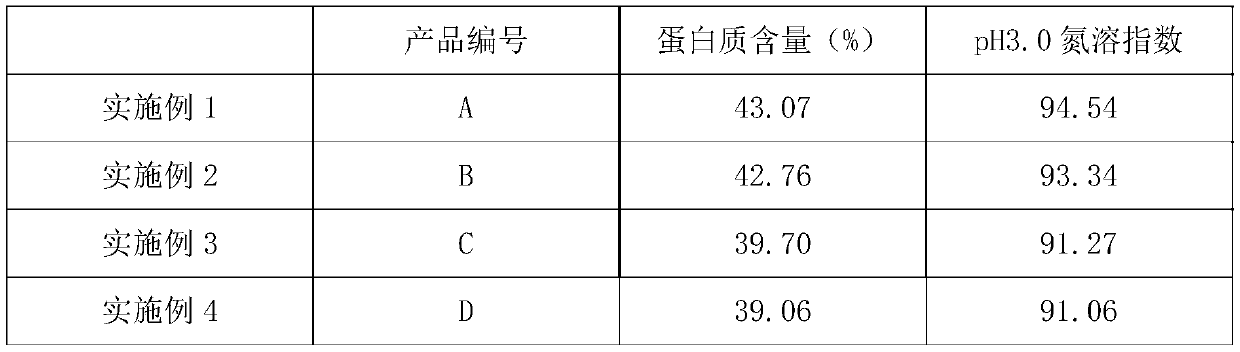

Embodiment 1

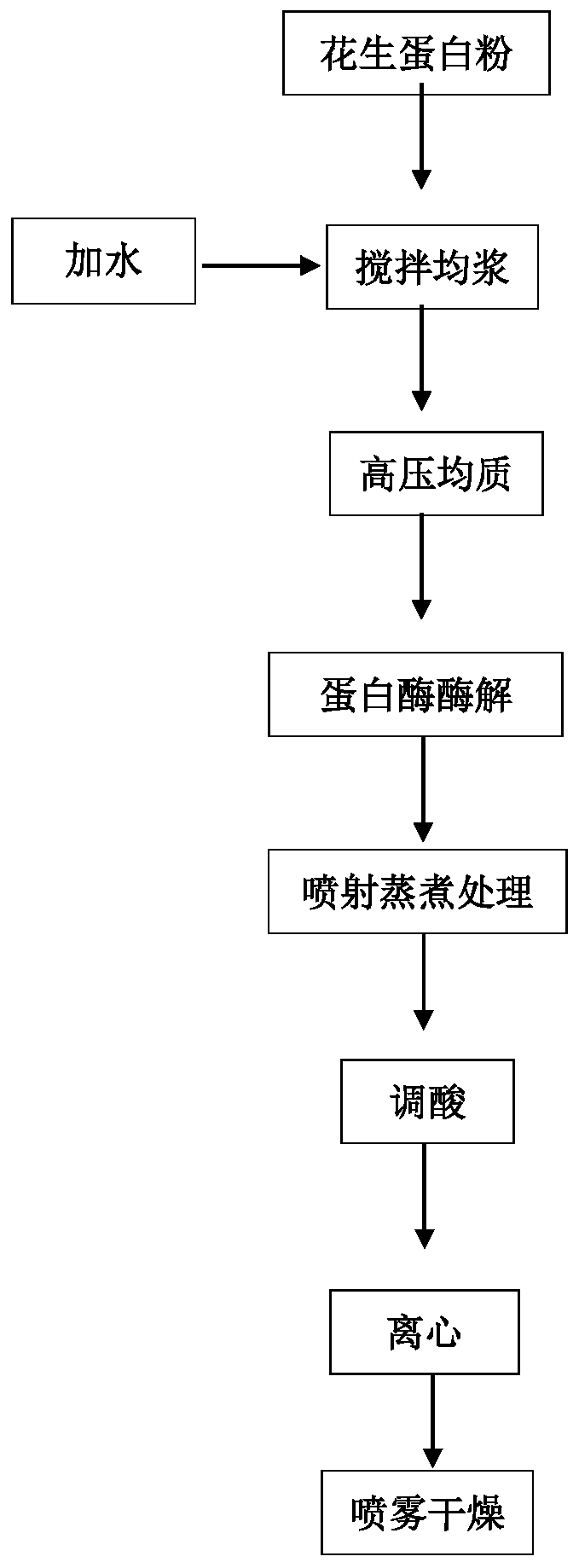

[0039] This embodiment provides a kind of preparation method of acid-soluble peanut protein, the technical process sees figure 1 Including the following steps:

[0040] (1) Pretreatment: Dissolve peanut protein powder (made from Baisha 1016) in deionized water at a solid-to-liquid mass ratio of 1:40, and stir until completely dissolved to obtain a peanut protein slurry;

[0041] (2) High-pressure homogenization: the peanut protein slurry was subjected to high-pressure homogenization at 50 MPa for 30 minutes to obtain a peanut protein liquid;

[0042] (3) Enzymolysis treatment: use 1000U / g of neutral protease to enzymolyze the peanut protein solution at 55°C for 50min;

[0043] (4) Jet cooking treatment: add the enzymatically hydrolyzed peanut protein solution into a jet cooker, spray cook at 110°C for 90 seconds, and cool the material at the discharge port with cold water to room temperature;

[0044] (5) acid adjustment treatment: use citric acid solution as a pH regulator,...

Embodiment 2

[0047] This embodiment provides a kind of preparation method of acid-soluble peanut protein, the technical process sees figure 1 Including the following steps:

[0048] (1) Pretreatment: Dissolve peanut protein powder (produced by Yuhua 9326) in deionized water with a solid-to-liquid mass ratio of 1:30, and stir until completely dissolved to obtain a peanut protein slurry;

[0049] (2) High-pressure homogenization: the peanut protein slurry was subjected to high-pressure homogenization at 60 MPa for 20 minutes to obtain a peanut protein liquid;

[0050] (3) Enzymolysis treatment: use 1000U / g of neutral protease to enzymolyze the peanut protein solution at 55°C for 50min;

[0051] (4) Jet cooking treatment: add the enzymatically hydrolyzed peanut protein solution into a jet cooker, spray cook at 110°C for 100 seconds, and cool the material at the outlet with cold water to room temperature;

[0052] (5) acid adjustment treatment: use citric acid solution as a pH regulator, adj...

Embodiment 3

[0055] This embodiment provides a kind of preparation method of acid-soluble peanut protein, the technical process sees figure 1 Including the following steps:

[0056] (1) Pretreatment: Dissolve peanut protein powder (known from Zhonghua No. 4) in deionized water at a solid-to-liquid mass ratio of 1:20, and stir until completely dissolved to obtain a peanut protein slurry;

[0057] (2) High-pressure homogenization: the peanut protein slurry was subjected to high-pressure homogenization at 60 MPa for 20 minutes to obtain a peanut protein liquid;

[0058] (3) Enzymolysis treatment: use 800 U / g of neutral protease to enzymolyze the peanut protein solution at 55° C. for 50 minutes;

[0059] (4) Jet cooking treatment: add the enzymatically hydrolyzed peanut protein solution into a jet cooker, spray cook at 110°C for 110 seconds, and cool the material at the outlet with cold water to room temperature;

[0060] (5) Acid adjustment treatment: use citric acid solution as a pH regula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com