Expanded graphite flame-retardant fire-extinguishing material and preparation method thereof

A technology of expanded graphite and fire-extinguishing materials, which is applied in fire-retardant coatings, conductive coatings, epoxy resin coatings, etc., to improve the dispersion effect and prevent agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

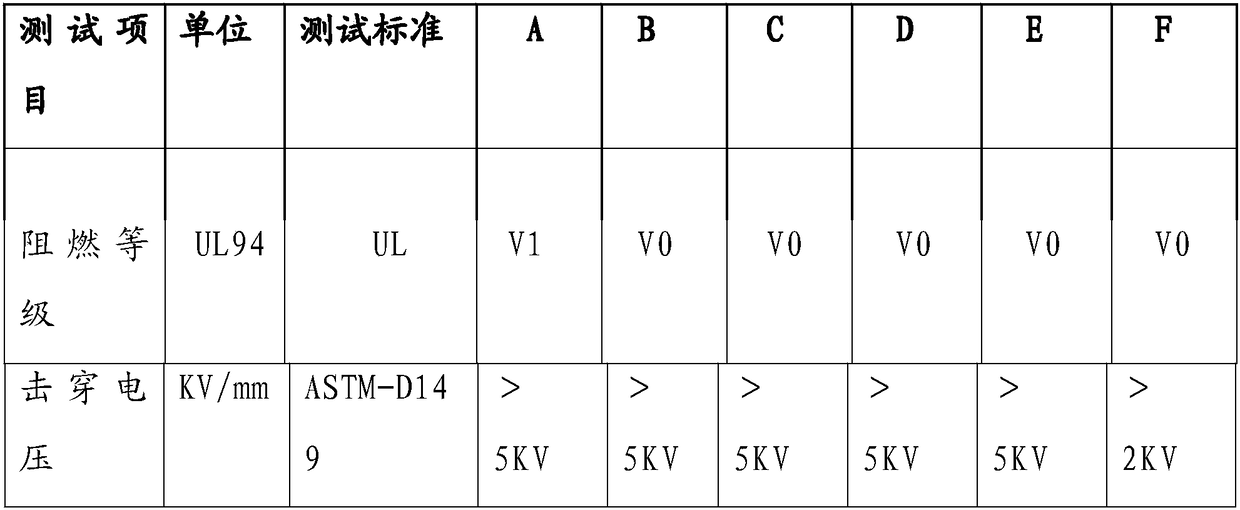

Examples

Embodiment 1

[0028] Disperse 3 parts of coupling agent and 60 parts of thermal and conductive powder at high speed, and carry out surface treatment on the thermal and conductive powder. The coupling agent is evenly coated on the surface of the thermal and conductive powder, and the two are mixed to form a conductive filler, thereby enhancing the conductive filler. Compatibility when mixed with the subsequent resin matrix. Then put the conductive filler, 40 parts of organic resin, 2 parts of curing agent, 0.5 parts of expanded graphite and 2.5 parts of additives into a high-speed disperser to mix and disperse. The additives are dispersants and leveling agents. The dispersion time is 5 minutes. 800 rpm; vacuum degassing after dispersion to form conductive glue A. Calender or coat the conductive adhesive solution A on the substrate PET plastic, heat at 130°C for 20 minutes, bake and cross-link to solidify, and shape it into a sheet, coil or heterogeneous component.

Embodiment 2

[0030] Disperse 3 parts of coupling agent and 60 parts of thermal and conductive powder at high speed, and carry out surface treatment on the thermal and conductive powder. The coupling agent is evenly coated on the surface of the thermal and conductive powder, and the two are mixed to form a conductive filler, thereby enhancing the conductive filler. Compatibility when mixed with the subsequent resin matrix. Then put the conductive filler, 40 parts of organic resin, 2 parts of curing agent, 1 part of expanded graphite and 2.5 parts of additives into a high-speed disperser to mix and disperse. The additives are dispersants and leveling agents. The dispersion time is 5 minutes, and the dispersion speed 800 rpm; vacuum degassing after dispersion to form conductive glue B. Calender or coat the conductive adhesive solution B on the substrate PET plastic, heat at 130°C for 20 minutes, bake and cross-link to solidify, and shape it into a sheet, coil or heterogeneous component.

Embodiment 3

[0032] Disperse 3 parts of coupling agent and 60 parts of thermal and conductive powder at high speed, and carry out surface treatment on the thermal and conductive powder. The coupling agent is evenly coated on the surface of the thermal and conductive powder, and the two are mixed to form a conductive filler, thereby enhancing the conductive filler. Compatibility when mixed with the subsequent resin matrix. Then put conductive filler, 40 parts of organic resin, 2 parts of curing agent, 1.5 parts of expanded graphite and 2.5 parts of additives into a high-speed disperser to mix and disperse. The additives are dispersant and leveling agent. The dispersion time is 5 minutes, and the dispersion speed 800 rpm; vacuum degassing after dispersion to form conductive glue C. Calender or coat the conductive adhesive C on the substrate PET plastic, heat at 130°C for 20 minutes, bake, cross-link and solidify, and shape it into a sheet, coil or heterogeneous component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com