A kind of preparation method of active oligopeptide

An oligopeptide and ultrafiltration equipment technology, which can be used in the preparation methods of peptides, chemical instruments and methods, preparations for skin care, etc., and can solve the problems of poor control of enzymatic hydrolysis and low yield of oligopeptides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of embodiment 1 rice protein

[0031] (1) Protein extraction: Take 10kg of broken rice, crush it to 60 mesh, add 100L water and stir evenly, adjust the pH to 13, put it in a water bath at 50°C, stir in the water bath for 3 h, centrifuge at 5000 r / min for 20 min, and keep The supernatant was adjusted to pH 5.5 with 0.1 M HCl, and stood at 4 °C for 30 min to collect protein precipitates, which were freeze-dried and pulverized to obtain coarse rice protein.

[0032] (2) Protein removal: Add water and stir evenly according to the ratio of material to liquid 1:10, adjust the pH to 5.5, place in a water bath at 55 ℃, add 35U / g amylase and 10U / g cellulase according to the amount of crude protein, Stir in a water bath for 3 h, centrifuge at 5000 r / min for 20 min, collect the protein precipitate, and freeze-dry and pulverize to obtain 512.4 g of rice protein, with a protein yield of 5.12%.

Embodiment 2

[0033] Example 2 Preparation of antioxidant oligopeptides

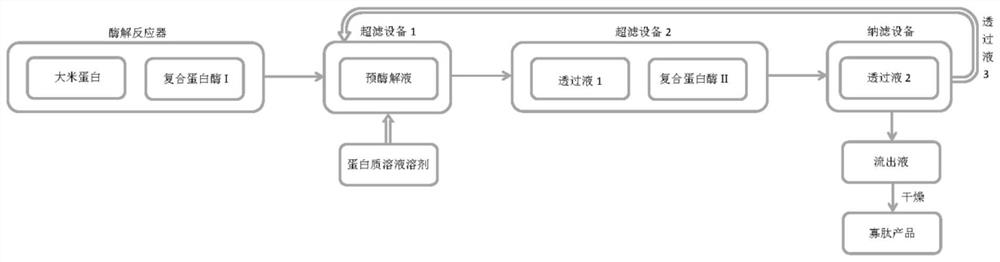

[0034] (1) Take the rice protein prepared in Example 1, add pH 7.5 PBS buffer solution to prepare 10 L of protein solution with a concentration of 10 mg / mL, stir well, put it in an enzymatic hydrolysis reactor at 55°C, and prepare according to the amount of rice protein Add compound protease I comprising 1600 U / g alkaline protease, 2000 U / g trypsin and 2000 U / g neutral protease, and stir for 30 minutes for pre-enzymolysis to obtain a pre-enzymolysis solution;

[0035] (2) Pump the pre-enzymolysis liquid into ultrafiltration equipment 1, enzymolyze at 55°C for 20 minutes, turn on ultrafiltration equipment 1 (Millipore tangential flow plate regenerated cellulose membrane, membrane molecular weight cut-off 5000Da), and obtain permeate 1;

[0036] According to the amount of rice protein, compound protease II including 1500 U / g papain, 1500 U / g neutral protease and 1000 U / g telopeptidase was added to the permeate 1, and th...

Embodiment 3

[0041] Example 3 Preparation of antioxidant oligopeptides

[0042] (1) Take the rice protein prepared in Example 1, add pH 8.0 PB buffer solution to prepare 10 L of protein solution with a concentration of 8 mg / mL, stir well, put it in an enzymatic hydrolysis reactor at 50°C, and prepare according to the amount of rice protein Add compound protease I comprising 1600 U / g alkaline protease, 2000 U / g trypsin and 2000 U / g neutral protease, and stir for 20 minutes for pre-enzymolysis to obtain a pre-enzymolysis solution;

[0043] (2) Pump the pre-enzymolysis liquid into ultrafiltration equipment 1, enzymatically hydrolyze at 50°C for 30 minutes, turn on ultrafiltration equipment 1 (Millipore tangential flow plate regenerated cellulose membrane, membrane molecular weight cut-off 5000Da), and obtain permeate 1;

[0044] According to the amount of rice protein, compound protease II including 1200 U / g papain, 1000 U / g neutral protease and 800 U / g telopeptidase was added to the permeate...

PUM

| Property | Measurement | Unit |

|---|---|---|

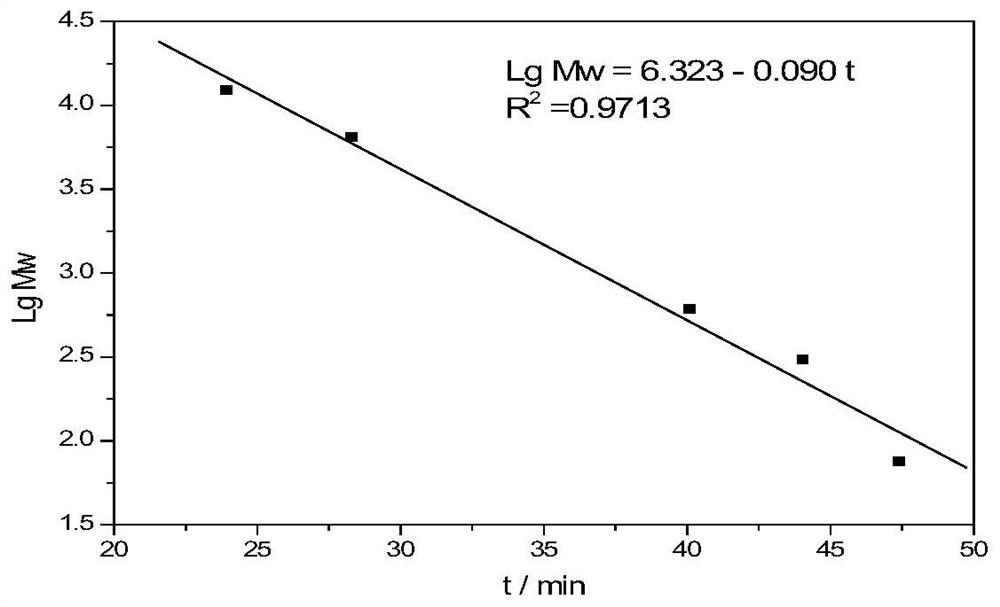

| molecular weight distribution | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com