A method and device for producing methane gas and lignin by using straw

A technology of lignin and methane gas, applied in the direction of supporting/immobilizing microorganisms, sterilization methods, gas production bioreactors, etc., can solve the problems of long process flow, high investment, high production cost, etc., and achieve simple process flow , Improve the efficiency of enzymatic hydrolysis and reduce the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

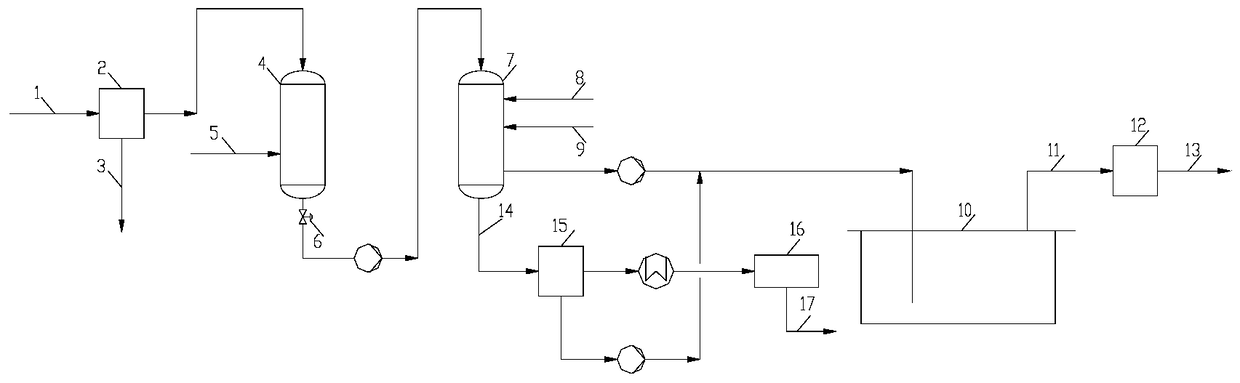

[0028]Using corn stalks as the raw material 1, the corn stalk raw material 1 is first sent to the impurity removal and drying equipment 2 to remove water, soil, ash and other impurities, and the impurities and water 3 are discharged from the lower end. Then the dried and impurity-removed corn stalks are mechanically chopped into small sections of 8 cm and then sent to the gas explosion equipment 4, filled with 1.5 MPa saturated gas explosion steam 5, keeping the internal pressure of the equipment stable for 100 seconds, and opening the gas explosion equipment 4 The pressure relief solenoid valve 6 at the bottom releases the pressure instantly to complete the gas explosion process, and the raw material 1 is crushed into 0.8mm straw particles. The crushed straw is sent into the hydrolysis device 7 by the third vacuum pump, and straw hydrolytic enzyme 8 and hydrolyzed water 9 are added thereto, so that the mass ratio of straw in each hydrolysis tank: straw hydrolytic enzyme: hydro...

Embodiment 2

[0031] The straw raw material 1 is sent to the impurity removal and drying equipment 2 to remove impurities such as moisture, soil and ash, and the impurities and water 3 are discharged from the lower end. Then dry, the rice straw machine after impurity removal is chopped into 5cm segments and then sent to the gas explosion equipment 4, filled with the saturated gas explosion steam 5 of 1.5MPa therein, keeps the pressure in the gas explosion equipment 4 stable for 120s, and opens the gas explosion equipment. The pressure relief electromagnetic valve 6 at the bottom of the explosion device 4 releases the pressure instantaneously to complete the gas explosion process, and the straw raw material 1 is crushed into straw particles with a particle diameter of 0.6 mm. The crushed rice straw is sent into the hydrolysis equipment 4 by the third vacuum pump, and straw hydrolytic enzyme 8 and hydrolysis water 9 are added to each hydrolysis tank in the hydrolysis equipment 4, so that the s...

Embodiment 3

[0034] This embodiment is a preferred scheme of a device for producing methane gas and fiber-containing lignin by utilizing straw, and the reaction of Embodiment 1 or 2 can be carried out in the device of this embodiment. It includes straw removal and drying equipment 2, mechanical shredding device, gas explosion equipment 4, hydrolysis equipment 7, and anaerobic fermentation tank 10. The gas explosion equipment 4 is respectively fed with dried and mechanically chopped straw and gas Explosion steam 5, the outlet is connected to the pressure relief solenoid valve 6 and the third vacuum pump leading to the hydrolysis equipment 7. The hydrolysis equipment is fed with straw powder, hydrolytic enzyme 8 and hydrolyzed water 9 respectively, one path is connected to the first vacuum pump leading to the anaerobic fermentation tank 10 , and the other path is connected to the lignin pulp filter 15 .

[0035] The outlet of the lignin pulp filter 15 is connected to a drying device, anaerob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com