A kind of preparation method of black tea concentrate

A technology for concentrate and black tea extract, applied in the field of food processing, can solve the problems of single type of tea concentrate and large market share of black tea beverages, and achieve the effects of high product yield, rich taste components, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

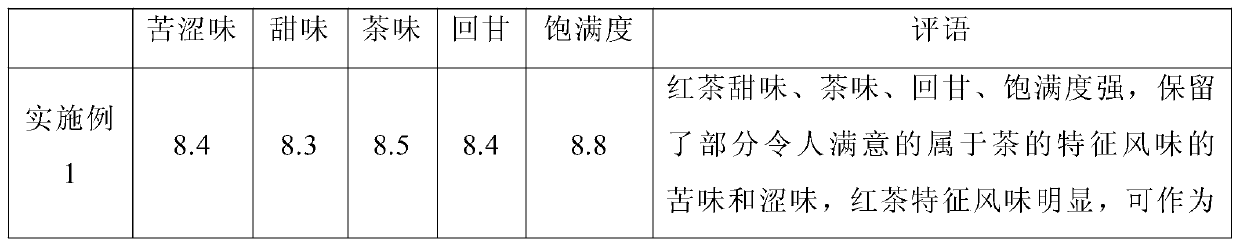

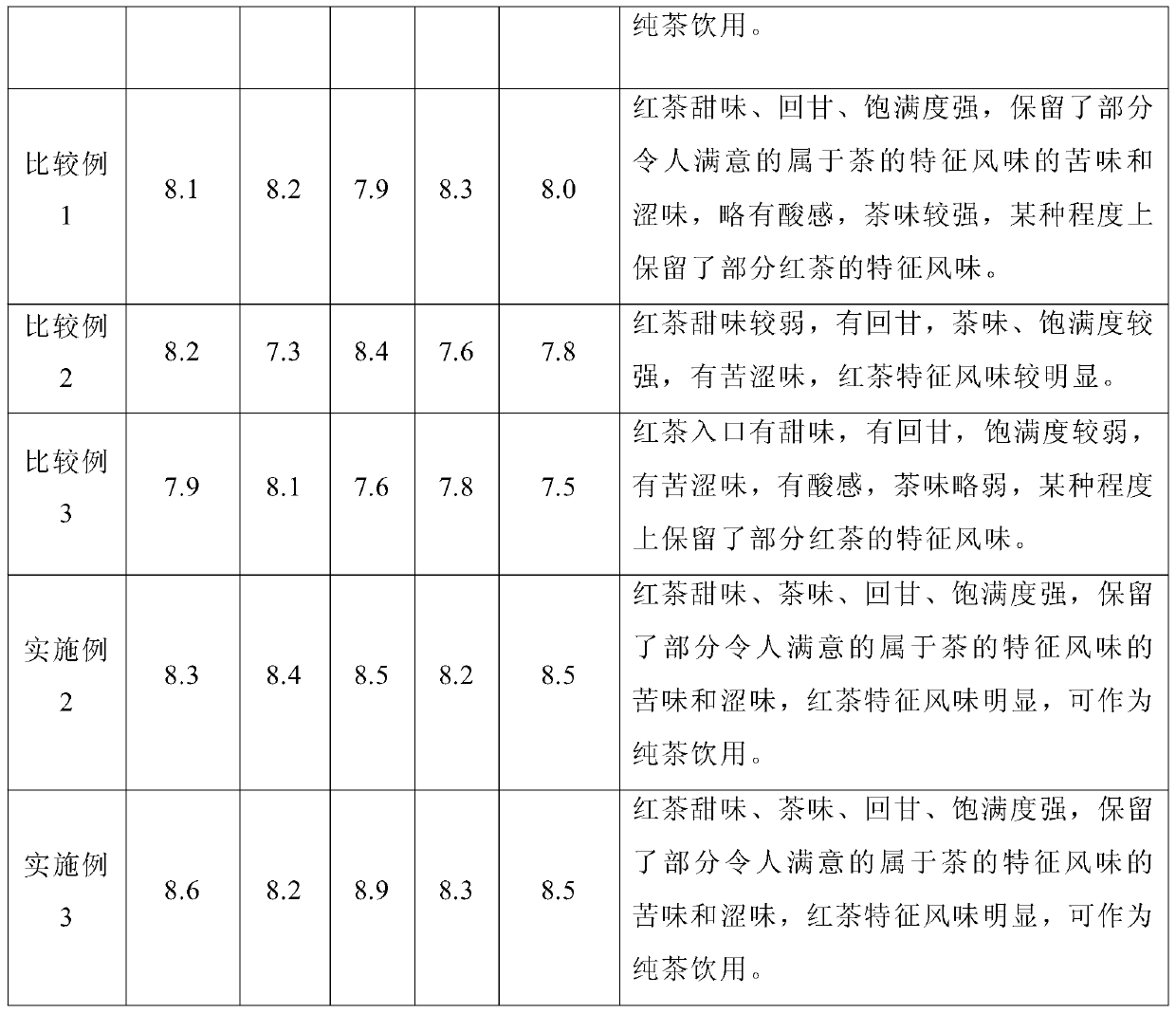

Examples

Embodiment 1

[0059] A preparation method of black tea concentrate, the steps are as follows:

[0060] (1) Tea extraction: use closed extraction equipment to extract tea leaves in hot water, put in 1000kg of tea leaves, add 10000kg~15000kg of RO water at 70℃~95℃, extract for 0.5 hours to 2.5 hours, and cool to 40℃~50 ℃.

[0061] (2) Enzymolysis reaction: add tannase (for example, Tannase-KT05, Kikkoman) 0.2kg, pectinase (for example, RAPIDASE TF, DSM) 10kg, α-amylase (for example, Mycolase, DSM ) 6kg, glucoamylase (for example, Amylase AG 300L, Novozymes) 3kg, add protease (for example, Protease A2SD, Amano) 25kg, enzymolysis reaction for 4 hours to 8 hours, add exoprotease (for example, Flavourzyme 1000L, Novozymes) 2kg, continue the reaction and enzymolysis for 2 hours to 8 hours, and the enzymolysis temperature during the enzymolysis reaction process is controlled at 40°C to 50°C.

[0062] (3) Separation and filtration: After the enzymolysis reaction is completed, use a filter press to...

Embodiment 2

[0073] A preparation method of black tea concentrate, the steps are as follows:

[0074] (1) Tea extraction: use closed extraction equipment to extract tea leaves in hot water, put in 1000kg of tea leaves, add 10000kg~15000kg of RO water at 70℃~95℃, extract for 0.5 hours to 2.5 hours, and cool to 40℃~50 ℃.

[0075] (2) Enzymolysis reaction: add tannase (for example, Sumizyme TAN, New Japan) 0.2kg, add pectinase, Pectinase PL (Amano) 3kg, RAPIDASE PRESSL (DSM) 1kg, ROHAPECT B1L (Germany AB) 2kg, α-amylase (for example, Mycolase, DSM) 6kg, glucoamylase (for example, Amylase AG 300L, Novozymes) 3kg, add protease, ProteAX (Amano) 10.5kg, COROLASE 7089 (Germany AB) 20kg , after enzymatic hydrolysis reaction for 4 to 6 hours, add 2 kg of exoprotease (for example, Flavourzyme 1000L, Novozymes) and continue the reaction and enzymatic hydrolysis for 2 to 8 hours.

[0076] (3) Separation and filtration: After the enzymolysis reaction, use a horizontal spiral centrifuge to separate the...

Embodiment 3

[0081] A preparation method of black tea concentrate, the steps are as follows:

[0082] Except in embodiment 1 with protease (for example, Protease MSD, Amano) 17.5kg, protease (for example, ProteAX, Amano) 7.5kg replaces protease (for example, Protease A2SD, Amano) 25kg, carry out exactly the same as embodiment 1 Operation, the black tea concentrate of product 3 of the present invention is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com