Vacuum mixing method and system

A vacuum mixing and mixing technology, applied in chemical instruments and methods, mixers, dissolving and other directions, can solve problems such as failure to use or process effects, unstable mixing quality, troublesome maintenance and cleaning, etc. Simple, easy to promote and apply, with high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

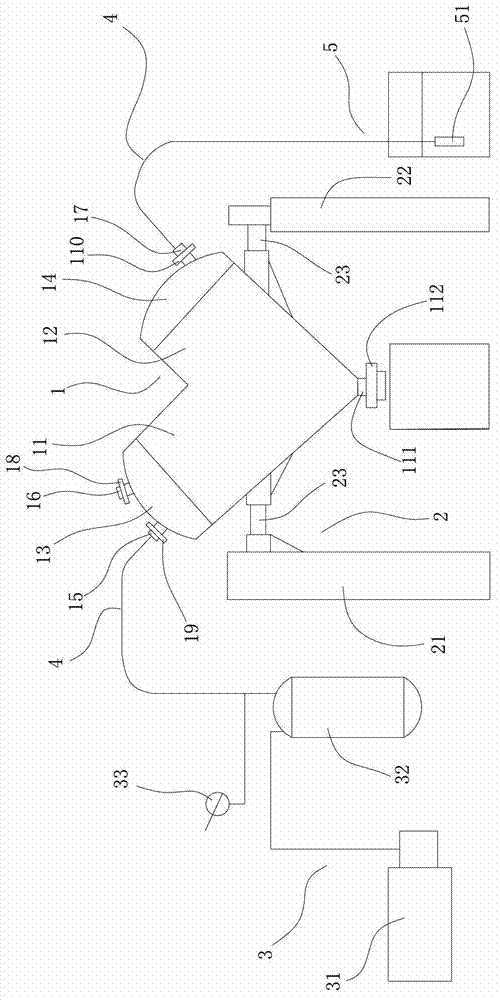

[0032] Example: see figure 1 , a kind of vacuum mixing method of the present invention, it comprises the following steps:

[0033] (1) Set up a mixing bin 1, which can be completely sealed after loading. The mixing bin 1 is a V-shaped bin that facilitates uniform mixing of materials;

[0034] (2) A power mechanism 2 is set up, and the mixing bin 1 is flipped and mixed through the power mechanism 2;

[0035] (3) Install a vacuum device 3, connect the vacuum device 3 with the mixing bin 1 through a flexible pipe 4, and vacuumize the mixing bin 1, and use pressure difference to remove the powder or lumps. The material in the form of liquid or paste is sucked into the mixing bin 1, and the mixing bin 1 is kept in a vacuum state during the turning and mixing operation;

[0036] (4) A feeding device 5 is provided, and the feeding device 5 includes a flexible pipe 4 connected to the mixing bin 1 and a feeding suction nozzle 51 arranged at the end of the flexible pipe 4;

[0037] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com